!

!

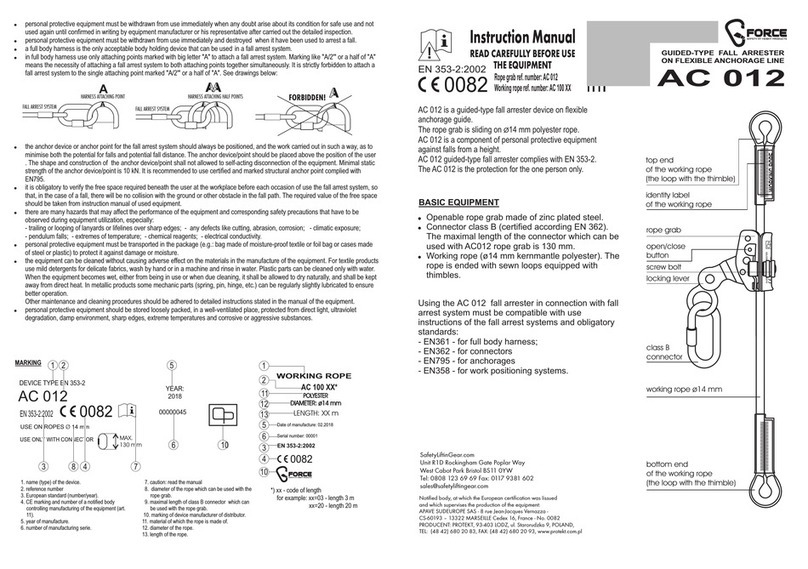

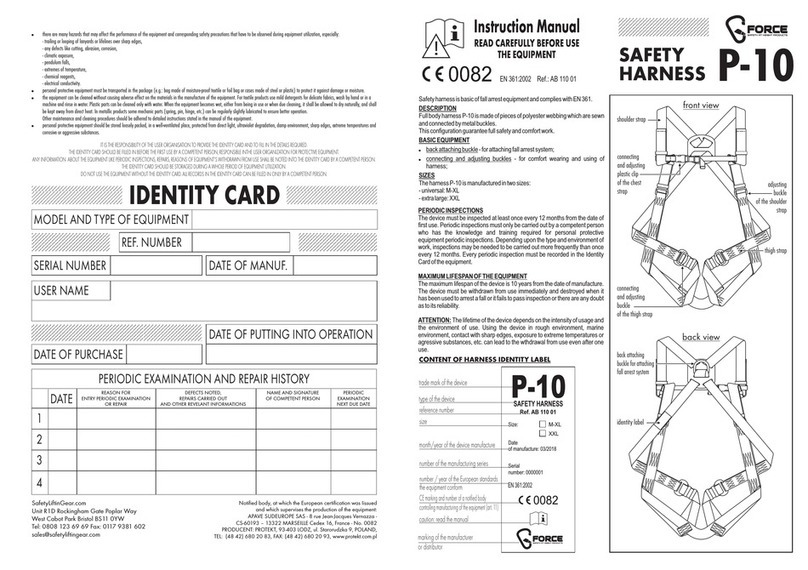

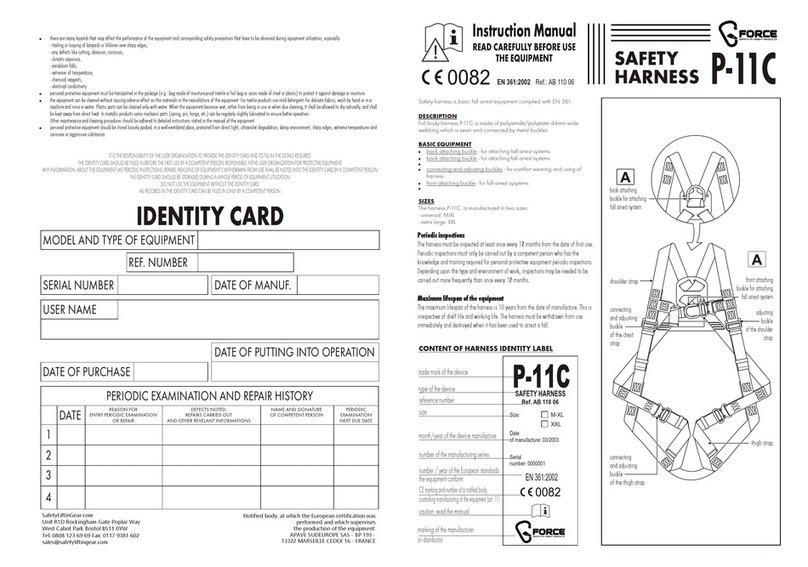

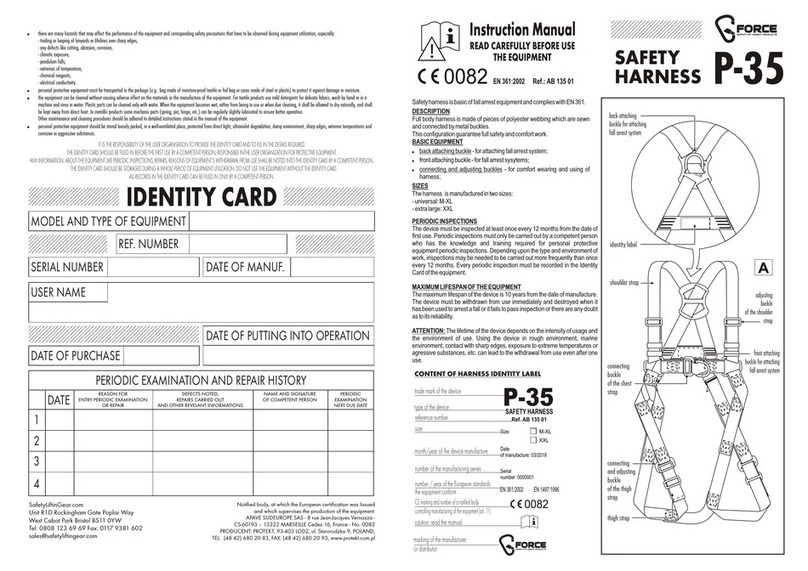

the fall arrest system must be connected only to the attaching elements of the harness marked by capital letter A.

The fall arrest system must be connected only to the front or back attaching buckle.

The back attaching buckle is marked by a capital letter A - marked on the crossing plate with arrows indicating back attaching

buckle - 1.

The front attaching buckle is marked by a capital letter A on the label placed near the buckle - 2.

See drawings below.

structural anchor point for connecting fall arrest system should be situated above the working position and should have static

