Advanced Poly-Packaging Advanced Poly-Bagger T-1000-S18H User manual

0

T-1000

Advanced Poly-Bagger™

(Model T-1000-S14)

___________________________________________________________________________

Operation Manual, Version 9 Revision G

1

Acknowledgments

Written By: David Kolinski-Schultz

Reviewed By: Stuart Baker

Copyright

Nov 2018 (Ver 9G) Apr 2018 (Ver. 9F) Jan 2018 (Ver. 9E) Nov 2017 (Ver. 9D), 2014 (Ver. 8), 2010 (Ver. 7) 2009 (Ver. 6),

2007 (Ver. 5), 2006 (Ver. 4), 2003 (Ver. 3), 2001 (Ver. 2), 1995 (Ver. 1), Advanced Poly-Packaging, Inc. (APPI). All rights

reserved.

This manual and the program operating the equipment described in it are copyrighted. You may not copy this manual in whole or

part without the consent of Advanced Poly-Packaging, Inc.

All information pertaining to the promotion, sale, distribution, operation and maintenance of the T-1000-S14 ADVANCED

POLY-BAGGER including this manual, drawings, schematic, wiring diagrams, VHS video tapes, brochures, specification sheets,

figures, charts, or any other information, due to its proprietary design and manufacture remain the property of Advanced Poly

Packaging, Inc. Unauthorized duplication, distribution or disclosure to third parties without the expresses permission of

Advanced Poly-Packaging, Inc. is strictly prohibited.

Trademarks

T-1000-S14 is a trademark of Advanced Poly-Packaging, Inc. Advanced Poly-Packaging, Inc. owns also the following

trademarks: Advanced Poly-Bags, Advanced Poly-Bagger, Seal-a-Print, Roll-a-Print, Twin-Seal, Advanced Poly-Pack, Advanced

Poly-Bag, and Advanced Bag.

Limited Warranty and Disclaimer

Warranty period is 12 months or 1,000,000 cycles whichever comes first. The warranty commences on the date of delivery of the

equipment to the Purchaser. APPI warrants to the Purchaser that the equipment is free from defects in workmanship or material

under normal use and service. During the warranty period, APPI agrees to repair or replace, at its sole option, without charge to

Purchaser, any defective component part of the equipment. To obtain service, Purchaser must return the equipment or component

to APPI or an authorized APPI distributor or service representative in an adequate container for shipping. Any shipping charges,

insurance, or other fees must be paid by Purchaser and all risk for the equipment shall remain with Purchaser until such time as

APPI takes receipt of the equipment. Upon receipt, APPI, the authorized distributor or service representative will promptly repair

or replace the defective component and then return the equipment or component to Purchaser, shipping charges, insurance, and

additional fees prepaid. APPI may use reconditioned or like new parts or units, at its sole option, when repairing any component

or equipment. Repaired products shall carry the same amount of outstanding warranty as from original purchase. Any claim

under the warranty must include a dated proof of delivery. In any event, APPI's liability for defective components or equipment is

limited to repairing or replacing the components. This warranty is contingent upon proper use of the equipment by Purchaser and

does not cover: expendable component part such thermocouple wire, heater cartridge, rollers, bushings, and the like; or if damage

is due to accident, unusual physical, electrical or electromechanical stress, neglect, misuse, failure of electric power, water

damage (from airlines), improper environmental conditions, transportation, tampering with or altering of the equipment,

packaging of corrosive or contaminating products or other products damaging to components, and equipment or components not

owned or in the possession of original Purchaser. APPI will not be liable for loss of production, profits, lost savings, special,

incidental, consequential, indirect, or other similar damages arising from breach of warranty, breach of contract, negligence, or

their legal action even if APPI or its agent has been advised of the possibility of such damages or for any claim brought against

the Purchaser by another party. This warranty allocates risks of equipment failure between Purchaser and APPI. APPI's pricing

reflects this allocation of risk and the limitations of liability contained in this warranty. The warranty set forth above is in lieu of

all other express warranties, whether oral or written. The agents, employees, distributors, and dealers of APPI are not authorized

to make modifications to this warranty, or additional warranties binding on APPI. Accordingly, additional statements such as

dealer advertising or presentations, whether oral or written, do not constitute warranties by APPI and should not be relied upon.

Warranty on equipment is considered void when outstanding balances become delinquent (over 30 days late - 60 days after ship

date). Equipment Integration to other Equipment: APPI assumes no responsibility for the integration of its products to other

products or within a system unless APPI performs the integration, testing and provides the results of the tests to the purchaser in

writing. Furthermore, APPI assumes no responsibility for bag sizing whether suggested or recommended.

