Advanced Illumination Pulsar 320 User manual

P u l s a r 3 2 0 M a n u a l

Pulsar 320

Strobe Controller

Operator’s Manual

& Installation Guide

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

The shipping container should contain the following items:

Packing List

Qty Ai Part #

1

2

1

1805314

1

1777989

Description

Pulsar 320 Controller

3 Pin,Trigger input connectors

2 Pin, Power input connector

USB Cable 172-1024

(x2)

(1)(1) (1)

2

A d v a n c e d i l l u m i n a t i o n , I n c.

2 4 P e a v i n e D r

R o c h e s t e r V T 0 5 7 6 7

8 0 2 . 7 6 7 . 3 8 3 0

050051 REV-03Manual, Operation, Pulsar 320

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

Pulsar 320 Controller

Operator’s Manual

Table of Contents

1.0 Introduction

1.1 Safety

1.2 Warranty

1.3 Return Policy

2.0 Features

2.1 Light Head Outputs

2.2 User Interface

2.2.1 Remote Operation

2.2.2 Local Control

2.3 Diagnostics

3.0 Quick Start

3.1 Pulsar 320 Controller Cable Connections

3.1.1 Power

3.1.2 Light Head

3.2 Pulsar 320 Status Indicator Lights

3.2.1 Green

3.2.2 Amber

3.2.3 Red

3.3 USB Control

4.0 Operation

4.1DenitionofTerms

4.1.1 Duty Cycle

4.1.2 Latency

4.1.3 Led and Light Head Characteristics

4.1.3.1 LED forward voltage

4.1.3.2 LED thermal resistance

4.1.3.3 LED voltage slope

4.1.3.4 Light head characteristics

4.1.4 Period

4.1.5 Pulse Width

4.1.6 Repetition Rate

4.1.7 Signatech II

4.1.8 Strobe modes

4.1.9 Trigger

4.1.10 Trigger Delay

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7

8

12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

4.2 Pulsar 320 Controller Cable Connections

4.2.1 Power

4.2.2 Trigger

4.2.3 Ethernet

4.2.4 USB

4.2.5 Light Head

4.3 Pulsar 320 Status Indicator Lights

4.3.1 Green

4.3.2 Amber

4.3.3 Red

4.4 Host Computer Control (Remote)

4.4.1 Software Installation

4.4.2 Running Under Host Computer Control

4.4.2.1 CongurePulsar320

4.4.2.2 Launch Pulsar 320 Controller User Interface

4.4.2.3 Pulsar 320 Utility Dialog Box Status Indicators

4.4.2.3.1 Light Head

4.4.2.3.2 USB Connection

4.4.2.3.3 Status Panels

4.4.2.4 Pulsar 320 User Interface Output Controls

4.4.2.4.1 Select Channel

4.4.2.4.2 Program Button

4.4.2.4.3 Mode

4.4.2.4.4 Control Settings

4.4.2.4.5 Protection

4.4.2.4.6 Triggers

4.4.2.4.7 Test

4.5 External Trigger Interface

4.5.1AlternateTriggerCongurations

5.0 Custom Programming

6.0 Troubleshooting

6.1 Pulsar 320 Status Indicator Lights

6.2 Error Codes

7.0 Specifications

8.0 Advanced Users Section

9.0 Appendix

A: Trigger Connection Diagram

B: Pulsar 320 Loader Utility

C: Installation Drawing

D: TCP/IP Setup Instructions

4

. . . . . . . . . . . . . . . . . . . . . . . . . . 25

25

27

31

32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

Pulsar 320 Figures & Tables

5

List of Figures

Figure 1: Pulsar 320 front panel

Figure 2: 24V power supply connection

Figure 3: Pulsar 320 Light head output connection

Figure 4: Status indicator lights

Figure 5: USB dialog open

Figure 6: USB Connected

Figure 7: Ready to program test mode

Figure 8: USB Connection

Figure 9: Light Head Connection Diagram

Figure 10A: Software Installation Window

Figure 10B: Software Installation, Program Group

Figure 11A: GUI Dialog Window

Figure 11B: TCP/IP Dialog Window

Figure 11C: Settings Window

Figure 11D: Query Window

Figure 12: Trigger Connector

Figure 13: Trigger Pinout

Figure 14: S1, SW2 & SW3 locations

Figure 15: Trigger Connection Diagram

Figure 16: Cognex Connection Diagram

Figure 17: IPD Connection Diagram - Typical Trigger Wiring

Figure 18: IPD Connection Diagram -Vision Appliance, Relay/PLC Module

Figure 19: Pulsar 320 Loading Utility

Figure 20: Installation Drawings

Figure21:WindowsIPConguration

Figure 22: Local Area Properties

