aditec MKA 500 User manual

User Manual

MKA 500 / MKA 800

Programmable Controller for

Cooking, Universal, Baking and Boiler System

as well as Autoclaves

Version V00.13

Issue 21.02.2023_01

Measurement and

Control technology

Hardware development

Software development

Specialised electronics

Food technology

Process visualisation

aditec gmbh

Talweg 17

D-74254 Offenau

Tel.:+49(0)7136 96122-0

Fax:+49(0)7136 96122-20

www.aditec.net

eMail: info@aditec.net

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 2

Contents

1 Introduction..........................................................................................................................................5

1.1 Overview.........................................................................................................................................5

2 Operating controls ..............................................................................................................................6

2.1 Operating controls MKA 500...........................................................................................................6

2.2 Operating controls MKA 800...........................................................................................................7

2.3 Button functions ..............................................................................................................................8

2.3.1 MKA 500...................................................................................................................................8

2.3.2 MKA 800...................................................................................................................................9

2.3.3 Skipping between nominal values............................................................................................9

2.4 LED Display ..................................................................................................................................10

2.4.1 LED Display MKA 500............................................................................................................10

2.4.1 LED Display MKA 800............................................................................................................10

2.5 Status and use of button relays and aggregate relays (if enabled)..............................................11

2.6 Interval times.................................................................................................................................11

3 Control elements ...............................................................................................................................12

3.1 Entering values (Edit box).............................................................................................................12

3.2 General text entry (Edit box).........................................................................................................12

3.2.1 Sequence of the characters:..................................................................................................13

3.2.2 Deleting a character:..............................................................................................................13

3.3 Buttons..........................................................................................................................................13

3.4 Check boxes .................................................................................................................................13

3.5 List boxes......................................................................................................................................14

3.6 Drop boxes....................................................................................................................................14

4 Relevance of the nominal values.....................................................................................................14

4.1 Entering nominal values................................................................................................................14

4.2 Switching off nominal values.........................................................................................................14

4.3 Nominal temperature ....................................................................................................................15

4.4 Nominal core temperature ............................................................................................................15

4.5 Step time.......................................................................................................................................15

4.6 Optional nominal values................................................................................................................15

4.6.1 Delta temperature (Delta-T process) .....................................................................................16

4.6.2 FC value.................................................................................................................................16

4.6.3 Aggregate modules (direct relay actuation) ...........................................................................17

4.6.4 Optional control loops ............................................................................................................17

4.6.5 Step-by-step control...............................................................................................................18

4.7 Shut-down condition .....................................................................................................................18

4.8 Negative core shut-down (Shower/Cooling).................................................................................18

4.9 Pre-heating function......................................................................................................................19

5 Standby...............................................................................................................................................19

6 Program set-up..................................................................................................................................20

6.1 Program set-up (Standby) MKA 500.............................................................................................20

6.1.1 Entering a temperature ..........................................................................................................20

6.1.2 Entering a core temperature ..................................................................................................20

6.1.3 Entering an operating time.....................................................................................................21

6.1.4 Optional nominal values.........................................................................................................21

6.2 Program set-up (Standby) MKA 800.............................................................................................21

6.2.1 Entering a temperature ..........................................................................................................21

6.2.2 Entering a core temperature ..................................................................................................21

6.2.3 Entering an operating time.....................................................................................................22

6.2.4 Optional nominal values.........................................................................................................22

6.3 Program start ................................................................................................................................22

6.3.1 Start from standby MKA 500..................................................................................................22

6.3.2 Start from standby MKA 800..................................................................................................22

6.3.3 Starting a program with a batch number MKA 500................................................................23

6.3.4 Starting a program with a batch number MKA 800...............................................................23

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 3

6.3.5 Starting a program with starting time MKA 500 .....................................................................23

6.3.6 Starting a programms with starting time MKA 800.................................................................24

6.4 Programming mode ......................................................................................................................24

6.4.1 Programming mode MKA 500................................................................................................24

6.4.2 Programming mode MKA 800................................................................................................26

6.4.2.1 Program –Step selection....................................................................................................26

6.4.2.2 Program entry......................................................................................................................27

6.4.2.3 Changing nominal values within a step...............................................................................27

6.4.2.4 Terminating programming mode.........................................................................................27

6.5 Linking programs ..........................................................................................................................28

6.6 Copying, deleting and inserting programs/steps ..........................................................................28

7 Operating mode - displays and settings........................................................................................30

7.1 Nominal values .............................................................................................................................30

7.1.1 Aggregate/relais and digital inputs display.............................................................................31

7.1.2 Aggregate modules................................................................................................................31

7.1.3 Optional control loops ............................................................................................................32

7.2 Status bar......................................................................................................................................32

7.2.1 Program progression (from version V00.06 onwards)...........................................................32

7.2.2 Remaining program runtime...................................................................................................32

