www.tamcodampers.com

© T.A. Morrison & Co. Inc., 2017

FRONT / TOP END UP / RIGHT HAND

CALL TAMCO CUSTOMER SERVICE WITH ANY

QUESTIONS CONCERNING TAMCO SMOKE DAMPERS.

DO NOT ADJUST LINKAGE MECHANISM.

IF PROBLEM STILL EXISTS AFTER VERIFICATION AND

CORRECT ACTION, CALL TAMCO CUSTOMER SERVICE.

Note that all technical information available on TAMCO’s website at

www.tamcodampers.com supersedes and takes precedence over all

information contained within the printed catalog.

READ ENTIRE INSTALLATION GUIDELINES MANUAL

BEFORE INSTALLING DAMPERS.

CHECK ALL DAMPER SIZES AND TAGS TO ENSURE

THAT SMOKE DAMPERS ARE INSTALLED IN THEIR

CORRESPONDING OPENINGS.

TAMCO UL/ULC APPROVED SMOKE DAMPER |

Installation Guidelines

For Series 1000 SM & 1000 SM-M

Applies to all Options and Install Types

1

>Any alteration to or deviation from TAMCO's UL Classified, Smoke

Damper Installation Guidelines must be approved by the local AHJ

(Authority Having Jurisdiction).

>Angle clips described in these installation guidelines are minimum

16 ga (1.5 mm) zinc-plated or stainless steel or .125” (3 mm) extruded

aluminum. Angle legs are to be a minimum 1” x 1” (25.4 mm x

25.4 mm) and are to be a minimum ½” (12.7 mm) wide with 0.15"

(4 mm) diameter screw holes. Continuous or full-length zinc-plated,

extruded aluminum, or stainless steel angles are also acceptable.

>Smoke dampers must be installed at, or adjacent to, but no more

than 24" (609 mm) from the point where the duct or opening passes

through the smoke barrier. This must be done in accordance with

NFPA 90A.

>Duct air inlets, outlets or branches shall not be located between the

smoke damper and the smoke barrier.

>Smoke dampers must not be installed in fiberglass-lined ducts in a

manner that will damage the lining material, or interfere with damper

blade operation.

>Provide a duct hanger at a smoke damper location, when the duct

strength is inadequate for the damper and its operator.

>An access door must be provided, if the damper actuator is mounted

inside the duct.

GENERAL INSTALLATION NOTES:

&

>Smoke dampers must be installed square and free from racking, to

ensure proper operation and performance.

>Dampers must be installed without stretching or compression, to

allow them to maintain their original factory adjustment, thereby

retaining their low leakage rating.

