USER INFORMATION

User Information shall be provided to the user of the product. NFPA Standard 1983, incorporated

into the 2022 edition of NFPA 2500 recommends separating the User Information from the equipment

and retaining the information in a permanent record. The standard also recommends making a copy

of the User Information to keep with the equipment and that the information should be referred to

before and after each use.

Additional information regarding life safety equipment can be found in NFPA 1500 and NFPA 1858

and NFPA 1983, incorporated in the 2022 edition of NFPA 2500.

LIFESPAN / INSPECTION / RETIREMENT

The equipment has a lifespan of 10 years from the date of manufacture shown on the product label.

The type of use, intensity of use, and environment of use are all factors in determining serviceability

of the equipment. A single exceptional event can be cause for retirement after only one use, such as

exposure to sharp edges, extreme temperatures, chemicals, or harsh environments. Any concerns

about its safe use is cause for retirement. Remove retired equipment from service and destroy it to

prevent further use.

A device must be retired when:

• It fails to pass inspection.

• It fails to function properly.

• It has illegible product labels or markings.

• It shows signs of damage or excessive wear.

• It has been subjected to shock loads, falls, or abnormal use.

• It has been exposed to harsh chemical reagents.

• It has an unknown usage history.

• You have any doubt as to its condition or reliability.

• When it becomes obsolete due to changes in legislation, standards, technique or incompatibility

with other equipment.

Inspect the equipment according to your department’s policy for inspecting life safety equipment.

CMC recommends a detailed inspection by a competent person at least once every 12 months

depending on current regulations and conditions of use. Record the date, inspector name, and

inspection results in the equipment log as well as any other relevant information to track the usage

history.

Before each use, the user should:

• Conrm the equipment is functioning properly.

• Verify the presence and legibility of the product labels and markings.

• Check soft components for cuts, worn or frayed areas, broken bers, soft or hard spots,

discoloration, or melted bers. Check the stitching for pulled threads, abrasion, or breaks.

• Check hard components for excessive wear or indications of damage such as deformation,

corrosion, sharp edges, cracks, or burrs. Minor nicks or sharp spots may be smoothed with

emery cloth or similar.

• Check for the presence of dirt or foreign objects that can affect or prevent normal operation

such as grit, sand, rocks, and debris.

During Each Use, the user should:

• Conrm all pieces of equipment in the system are correctly positioned with respect to each

other.

• Monitor the condition of the equipment and its connections to other equipment in the system.

• Do not allow anything to interfere with the operation of the equipment or its components.

• Prevent foreign objects from interfering with moving parts.

LIMITATIONS AND PROPER USE

The AirBag is designed to extricate non-ambulatory subjects during helicopter hoist or short haul

operations. It is certied to NFPA litter specications and has breaking strengths as specied in

the certication section of this document. The AirBag is designed to be compatible with most

backboards, rigid litters and vacuum splints. Bi-lateral patient access ports allow for patient

monitoring and access when the bag is closed. All exterior side handles are load bearing, however

the recommended hoisting point is from the bridle D-rings. If the AirBag needs to be carried to an

improved extraction area, the bridles can be stowed in the side pockets. See below for additional

product-specic guidance.

PRE-DEPLOYMENT

Prior to placing the AirBag in service, make sure that the individual bridle legs are adjusted properly.

The AirBag should have a slightly head-up attitude. Verify that there is enough oor clearance to

allow a transition of the AirBag into the aircraft. Once initial adjustments to the bridle legs are made,

adjustments in the eld should not be necessary.

USING THE HELITACK AIRBAG

• The patient is typically pre-packaged on a backboard, rigid litter, or vacuum splint.

• Deploy and open the AirBag adjacent to the patient. Place the packaged patient inside the

AirBag. Use the interior straps to secure the patient inside the AirBag.

• The 1 inch head straps are intended to be threaded through the top backboard handles or

litter rails to prevent sliding during use.

• In preparation for lift, close the AirBag. Connect and cinch the exterior straps.

• Connect both of the bridle D-rings into the hoist hook. Do not attach the hoist hook to the

handles or any other point on the AirBag.

• If an attendant is utilized, they should be independently connected into the hoist hook. The

attendant should be positioned in a manner that will assist with the cabin transition and with

clearing the AirBag from aircraft landing gear.

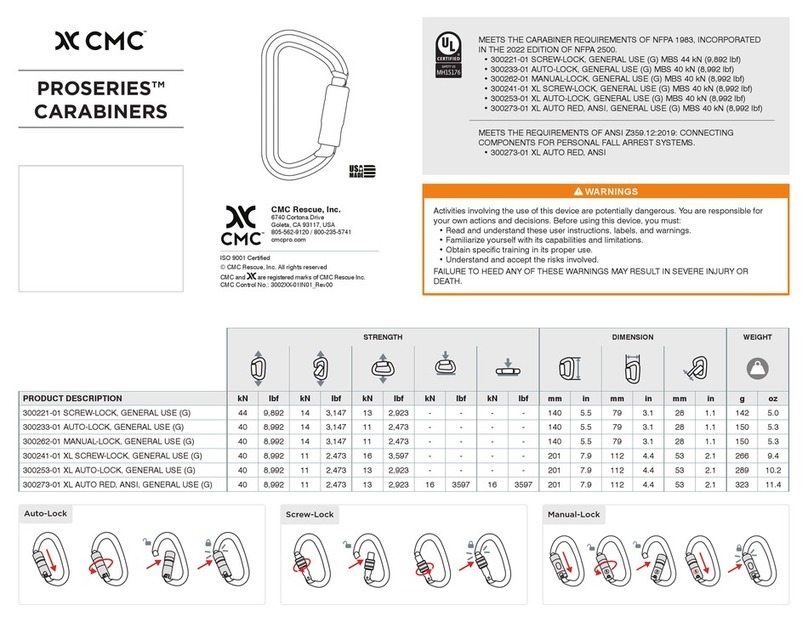

WARNING: Use only with locking hoist hooks. If carabiners are used, make sure they are of the

locking type. CMC recommends using auto-locking carabiners for aviation related

applications.

TAGLINE ATTACHMENT

A tagline (if utilized) can be connected to any of the exterior yellow handles.

WARNING: Do not attach a tagline to the D-Rings, carabiners, or any point not mentioned in

the statement above. A weak-link must always be used with a tagline.

CARRYING, MAINTENANCE & STORAGE

During all use, carrying, storage, and transport keep the equipment away from acids, alkalis, exhaust

emissions, rust and strong chemicals. Do not expose the equipment to direct heat, ame, or high

temperatures or other adverse environmental conditions. If the equipment becomes soiled, it can

be washed in cold water with a mild detergent that is safe for use with nylon and polyester. Rinse

thoroughly. Do not use a pressure washer. Air dry in temperatures between 10° C and 30° C. Do not

dry the equipment in direct sunlight or using an automatic dyer. Lubricate moving parts as needed.

During storage and transport, protect the equipment from heat, direct sunlight, moisture, chemicals,

and external loads or impacts. Do not store where the equipment may be exposed to moist air,

particularly where dissimilar metals are stored together. Consult with the manufacturer in case of any

doubt.

WARRANTY & REPAIRS

If your CMC product has a defect due to workmanship or materials, please contact CMC Customer

Support at

[email protected] for warranty information and service. CMC’s warranty does not cover

damages caused by improper care, improper use, alterations and modications, accidental damage

or the natural breakdown of material over extended use and time. All repair work shall be performed

by the manufacturer. All other work or modications void the warranty and releases CMC from all

liability and responsibility as the manufacturer.