2

Table of Contents

Chapter 1: Introduction 6

1.1 Welcome.......................................................................................................................... 7

1.2 Overview.......................................................................................................................... 7

1.3 Standard Features............................................................................................................. 7

1.4 System Integration........................................................................................................... 8

1.5 Available Options ............................................................................................................ 9

1.6 Using this Manual - Typographical Conventions.......................................................... 11

1.7 Contact Information....................................................................................................... 11

1.8 Warranty Registration.................................................................................................... 13

Chapter 2: Safety, Getting Started 14

2.1 Chapter Summary .......................................................................................................... 15

2.2 Safety, Risks .................................................................................................................. 15

2.3 Installation Procedures................................................................................................... 16

2.4 Note on Adjustments to the T-1000-S14....................................................................... 17

2.5 Air and Power Requirements......................................................................................... 17

2.6 Assembly Instructions.................................................................................................... 17

2.7 Air and Power Hookup .................................................................................................. 18

2.8 Main Power.................................................................................................................... 22

2.9 Bag Threading................................................................................................................ 22

2.10 Cycle Operation of the T-1000-S14............................................................................... 22

2.11 Quick Setup Procedures................................................................................................. 23

Chapter 3: Touch Screen Operation 26

3.1 Touch Screen Operation ................................................................................................ 27

3.2 Touch Screen Specifications / Features......................................................................... 27

3.3 Touch Screen Program, Overview................................................................................. 27

3.4 Introductory Screen........................................................................................................ 27

3.5 Operation Screen............................................................................................................ 28

3.6 Main Menu..................................................................................................................... 28

3.7 Settings Screen............................................................................................................... 28

A. Fill Time......................................................................................................................... 29

3

B. Air Pulse......................................................................................................................... 29

C. Seal Point ....................................................................................................................... 29

D. Seal Time ....................................................................................................................... 29

E. Reverse........................................................................................................................... 30

F. Blow Off ........................................................................................................................ 30

G. Index Speed.................................................................................................................... 30

H. Seal Temperature ........................................................................................................... 30

3.8 Options Menu................................................................................................................. 30

3.9 LS-10 Load Shelf........................................................................................................... 31

3.10 FS-10 Flat Seal Assembly.............................................................................................. 31

3.11 FS-30 Heavy-Duty Flat Seal Assembly......................................................................... 31

3.12 CS-10 Compartment Seal .............................................................................................. 32

3.13 TS-10 Twin Seal Feature............................................................................................... 32

3.14 Ti-1000Z Printer ............................................................................................................ 32

3.15 CF-10 Counting Funnel ................................................................................................. 33

3.16 BO-30 Bag Opening Device.......................................................................................... 34

3.17 LC-10 Light Curtain ...................................................................................................... 34

3.18 BO-20 Bag Open Detector............................................................................................. 36

3.19 TIZ RAP / Accumulator................................................................................................. 36

3.20 AF-10 Accumulating Funnel ......................................................................................... 36

3.21 US-5000 / US-5500 Semiautomatic Net Weigh Scale .................................................. 37

3.22 PB-20 Optical Palm Buttons.......................................................................................... 37

3.23 TS-10 Trim Seal Assembly............................................................................................ 37

3.24 ES-10 E-Stop Circuit ..................................................................................................... 37

3.25 Adjustable Stand Screen................................................................................................ 38

3.26 DF-20 Part Diverter (Diverting Funnel)........................................................................ 38

3.27 MV-20 Seal Validation.................................................................................................. 39

3.28 Medical Flat Seal ........................................................................................................... 40

3.29 BF-10 Bag Deflator........................................................................................................ 40

3.30 UF-5000 Infeed Conveyor Operation Screen................................................................ 41

3.31 BV-10 Barcode Verification Option.............................................................................. 41

3.32 Ti-1000 Inline Printer .................................................................................................... 42

3.33 Counters Screen............................................................................................................. 42

3.34 Continuous Strip Screen ................................................................................................ 42

4

3.35 Temperature Calibration Screen .................................................................................... 43

3.36 Technical Assistance & Troubleshooting Screens......................................................... 44

3.37 Bagger Auxiliary Options.............................................................................................. 44

3.38 Pass Code Setup Screen................................................................................................. 44

3.39 Bagger Factory Settings................................................................................................. 45

3.40 Bag Registration............................................................................................................. 47

3.41 Job Save and Recipe Management ................................................................................ 48

A. Internal Memory (PLC) ................................................................................................. 49

B. External Memory (USB)................................................................................................ 49

3.42 Memory Files and Data Structures ................................................................................ 50

3.43 PLC Info......................................................................................................................... 55

3.44 Options Enable Screen................................................................................................... 55

3.45 License Activation ......................................................................................................... 56