7.2.3 Messages (system status messages)....................................................................................32

7.2.4 Alarms ....................................................................................................................................33

7.3 Alarm signal ..................................................................................................................................33

7.4 Program runtime, operating time display in operating mode........................................................33

8 Profile settings...................................................................................................................................34

8.1 Setting date and time of day.........................................................................................................34

8.1.1 Automatic change-over between summer and normal time ..................................................35

8.2 Display settings.............................................................................................................................35

8.3 Status bar display .........................................................................................................................36

8.4 Enabling signal relay.....................................................................................................................37

8.5 Enabling a batch number..............................................................................................................38

8.6 Data logger ...................................................................................................................................39

8.6.1 Copying data onto a USB stick ..............................................................................................40

8.7 Enabling VisuNet program............................................................................................................41

8.8 Version number display ................................................................................................................41

8.9 Sensor information........................................................................................................................42

8.10 Screen saver...............................................................................................................................43

9 Power failure......................................................................................................................................43

10 List of errors (possible problems).................................................................................................44

11 Connecting the controller to a PC .................................................................................................45

11.1 Connection cables, different types of connection.......................................................................45

11.1.1 Connection via an Ethernet interface:..................................................................................45

11.1.2 Connection via a RS485 interface: ......................................................................................45

11.2 Enable VisuNet ...........................................................................................................................46

12 Technical data..................................................................................................................................46

12.1 MKA 500 .....................................................................................................................................46

12.2 MKA 800 .....................................................................................................................................46

13 Dimensions / connection diagrams...............................................................................................46

13.1 Dimensions / connection diagrams MKA 500.............................................................................46

13.2 Dimensions / connection diagrams MKA 800.............................................................................47

14 Additional boards / Interface options............................................................................................48

15 Index .................................................................................................................................................49

16 Safety instructions ..........................................................................................................................50

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 4

Symbols used in this user manual

The following symbols are used in this user manual to highlight important information:

Symbol

Description

See page / press button

Press several buttons simultaneously

This symbol indicates a useful hint or gives a tip.

Factory setting

Display is flashing

Be aware!

This symbol points out measures you should take in order to avoid

potential problems.

Code is supported by the service program

Press a button for 3 seconds or wait 3 seconds.

Indicates a sequence of actions that should be executed one after the

other.

SP

3 Sec.

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 5

1 Introduction

1.1 Overview

Process controllers MKA 500 and MKA 800 with 2,7" LED display (128 x 64 Pixel and

16 grey scales) various interfaces and industry-standard housing are designed for use in cooking,

universal, baking and boiler systems as well as autoclaves and can be adapted to many other

applications.

In their standard version, the controllers are equipped with

4 Pt100 temperature inputs and

2 convertable inputs for either Pt100 and current 4-20mA / voltage 0-10V or thermo- elements

(conforming to DIN EN 60584).

For communication the following interface is available: Mini USB interface

To facilitate adaptation for different applications, each control loop can be used as 2 point controller,

XP controller or with PID behaviour.

MKA 500:

The standard version has 5 relay outputs

(1 normally open contacts and 4 change-over

contacts) as well as 5 virtual relays.

MKA 800:

The standard version has 10 relay outputs

(6 normally open contacts and 4 change-over

contacts) as well as 5 virtual relays.