Figure 23: Internet Protocol Properties

Figure24:WindowsIPConguration

Figure25:USBPortConguration

Figure 26: Pulsar TCP/IP Connection and IP Dialog Window

List of Tables

Table 1: Light head output connector pin description

Table 2: Trigger connector pin description

Table3:Specications

Table 4: Internal switch functions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

9

10

10

11

11

12

16

17

18

18

19

20

20

20

24

24

31

33

34

34

35

36

39

40

41

41

42

45

46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

17

24

26-29

30

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

1.0 Introduction

The Pulsar 320 Controller, used in conjunction with an external 24VDC

power supply, is a compact, 2 output, high power pulse (strobe only) current

sourceincorporatingawiderangeofexibilityinselectingtheoperating

parameters. The unit may be controlled and operated locally (with optional

local control interface) or remotely via a USB interface and host computer.

In addition, the unit employs built in Ethernet connectivity.

The balance of this manual contains the necessary operating instructions,

specicationsandotherdetailsrequiredtoallowtheusertoutilizethefull

capabilities of the Pulsar 320.

1.1 Safety

The Pulsar 320 is designed to protect Advanced illumination light heads

havingtheSignatechIorSignatechIIlightheadidenticationparameters.

WhenusinglightheadsconguredforSignatechI,anadaptercablemustbe

used to connect these lights to the Pulsar 320.

In certain modes of operation, the output voltages and currents provided by

the Pulsar 320 could result in a potentially injurious or fatal electrical shock.

For this reason, light heads should be connected BEFORE the

power switch is turned on. At no time should the operator touch the

output connector pins or light head leads when the power is on.

During normal operation, the Pulsar 320 may reach light head output

voltagesashighas100volts.Forspecicapplications,ortocomplywith

localcodes,thePulsar320maybeconguredtolimitthelightheadoutput

voltage to a maximum of 48 volts. Please contact Advanced illumination

whenthisrequirementexists.

Advanced illumination makes no warranty, expressed or implied, if

illumination or other devices produced by manufacturers other than

Advanced illumination are connected to the Pulsar 320.

1.2 Warranty

Every Advanced illumination, Inc. (Ai) product is thoroughly inspected and

tested before leaving the factory. Products are warranted to be free of

defects in workmanship and materials for a period of TWO YEARS from the

6

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

original date of purchase. Should a defect develop during this period, return

the complete product, freight prepaid, to one of Ai’s distributors or to the

Ai factory. Ai will inspect the unit, and if a defect is found will, at our option,

repair or replace the product without charge. Ai disclaims liability for any

implied warranties, including implied warranties or “merchantability” and

“tnessforaspecicpurpose.”

Aicannotbeheldresponsiblefortheunauthorizedorinappropriateuseof

our products.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES.

InnoeventshallAdvancedillumination,Inc.beliableforconsequential,

special, incidental or indirect damages of any kind arising from the sale or

use of products.

1.3 Return Policy

Standard Products may be returned within 30 days of receipt of the order.

Products must be in resalable condition, in function and appearance, with

shipping charges prepaid. A restocking fee of 15% will be applied to all

items accepted for return to stock. If you need to make a return, please

call our Customer Service Department at 802.767.3830 x237 for a Return

MerchandiseAuthorization(RMA)number.Clearlymarktheoutsideof

the package with the RMA number.

