10 American Dryer Corp. 113362- 25

Exhaust Requirements _______________

Exhaust ductwork should be designed and installed by a

qualified professional. Improperly sized ductwork will create

excessive back pressure, which results in slow drying,

increased use of energy, and shutdown of the burner by the

airflow (sail) switch, burner hi-limit, or lint chamber hi-limit

protector thermostat. The dryer must be installed with a

proper exhaust duct connection to the outside.

The design of the flue system shall be such that any

condensate formed when operating the appliance from cold

shall either be retained and subsequently re-evaporated or

discharged.

CAUTION: This dryer produces combustible lint and

must be exhausted to the outdoors.

Improperly sized or installed exhaust ductwork can

create a potential fire hazard.

The ductwork should be laid out in such a way that the

ductwork travels as directly as possible to the outdoors with

as few turns as possible. Single or independent dryer

venting is recommended. It is suggested that the use of

90° turns be avoided; use 30° and/or 45° bends instead.

The radius of the elbows should preferably be 1-1/2 times

the diameter of the duct. All ductwork should be smooth

inside with no projections from sheet metal screws or other

obstructions, which will collect lint. When adding ducts, the

duct to be added should overlap the duct to which it is to be

connected. All ductwork joints must be taped to prevent

moisture and lint from escaping into the building. Inspection

doors should be installed at strategic points in the exhaust

ductwork for periodic inspection and cleaning of lint from

the ductwork.

IMPORTANT: Exhaust back pressure measured by a

manometer/magnehelic in the exhaust duct must be no

less than 0 and must not exceed 0.3 in WC (0.74 mb).

NOTE: It is recommended that exhaust or booster fans

not be used in the exhaust ductwork system except where

necessary to maintain exhaust back pressure (in the

exhaust duct) between zero and 0.3 inch water column.

Where employed, booster fans must not activate the dryer

airflow proving switch (sail switch) when the dryer is not in

operation.