Figure 1: MKA 500 + MKA 800

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 6

2 Operating controls

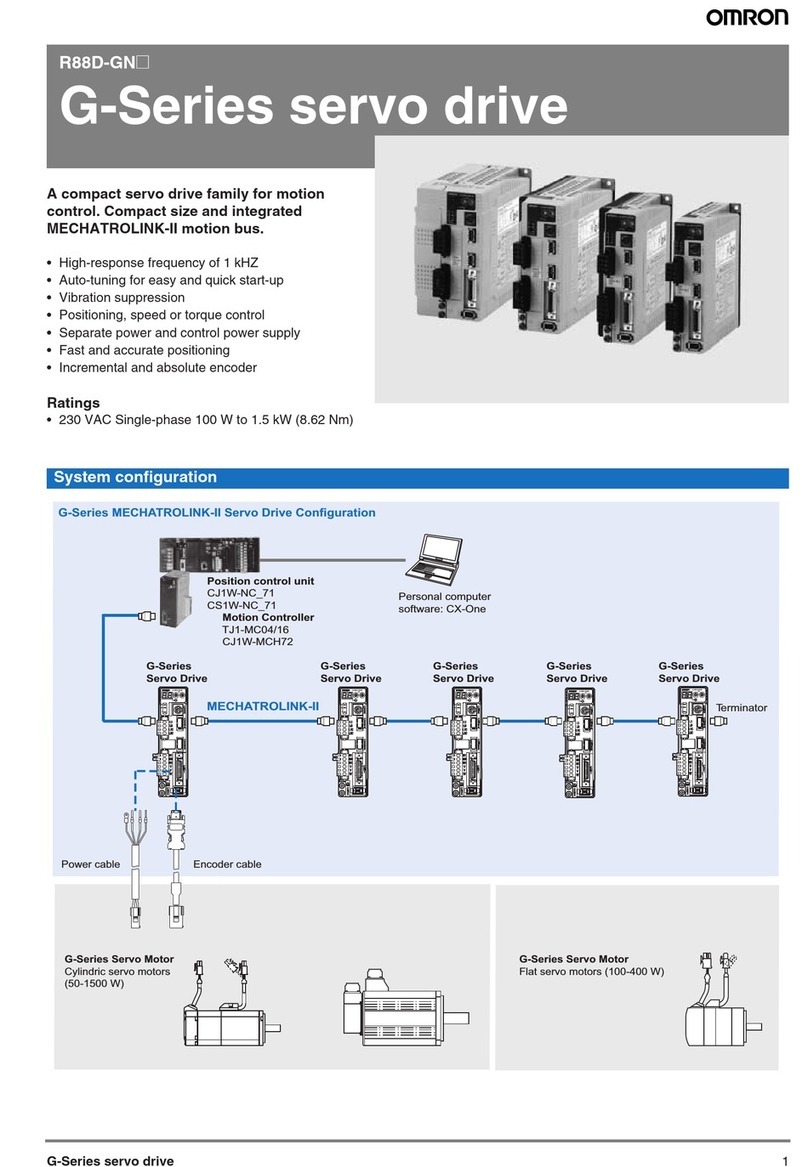

2.1 Operating controls MKA 500

Actual value temperature (Temp) / short cut button I

Nominal values / short cut button I/ Nominal Delta value

Actual value core temperature / short cut buttons II and III

Nominal values short cut buttons II and III

Actual value step time/program runtime/remaining program time/ cut button IV

Nominal step time/ cut button IV

Current time of day

Temp. button / short cut button I

Core button / short cut button II

Humidity button cut button III

Time button /left/ cut button IV

Start/Stop button /right

Cursor button down

Cursor button up

Delta button

Line button (press up and down button simultaneously)

