aci ACCESS series User manual

Other manuals for ACCESS series

16

This manual suits for next models

24

Table of contents

Other aci Transmitter manuals

aci

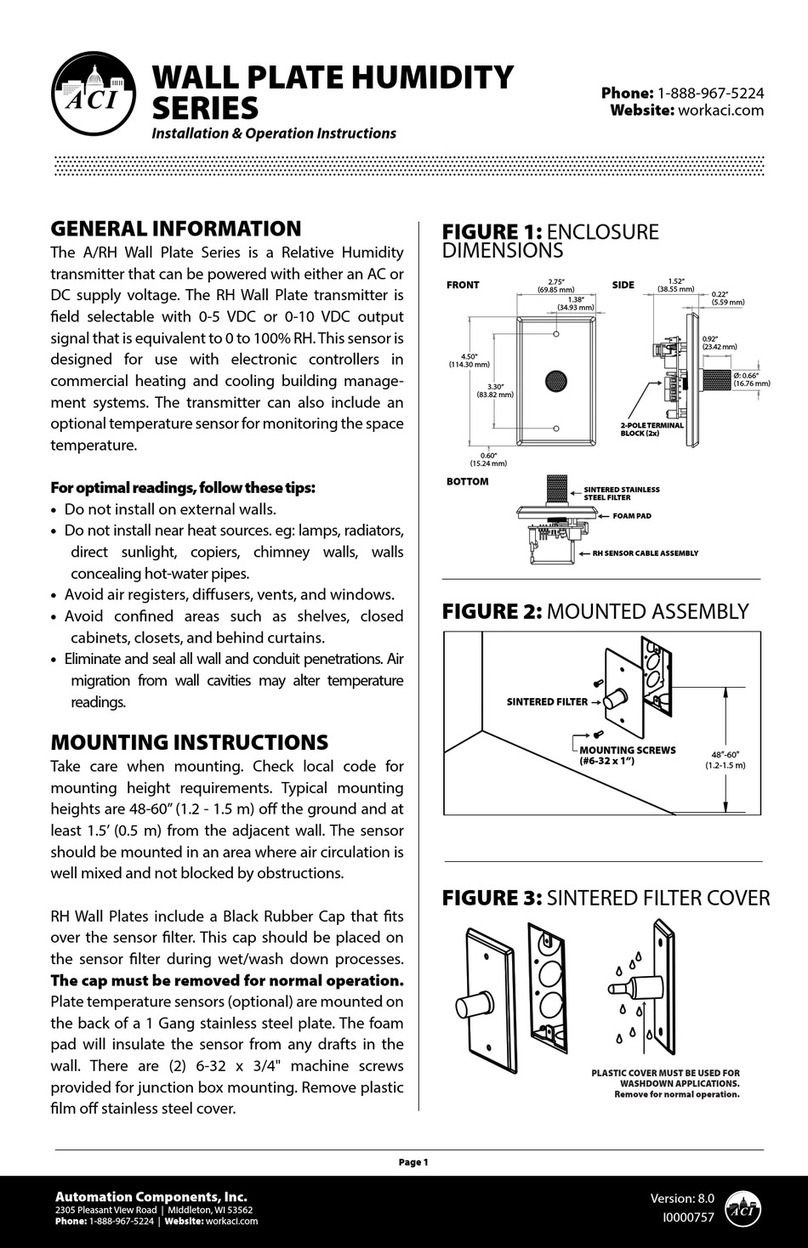

aci WALL PLATE HUMIDITY Series Installation instructions

aci

aci Room Series Installation instructions

aci

aci B5C User manual

aci

aci ACCESS series User manual

aci

aci CTS-M5 User manual

aci

aci Room Series Installation instructions

aci

aci STRAP ON Series Installation instructions

aci

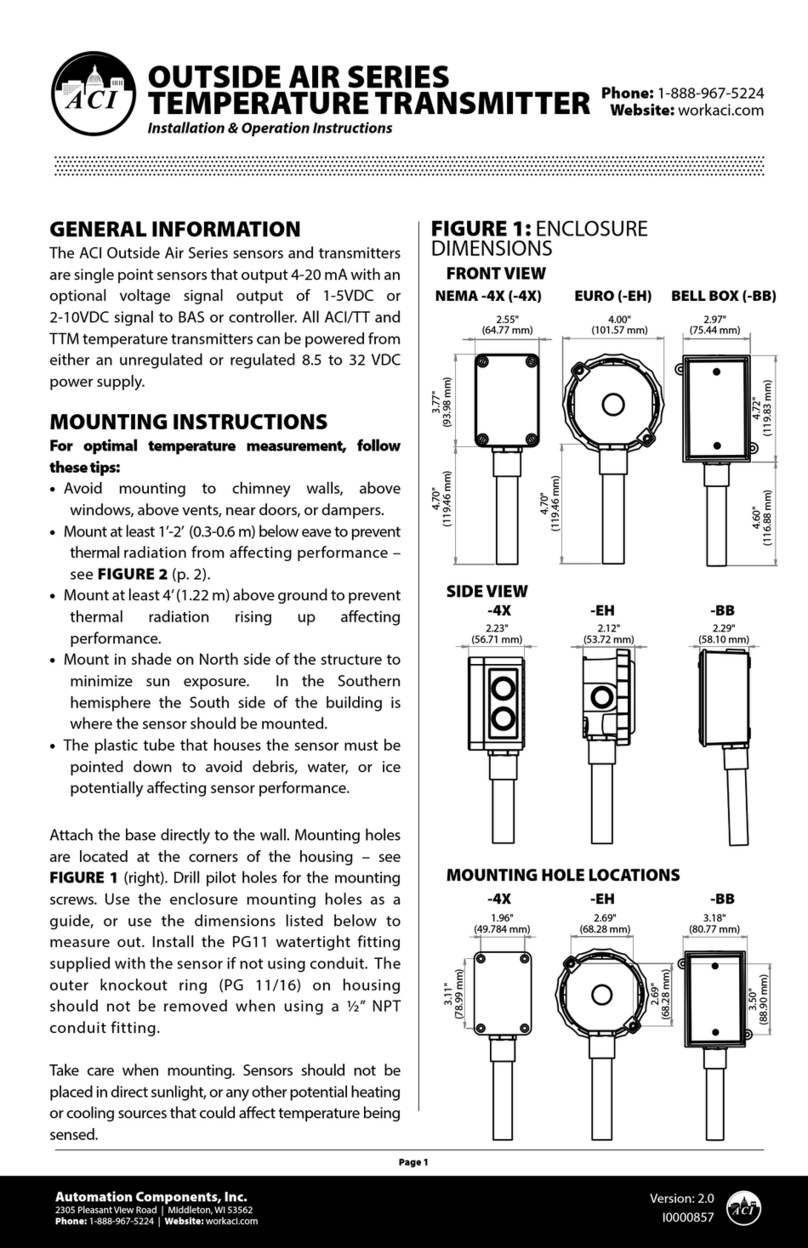