NO RETURNS CAN BE ACCEPTED FOR STANDARD

VARIATION, CUSTOM VARIATION,AND CUSTOM

PRODUCTS.

Therearecurrentlyover100,000uniquecongurationsoftheAiproduct

line.Therefore,wecannotrestockalightbuilttoyourspecications.We

would be glad to help you order your light if you are unsure of the correct

partnumberoryourexactrequirements.

7

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

2.0 Features

The following is a brief overview of the features provided by the Pulsar 320.

These features will be covered in greater detail within the Operation and

Specicationsectionsofthemanual.

2.1 Light Head Outputs

Two outputs capable of high power are provided. Each will provide up to

50A of pulse current drive. The current of each channel is independently

selectable. Output pulse widths can be set between 1 and 100 milliseconds

in1microsecondincrementsatpulserepetitionratesupto400Hz.

2.2 User Interface

2.2.1 Remote Operation: Remote operation via a host computer

allowstheoperatortomakefulluseoftheexibilityofferedbythePulsar

320. Communication is accomplished by both a USB interface and Ethernet.

Operating parameters are set by user friendly Windows based Pulsar 320

controller software. Supported operating systems are Windows 2000,

Windows XP, and Windows Vista.

2.2.2 Local Control (future implementation): An optional local control

is available which allows complete control of all Pulsar 320 settings and

features. A 2X16 LCD display along with four front panel momentary

switches allows users to easily navigate the Pulsar 320’s many features and

set points.

2.3 Diagnostics

A comprehensive set of diagnostic routines and indicators are provided.

Error codes are displayed by the Pulsar 320 via LED indicators on the front

panel.Codedenitionsarefoundinsection6.0“Troubleshooting”where

diagnostics are covered in greater detail.

3.0 Quick Start

Thepurposeofthissectionistoallowtheoperatortoperformaquick

functional test. This will permit an easy checkout of the Pulsar 320 and

attached light head for proper operation.