Display

1

2

3

4

5

6

7

8

9

10

11

12

15

16

17

Figure 2: Operating controls MKA 500

13

14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 7

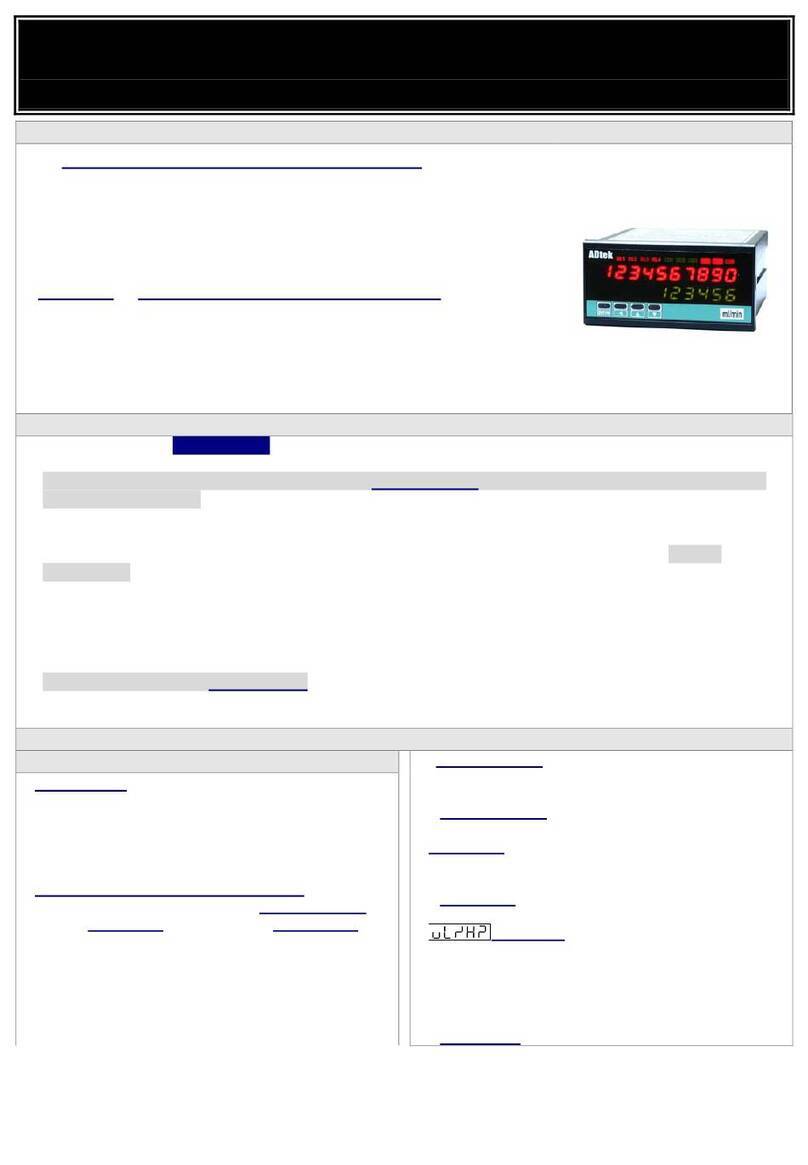

2.2 Operating controls MKA 800

Figure 3: Operating controls MKA 800

Actual value temperature

Nominal value temperature

Actual value core temperature

Nominal value core temperature

Actual value step time/program runtime/remaining program time

Nominal step time

Current time of day

Temperature button

Core temperature button

Time button

Button for free configuration (e.g. Delta temperature)

"Prog" button

"Step" button

"Line" button

"Start/Stop" button

Button controlling the cursor position on the display

Button for changing nominal values /selecting settings

"Enter" button / Confirming settings

1

2

3

4

5

6

8

9

11

12

13

10

17

16

14

15

7

19

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 8

2.3 Button functions

2.3.1 MKA 500

Button

Description

Function

Temperature

„Temp“

Short cut button for entering the following nominal values:

temperature (min, max)

Core

temperature

„Core“

Short cut button for entering the following nominal values: core

temperature

„Humidity“

Short cut button for entering the following nominal values:

humidity (min, max)

„Time“

Short cut button for entering the following nominal value: step time

Delta

Short cut button for entering the following nominal value: Delta

Start/Stop

Starting and stopping programs

Cursor

buttons

Moving the cursor within the display,

selecting specific settings

Line

Confirming an entry and focussing the next item by briefly

pressing both cursor buttons simultaneously.

Leaving the screen (code) by pressing

and holding both cursor buttons

simultaneously.

Table 1: Button functions MKA 500

3 Sec.

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 9

2.3.2 MKA 800

Button

Description

Function

Temperature

„Temp“

Shortcut button for entering:

Nominal temperature (min, max)

Core

temperature

„Core“

Shortcut button for entering:

Nominal core temperature

„Time“

Short cut button for entering:

Nominal step time

Start/Stop

Starting and stopping programs

Cursor

Moving the cursor within the display,

Selecting certain settings

Settings

Changing nominal values,

Selecting settings

Enter

Confirming settings

Prog.

Selecting a program

Step

Selecting a program step

Line

Confirming an entry and focussing the next item by clicking

once.

Leaving the screen (code),

by pressing for at least 3 sec.

Shortcut

buttons

Shortcut buttons: Shortcut buttons I-IV

(e.g. Delta temperature, humidity, single step control,

aggregate modules)

Table 2: Button functions MKA 800

2.3.3 Skipping between nominal values

If several nominal values have been allocated to one button and you press it, e.g. , the

nominal value that was selected last will be focussed. Further nominal values can be displayed

by pressing the button again.

3 Sec.

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 10

2.4 LED Display

2.4.1 LED Display MKA 500

Button

LED off

LED on

Relevance

Temperature

„Temp“

LED „is flashing“ when a nominal value is

changed.

Core temperature

„Core“

LED „is flashing“ when a nominal value is

changed

„Humidity“

LED „is flashing“ when a nominal value is

changed.

Delta

LED „is flashing“ when a nominal value is

changed.

„Time“

LED „is flashing“ when a nominal value is

changed.

Start / Stop

LED „is flashing“ when the controller is in waiting

mode or pause mode, if there has been an alarm

or the end of a program has been reached. LED

is lit when the controller is in operation.

Table 3: LED Display MKA 500

2.4.1 LED Display MKA 800

Button

LED off

LED on

Relevance

Temperature

„Temp“

LED „is flashing“ when a nominal value is

changed.

Core temperature

„Core“

LED „is flashing“ when a nominal value is

changed

„Time“

LED „is flashing“ when a nominal value is

changed

Start / Stop

LED „is flashing“ when the controller is in

waiting mode or pause mode, if there has

been an alarm or the end of a program has

been reached. LED is lit, when the controller

is in operation

Prog.

LED „is lit“ when a program is selected

Step

LED „is lit“ when a step is selected

Shortcut buttons

LED „is flashing“ when a nominal value is

changed.

Table 4: LED display MKA 800

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 11

2.5 Status and use of button relays and aggregate relays (if

enabled)

MKA 500

MKA 800

Aggregate button is activated

Aggregate button is de-activated

2.6 Interval times

When the relay is active, the text of the nominal value is highlighted in white.

