Due to continuous product development Advanced Air (U.K.) Ltd

reserves the right to change any information without prior notice.

Burrell Way,

Thetford, Norfolk,

IP24 3QU, England

Tel: +44 (0) 1842 753624

Fax: +44 (0) 1842 762032

Email: sales@advancedair.co.uk

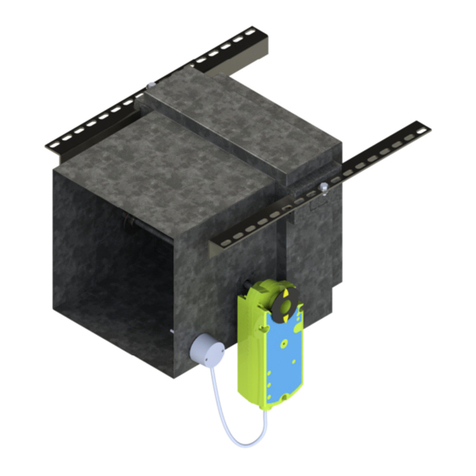

2500 Series

Fire Smoke Dampers

Date Issue Spec. No. Page No.

04/03/14 Rev 2 CE –FSD Sub

PATENT APPLIED FOR

7

HEVAC Wall Installation - E120

Installation & Maintenance Instructions

Installation Procedure

1. Vertical builders work barrier to have an appropriately

sized lintel to ensure an opening clearance for the

expansion frame.

2. The opening in the wall must be cleaned, free of dust and

any other contaminants which could impair the mortar

adhesion. A clearance gap 25mm (min) to 50mm (max)

must be maintained around the expansion frame of the

fire damper (barrier contractor).

3. The damper shall be fitted centrally in the wall opening.

4. The tabs on the factory fitted galvanized steel expansion

frame shall be bent out to tie the damper into the wall with

the penetration seal.

5. The “Penetration Seal” must have a structural and fire

rated compatibility with both the barrier and the damper

and have sufficient strength to retain the fire damper

within the wall in a fire situation. (4:1 Mortar Mix).

6. The Mortar Mix will be applied up to the installation frame

face, take care not to leave any air pockets in the mix.

7. The ductwork connecting to the damper spigots must

overlap by 40mm, leaving a 10mm clearance for any duct

expansion in a fire situation.

8. All ductwork connections must be sealed with an

approved ductwork sealer, and fixed with low resistance

fixings such as: aluminium alloy rivets or nylon bolts.

9. All connecting ductwork must be independently supported

within 1meter of the connections.

10. An Access cover should be fitted on the appropriate side

of the barrier to enable inspections and maintenance

work.

Pre Installation Notes

1. Ensure that the damper is kept in a clean dry

environment and that there is no damage to the damper.

2. Remove all packaging and transit ties before installation.

Maintenance Procedure

These dampers are installed as a life-safe product and will require regular physical and visual examinations. It is essential

that that the assembly is kept in a clean, dust free condition at all times.

It is essential that an access door has been provided in the adjacent ductwork to facilitate the inspection and maintenance.

Ensure that no physical restriction of the blades has occurred during the installation process.

Remove any dirt or debris built up in the damper, apply a little WD lubricant or light oil, any excessive oils should be wiped

away.

Check the operation of any ancillary products that may be fitted.

Examine the fusible link to ensure that no corrosion has occurred and that the plates are free from distortion and are in good

condition to operate when required.

Close the blade pack by manual operation and examine the blades to ensure;

They are in the fully closed position and have located in the ramps.

They are all position in the frame correctly i.e. square to the frame.

They are all in a clean condition.

The period between maintenance checks can best be ascertained by system conditions or as directed by local regulations

for ventilation plant and ancillaries, but should not exceed a maximum interval in excess of twelve months.

The report should be completed following the Maintenance Procedure included within this document.