aci OUTSIDE AIR Series Installation instructions

aci

aci Room Series Installation instructions

aci

aci Room Series Installation instructions

Popular Transmitter manuals by other brands

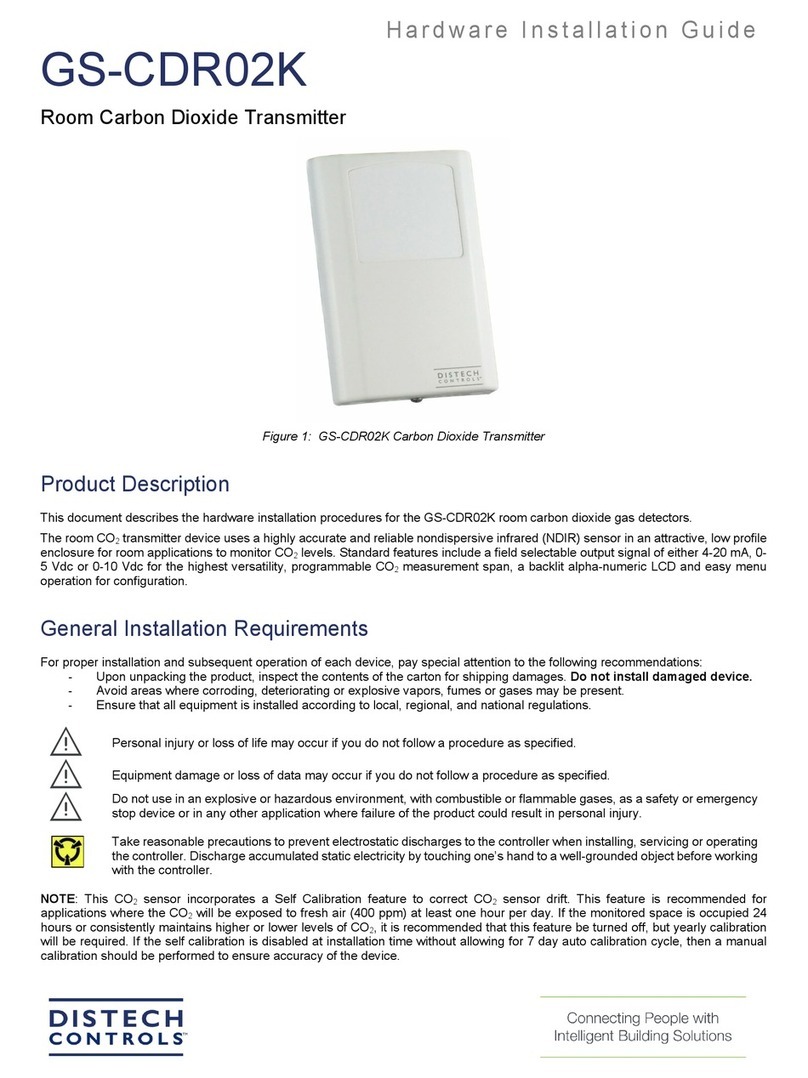

Distech Controls

Distech Controls GS-CDR02K Hardware installation guide

Emerson

Emerson Rosemount 5408 Reference manual

Vaisala

Vaisala HUMICAP HMT310 user guide

M-system

M-system M3LM instruction manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS ALPHA RES 1000 RESISTIVITY... instruction manual

Emerson

Emerson Rosemount 2051G quick start guide