Aggregate

button

Relay name

Relay status

Button status

inactive

active

Relay off

Relay on

K5: off (Text grey)

K4: on (Text white)

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 12

3 Control elements

3.1 Entering values (Edit box)

MKA 500:

Values/numbers are entered by

using the arrow buttons.

Figure 4: Value entry

MKA 800:

Enter numbers via the navigation

pad

How to enter values:

▪Cursor is flashing in the position ‚far right’: „00“.

▪When you are making an entry, the cursor is at first in the position ‚far right: „00“. Use the

button (MKA500) / (MKA800) to increase the value and button (MKA500) / (MKA800)

to reduce the value. The numbers will automatically shift to the left „10“. The number value you enter is

limited by the limit value range.

▪When you press the arrow button ‚left’, you can change the individual digits.

Entering negative values

MKA 500

MKA 800

Certain nominal values can be negative numbers (e.g. temperature

values). In order to enter a negative value you have to press the

arrow button „down“ until you go past value 0, when a minus („ - „)

sign will appear in front of the numbers

Entering positive values:

MKA 500

MKA 800

When you want to change a negative number into a positive one, you

can position the cursor on the „-“ sign and overwrite it with a „+“ via

the arrow button „up“ or you can enter a value higher than „0

Hint

Scrolling characters:

MKA 500

MKA 800

Use the arrow buttons „up“ / „down“ (keep pressed) to

scroll a character.

3.2 General text entry (Edit box)

How to enter text:

▪Cursor is flashing in the first position: „_“.

▪When you are making an entry the cursor is at first in the position „_ “. Use the button

(MKA500) / (MKA800) to scroll up the characters (number/letter/ special character), or

the (MKA500) / (MKA800) button to scroll them down. Us the arrow buttons ‚left’

or ‚right‘ to change the individual digits. In this way you can take the cursor to any position

in the entry box.

Characters can only be entered in the position that is flashing. Press the relevant button „up“

or „down“ until the required character appears. The first character is a blank.

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 13

3.2.1 Sequence of the characters:

Numbers:

' '

'0'

'1'

'2'

'3'

'4'

'5'

'6'

'7'

'8'

9'

Letters:

'A'

'B'

'C'

'D'

'E'

'F'

'G'

'H'

'I'

'J'

'K'

'L'

'M'

'N'

'O'

'P'

'Q'

'R'

'S'

'T'

'U'

'V'

'W'

'X'

'Y'

'Z'

'a'

'b'

'c'

'd'

'e'

'f'

'g'

'h'

'i'

'j'

'k'

'l'

'm'

'n'

'o'

'p'

'q'

'r'

's'

't'

'u'

'v'

'w'

'x'

'y'

'z'

Special characters:

'.'

',‘

':'

';'

'!'

' " '

'$'

'%'

'&'

'/'

'('

')'

'{'

'}'

'['

']'

'='

'?'

'+'

'-'

'*'

'_'

'#'

'@'

'~'

Table 5: Table of characters

3.2.2 Deleting a character:

If you want to overwrite a character use the arrow buttons ‚left’ and ‚right’ to take the cursor to the

required position and enter the new character in this position.

If you want to delete a character, take the cursor to the right of the position you want to delete.

Press the „Temp“ button to backspace and the character is deleted

Hint

Scrolling through the characters:

MKA 500

MKA 800

Use the arrow buttons „up“ / „down“ (keep pressed) to

scroll a character.

3.3 Buttons

The button allows the user to trigger an assigned function.

When the button is focussed (frame around the info text), it can be activated by

using the ‚Line‘ button. If several buttons exist, you can use the arrow buttons “up”

or “down”, respectively, to focus the subsequent or previous button.

3.4 Check boxes

Check boxes allow you to set e.g. a status. When a check box is focussed (frame

around the info text) you can change its status from selected (Relay 1) to not

selected (Relay 2,3) by using the ‚Line‘ button. If several check boxes exist you

can use the arrow buttons “up” or “down” respectively to focus the subsequent or

previous check box

Figure 6:

Check box

Figure 5:

Button

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 14

3.5 List boxes

List boxes allow you to clearly display items, e.g. codes, in a list. Use the arrow

buttons “up” and “down” to focus an entry (background = white, writing = black) and

the ‚Line‘ button to select it. The scroll bar gives you only an overview. The scroll bar

is automatically moved when the last item of the visible segment is focussed with the

arrow buttons.

3.6 Drop boxes

A drop box is used to select one item from a shown list of items.

Initially, the previously selected item is shown. Use the arrow

buttons “up” or “down” respectively to focus the subsequent or

previous item. When you press the ‚Start‘ button, a menu of all

available items on the list will flick open and you can use the

arrow buttons “up” or “down” respectively to focus the

subsequent or previous item. (background = grey, writing =

white). The currently selected item is shown on the menu tab.

