Acromag XMC610 Series User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

XMC610 Series Ethernet Network Interface Cards

USER’S MANUAL

ACROMAG INCORPORATED

30765 South Wixom Road

Wixom, MI 48393-2417 U.S.A.

Tel: (248) 295-0310

Copyright 2019, Acromag, Inc., Printed in the USA.

Data and specifications are subject to change without notice.

8501124D

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 1 -

http://www.acromag.com

- 1 -

www.acromag.com

Table of Contents

1.0 RELATED PUBLICATIONS ................................................................................3

2.0 GENERAL INFORMATION .................................................................................4

2.1 Intended Audience ................................................................................................. 4

2.2 Preface ................................................................................................................... 4

2.2.1 Trademark, Trade Name and Copyright Information.........................................................4

2.2.2 Class A Product Warning ..................................................................................................4

2.2.3 Environmental Protection Statement ...............................................................................4

2.3 Product Overview................................................................................................... 5

2.4 Ordering Information ............................................................................................. 5

2.5 Key Features........................................................................................................... 6

2.6 Software Support ................................................................................................... 7

Windows...............................................................................................................................7

VxWorks...............................................................................................................................7

Linux.....................................................................................................................................7

2.7 Block Diagrams....................................................................................................... 8

Figure 2.7.1: XMC611 Block Diagram.........................................................................................8

Figure 2.7.2: XMC612 Block Diagram.........................................................................................8

Figure 2.7.3: XMC613 Block Diagram.........................................................................................8

3.0 PREPARATION FOR USE ...................................................................................9

3.1 Unpacking and Inspecting....................................................................................... 9

3.2 Installation Considerations................................................................................... 10

3.3 Board Configuration ............................................................................................. 10

4.0 HARDWARE INFORMATION......................................................................... 11

4.1 Connector Information......................................................................................... 11

4.1.1 P15 Primary XMC Connector ..........................................................................................11

4.1.2 P16 Secondary XMC Connector (XMC613 Only) ..............................................................12

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 2 -

http://www.acromag.com

- 2 -

www.acromag.com

4.1.3 SFP Connectors (XMC612 Only)......................................................................................13

4.1.4 RJ45 Connectors (XMC611 Only) ....................................................................................13

5.0 SERVICE AND REPAIR .................................................................................... 14

5.1 Service and Repair Assistance............................................................................... 14

5.2 Preliminary Service Procedure.............................................................................. 14

5.3 Where to Get Help................................................................................................ 14

6.0 SPECIFICATIONS .............................................................................................. 15

6.1 Physical ................................................................................................................ 15

6.2 Power Requirements............................................................................................ 15

6.3 Environmental Considerations.............................................................................. 16

6.3.1 Operating Temperature .................................................................................................16

6.3.2 Relative Humidity ..........................................................................................................16

6.3.3 Vibration and Shock Standards ......................................................................................16

6.3.4 EMC Directives...............................................................................................................17

6.4 Reliability Prediction ............................................................................................ 17

7.0 CERTIFICATE OF VOLATILITY..................................................................... 18

8.0 REVISION HISTORY......................................................................................... 19

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 3 -

http://www.acromag.com

- 3 -

www.acromag.com

IMPORTANT SAFETY CONSIDERATIONS

It is very important for the user to consider the possible adverse effects of power, wiring, component, sensor, or

software failures in designing any type of control or monitoring system. This is especially important where

economic property loss or human life is involved. It is important that the user employ satisfactory overall

system design. It is agreed between the Buyer and Acromag, that this is the Buyer's responsibility.

1.0 RELATED PUBLICATIONS

The following specifications provide necessary information for in depth understanding of this product

and its use in a system architecture.