3.46 Production Graph and Temperature Graphs.................................................................. 57

3.47 Operation Mode Timers, Alarms, & Alarm Data .......................................................... 57

3.48 Bagger Machine Info ..................................................................................................... 58

3.49 Warning and Message Screens ...................................................................................... 58

Chapter 4: Adjustments Maintenance, Troubleshooting 60

4.1 Machine Adjustments .................................................................................................... 61

4.2 Compression (Nip) Roller Adjustment.......................................................................... 61

4.3 Dancer Assembly Adjustments (Roller Shaft)............................................................... 64

4.4 Dancer Bar and Brake Strap Adjustment....................................................................... 64

4.5 Upper Roller Guides...................................................................................................... 64

4.6 PTFE Adjustment........................................................................................................... 66

4.7 PTFE Replacement ........................................................................................................ 66

4.8 Pressure Bar Adjustment................................................................................................ 67

4.9 Sealer Cylinders Adjustment ......................................................................................... 67

4.10 Pressure Bar (Rubber) Replacement.............................................................................. 67

4.11 Anti-Jam Adjustment..................................................................................................... 71

4.12 Heater Cartridge Replacement....................................................................................... 73

4.13 Replace Thermocouple Wire ......................................................................................... 75

4.14 Preventative Maintenance and Scheduled Maintenance................................................ 75

4.15 Preventative Maintenance Checklist.............................................................................. 76

4.16 Scheduled Maintenance Chart ....................................................................................... 77

5

4.17 Preventative Maintenance Chart.................................................................................... 77

4.18 Spare Parts Kits.............................................................................................................. 78

4.19 Troubleshooting Guide .................................................................................................. 80

4.20 Troubleshooting Checklist............................................................................................. 80

4.21 PLC IO Listing............................................................................................................... 82

4.22 Schematics ..................................................................................................................... 86

A. Electrical Drawings........................................................................................................ 86

B. Pneumatic Piping Diagrams........................................................................................... 99

Chapter 5: Parts and Drawings 108

5.1 T-1000-S14 Advanced Poly-Bagger............................................................................ 109

5.2 Base Assembly............................................................................................................. 111

5.3 Upper Column Assembly............................................................................................. 112

5.4 Covers and Guarding ................................................................................................... 113

5.5 Flat Load Shelf Assembly............................................................................................ 114

5.6 Dancer Assembly......................................................................................................... 115

5.7 Touch Screen Assembly .............................................................................................. 118

5.8 Seven Inch Touch Screen............................................................................................. 119

5.9 Main Frame Assembly................................................................................................. 121

5.10 Upper Roller Assembly................................................................................................ 123

5.11 Air Knife Assembly..................................................................................................... 124

5.12 Sealer Frame Assembly: Drop Frame.......................................................................... 126

5.13 NBO Wide Seal Frame Assembly................................................................................... 129

A. Pressure Bar Subassembly........................................................................................... 132

B. Heater Bar Subassembly.............................................................................................. 133

C. PTFE Guide Subassembly ........................................................................................... 134

D. Grooved Roller Mounting Subassembly...................................................................... 135

E. Bag Finger Grounding Subassembly........................................................................... 136

F. Latch Subassembly ...................................................................................................... 137

G. Manifold Assembly...................................................................................................... 138

5.14 Electrical Panel ............................................................................................................ 139

5.15 Bag Blow Off (Optional) ............................................................................................. 141

5.16 Bag Deflator (Optional)............................................................................................... 142

5.17 Notes............................................................................................................................ 143

7

1.1 Welcome

Now that you have decided to upgrade your packaging facilities with the T-1000-S14 Advanced Poly-

Bagger™ from Advanced Poly-Packaging, Inc., we thank you for selecting our equipment, materials, and

service. Where labor reduction and fast changeover are important, the T-1000-S14 uses Advanced Poly-

Bags (pre-opened bags on rolls) manufactured by Advanced Poly-Packaging, Inc. Extensively equipped

with several "built-in," ready-to-use options, the T-1000-S14 can package various industrial, medical,

molded and food products. With bag sizes that range from 4" x 3" to 11" x 16" and mil thickness from 1

mil to 4 mils, we hope the T-1000-S14 will meet all your bagging needs. T-1000 Advanced Poly-

Bagger™ is a general-purpose bagging system designed for manual or automatic packaging of a variety

of products.

1.2 Overview

The T-1000-S14 Advanced Poly-Bagger™ is a general-purpose bagging system designed for manual and

automatic packaging of a variety of products. The T-1000-S14 is designed to lower your packaging costs

with high speeds, versatility, reliability, and simplicity.