resistance min. 10 kN. The shape of the structural anchor point should not letself-acting disconnection of fall arrest system.

It is recommended to use certified and marked structural anchor point complied with EN 795.

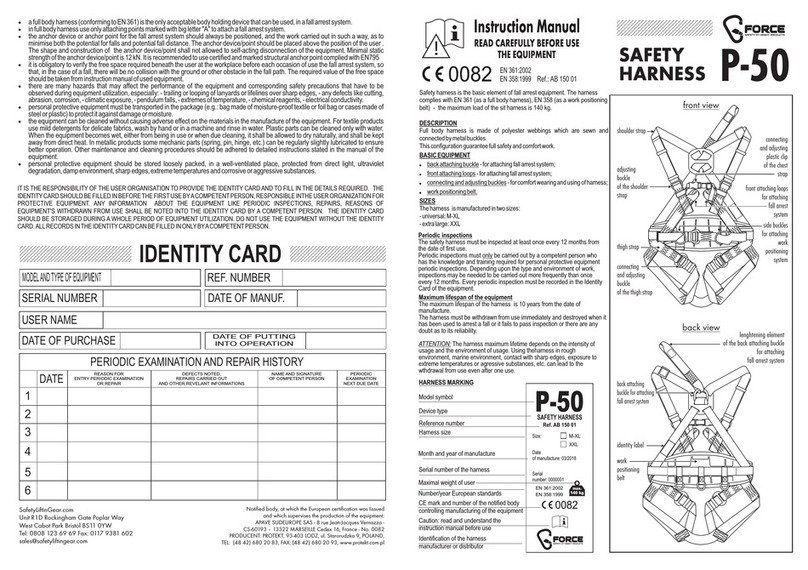

HOW TO PUT ON THE HARNESS

Harness is put on correctly if:

all straps are correctly adjusted (neither too loose nor too tight).

back attaching buckle is correctly positioned at the level of the shoulder blades.

front chest strap is correctly positioned at the middle of the chest.

the ends of all the straps must be kept by plastic loops.

Take the harness by the back attaching

buckle.

Put on the shoulder straps one after one,

take care do not twist them.

Connect chest strap buckle and adjust

the tension the chest strap.

Pull one and then other thigh straps

through crottch, take care do not twist

them.