ANSI/VITA 42.0 –2008 XMC Base Specification

ANSI/VITA 42.3 –2006 XMC PCI Express Protocol Layer Standard

IEEE 802.3 –2008 IEEE Standard for Ethernet

INF-8074i Specification for SFP Transceiver

SFF-8431 Enhanced Small Form Factor Pluggable Module

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 4 -

http://www.acromag.com

- 4 -

www.acromag.com

2.0 GENERAL INFORMATION

2.1 Intended Audience

This users’ manual was written for technically qualified personnel who will

be working with networking devices using this XMC module. It is not

intended for a general, non-technical audience that is unfamiliar with XMC

modules and their application.

2.2 Preface

The information contained in this manual is subject to change without

notice, and Acromag, Inc. (Acromag) does not guarantee its accuracy.

Acromag makes no warranty of any kind with regards to this material,

including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose. Further, Acromag assumes no responsibility

for any errors that may appear in this manual and makes no commitment to

update, or keep current, the information contained in this manual. No part

of this manual may be copied or reproduced in any form, without the prior

written consent of Acromag,

2.2.1 Trademark, Trade Name and Copyright Information

© 2018 by Acromag Incorporated.

All rights reserved. Acromag and Xembedded are registered trademarks of

Acromag Incorporated. All other trademarks, registered trademarks, trade

names, and service marks are the property of their respective owners.

2.2.2 Class A Product Warning

This is a Class A product. In a domestic environment this product may cause

radio interference, in which case the user may find it necessary to take

adequate corrective measures.

2.2.3 Environmental Protection Statement

This product has been manufactured to satisfy environmental protection

requirements where possible. Many components used (structural parts,

circuit boards, connectors, etc.) are capable of being recycled. Final

disposition of this product after its service life must be conducted in

accordance with applicable country, state, or local laws or regulations.

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 5 -

http://www.acromag.com

- 5 -

www.acromag.com

2.3 Product Overview

The XMC610 series modules are XMC modules that use the Intel I350

Ethernet Controller to provide four 1-Gigabit Ethernet interfaces. These

modules interface with the PCIe bus via four high-speed serial lanes on the

XMC P15 connector.

The XMC611 provides the interfaces via four RJ45 connectors available on

the front panel. The XMC612 provides the interfaces via four SFP connectors

available on the front panel. The XMC613 provides the interfaces as

1000BASE-T connections available as Rear I/O via the P16 connector.

2.4 Ordering Information

The following table lists the orderable models and their corresponding

operating temperature range. All models support extended temperature

operation.

MODELS

Description

OPERATING

TEMPERATURE RANGE

XMC611

4-Port RJ45 1GbE NIC XMC

-40C to +85C1

XMC612

4-Port SFP 1GbE NIC XMC

-40C to +85C1,2

XMC613

4-Port Rear I/O 1GbE NIC XMC

-40C to +85C1

1. For applications requiring elevated operating temperatures, a minimum

airflow of 200LFM is recommended.

2. The temperature rating does not apply to the SFP transceiver modules.

Please consult the manufacturer’s documentation of the SFP module to

determine its operating temperature range.

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 6 -

http://www.acromag.com

- 6 -

www.acromag.com

2.5 Key Features

PCIe Bus –The PCI Express Gen 2 interface operates at a bus speed of 5

Gbps per lane per direction. The XMC610 modules utilize a x4 PCIe

interface.

IEEE 802.3 Auto-negotiation –Automatic link configuration for speed,

duplex, and flow control.

IEEE 1588 and 802.1AS Precision Timing –Time-stamping and

synchronization of time sensitive applications. Distribute common time to

connected devices.

IEEE 802.3az Energy Efficient Ethernet (EEE) –Power consumption is

reduced by approximately 50% during idle state.

DMA Coalescing –Reduces platform power consumption by coalescing,

aligning, and synchronizing DMA transfers. Enables synchronizing port

activity and power management of memory, CPU, and other internal

circuitry.

8 Tx and Rx Queue Pairs per Port –Supports VMware NetQueue and

Microsoft VMQ.

Flexible Port Partitioning (PCI-SIG SR-IOV) –Up to 32 Virtual Functions (VFs)

appear as Ethernet Controllers in Linux OSes that can be assigned to VMs,

Kernel processes, or teamed using Linux Bonding Drivers.