High Speeds: Indexes, opens, seals, and tears off a bag at very high rates of speed. Actual packaging

speed depends on the bag size, equipment options, product characteristics and loading method.

Versatility: Mobile on rugged castors for packaging at any production station in your facility. Ideal for

numerous short runs with virtually no production loss for job changeovers since all that is required is a

roll change and recalling the bag settings from memory.

Reliability: Crafted from the highest quality components and materials to withstand the most rigorous

manufacturing environment. Sturdy mounts with castors and a rugged frame guarantee long life and

usefulness with minimal maintenance.

Simplicity: A user-friendly, menu-driven touch screen program allows operators to set up the bag,

options, and auxiliary equipment, save settings in memory and recall those settings for repeat runs.

1.3 Standard Features

The machine comes standard with the following features:

Anti-Jam Device: Detects rigid objects of at least 3/8" to safeguard the equipment and product. During

the loading and sealing operation, this device will automatically reverse the pressure bar and discontinue

cycle operation if an obstruction is detected.

Auxiliary Automatic Operation –Integrates automatically to vibratory counters, scales and other in-

feed equipment.

Castors Assembly: Rugged castors are standard for plant mobility.

Communications Ports: Provides for auxiliary communications and screen data transfer.

8

Continuous Strip Option: Leave bags connected in an "endless" strip or a predetermined number of

strips of sealed bags.

Counters –Preset, Total and Maintenance counters are provided.

Energy Conservation and Component Saver: To extend its life and conserve energy in your plant, the

T-1000-S14 is programmed to sequentially shut down components when not in use for extended periods

of time. Electric current to the heater bar will discontinue and place the T-1000-S14 in Stop mode during

a preset period of nonuse. Shortly thereafter, air flow will be shut off, preserving compressed air. A

screen saver is also provided.

Internal (PLC) and External (USB) Recipe Management System: Stores up to twenty-four recipe

settings internally, or hundreds of recipes externally. Optional Ethernet card can allow for remote recipe

management.

Maintenance Counter / Chart: Periodically check this counter (total machine cycles) to determine

preventative maintenance and component inspection intervals.

Pass Code Protection: Settings screens can be protected from alterations by unauthorized individuals.

Once turned on, this function acts as a “screen save” feature. After a preset amount of time, the pass code

screen will be displayed from the Bagger Operation screen. Factory settings are protected by a Level 1

pass code and should only be accessed by authorized maintenance personnel.

Predetermining Counter: Preset the T-1000-S14 to stop after a predetermined number of bags have been

packaged. Set the quantity of finished bags to complete a work order or fill a shipping container. Once the

work order is complete or the container is full, the T-1000-S14 stops to alert the operator to begin the next

work order or to push aside the box and begin filling another. Pressing anywhere on the screen resets the

counter and starts the bagging operation with minimum delay.

Totalizing Counter: Reset this counter at the beginning of each shift or day to record packaging

production over a period of time.

1.4 System Integration

The T-1000-S14 is preprogrammed to integrate automatically with major brand vibratory counters and

feeders, weigh scales, volumetric fillers, auger fillers and infeed conveyors. As an OEM for numerous

equipment manufacturers of infeed systems, we offer the best available system with the T-1000-S14

Advanced Poly-Bagger as the integral packaging component. However, APPI cannot be responsible for

the successful integration of third party equipment, unless approved and integrated by APPI.

FREE CONSULTATION AND PRODUCT EVALUATION: We invite you to call to discuss your

packaging requirements and our free product packaging analysis.

9

1.5 Available Options

Although the T-1000-S14 is equipped with many "built-in" options, various auxiliary options and

equipment can easily be added for special purpose packaging. The following options may be purchased

from Advanced Poly-Packaging, Inc:

AF-10 Accumulating Funnel: A special purpose funnel that collects and holds product until it is ready to

be dropped. A funnel to help contain the product can also be inserted.

Bag Deflator: This option quickly mounts to the sealer bar and squeezes the air from the bag while

sealing.

Bag in Bag Option:A conveyor feeds bagged product to a second bagger to be bagged again.

Bag Out Sensor:If the bag material ends, a message will be displayed indicating that the machine is out

of bags or that a threading or web breakage issue has occurred.

Base Height Adjustment: An electronic mechanism that raises or lowers the base of the bagger, allowing

for more versatility and convenience. Without this option, the operator must raise or lower the bagger

manually.

BO-20 Bag Open Detector:This option will detect whether or not a bag is blown open, or whether or not

a funnel is inserted into the bag for validation that the bag is ready to receive product.

BO-30 Bag Opening Device:This device enters the bag with one or more “fingers” and pulls the bag

open to a stop.