Use the ‚Time‘ button to shut the drop box and the newly

chosen item is automatically selected.

4 Relevance of the nominal values

The controller allows you to pre-program different nominal values within a program step. In the

following chapter, the relevance of the individual nominal values is explained.

Be aware

Depending on the system and the application, nominal values can be configured in different

ways for individual processes. This means that you may find that not all the nominal values

described here are available in your controller (it depends on your specific configuration).

This manual describes all the available values

4.1 Entering nominal values

Nominal value entry will be automatically cancelled after 10 seconds, if none of the buttons have

been pressed.

The nominal value that is shown at that time is saved.

4.2 Switching off nominal values

Be aware

Switching off nominal values:

Nominal values in the controller can also be negative. Therefore value „0“ is also a valid

nominal value. If you want to switch off a nominal value in a program step, e.g. the core

temperature, the button (MKA500) / (MKA800) has to be pressed repeatedly until

the value „OFF“ appears.

Figure 8:

Drop box

Menu tab

Dop box

Menu

Figure 7:

List box

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 15

4.3 Nominal temperature

Nominal value for chamber temperature control. The chamber temperature is regulated via the

heating relay (when the actual value is smaller than the nominal value) and/or cooling relay

(when the actual value is higher than the nominal value). If two nominal values, „Chamber min“

and „Chamber max“, have been enabled for temperature control, the heating process will use

nominal value „Chamber min“ and the cooling process will use „Chamber max“.

Be aware

Temperature control with low pressure steam via humidifying:

The temperature is controlled with low pressure steam and not through heating. Low

pressure steam is blown into the chamber via the humidifying valve with 2 Point behaviour.

Activation of temperature control with low pressure steam via humidifying:

Enter value 100 as the min. value for humidity (transiently or in programming mode).

This function is only available, if it has been enabled by the service technician!

4.4 Nominal core temperature

Be aware

Shut-down condition:

If you have enabled the nominal core temperature value in a step and the core sensor

reaches this nominal value, the step will be terminated.

The controller works with two types of core shut-down:

Positive core shut-down (heating operation)

If the pre-programmed nominal temperature value is higher than the nominal core

temperature value, the controller will switch to the next step as soon as the actual core

temperature is higher or equal to the nominal core temperature.

Negative core shut-down (cooling operation)

If the pre-programmed nominal temperature value is lower than the nominal core

temperature value, the controller will switch into the next step. When the actual core

temperature is lower or equal to the nominal core temperature, the controller will also switch

into the next step.

4.5 Step time

The step time is the duration of a step.

Entering a step time

While a step is running, the step time is counted backwards. When the pre-programmed step

time has elapsed, the controller will switch into the next step.

Be aware

No pre-set step time:

If you have not entered a step time, the time will be counted forward while the step is

running. (in this way you always know how long the step has been in operation).

4.6 Optional nominal values

A service technician can make further nominal values available by changing the configuration of

the controller. The relevance of these nominal values can vary, this is why your service

technician should explain them to you. The following description is just a list of possible

applications.

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 16

4.6.1 Delta temperature (Delta-T process)

Cooking with the Delta-T process (Delta temperature control) allows you to heat the product

gently and evenly. When using this process the chamber temperature is always kept higher, by

the nominal Delta value, than the actual core temperature of the product. This means the

temperature difference between the surface and the core of the product always remains constant.

The pre-set nominal temperature value is used as an upper limit value for temperature control.

A lower nominal Delta value will prolong the duration of the cooking process and the heating

process is gentler, a higher nominal Delta value will speed up the cooking process.

Hint

Apart from a nominal temperature value and a nominal Delta value, you can also enter a

nominal core value, which will be used as core shut-down condition for the step.

4.6.2 FC value

Hint

Bacteria have to be killed through pasteurisation (FC70) / sterilisation (FC121). How

thoroughly the bacteria are killed depends on the temperature and the length of time this

temperature is maintained. A mathematical formula can be applied to this process. The

degree to which the bacteria are killed is called FC value.

The process:

It is the aim of sterilisation to kill all the bacteria and their spores. How thoroughly the

bacteria are killed depends on the temperature and the length of time this temperature is

maintained. A mathematical formula can be applied to this process.

( ) ( )

=

−

−

teSamplingra

FValuez

mperatureeferenceterTaturecoretemper ref

60

10

The degree to which the bacteria are killed is called F-value.

For meat cans F-value 1 means the bacteria extermination which is achieved at a core

temperature of 121,1°C, when maintained for one minute. How thoroughly the bacteria are

killed also depends on the acidity of the conserved product. Acidic conserves, fruit juices,

pickled gherkins etc have a higher killing rate and therefore a different FC value table than

normal meat conserves with a PH value between 5 and 7.