TCP/UDP, IPv4/IPv6 Checksum Offloads –Extended Tx descriptors provide

increased offload capabilities.

Jumbo Frame Packet Support –Improves system performance related to

handling of network data on multiprocessor systems.

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 7 -

http://www.acromag.com

- 7 -

www.acromag.com

2.6 Software Support

The XMC610 series products require support drivers specific to your

operating system. Supported operating systems include: Linux, Windows,

and VxWorks.

Windows

Acromag does not provide a custom Windows driver for these products. The

Windows driver for the Intel I350 Ethernet Controller is available at

www.intel.com.

VxWorks

Acromag does not provide a custom VxWorks driver for these products. The

VxWorks driver for the Intel I350 Ethernet Controller is available at

www.intel.com. The Intel Ethernet driver is included in the default VxWorks

7.0 installation.

Linux

Acromag does not provide a custom Linux driver for these products. The

Linux driver for the Intel I350 Ethernet Controller is available at

www.intel.com.

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 8 -

http://www.acromag.com

- 8 -

www.acromag.com

2.7 Block Diagrams

Figure 2.7.1: XMC611 Block

Diagram

Figure 2.7.2: XMC612 Block

Diagram

Figure 2.7.3: XMC613 Block

Diagram

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 9 -

http://www.acromag.com

- 9 -

www.acromag.com

3.0 PREPARATION FOR USE

IMPORTANT PERSONAL AND PRODUCT SAFETY CONSIDERATIONS

It is very important for the user to consider the possible safety implications

of power, wiring, component, sensor, or software failures in designing any

type of control or monitoring system. This is especially important where

personal injury or the loss of economic property or human life is possible. It

is important that the user employ satisfactory overall system design. It is

understood and agreed by the Buyer and Acromag that this is the Buyer's

responsibility.

WARNING: This board utilizes static sensitive components and should only

be handled at a static-safe workstation. This product is an electrostatic

sensitive device and is packaged accordingly. Do not open or handle this

product except at an electrostatic-free workstation. Additionally, do not

ship or store this product near strong electrostatic, electromagnetic,

magnetic, or radioactive fields unless the device is contained within its

original manufacturer’s packaging. Be aware that failure to comply with

these guidelines will void the Acromag Limited Warranty.

3.1 Unpacking and Inspecting

Upon receipt of this product, inspect the shipping carton for evidence of

mishandling during transit. If the shipping carton is badly damaged or water

stained, request that the carrier's agent be present when the carton is

opened. If the carrier's agent is absent when the carton is opened, and the

contents of the carton are damaged, keep the carton and packing material

for the agent's inspection.

For repairs to a product damaged in shipment, refer to the Acromag Service

Policy to obtain return instructions. It is suggested that salvageable shipping

cartons and packing material be saved for future use in the event the

product must be shipped.

This board is physically protected with packing material and electrically

protected with an anti-static bag during shipment. However, it is

recommended that the board be visually inspected for evidence of

mishandling prior to applying power.

The board utilizes static-sensitive components and should only be handled at

a static-safe workstation.