BV-10 Barcode Verifier: Verifies that a barcode is readable. If no barcode is detected, or if a barcode is

not correctly formatted (as per software settings in the barcode verifier), then a “No Read” message will

be displayed.

CF-10 Counting Funnel: This option automatically cycles the bagger when a preset number of parts

have fallen through the funnel.

CS-10 Compartment Seal: Seals the bag twice to create two separate compartments within the same bag.

DF-10 Diverting Funnel: This feature is used to count bags from the bagger and divert them for further

packaging operations, including counting into cartons.

Dual Printing: Special programming allows the T-1000-S14 to operate with both the Next Bag Out

printer and an offline printer in order to print on both sides of the bag. The offline printer is mounted

upside down on the back of the bagger.

10

E-Stop: This option can be used to stop the cycle operation of the T-1000-S14 and possibly other

auxiliary infeed or outfeed equipment purchased with the T-1000-S14.

FS-10 Flat Seal Assembly: Helps decrease/eliminate wrinkles in the seal by pulling the sides of the bag.

Increases bag integrity.

FS-30 Heavy Duty Flat Seal Assembly (Drop Frame): Uses two movements to further assist in

flattening the film to decrease wrinkles or folds in the seal.

LAN Connection: Provides for Ethernet communication.

LC-10 Light Safety Curtain: If funnels are removed, APPI highly recommends the addition of this

option to prevent injuries. This option, when activated, prevents outputs (voltage) to valves that cause the

seal bar to activate. Additionally, the stepper motor stops when blocked.

LS-10 Load / Support Shelf: Provides support for heavier packages when dropped into bag. Sizes: 10",

15" or 20" long.

MV-10 Seal Validation: Additional components provide a secondary means of detecting a failure or out

of range condition for components that affect seal quality.

NBO Next Bag Out Printer: An inline printer installed within the T-1000-S14 capable of printing the

next bag out in the bagging sequence. This feature prevents mislabeling of pharmaceuticals, prescriptions

or high cost items and allows part numbers or other printing information to be changed with every bag.

OFS-10 Output Fault Signal with SL-10 Stack Light: For automatic bagging operations with third

party or production equipment, this signal provides a fault when the bagger is inoperative (due to out of

bag conditions or other faults).

PB-20 Dual Palm Buttons: Decreases the possibility of injury to hands and fingers. The operator must

push two buttons simultaneously to actuate the seal bar.

Roll-a-Print 1400 or 2800 Single or Dual Thermal Inline Printer: Prints bar codes and graphics

directly to the surface of the front or both the front and back of the bag.

Ti-1000 Thermal Transfer Inline Printer: Prints bar codes, graphics, etc. by downloading pre-

formatted labels, generated via label software. (PC or Terminal and software required)

TS-10 Trim Seal Assembly: Trims excess film from the bag above the seal to enhance the appearance of

the package. Great for retail products.

Twin-SealTM: Seal the bag a second time, 3/8" from the first seal, for additional bag integrity.

11

UC-2400 Vibratory Parts Counter: Automatic parts counter feeds fasteners, electronic components,

injected molded parts and many other types of product, then drops the final count into the bag, carton, or

infeed conveyor.

UF-2000 Takeaway Conveyor: Removes packaged product to a packing station or directly feeds a

carton or table, conveying the product from floor level. The conveyor fits perfectly underneath the

T-1000-S14 and takes the product away. Small, lightweight, and equipped with castors, use this conveyor

anywhere in the plant. Designed for 24 hour / 7 days a week operation.

UF-5000 Infeed Conveyor: Kit packaging infeed conveyor. Instead of loading parts directly into the bag,

load parts into compartments on the conveyor. Packaging kits can be loaded into the compartments by

hand or automatically with parts or scales.

US-4000 Check Weigh Scales: When you must guarantee the contents of the bags or kits, APPI offers

check weigh scales with incredible accuracy, speed, and reliability. A history of weights is standard,

along with job/recipe saves.

US-5000 / 7000 / 9000 Semiautomatic (US-5000) or Automatic Scale (US-7000 and US-9000): Feeds

a weighed/counted batch of product into bags.

Other options may have been added since the date this list was printed. Please call for additional or

custom options pricing.

1.6 Using this Manual - Typographical Conventions

The following manual conventions are frequently used to assist in understanding important information,

alerting the operator of potentially dangerous or damaging practices, and the normal functions of the

T-1000 Advanced Poly-Bagger™.

text Normal text

<ENTER> Used to show Touch Screen keys

Italics Used for emphasis

Note: Identifies important information.

CAUTION: Warning messages - To avoid physical harm, damage to equipment or damage to

the product. Be sure to read these messages carefully.