8

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

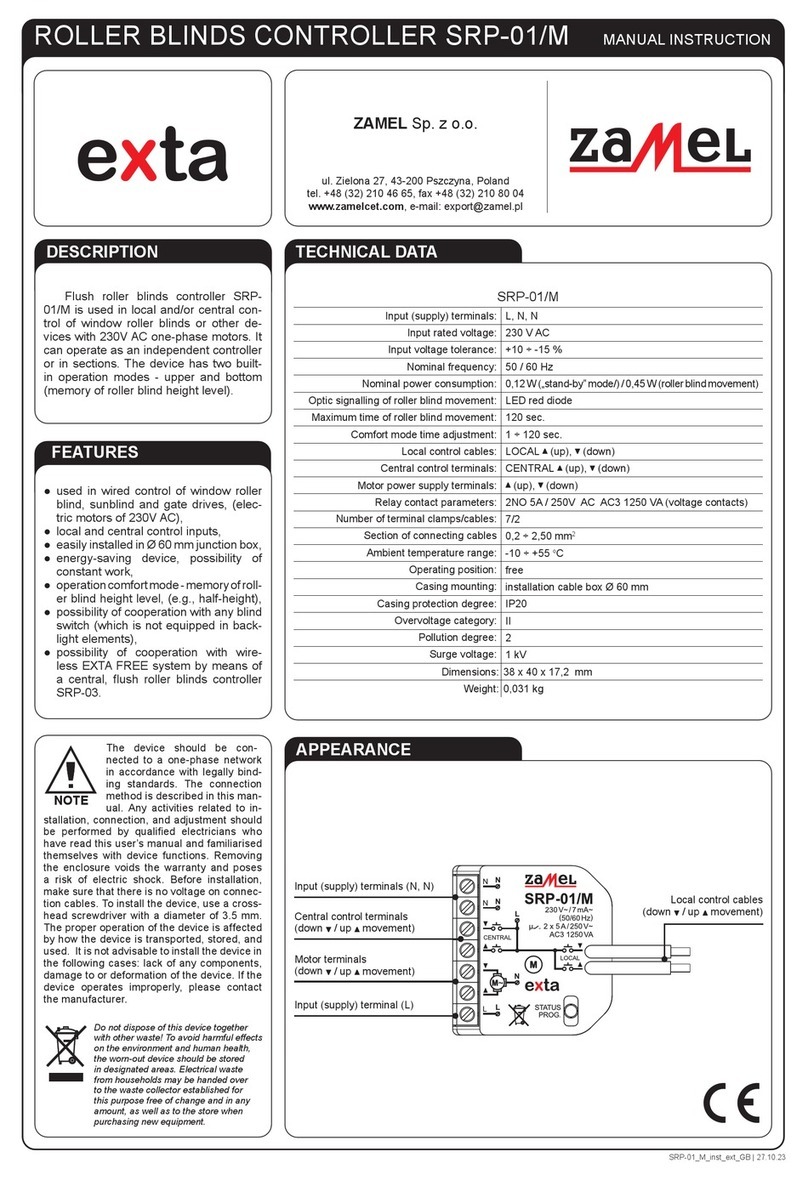

3.1 Pulsar 320 Controller Cable Connections:

Two physical cable connections will be

requiredtooperatethePulsar320and

light head in self test mode. Figure 1

shows the front panel of the Pulsar 320.

3.1.1 Power: ThePulsar320requires

an external 24 volt supply for operation.

A power cable is provided. The black

wire is negative and the red wire is

positive. Plug the 2 pin connector

into the socket labeled “VDC INPUT”.

Observe the polarity markings on the

panel below theVDC INPUT socket.

Refer to section 4.2.1 for more details

regarding the 24 volt supply.

3.1.2 Light Head: Figure 3 shows how the output connectors on the

front panel of the Pulsar 320 mates with the light head connectors. Plug the

Figure 2: 24v Supply Connection

9

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

connector(s) from the light head(s)

into the 5 pin socket in the front of

the Pulsar 320 as shown in Figure 3.

3.2 Pulsar 320 Status Indicator

Lights:

The Pulsar 320 has three LED

indicator lights as shown in Figure 4

3.2.1 Green: This light indicates

that the Pulsar 320 has power either from the USB connection to the host

computer or the main 24VDC power connection.

3.2.2 Amber: The amber light indicates

the operational status of the Pulsar 320.

A blink rate of once per second indicates

normal operation. A blink rate of 5 times

per second indicates an error condition.

3.2.3 Red: The red light blinks an error

code in the case of an error condition.

The condition is indicated by three sets of

sequentialashes.Forexample:4ashes

followedby2ashesfollowedby3ashes

indicateanerrorcodeof423whichsignies

that the main power switch is off. Two common error codes are:

• 351: No light head detected.

• 423:The main power switch is off.

Refer to section 6.0 “Troubleshooting” for more detailed error code

information.

3.3 USB Control

1. Connect Pulsar 320 USB cable to host PC, 24vDC, and

applicable light head

2. Switch the main rocker power switch ON. A green power

LEDwililluminate,followedbyaashingamberLED.

10

Figure 3: Pulsar 320 Light Head

Output Connection

Figure 4: Status Indicator Lights

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

3. Launch Pulsar 320 Utility

4. Choose USB

5. Select a USB port. Use port 0 by default. Press Connect

6. Upon Connecting to a USB port, the strobe settings

window will open (Fig 6) - Grayed-out outputs mean

no light is connected.

7. Test the light head: Press SETUP radio button.

a. The light head should immediately enter a continuous current

mode that will allow for visible detection that the light is

working. This mode is useful for orientating the light in the

system.

b. This mode should NOT be used for inspection purposes as it

will provide indeterminate results.

c. Thismodemaymakethelightappeartoicker-thisisnormal.

11

Figure 6: USB Connected

Figure 5: USB Dialog Open

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

8. Test the light in TEST MODE

a. Press TEST radio button

b. Set Pulse Width slider to 1000

c. Set current to 10

d. Press PROGRAM

Thelightshouldashat10Hzwithnoexternaltriggerapplied.