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 10 -

http://www.acromag.com

- 10 -

www.acromag.com

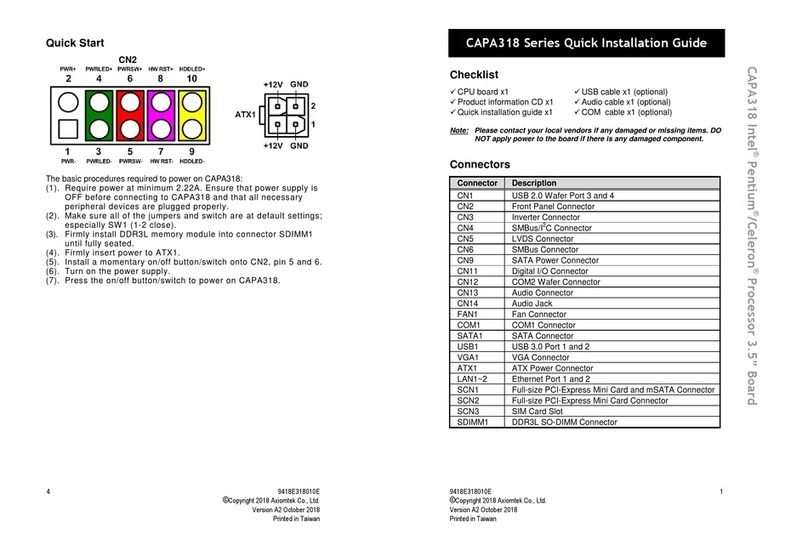

3.2 Installation Considerations

IMPORTANT: Adequate air

circulation must be provided to

prevent a temperature rise

above the maximum operating

temperature.

Refer to the specifications for loading and power requirements. Be sure that

the system power supplies can accommodate the power requirements of

the carrier board, plus the installed XMC modules, within the voltage

tolerances specified.

The dense packing of the XMC module to the carrier/CPU board restricts air

flow within the card cage and is cause for concern. Adequate air circulation

must be provided to prevent a temperature rise above the maximum

operating temperature and to prolong the life of the electronics. If the

installation is in an industrial environment and the board is exposed to

environmental air, careful consideration should be given to air-filtering.

In a conduction cooled assembly, adequate thermal conduction must be

provided to prevent a temperature rise above the maximum operating

temperature.

3.3 Board Configuration

Power should be removed from the board when installing XMC modules,

cables, termination panels, and field wiring.

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 11 -

http://www.acromag.com

- 11 -

www.acromag.com

4.0 HARDWARE INFORMATION

4.1 Connector Information

4.1.1 P15 Primary XMC Connector

The P15 XMC connector is wired per the VITA 42.0 standard. The P15

connector provides four lanes of PCI Express to the Intel Quad GbE Controller.

The PCIe interface is connected per the VITA 42.3 standard.

Table 4.1.1: Primary XMC

Connector P15

Pin

A

B

C

D

E

F

1

PET00+

PET00-

+3.3V

PET01+

PET01-

N.C.

2

GND

GND

TRST#

GND

GND

MRSTI#

3

PET02+

PET02-

+3.3V

PET03+

PET03-

N.C.

4

GND

GND

TCK

GND

GND

MRSTO#

5

N.C.

N.C.

+3.3V

N.C.

N.C.

N.C.

6

GND

GND

TMS

GND

GND

N.C.

7

N.C.

N.C.

+3.3V

N.C.

N.C.

N.C.

8

GND

GND

TDI

GND

GND

N.C.

9

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

10

GND

GND

TDO

GND

GND

GA0

11

PER00+

PER00-

MBIST#

PER01+

PER01-

N.C.

12

GND

GND

GA1

GND

GND

MPRSNT#

13

PER02+

PER02-

+3.3AUX

PER03+

PER03-

N.C.

14

GND

GND

GA2

GND

GND

MSDA

15

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

16

GND

GND

MVMRO

GND

GND

MSCL

17

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

18

GND

GND

N.C.

GND

GND

N.C.

19

REFCLK0_P

REFCLK0_N

N.C.

WAKE#

ROOT#

N.C.

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 12 -

http://www.acromag.com

- 12 -

www.acromag.com

4.1.2 P16 Secondary XMC Connector (XMC613 Only)

The P16 connector is used to provide Rear network I/O support and thus will

only be populated on the XMC613 conduction-cooled model. The P16

secondary XMC connector connects the four 1000BASE-T Ethernet interfaces

as shown in Table 4.1.2.