1.7 Contact Information

To better serve your bagging needs, call (330) 785-4000 or toll free 1-(800) 754-4403 for convenient

service solutions, Monday through Thursday, 9:00 AM to 5:30 PM EST, or Friday 9:00 AM to 5:00 PM

EST. For technical assistance with current machinery, ask for Service. To order spare parts for your

system, ask for Parts. To order auxiliary equipment for your current system, ask for Machine Sales. To

place an order for bags, ask for Bag Sales.

You may also contact any of these departments by email:

Reach Service at Service@advancedpoly.com

13

1.8 Warranty Registration

This section must be completed and returned to Advanced Poly-Packaging, Inc. to register the T-1000

Bagger for Warranty Protection.

Serial Number:

(Serial Number located on the back panel)

Company Name and Address Contact Name(s) / Title(s) / Phone Number

________________________________

________________________________

________________________________

________________________________________

________________________________________

________________________________________

Please fax or mail this page to:

Service Manager

Advanced Poly-Packaging, Inc.

1331 Emmitt Road

Akron, OH 44306

USA

Fax # (USA) 330-785-4010

Or email the information above to: service@advancedpoly.com

15

2.1 Chapter Summary

This chapter describes procedures to receive and set up the T-1000-S14, including uncrating instructions,

environmental, air and power requirements, risks, required safety precautions, quick start procedures

assembly instructions and height adjustments. Additionally, this chapter describes safety precautions, how

to power on the T-1000-S14 and how to properly thread bags through the machine.

2.2 Safety, Risks

The equipment has been designed with features to reduce the possibility of injury. Despite safety

precautions, operators may receive lacerations, minor burns or crushed or broken bone injuries if coming

in contact with the heater bar or other moving components. Please carefully read the following

precautions to operate the equipment properly and avoid injury.

Although no special personal protective equipment is required to operate the equipment, eye protection,

gloves or other protection should be worn depending on the characteristics of product being packaged or

the method of loading the product.

Please carefully read the following precautions to operate the equipment properly and avoid injury:

CAUTION: Initial Setup of the machine must be performed by Specialized Personnel. Qualified

Service Engineers should uncrate, assemble (if required), test and connect power sources, test the

equipment for proper operation and otherwise setup the equipment for use.

CAUTION: Maintenance must be performed by Specialized Personnel. Qualified Service Engineers

must remove guards or covers to gain access to electrical or mechanical areas.

CAUTION: To avoid injury do not reach under the equipment or guards. Do not place hands or

fingers in the seal area, near the seal or heater bar, load shelf, or other moving components.

CAUTION: To avoid injury, do not operate the equipment if funnels, guards, or covers or other access

panels have been removed. If any of these safety measures have been removed or modified or if any

openings have been increased, the operator will have access to moving components and extreme

temperature areas that can cause crush, cut, or burn injuries to hands or fingers.

CAUTION: To avoid injury, do not reach under guards or elsewhere under the machine.

CAUTION: Do not remove or loosen fasteners on the frame. If loosened the equipment may drop

suddenly causing injury or damage to the machine.

CAUTION: Do not attempt to adjust the height without assistance and without supporting the weight

of the machine. Attempting to make a height adjustment without assistance could cause the machine to

drop suddenly, causing severe injury. APPI offers several optional accessories that can reduce the risk

of injury during height adjustments. These accessories include carts, motorized height adjustment

components and stabilizing bars.

16

CAUTION: Ensure that any height adjustments allow for sufficient movement of the operator.

Improper height adjustments could negatively affect operator movement, causing strain, added stress,

discomfort, and fatigue.

CAUTION: Be careful when opening the seal frame as it may drop suddenly causing injury or

damage to the equipment.

CAUTION: To avoid injury, avoid coming in contact with pinch points including rollers, automatic

funnel doors or other moving components.

CAUTION: To avoid injury, avoid contact with Roller "Fingers" as they may be sharp.

CAUTION: Exercise care when adjusting or relocating the touch screen. Movement of the touch

screen could cause unexpected movement of the machine and injury to the operator.

CAUTION: If control or air pressure settings are set too high, higher noise levels may result from

increased part on part contact or part on machinery contact. Limit these settings and add guards or

covers to reduce airborne noise.

CAUTION: Exercise extreme care when clearing jams, replacing materials, changing controls or

mechanical settings, and cleaning internal parts. Be sure to de-energize energy sources prior to

removing guarding. Failure to do so may result in unexpected movement or flying objects, which could

cause crush, cut, or eye injuries.

CAUTION: Maintenance must be performed by specialized personnel. Qualified service engineers

must remove guards or covers to gain access to electrical or mechanical areas.

