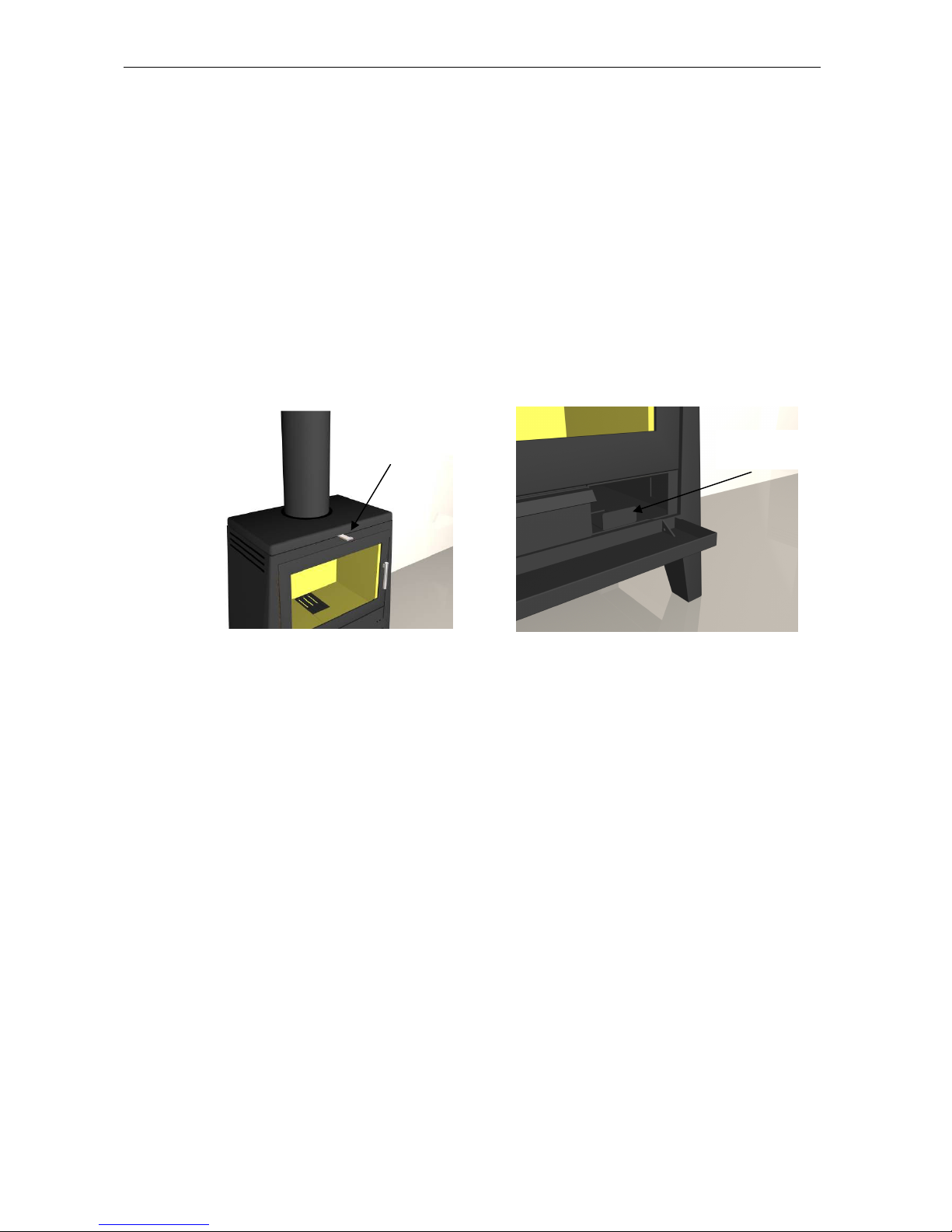

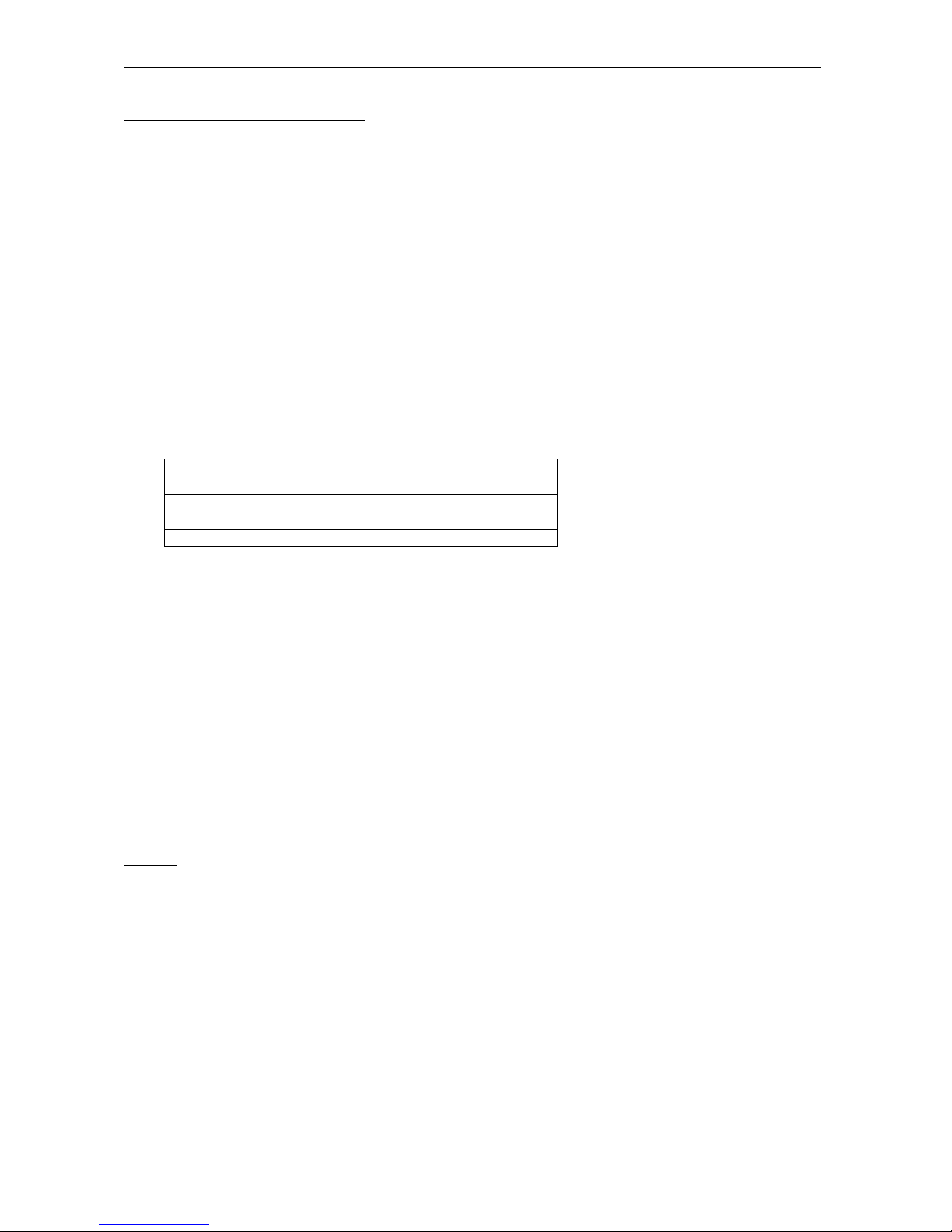

Regulation of the Aduro-tronic control

The control is pre-set to allow primary air intake for the first 5 minutes. This setting has been used during

testing at the Danish Technological Institute using ‘standard’ sized logs and with optimum moisture content

of 17-20%. Standard size logs are approx. 30 cm long and 10 x 10 cm in thickness. A standard chimney was

also used for testing. In practice, such circumstances can differ, which is why the Aduro-tronic control can be

adjusted to your circumstances. If you want a slower intake of primary air: (e.g. for a slower flue draught,

larger sized wood or for longer intervals between stoking) Adjust the screw on the front of the control level

using a small screwdriver to slow closure rate. If the screw is turned to the right closing time is increased and

if turned to the left closing time is reduced.

3.9 Ventilation/fresh air supply

In order for the wood burning stove to function at optimum efficiency, air is needed for the combustion

process. There must be sufficient fresh air coming into the room containing the wood burning stove. In very

well-insulated houses, or houses with powerful cooker hoods and/or air conditioning systems, a vacuum can

be created around the wood burning stove, leading to smoke leakage and poor combustion. In these

circumstances, it might be necessary to open a window to provide air for combustion and to equalize the

vacuum. Alternatively, you could fit an air vent in the room containing the wood burning stove.

4.0 The chimney

Data for chimney calculation:

Wood

Flue temperature at [20 °C] 286

Chimney draught at testing power

[mbar]/[Pa] 0.12/12

Flue gas mass flow [g/s] 6.3

The optimum combustion is achieved at a constant chimney draught of 0.10 to 0.1 mbar measured in the

flue pipe above the stove. There are many factors that affect the chimney draught, including the outside