At this point the attached light head(s) will be ON. Any further adjustments

can be made at any time using the same procedure as above. Adjusting PW

will change the duration of the output pulse, and adjusting CURRENT will

change the output level of the output pulse. Keep in mind that TEST mode

alwaysproducesa10Hzrepetitionratepulse.

The Pulsar 320 can communicate via ETHERNET. For instructions on

this, please refer to the TCP/IP setup guide in Appendix D.

4.0 Operation

The following section details the procedures for operation of the Pulsar 320

Controlleranddenesitsvariousoperatingmodes.

4.1 Denition of Terms

The following terms are used within this manual and, more generally, in

relation to machine vision illumination.

12

Figure 7: Ready to Program Test Mode

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

4.1.1 Duty Cycle: The ratio of the time the light head is “on” (pulse

width, Pw) to the time it is “off” (period,Tp). Calculated as (Pw / Tp) x 100.

The result is expressed in percent. The Signatech II feature of the Pulsar

320 allows the Pulsar 320 to limit the maximum duty cycle based on the

characteristics of the driven light head.

4.1.2 Latency: The time between the receipt of a trigger signal and

initiation of the output drive pulse. The latency is the sum of the rise-times

and propagation delays within the trigger processing circuitry. This time is

purposely kept to a minimum.

4.1.3 LED and Light head Characteristics: Many factors contribute

totheoperationalparametersofanLEDlighthead.TooptimizePulsar

320/light head operation, these characteristics are stored as part of the

information provided to the Pulsar 320 by the Signatech II circuit within

the light head. Some of the variables that affect how the light head can be

driven are outlined below.

4.1.3.1 LED Forward Voltage: The forward voltage drop across an LED

(VFWD) depends upon the nature of the semiconductor junction and the

currentthroughtheLED.ThespeciedVFWDforanLEDisusuallygiven

at its recommended operating current. Please note that when driven by

high current pulses,VFWD can increase by 10 to 20 times. For this reason

voltage levels at the Pulsar 320 output can be as high as 100 volts.

4.1.3.2 LED Thermal Resistance: A measure of temperature difference

between the LED junction and the LED connection to an external heat sink.

Overheating of the junction is the primary cause of failure in LEDs. The

value of the LED thermal resistance, combined with the heat sink thermal

resistance and the overall thermal time constant determine the maximum

pulse width, pulse current, and duty cycle of the light head.

4.1.3.3 LED Voltage Slope: The relationship between VFWD and the

forwardcurrentIFWD,usedbySignatechIItocalculatethevoltagerequired

to provide the desired current.

4.1.3.4 Light head Characteristics: Also contained within the data

provided by Signatech II to the Pulsar 320 are the number and type of LEDs

in each string and the number of parallel strings connected to each channel.

13

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

4.1.4 Period: The length of time between two successive pulses or the

reciprocalofthepulsefrequency.

4.1.5 Pulse Width: The length of time the light head is activated by the

Pulsar 320. This is typically measured between the 50% amplitude points of

the pulse.

4.1.6 Repetition Rate: The rate at which successive pulses are initiated.

Alsoknownasfrequency,whichismeasuredinHertz(cyclespersecond).

Repetition rate is usually multiple times per second.

4.1.7 Signatech II: A proprietary feature of Ai light heads and the Pulsar

320. SignatechidentiesthetypeoflightheadconnectedtothePulsar320

and maintains safe operating limits for each type. The Pulsar 320 can be set

so that Signatech preferentially limits pulse current, pulse width, or period to

remain within the safe power dissipation range of the light head.

4.1.8 Strobe Modes:Thestrobemodeisusedto“freeze”amovingitem

at a particular moment in time. Typically, with LED illumination sources,

the strobe mode involves driving the light head with a high current, short

duration pulse. This provides a very intense light output pulse. As long as

the duty cycle is kept short, no damage to the LEDs occur as a result of the

high current.

4.1.9 Trigger: The signal which initiates an output from the Pulsar 320 to

the light head. The trigger signal is normally generated by an external source

such as a camera or other sensor. Several modes of trigger operation are

provided for in the Pulsar 320. The trigger may start on either a rising or

falling edge. For test purposes, the Pulsar 320 also has an internal trigger

source.