CAUTION: Maintenance must be performed regularly to ensure that the machine is operating

properly and to protect against injury. Routine maintenance includes: periodic inspections, the

replacement of worn or damaged components, the tightening of loose bolts or components, and regular

cleaning and adjustments. Contact APPI and/or service centers for service support if there is not

sufficient maintenance staff at your facility to perform regular maintenance.

2.3 Installation Procedures

The T-1000-S14 is transported as a single unit in a custom crate designed to protect the machine during

shipment. It is shipped completely assembled except for a few items that are easily attached during

installation. A final adjustment is also necessary to ensure proper placement of the touch screen, dancer

assembly, foot switch, funnel, and guards.

Unpacking: After removing the stretch wrapping, remove the outer crate from the skid that contains the

T-1000-S14. Unfasten the base support brace from the skid. Carefully lower the T-1000-S14 from the

skid. Transport the T-1000-S14 to the operating location prior to placing the touch screen in position and

unfastening the dancer assembly.

17

Operating Environment: The T-1000-S14 should be placed in an area free of excessive heat, moisture,

dirt, and dust. Operating room temperature should range from 50°F to 100°F (10°C to 87.77°C).

2.4 Note on Adjustments to the T-1000-S14

Upon receipt, it is not unusual for the T-1000-S14 to be out of alignment due to shipping and excessive

handling. Unless physically damaged, the T-1000-S14 will function properly after minor adjustments are

made. Refer to Chapter 4 for information on adjustments to the T-1000-S14.

2.5 Air and Power Requirements

Power Requirements: Provisions must be made for 115 VAC, 50/60 Hz line current with ground. The

full load current for the T-1000-S14 is 12 Amps. APPI recommends a dedicated 20 Amp circuit for the T-

1000-S14.

Note: A qualified electrician should ensure that voltages are as required, amperage is sufficient, power

outlets are the required 115 VAC and power outlets are properly grounded before hooking up the

power. If the unit is not properly grounded, it will produce a shock and will not function properly.

Air Requirements: At least 2 CFM free air is required, regulated to 60 PSI (413.68 kPa). Air should be

dry and oil-free.

Note: Running the T-1000-S14 at a higher PSI setting than 60 PSI (413.68 kPa) will cause excessive

wear and may cause damage to components on the machine or parts being packaged. The anti-jam

function may also be adversely affected.

2.6 Assembly Instructions

Choose an operating location considering traffic flow, availability of bag supplies, supply of product to be

packaged, takeaway of finished packages, placement of auxiliary infeed equipment and placement of

takeaway conveyor(s). At the operating location, the first step is to remove any inner packaging, banding,

or wires.

Touch Screen Assembly / Position: The touch screen has been secured for transportation in a "face-in"

position with protective wrapping. Holding the touch screen to prevent it from falling, loosen the set

screw located in the clamp collar at the top of the upper “T” column. Pull the shaft from the clamp collar

approximately 6" (15.24 cm) and tighten the collar. Holding the touch screen module, loosen the “ball”

clamp lever and position the touch screen. See Figure 2-1.

CAUTION: To avoid damage to the touch screen module, hold the screen until it is in the desired

position and then be sure the screws and ball clamp lever are securely tightened.

Dancer Assembly: The dancer assembly, located on the stand at the rear of the T-1000-S14, is secured

with tape strapping during shipment. After the removal of the strapping, the dancer should be checked to

ensure it will rotate freely in a semicircular path. The shaft assembly may then be inserted into the dancer

frame brackets so it is over the brake stop for tension.

18

CAUTION: The seal bar should not come in contact with the funnel during sealing. Raise the funnel

to avoid contact.

CAUTION: To avoid injury, do not operate the T-1000-S14 without a funnel, guard or covers properly

positioned. APPI offers a variety of funnels and chutes. Guarding may need to be added to prevent

operators from reaching in, around or under the guard or funnels.

CAUTION: To avoid injury, do not reach underneath guards while the machine is plugged in.

Machine Height Adjustment: The height of the T-1000-S14 is adjustable. To change the height of the

machine, three people are required; two people holding the weight of the machine, and one person

loosening the two bolts located on the leg and clamping the outer leg to the inner leg. See Figure 2-2.

Raise or lower the T-1000-S14 to the desired height and tighten the two bolts.

CAUTION: Unless properly supported, the T-1000-S14 will drop suddenly when loosening the height

adjustment bolts. This may cause damage to the machine or injury to individuals.

CAUTION: Do not attempt to adjust the height without the assistance of at least two other people

supporting the weight.

2.7 Air and Power Hookup

This section describes how to hook up air and power and the air and power requirements.

Note: A qualified electrician should ensure power outlets are the required 115 VAC and properly

grounded before hooking up power. If the unit is not properly grounded, it will produce a shock and

the machine will not work properly.