In order to avoid confusion, two further indicators can be added to the F-value, e.g. FC 121-

10 (z-value), this means that at a core temperature of 121,1°C and a time of one minute, the

F-value = 1. If the temperature is increased by 10°C, the F-value increases 10-fold.

Example of FC-value 121: Example FC-value 70:

( )

−

=10 1.121

10121 CaturecoretemperT

FC

( )

−

=10 70

1070 CaturecoretemperT

FC

Hint

Depending on the setting, the nominal FC value is shown as displayed below.

▪FC70 (pasteurisation), see example FC value 70

▪FC121 (sterilisation), see example FC value121.

▪FC-UD, user defined settings

Be aware

Shut-down condition:

When the pre-programmed FC-value has been reached, the controller will automatically

switch into the next step or terminate the program, respectively.

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 17

4.6.3 Aggregate modules (direct relay actuation)

Up to 5 aggregate modules can be pre-programmed, thereby influencing the switching behaviour

of specific relays and the connected hardware (aggregates). The configuration determines which

nominal values may be entered and they can vary depending on the system. For example an

aggregate can be simply switched on or off, or the interval times of a clocking relay can be

changed

Item 6.1.4, Optional nominal values MKA 500, p. 21

Item 6.2.4, Optional nominal values MKA 800, p. 22

The names for the aggregate modules shown in standby, operating and programming mode are

generated from the relay names.

Current interval times for the aggregate modules are shown during operation:

Depending on which switching behaviour has been configured by the service technician, different

nominal value will be available to the end user in standby, operating and programming mode.

During operation the current actual value and the current nominal value is shown. If you have set

a switch-on interval and a switch-off interval for an aggregate module, the interval times will be

shown alternately in the actual value display.

The status of the aggregate module button (without delay) is shown on the button.

Be aware

If a nominal value is changed during operation via VisuNet, the display will be updated

(reset).

4.6.4 Optional control loops

Up to 6 optional regulators can be programmed. The configuration determines which nominal

values may be entered and they can vary depending on the system. In this way the end user

has the option of programming the nominal values of these regulators for the different program

steps.

Be aware

The configuration determines the significance of the nominal values of the individual

regulators.

If additional control loops or additional sensors have been configured for the process that is

currently in operation, their current temperature values (actual values) will be displayed.

Item 6.1.4, Optional nominal values MKA 500, p. 21

Item 6.2.4, Optional nominal values MKA 800, p. 22

Actual value 1

Nominal value 1

Actual value 3

Nominal value 3

Actual

value 2

Nominal value 2

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 18

4.6.5 Step-by-step control

▪The controller can be configured to pause at the end of every step. The message „Stop: one

step control active“will be shown and the signal relay will be energised for a time interval that

can be pre-programmed.

The following message will

appear on the display:

- Press "Yes" to switch into the next step

- Press "No" to close the message and return to the operating

page.

There are 4 ways of how to proceed::

1. The operator can manually enter a step number and the

program will continue with the selected step.

2. The nominal value that caused the program to pause, e.g.

step time, can be changed. Then press the „Start/Stop“

button and the controller will repeat the step which was

paused

3. The nominal value for step-by step control can be changed

to „OFF“ , Then press the „Start/Stop“ button and the

controller will continue the program with the next step ( if

programmed).

4. Keep the „Start/Stop“ button pressed, which will lead to the

immediate termination of the program.

4.7 Shut-down condition

As soon as at least one of the shut-down conditions has been fulfilled, the program step will be

terminated. If a nominal value has not been pre-programmed (OFF), the related switch-off condition

is disabled.

Shut-down conditions are:

▪Nominal step time has elapsed and has reached 00.00

▪Nominal core value has been reached

▪Negative core shut-down (cooling, e.g. shower)

▪Nominal FC-value has been reached

▪Nominal humidity value has been reached

Unplanned shut-down if:

▪„Stop“ button is pressed which leads to a program termination

▪There is a temperature sensor fault which always leads to a program termination

▪There is a core sensor fault, program termination only when a nominal value has been pre-

programmed

▪There is a humidity sensor fault, program termination only when a nominal value has been

pre-programmed

Be aware

An empty (not valid) program step will immediately be terminated or not even started. A

program step is considered valid when one process has been pre-programmed.

4.8 Negative core shut-down (Shower/Cooling)

In order to pre-program a negative core shut-down, the nominal temperature value you enter has

to be lower than the nominal core temperature value.

The program step will end when the actual core temperature falls below the nominal core

temperature. If an operating time has also been entered, the program step will end when the

operating time has run out or when the actual core temperature falls below the nominal core

temperature. This means the program step will end when at least one of the shut-down conditions

has been fulfilled.

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 19

4.9 Pre-heating function

The pre-heating function has an influence on how the step time is counted while a program is

running. When this feature is activated, the controller only starts counting the step time when the

nominal chamber temperature is reached for the first time.(„Act. temp“ is higher than nominal

value „Temp min“).