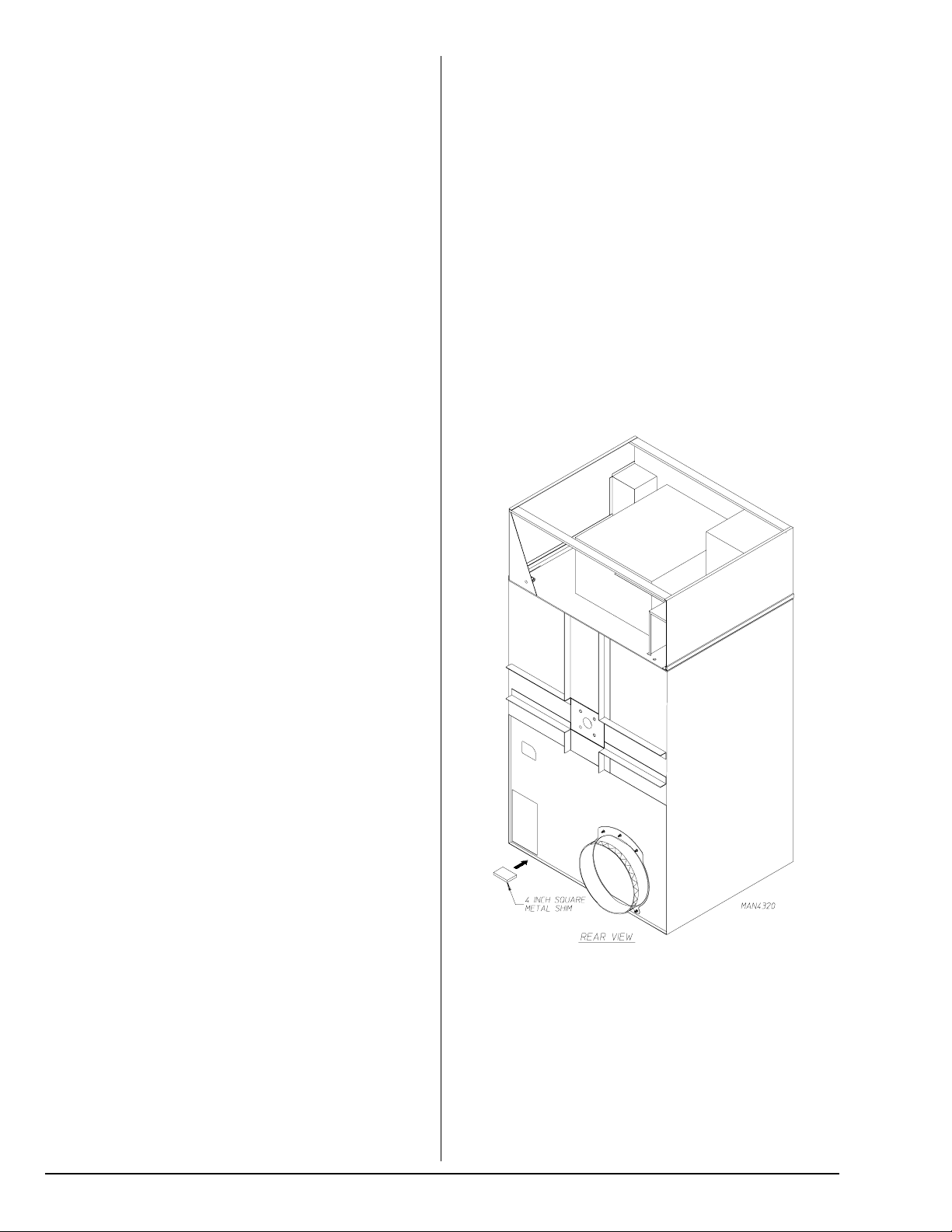

When the exhaust ductwork passes through a wall, ceiling,

or roof made of combustible materials, the opening must

be 2-inches (5.08 cm) larger than the duct (all the way

around). The duct must be centered within this opening.

As per the National Fuel Gas Code, “Exhaust ducts for

type 2 clothes dryers shall be constructed of sheet metal

or other noncombustible material. Such ducts shall be

equivalent in strength and corrosion resistance to ducts

made of galvanized sheet steel not less than 26 gauge

(0.0195-inches [0.50 mm]) thick.”

Fresh Air Supply Requirements ______

This appliance may only be installed in a room that meets

the appropriate ventilation requirements specified in the

national installation regulations.

When the dryer is operating, it draws in room air, heats it,

passes this air through the tumbler, and exhausts it out of

the building. Therefore, the room air must be continually

replenished from the outdoors. If the make-up air is

inadequate, drying time and drying efficiency will be adversely

affected. Ignition problems and sail switch “fluttering”

problems may result, as well as premature motor failure from

overheating. The dryer must be installed with provisions for

adequate combustion and make-up air supply.

Air supply (make-up air) must be given careful consideration

to ensure proper performance of each dryer. As a general

rule, an unrestricted air entrance from the outdoors

(atmosphere) of a minimum of 2-1/2 feet2(0.2322576 meters2)

is required for each dryer. (Based on 1 inch2[6.4516 cm2]

per 1,000 Btu [251.9958 kcal].)

To compensate for the use of registers or louvers used over

the openings, this area must be increased by approximately

33%. Make-up air openings should not be located in an area

directly near where exhaust vents exit the building.

It is not necessary to have a separate make-up air opening

for each dryer. Common make-up air openings are

acceptable. However, they must be set up in such a manner

that the make-up air is distributed equally to all the dryers.

EXAMPLE: For a bank of 4 dryers, 2 unrestricted openings

measuring 2 feet by 2-1/2 feet (0.61 meters by 0.762 meters)

are acceptable.

Allowances must be made for remote or constricting

passageways or where dryers are located at excessive

altitudes or predominantly low pressure areas.

IMPORTANT: Make-up air must be provided from a source

free of dry cleaning solvent fumes. Make-up air that is

contaminated by dry cleaning solvent fumes will result in

irreparable damage to the motors and other dryer

components.

NOTE: Component failure due to dry cleaning solvent

fumes will void the warranty.

A = 2 feet (0.61 meters)

B = 2-1/2 feet (0.762 meters)