4.1.10 Trigger Delay: Certainapplicationsrequirethataknown,xed

time elapse between the receipt of a trigger signal and the initiation of

an output pulse.This is the trigger delay. For example, if the trigger signal

is received from a position sensor, prior to the arrival of the item to be

inspected, a delay to account for that transit time would be introduced. If

the trigger signal originates from the camera at the start of the shutter

opening, a short delay might be introduced to assure the shutter is fully

open or that the illumination pulse occurs elsewhere within the frame time.

14

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

4.2 Pulsar 320 Controller Cable Connections

Four physical connections, one of which needs to be a USB or Ethernet will

berequiredtooperatethePulsar320andlighthead.Referbacktogure1

for an illustration of the Pulsar 320’s front panel.

4.2.1 Power: The input power connector is located near the bottom

centerofthePulsar320’sfrontpanel.ThePulsar320requiresanexternal

24voltsupplyforoperation.Thepowersupplyneedstohavesufcient

amperage rating to drive the light head in the desired mode of operation.

Advanced illumination recommends a minimum of 4A for full output

operation. A power cable is provided.The black wire is negative and the red

wire is positive. Plug the 2 pin connector into the socket labeled “INPUT”.

Observe the polarity markings on the right hand side of the connector

socket.

4.2.2 Trigger: The trigger input connectors are located at the upper right

of the Pulsar 320’s front panel. The differential trigger levels are CMOS/TTL

compatible but will accept input pulses as great as 30 V. Two input trigger

connectors are provided, one for each output. One trigger may be mapped

to both outputs. For more detailed triggering information refer to section

4.6 “External Trigger Interface”.

4.2.3 Ethernet: An RJ45 connector is located to the lower right of the

front panel and is provided for Ethernet connectivity. Standard protocols

supported are TCP/IP, UDP,TFTP via 10/100Base-T. For more detailed

information on Ethernet connectivity.

4.2.4 USB: The USB connector is located to the right and center of the

front panel.A host computer will communicate with the Pulsar 320 via

this USB connection. Connect the provided USB cable between the USB

connection on the host computer and the connector labeled USB on the

Pulsar 320. The Pulsar 320 is Microsoft HID USB compliant. Therefore, a

host computer with Windows 2000, Windows XP or Windows Vista will

auto-detect the Pulsar 320.

Figure 6 is a connection diagram for the output connector. Connect light

head(s) in accordance with Figure 6.

4.2.5 Light Head: Power to light heads is supplied by two independent

connectorsonthefrontpaneleachhaving5pins.Table1identiesthe

15

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

function of each pin for the 5 Pin power connector. Plug the connector

from each light head into the 5 pin socket as shown in Figure 3.

4.3 Pulsar 320 Status Indicator Lights

ThePulsar320hasthreeLEDindicatorlights.Referbacktogure4foran

illustration of these indicator lights.

4.3.1 Green: This light indicates that the Pulsar 320 has power either

from the USB connection to the host computer or the main 24VDC power

connection.

4.3.2 Amber: The amber light indicates the operational status of the

Pulsar 320. A blink rate of once per second indicates normal operation. A

blink rate of 5 times per second indicates an error condition.

4.3.3 Red: The red light blinks an error code in the case of an error

condition.Theconditionisindicatedbythreesetsofsequentialashes.For

example:4ashesfollowedby2ashesfollowedby3ashesindicatesan

errorcodeof423whichsigniesthatthemainpowerswitchisoff.Two

common error codes are:

•351: No light head detected.

• 423:The main power switch is off.

Refer to section 6.0 “Troubleshooting” for more detailed error code

information.

4.4 Host Computer Control (REMOTE)

T

otakefulladvantageoftheexibilityof

the Pulsar 320, software is provided which

permits the operating parameters to be set

by a host computer. The host computer

will be connected to the Pulsar 320 via a

USBportutilizingaUSBTypeBconnector.

(See Figure 7) The USB port is Microsoft

HID compliant.