There are two possible settings:

1) The program that is running is not interrupted and the step time counter starts automatically.

2) The program is paused and the display will show the message „Temperature reached!“, the

„Start/Stop“ button will be flashing. The program will only be resumed when the „Start/Stop“

button is pressed , at which point the step time counter will start.

Be aware

As soon as the nominal temperature has been reached, the message "Temperature

reached! Continue?" will be shown, even if the rest time interval is still running.

Hint

This function is pre-configured by your service technician!

5 Standby

As soon as the controller is connected to a power source it will automatically boot up. This can take up

to 1 minute.

Be aware

Please do not use pointy objects to operate the controller (e.g. pointed fingernails, biros,

sharpened pencils or screw drivers). Only use blunt, soft objects, as e.g. your finger tips, a

rubber or similar objects.

On the standby mask the current values and nominal values are shown as well as the current program

and step numbers.

Hint

During a data transfer between the PC and the controller the standby mask is hidden and an

status page is shown.

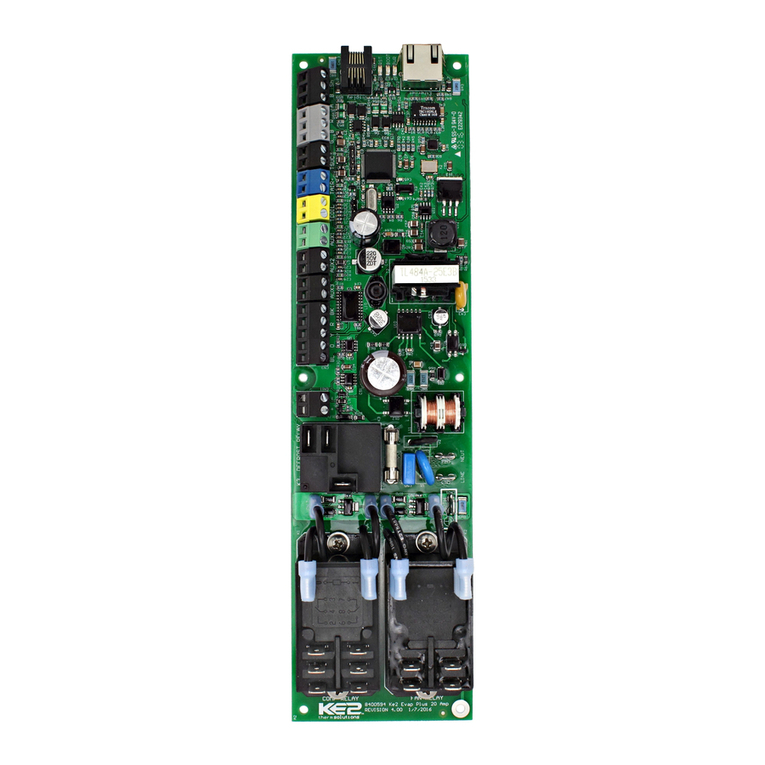

Figure 9: Standby

Actual value

Chamber temperature/

Short cut buttons

Time of day/ status bar/ Program/

Step number

Actual value

Core temperature/

Short cut buttons

Actual value

Step time/ Operating time/

Short cut buttons

Nominal values (chamber, FC-Wert,...)

Nominal values (core, FC value)

Nominal values (time, FC

value)

Unit(°C / °F)

Unit (°C / °F)

User Manual MKA 500 / MKA 800

Conforms to

Issue 21.02.2023_01 Page 20

Hint

Press any buttton, to leave standby. By pressing and holding the „Start“ button you can

always return to standby. (When the system is not in operation).

6 Program set-up

Be aware

The number of programs available may vary depending on the type of system you have and

the application. You can only access programming mode when the pre-set number of

programs is greater than 0 (please ask your service technician).If the number of programs

is set to 0, only one program (manual program) is available, you can set up this program

from standby.

6.1 Program set-up (Standby) MKA 500

6.1.1 Entering a temperature

6.1.2 Entering a core temperature

Changing

nominal value

ändern

LED flashing

Nominal value

is flashing

8

Saving nominal

value LED off

Changing

nominal value

LED flashing

Nominal value

is flashing

Saving nominal

value LED off

2

Figure 10: Data update

This manual suits for next models

1

Table of contents

Other aditec Controllers manuals

Popular Controllers manuals by other brands

motortronics

motortronics Msmart manual

Emerson

Emerson Bettis Q series Installation, operation & maintenance manual

DNF Controls

DNF Controls 2MCE-24P User manuals

Nexta Tech

Nexta Tech TOUCH-1SP quick start guide

Datalogic

Datalogic Controller SC6000 Reference manual

Carel

Carel ir33+ wide VCC quick start guide