Connecting of the steel buckles of the thigh straps and chest strap

Shortening Lengthening

Adjusting of the thigh straps and chest strap

1

9

2

10

3 4

Adjusting of the shoulder straps

Shortening Lengthening

5 6 7 8

12

ATTACHING FALL ARREST SYSTEM

!personal protective equipment shall only be used by a person trained and competent in its safe use.

!personal protective equipment must not be used by a person with medical condition that could affect the safety of the equipment user in normal and emergency use.

!a rescue plan shall be in place to deal with any emergencies that could arise during the work.

!it is forbidden to make any alterations or additions to the equipment without the manufacturer's prior written consent.

!any repair shall only be carried out by equipment manufacturer or his certified representative.

!personal protective equipment shall not be used outside its limitations, or for any purpose other than that for which it is intended.

!personal protective equipment should be a personal issue item.

!before use ensure about the compatibility of items of equipment assembled into a fall arrest system. Periodically check connecting and adjusting of the equipment components to avoid accidental loosening or

disconnecting of the components.

!it is forbidden to use combinations of items of equipment in which the safe function of any one item is affected by or interferes with the safe function of another.

!before each use of personal protective equipment it is obligatory to carry out a pre-use check of the equipment, to ensure that it is in a serviceable condition and operates correctly before it is used.

!during pre-use check it is necessary to inspect all elements of the equipment in respect of any damages, excessive wear, corrosion, abrasion, cutting or incorrect acting, especially take into consideration:

- in full body harnesses and belts - buckles, adjusting elements, attaching points, webbings, seams, loops;

- in energy absorbers - attaching loops, webbing, seams, casing, connectors;

- in textile lanyards or lifelines or guidelines - rope, loops, thimbles, connectors, adjusting element, splices;

- in steel lanyards or lifelines or guidelines - cable, wires, clips, ferrules, loops, thimbles, connectors, adjusting elements;

- in retractable fall arresters - cable or webbing, retractor and brake proper acting, casing, energy absorber, connector;

- in guided type fall arresters - body of the fall arrester, sliding function, locking gear acting, rivets and screws, connector, energy absorber;

- in connectors - main body, rivets, gate, locking gear acting.

!after every12 months of utilization, personal protective equipment must be withdrawn from use to carry out periodical detailed inspection. The periodic inspection must be carried out by

a competent person for periodic inspection. The periodic inspection can be carried out also by the manufacturer or his authorized representative.

In case of some types of the complex equipment e.g. some types of retractable fall arresters the annual inspection can be carried out only by the manufacturer or his authorized representative.

!regular periodic inspections are the essential for equipment maintenance and the safety of the users which depends upon the continued efficiency and durability of the equipment.

!during periodic inspection it is necessary to check the legibility of the equipment marking.

!it is essential for the safety of the user that if the product is re-sold outside the original country of destination the reseller shall provide instructions for use, for maintenance, for periodic examination and for

repair in language of the country in which the product is to be used.

!personal protective equipment must be withdrawn from use immediately when any doubt arise about its condition for safe use and not used again until confirmed in writing by equipment manufacturer or his

representative after carried out the detailed inspection.

!personal protective equipment must be withdrawn from use immediately and destroyed (or another procedures shall be introduced according detailed instruction from equipment manual) when it have been

used to arrest a fall.

,

!a full body harness is the only acceptable body holding device that can be used in a fall arrest system.

!the anchor device or anchor point for the fall arrest system should always be positioned, and the work carried out in such a way, as to minimise both the potential for falls and potential fall distance. The anchor

device/point should be placed above the position of the user . The shape and construction of the anchor device/point shall not allowed to self-acting disconnection of the equipment. Minimal static strength of

the anchor device/point is 10 kN. It is recommended to use certified and marked structural anchor point complied with EN795.

!it is obligatory to verify the free space required beneath the user at the workplace before each occasion of use the fall arrest system, so that, in the case of a fall, there will be no collision with the ground or

other obstacle in the fall path. The required value of the free space should be taken from instruction manual of used equipment.

THE ESSENTIAL PRINCIPLES FOR USERS OF PERSONAL PROTECTIVE EQUIPMENT AGAINST FALLS FROM A HEIGHT

11 12

A

A

Using the harness in connection with fall arrest system must be compatible with manual instructions of the fall arrest systems and

obligatory standards:

- EN353-1, EN353-2, EN355, EN354, EN360, EN362 - for the fall arrest systems;

- EN795 - for anchor devices;

- EN341 - for the rescue equipment.