16

Figure 8: USB Connection

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

Figure 9: Light Head Connection Diagram

Table 1: Pin Function Chart

17

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

4.4.1 Software Installation: Pulsar 320 Controller user interface

softwareisrequiredtosettheoperationalparametersofthePulsar320.

This utility program is included online at our website, and is installed as

follows:

Note:AdministratorAccesstothesystemisusuallyrequiredtoinstall

thesoftware.

Note: Supported operating systems are Windows XP through Windows

10.

1. The software can be found on our website under: Resources ->

Downloads -> Software -> Pulsar 320 Control Software.

2. Select setup.exe.

Figure 10A: Software Installation Window

Figure 10B: Software Installation, Program Group

18

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

3. Close all open applications if prompted and press OK.

4. Select a Program Group or use the default (Advanced Illumination) and

clickNext.(Seegure10B.)

Note: If for some reason the automatic installation program cannot be used,

the software can be manually installed as follows: Place the four support

lesfrom the downloads in the same folder on the PC.

1) MPDH8USB_TCP.dll

2) PulsarAPI.dll

3) Pulsar320Loader.exe

4.4.2 Running under Host Computer Control

4.4.2.1 Congure Pulsar 320: ThePulsar320comespre-congured

for normal use. See section 8 “Advanced User Section” for a complete

descriptionofoptionalcongurations.

4.4.2.2 Launch Pulsar 320 Controller user interface: To run the

program; go to Start -> Programs -> Advanced illumination -> Pulsar

Controller. Upon execution of the Pulsar Controller Utility program, the

dialogboxshowningure11Awillappear.

GUI Dialog Descriptions

A. OpenDialog:Openssavedconguration

B. SaveDialog:SavesactivecongurationtohostPC

C. USB: Opens USB connection dialog

19

Figure 11A: GUI Dialog Window

a d v a n c e d i l l u m i n a t i o n . c o m P u l s a r 3 2 0 M a n u a l

P u l s a r 3 2 0 M a n u a l

D. TCP/IP: Opens TCP/IP connection dialog

E. Settings:OpensPulsar320congurationsettingsdialog

1. Slew Rate: used to reduce output ripple/ringing on the output

light pulse. Using the proper slew rate setting may improve

lighting performance.

a. High: (default) Used when pulsing below 100uSec

b. Mid-High: Used when pulsing 100 - 500uSec

c. Mid-Low: Used when pulsing 500 - 1000uSec

d. Low: Used when pulsing >1000uSec

2. Differential Trigger: Default checked. Activates the differential trigger

inputs. Recommendation is to leave this on unless otherwise

instructed.

3. Advanced Settings: 48V output limit.

Default unchecked. Apply this setting

to clamp the output strobe voltage to

48V. This may reduce performance

signicantlyforcertainlightsources.

F. Query: Displays device information

Edit Network button allows for TCP/IP and

networkcongurationtooccurforthedevice.

20

Slew Rate

Settings

Channel 1

Channel 2

High

High

Differential Trigger

Trigger 1

Trigger 2

Advanced Settings

Limit Output to 48V

Set Close

Address

IPDialog

High

OK Cancel

Subnet

High

Gateway

High

Figure 11B: TCP/IP Dialog Window

Figure 11C: Settings Window

Device

Query

HW Version

FW Version

Network

IP Address

Edit Network OK

Serial Number

7200-000186-110

8200-000219-113

0000000235

Subnet Mask

Gateway

MAC Address

192.168.24.99

255.255.255.0

192.168.24.1

DA:8E:00:00:00:33

Figure 11D: Query Window

Table of contents

Other Advanced Illumination Controllers manuals

Popular Controllers manuals by other brands

National Instruments

National Instruments NI cRIO-9022 User manual and specifications

Chino

Chino CP350 Series instructions

UTC Fire and Security

UTC Fire and Security Interlogix TruPortal TP-SYS-BRD quick reference

Clauss

Clauss CIRCON 4260007480120 manual

Standa

Standa 8SMC1-USBhF user manual

SICK

SICK MSC800 operating instructions