Table 4.1.2: Secondary XMC

Connector P16

Pin

A

B

C

D

E

F

1

ENET0_P0_P

ENET0_P0_N

ENET3_ACT#

ENET0_P1_P

ENET0_P1_N

ENET3_LINK#

2

GND

GND

ENET2_ACT#

GND

GND

ENET2_LINK#

3

ENET0_P2_P

ENET0_P2_N

ENET1_ACT#

ENET0_P3_P

ENET0_P3_N

ENET1_LINK#

4

GND

GND

ENET0_ACT#

GND

GND

ENET0_LINK#

5

ENET1_P0_P

ENET1_P0_N

NC

ENET1_P1_P

ENET1_P1_N

NC

6

GND

GND

NC

GND

GND

NC

7

ENET1_P2_P

ENET1_P2_N

NC

ENET1_P3_P

ENET1_P3_N

NC

8

GND

GND

NC

GND

GND

NC

9

NC

NC

NC

NC

NC

NC

10

GND

GND

NC

GND

GND

NC

11

ENET2_P0_P

ENET2_P0_N

NC

ENET2_P1_P

ENET2_P1_N

NC

12

GND

GND

NC

GND

GND

NC

13

ENET2_P2_P

ENET2_P2_N

NC

ENET2_P3_P

ENET2_P3_N

NC

14

GND

GND

NC

GND

GND

NC

15

ENET3_P0_P

ENET3_P0_N

NC

ENET3_P1_P

ENET3_P1_N

NC

16

GND

GND

NC

GND

GND

NC

17

ENET3_P2_P

ENET3_P2_N

NC

ENET3_P3_P

ENET3_P3_N

NC

18

GND

GND

NC

GND

GND

NC

19

NC

NC

NC

NC

NC

NC

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 13 -

http://www.acromag.com

- 13 -

www.acromag.com

4.1.3 SFP Connectors (XMC612 Only)

On the XMC612 model, the four Gigabit Ethernet interfaces are available via

standard SFP connectors. The XMC612 is fully compliant with the SFP Multi-

Source Agreement and supports the use of all compliant SFP transceiver

modules.

Table 4.1.3: SFP Connectors

P1 –P4

11

VEER (GND)

VEER (GND)

10

12

RD-

RS1

9

13

RD+

RX_LOS

8

14

VEER (GND)

RS0

7

15

VCCR (+3.3V)

MOD_ABS

6

16

VCCT (+3.3V)

SCL

5

17

VEET (GND)

SDA

4

18

TD+

TX_DISABLE

3

19

TD-

TX_FAULT

2

20

VEET (GND)

VEET (GND)

1

4.1.4 RJ45 Connectors (XMC611 Only)

On the XMC611 model, the four Gigabit Ethernet interfaces are available via

standard RJ45 connectors.

Table 4.1.4: RJ45 Connectors

J1 –J4

Pin

Pin Description

1

TRD0+

2

TRD0-

3

TRD1+

6

TRD1-

4

TRD2+

5

TRD2-

7

TRD3+

8

TRD3-

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 14 -

http://www.acromag.com

- 14 -

www.acromag.com

5.0 SERVICE AND REPAIR

5.1 Service and Repair Assistance

Surface-Mounted Technology (SMT) are generally difficult to repair. It is

highly recommended that a non-functioning board be returned to Acromag

for repair. The board can be damaged unless special SMT repair and service

tools are used. Further, Acromag has automated test equipment that

thoroughly checks the performance of each board.

Please refer to Acromag's Service Policy Bulletin or contact Acromag for

complete details on how to obtain parts and repair.

5.2 Preliminary Service Procedure

CAUTION: POWER MUST BE TURNED OFF BEFORE SERVICING BOARDS

Before beginning repair, be sure that all the procedures in the "Preparation

for Use" section have been followed. Also, refer to the documentation of

your carrier board to verify that it is correctly configured. Replacement of

the board with one that is known to work correctly is a good technique for

isolating a faulty part.

5.3 Where to Get Help

If you continue to have problems, your next step should be to visit the

Acromag worldwide web site at https://www.acromag.com. Our web site

contains the most up-to-date product and software information.

Go to the “Support” tab or your specific XMC model ordering page.

