Prinng Reports .............................................................................................................................18

Internal Printers ..........................................................................................................................18

USB Printers ................................................................................................................................18

Conguring USB Printers .........................................................................................................18

Network Printers.........................................................................................................................18

Conguring Network Printers..................................................................................................18

Print Buon..............................................................................................................................19

Reports Opons.......................................................................................................................19

Reports.....................................................................................................................................19

Tank Tesng.......................................................................................................................................21

Stac tests......................................................................................................................................21

SCALD tests ....................................................................................................................................21

Stac Tesng ...............................................................................................................................22

Tank Test Requirements...........................................................................................................22

Test Types.................................................................................................................................22

Terms .......................................................................................................................................22

Ideal test condions ................................................................................................................23

Starng stac tests manually.........................................................................................................23

Stac Test Results .......................................................................................................................24

Test specicaons....................................................................................................................24

Naonal Work Group evaluaon.............................................................................................24

SCALD..........................................................................................................................................26

Why Connuously Test Tank Integrity? ......................................................................................26

Tesng Requirements .................................................................................................................27

Test Scheduling ...........................................................................................................................27

Test Results .................................................................................................................................27

Reasons the test might not complete ........................................................................................27

Viewing results............................................................................................................................28

Tank Leak Test Reports...................................................................................................................29

Prinng Tank Leak Test Reports..................................................................................................29

Sample Tank Leak Test Report ................................................................................................29

Web Browser Interface .....................................................................................................................31

Using the Web Interface................................................................................................................31

Navigaon Bar.............................................................................................................................32

Maintenance.....................................................................................................................................35

Console Care..................................................................................................................................35

LCD Touchscreen............................................................................................................................35

Calibraon...................................................................................................................................35

Internal Printer...............................................................................................................................36

Changing Printer Paper...............................................................................................................36

Paper specicaons....................................................................................................................36

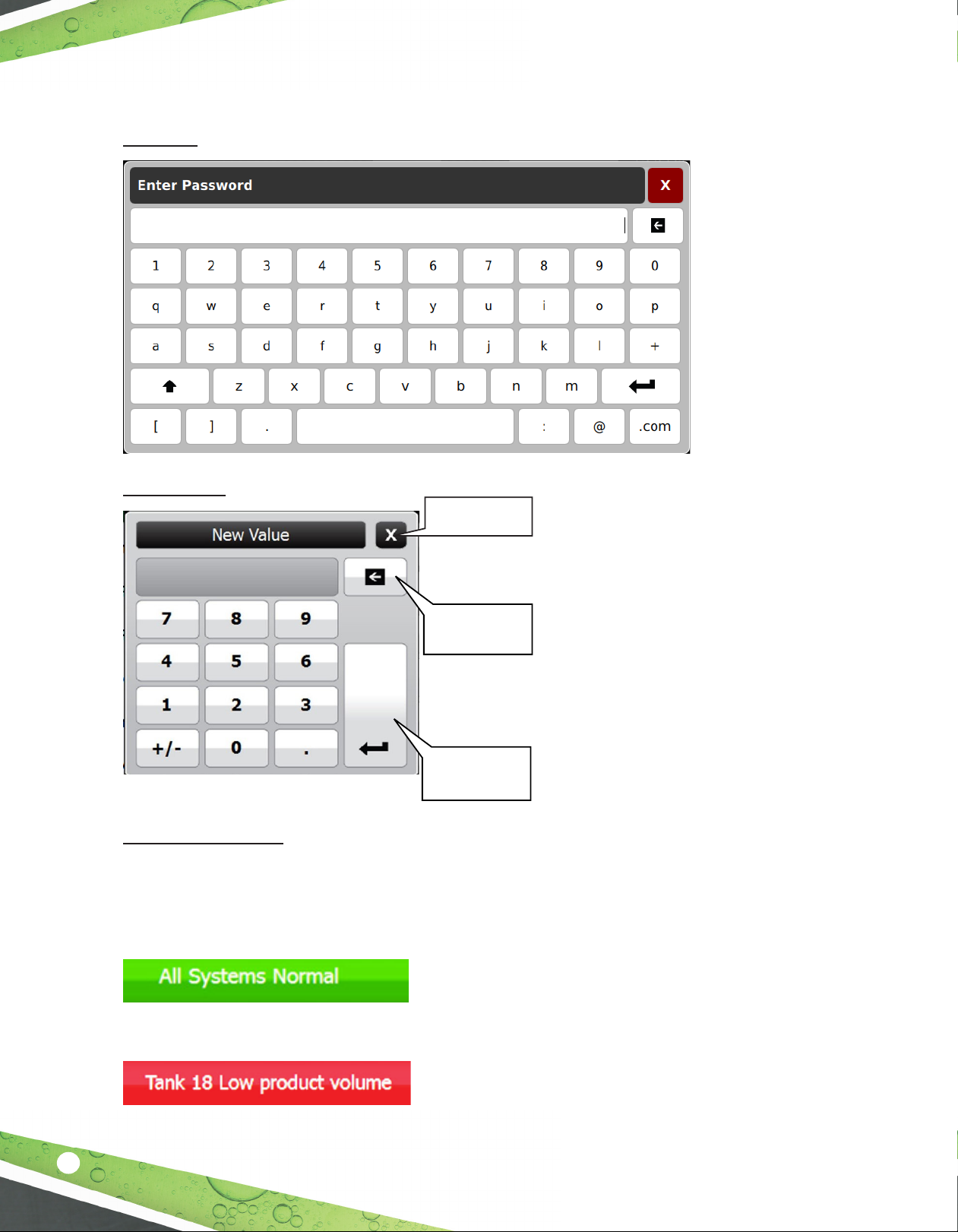

Alarms and Troubleshoong.............................................................................................................37