AEG installation manual 3

power unit exhaust

pipe

power unit

wall valve

hose coverage

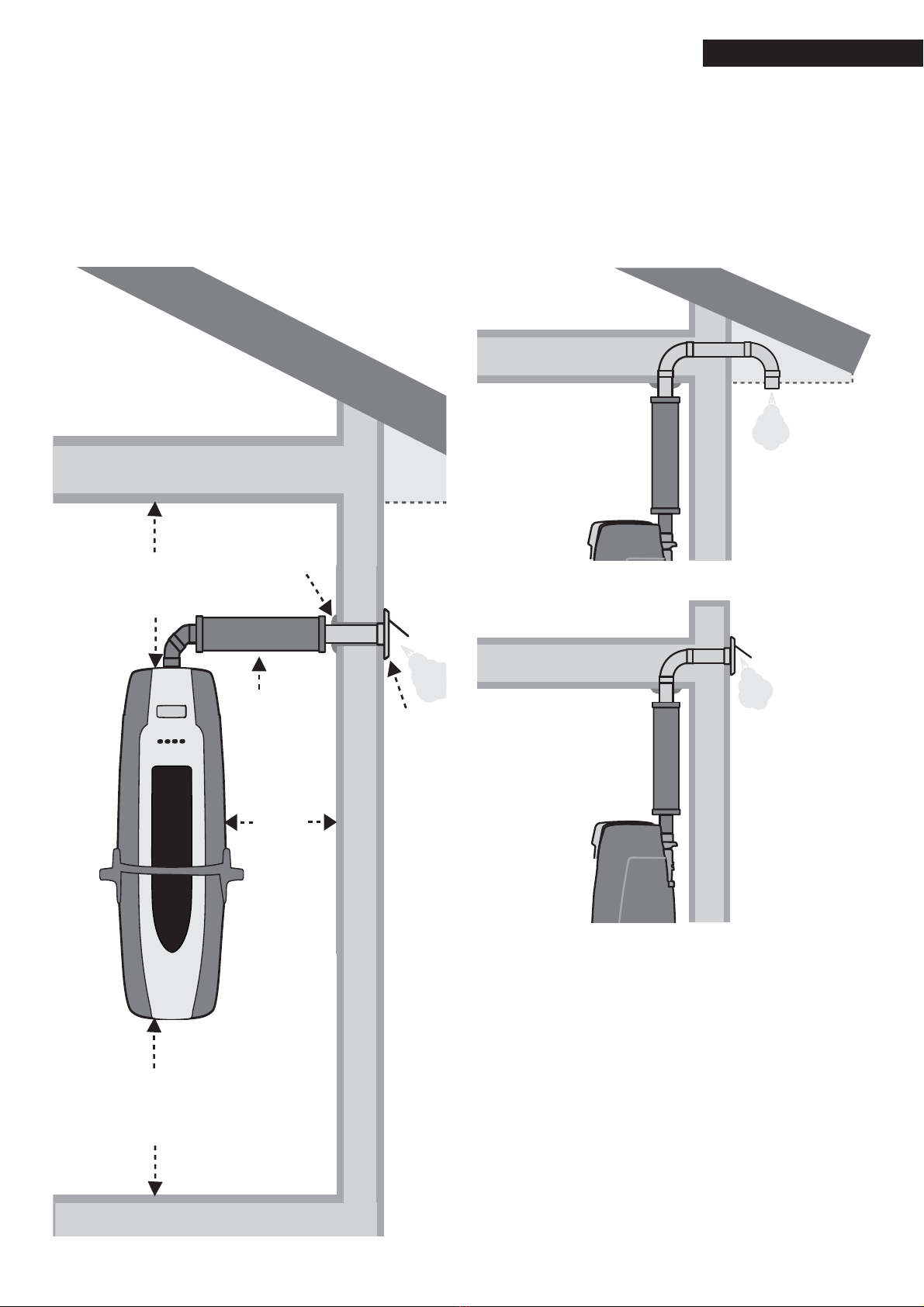

Location of the Power Unit

Place the power unit preferably in a heated area like the utility room,

garage, storage room, or laundry room. If the power unit is installed in a

cold storage room, the vacuum tubing and the exhaust pipe should be

insulated in order to avoid condensation.

In buildings with two or more stories, it is recommended to always place

the power unit on the lowest floor. If the equipment is placed on the upper

floor, the power unit must be more powerful so that even the heaviest

dust particles can be vacuumed and transferred into the dust container.