temperature, wind strength and surrounding buildings. If it is impossible to establish a sufficiently natural

chimney draught, the chimney can be fitted with a smoke extractor. If the chimney draught is too strong, a

damper can be fitted to regulate the chimney draught. Contact your local chimney sweep for more advice.

4.1 Inadequate draught in the chimney

If the chimney is too short, leaks or is inadequately insulated, there may be problems with the chimney

draught (let the chimney sweep assess this). The draught should be approx. 0.10–0.1 mbar in order to

provide satisfactory combustion and prevent smoke leakage.

If the chimney sweep judges the draught to be satisfactory, but you still have problems lighting a fire, try

extending the fire lighting phase/using more thin pieces of kindling, so that the chimney gets thoroughly

warm. The chimney will not draw at optimum effect until it is warm. The fire lighting phase can be prolonged

by using a lot of kindling and 1-2 firelighters. When a layer of embers has been formed, add 2–3 dry logs.

5.0 Maintaining and cleaning your wood burning stove

Gaskets

With time, the gaskets will wear, and, in order to avoid wild combustion, they must be replaced as required.

Glass

If the wood you burn is too moist, you will get soot stains on the glass pane. They can be easily removed

using a damp cloth that you dip in cold ash and rub on the sooty glass. Special cleaning agents are also

available to remove soot from glass.

Combustion chamber

The yellow tiles in the combustion chamber eventually wear out and they should be replaced when the

cracks are more that 0.5 cm. The durability of the tiles will depend on how often and how intensively the

stove is used. You can change the tiles yourself. They are available as a ready-to-use set. You can also buy

one-piece tiles that you can cut to the size of the worn plates yourself. Please consult your dealer.