Acromag’s application engineers can also be contacted directly for technical

assistance via email, telephone, or FAX through the contact information

listed below. Note that an email question can also be submitted from within

the Knowledge Base or directly from the “Contact Us” tab. When needed,

complete repair services are also available.

•Email: [email protected]

•Phone: 248-295-0310

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 15 -

http://www.acromag.com

- 15 -

www.acromag.com

6.0 SPECIFICATIONS

6.1 Physical

Length: 149.0 mm (5.866 in.)

Width: 74.0 mm (2.913 in.)

Stacking Height: 10.0 mm (0.394 in.)

Weight XMC611: 83.2 g

Weight XMC612: 98.5 g

Weight XMC613: 78.5 g

Unit weight does not include shipping materials.

6.2 Power Requirements

The XMC610 boards are powered entirely from the 3.3V supply

present on the XMC P15 connector. The 5V/12V VPWR supply is not

used on these boards.

The following power consumption values were measured with 2 ports

utilized, 4 ports utilized, and with all ports idle or all ports active.

Active ports were measured while operating with continuous network

traffic at link speed at full duplex.

XMC611

3.3V (mA)

Total Power (mW)

2 Ports Idle1

401

1323

2 Ports Active

885

2920

4 Ports Idle1

517

1706

4 Ports Active

1126

3717

XMC612

3.3V (mA)

Total Power (mW)

2 Ports Idle

494

1630

2 Ports Active

554

1830

4 Ports Idle

585

1932

4 Ports Active

701

2313

XMC613

3.3V (mA)

Total Power (mW)

2 Ports Idle1

401

1323

2 Ports Active

885

2920

4 Ports Idle1

517

1706

4 Ports Active

1126

3717

1. Energy Efficient Ethernet Enabled

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 16 -

http://www.acromag.com

- 16 -

www.acromag.com

6.3 Environmental Considerations

6.3.1 Operating Temperature

Table 6.3.1: Operating

Temperature

MODELS

Description

OPERATING

TEMPERATURE RANGE

XMC611

4-Port RJ45 1GbE NIC XMC

-40C to +85C1

XMC612

4-Port SFP 1GbE NIC XMC

-40C to +85C1,2

XMC613

4-Port Rear I/O 1GbE NIC XMC

-40C to +85C1

1. For applications requiring elevated operating temperatures, a minimum

airflow of 200LFM is recommended.

2. The temperature rating does not apply to the SFP transceiver modules.

Please consult the manufacturer’s documentation of the SFP module to

determine its operating temperature range.

6.3.2 Relative Humidity

The range of acceptable relative humidity is 5% to 95% non-condensing.

6.3.3 Vibration and Shock Standards

The XMC610 series products are designed to comply with the following

Vibration and Shock standards.

Vibration, Random Operating: Designed to comply with VITA 47 Class

V1. Shall withstand vibration from 5 to 100Hz. with Power Spectral

Density (PSD) = 0.04g2/Hz, for 1 hour per axis. Testing shall be in

accordance with MIL-STD-810, Method 514, Procedure 1

Shock, Operating: Designed to comply with VITA 47 Class OS1, 20g,

11ms half sine and terminal sawtooth shock pulses. 3 shock pulses in

each direction along 3 axes (36 shocks, total). Testing shall be in

accordance with MIL-STD-810, Method 516, Procedure 1.

Summarized below are the operating temperature range, airflow and other

environmental requirements and applicable standards for the XMC610

Series modules.

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 17 -

http://www.acromag.com

- 17 -

www.acromag.com

6.3.4 EMC Directives

Electromagnetic Compatibility (EMC): CE Marked, per EMC Directive

2014/30/EU Class A.

The XMC610 family is designed to comply with EMC Directive 2014/30/EU.

•Immunity per EN 61000-6-2:

Electrostatic Discharge Immunity (ESD), per IEC 61000-4-2.

Radiated Field Immunity (RFI), per IEC 61000-4-3.

Electrical Fast Transient Immunity (EFT), per IEC 61000-4-4.

Surge Immunity, per IEC 61000-4-5.