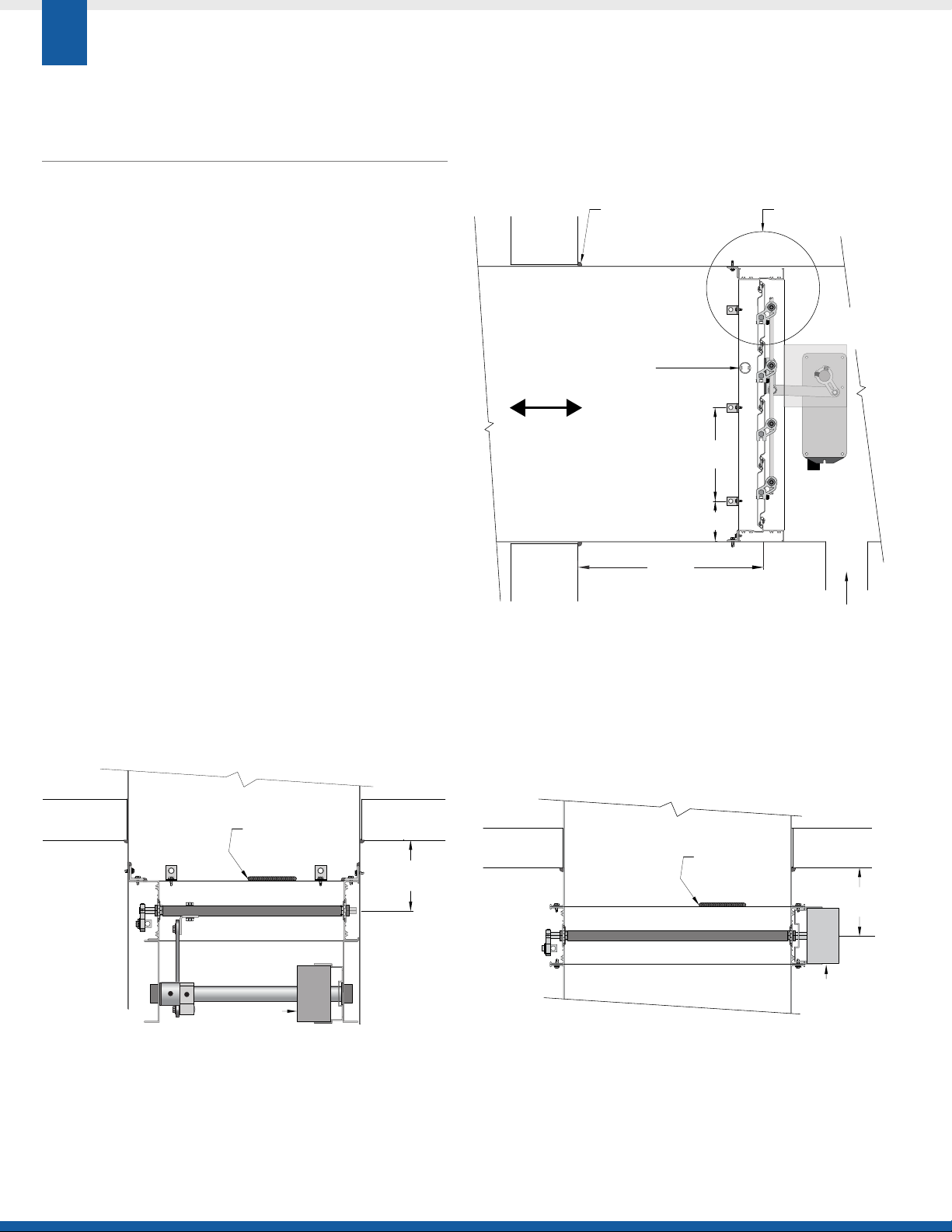

>TAMCO Smoke Dampers are approved to be installed either standing

in the vertical plane, or lying in the horizontal plane. If smoke

dampers are installed standing in the vertical plane, damper blades

must be horizontal.

>Only lift dampers via sleeve or damper frame. Never lift damper by

holding on to the damper blades or actuator.

>All connections on the back or rear side of the smoke damper frame

(opposite to sticker side), where the damper makes contact with the

duct, sleeve, or substrate must be sealed using a ⅛" (3.2 mm) bead of

silicone sealant. (See "Installation Procedures for Smoke Damper Install

Types" for recommended silicone seal brands.)

>When installing a multiple-section smoke damper assembly, all joints

where damper frames meet must be sealed, using a bead of silicone

sealant.

>TAMCO Smoke Dampers must be kept in an environment that is free

of dirt, dust, wall texture, paint over-spray, and other contaminants,

prior to and after installation, to ensure proper damper operation and

to guard against damage.

MANUFACTURER'S RECOMMENDATIONS:

&

>When smoke dampers arrive at the job site, inspect all material for

obvious and hidden damage. Report any damage or missing parts to

TAMCO Customer Service.

>Store dampers indoors to protect them from environmental

conditions and to avoid damage.

>All moving parts of the damper must be inspected and cycled at

intervals not greater than every twelve (12) months or in accordance

with the latest edition of NFPA 80, 90A, 92A, local codes and the

actuator manufacturer.

>Dry lubricants are recommended.

>Smoke dampers do not typically require maintenance, if the

environment they are installed in is kept dry and clean.

OPTIONS FOR SERIES 1000 SM & 1000 SM-M:

&

>MR Moisture Resistance Option

>SW Salt Water Resistance Option