The air supply should be fed to the T-1000-S14 with 3/8 ID flexible tubing. This tubing affixes to the

coupler adapter (quick disconnect not provided). Connect the air to the regulator by holding the regulator

firmly in one hand and pushing the airline connector on the male regulator connector. After connecting

air, the regulator should be adjusted so the gauge reads 60 PSI (413.68 kPa). Insert the T-1000-S14 power

cord into a 115 VAC, 60 Hz, grounded power outlet.

19

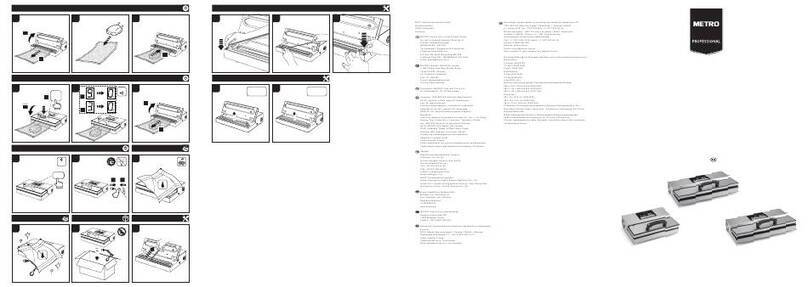

Figure 2-1

Loosen for

up/down

adjustment

Loosen for in/out adjustment

Loosen for clockwise/counterclockwise

adjustment and tilt adjustment

20

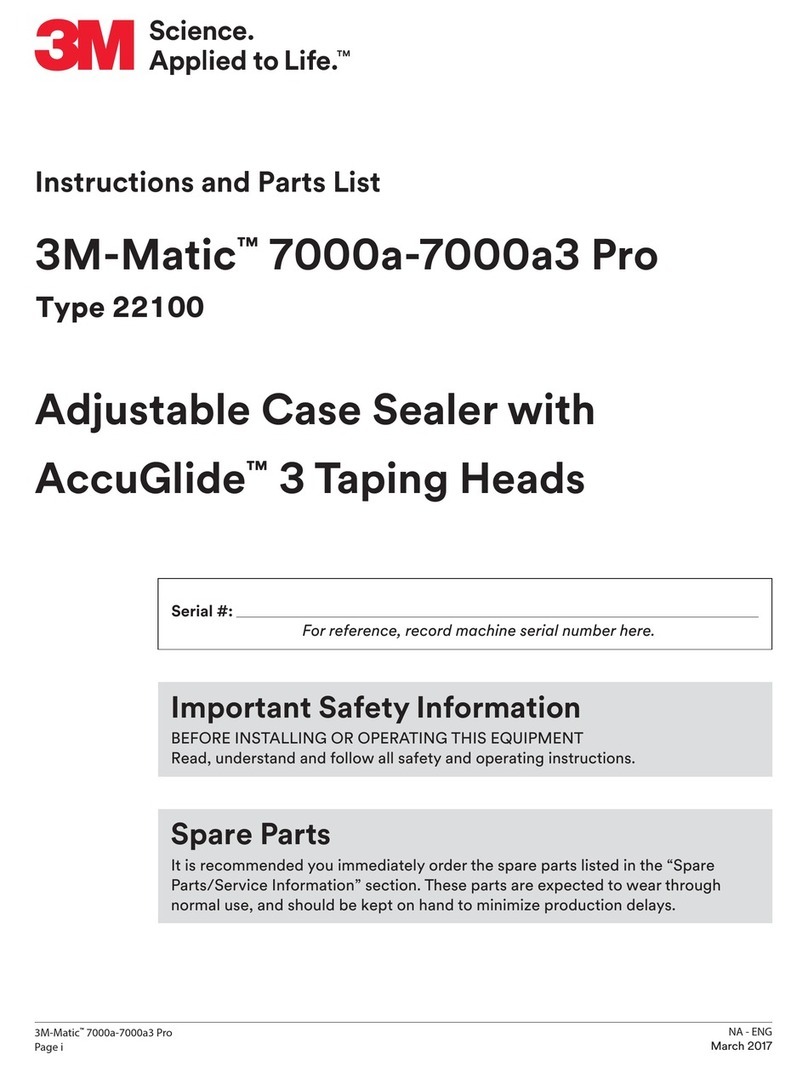

Figure 2-2

CAUTION:

Carefully loosen for

up/down adjustment while

two other people support

the T-1000-S14.

CAUTION:

If the bagger is not held in position by two people, the

weight of the machine may cause it to drop suddenly,

causing severe injury.

This manual suits for next models

2

Table of contents

Other Advanced Poly-Packaging Food Saver manuals