Conducted RF Immunity (CRFI), per IEC 61000-4-6.

•Emissions per EN 61000-6-4:

Enclosure Port, per CISPR 16.

Low Voltage AC Mains Port, per CISPR 16.

Note: This is a Class A product

FCC Conformity: These devices comply with Part 15, Class A of the FCC rules.

Operation is subject to the following two conditions: (1) These devices may not

cause harmful interference, and (2) these devices must accept any interference

received, including interference that may cause undesired operation.

6.4 Reliability Prediction

Table 6.4.1: XMC611 MTBF

Predictions

MTBF (Mean Time Between Failure): MTBF in hours using MIL-HDBK-217F,

FN2. Per MIL-HDBK-217, Ground Benign, Controlled, GBGC

Temperature

MTBF (Hours)

MTBF (Years)

Failure Rate (FIT1)

25°C

1,506,982

172.0

663.6

40°C

1,089,482

124.4

917.9

1FIT is Failures in 109hours.

Table 6.4.2: XMC612 MTBF

Predictions

MTBF (Mean Time Between Failure): MTBF in hours using MIL-HDBK-217F,

FN2. Per MIL-HDBK-217, Ground Benign, Controlled, GBGC

Temperature

MTBF (Hours)

MTBF (Years)

Failure Rate (FIT1)

25°C

1,846,170

210.7

541.7

40°C

1,257,870

143.6

795.0

1FIT is Failures in 109hours.

Table 6.4.3: XMC613 MTBF

Predictions

MTBF (Mean Time Between Failure): MTBF in hours using MIL-HDBK-217F,

FN2. Per MIL-HDBK-217, Ground Benign, Controlled, GBGC

Temperature

MTBF (Hours)

MTBF (Years)

Failure Rate (FIT1)

25°C

1,527,620

174.4

654.6

40°C

1,109,159

126.6

901.6

1FIT is Failures in 109hours.

XMC610 SERIES

USER’S MANUAL

Acromag, Inc. Tel: 248-295-0310 - 18 -

http://www.acromag.com

- 18 -

www.acromag.com

7.0 Certificate of Volatility

Certificate of Volatility

Acromag Models:

XMC611

XMC612

XMC613

Manufacturer:

Acromag, Inc.

30765 Wixom Rd

Wixom, MI 48393

Volatile Memory

Does this product contain Volatile memory (i.e. Memory of whose contents are lost when power is removed)?

□ Yes ■No

Type (SRAM, SDRAM,

etc.)

Size:

User Modifiable

□ Yes

□ No

Function:

Process to Sanitize:

Non-Volatile Memory

Does this product contain Non-Volatile memory (i.e. Memory of whose contents is retained when power is removed)?

■Yes □ No

Type (EEPROM, Flash,

etc.)

EEPROM

Size:

2 Kbit

User Modifiable

■Yes

□ No

Function:

FRU Records

Process to Sanitize:

Clear EEPROM by

erasing all bytes.

Type (EEPROM, Flash,

etc.)

EEPROM

Size:

128 Kbit

User Modifiable

□Yes

■No

Function:

I350 Configuration

Data

Process to Sanitize:

Clear EEPROM by

erasing all bytes.

Acromag Representative

Name:

Russ Nieves

Title:

Dir. of Sales and Marketing

Email:

Office Phone:

248-295-0310

Office Fax:

248-624-9234

This manual suits for next models

3

Table of contents

Other Acromag Computer Hardware manuals

Acromag

Acromag XVPX-6300 User manual

Acromag

Acromag APCe8675 User manual

Acromag

Acromag ACPS3320 User manual

Acromag

Acromag APCe7012E-LF User manual

Acromag

Acromag XVME-6700 User manual

Acromag

Acromag BusWorks XT Series User manual

Acromag

Acromag IOS-7200 User manual

Acromag

Acromag AVME9440 Series User manual

Acromag

Acromag APCe8775 User manual

Acromag

Acromag XMC630 Series User manual