When selecting the installation location, it is recommended that you

ensure that the placement does not disturb your neighbors or interfere

with your own comfort and activities. Make sure that there is a wall outlet

nearby for connection to the electrical network. If you are not sure about

the placement, contact your local building inspector or fire authority for

more information.

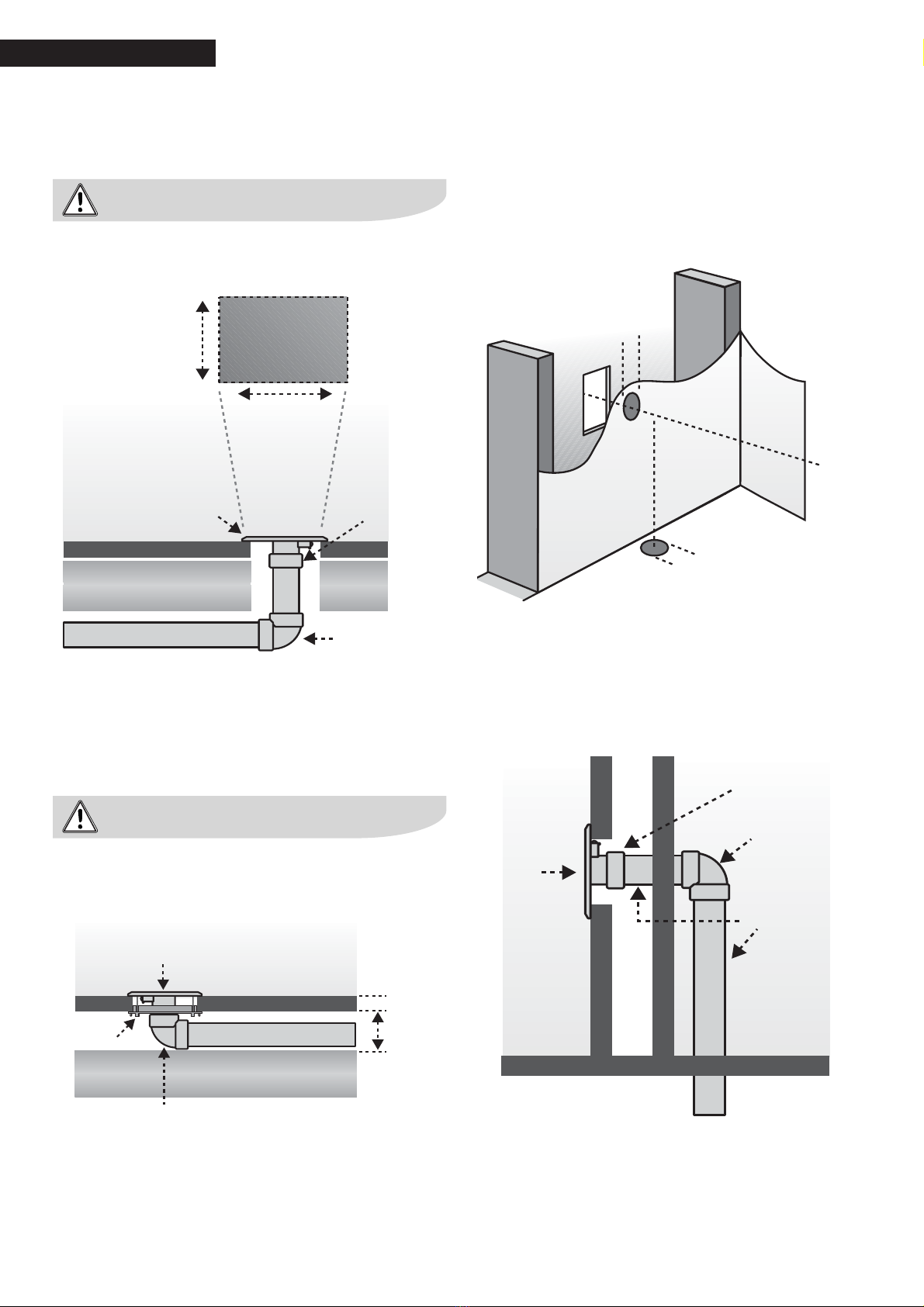

Location of Wall Inlet Valves

Wall inlet valves can be placed in the wall or in the floor. Place the inlets

preferably so that you can reach every corner of the room with a vacuum

hose that is 27 to 33 feet long (8m to 10m). There is a utility valve in the

power unit, which allows you to conveniently clean the space where the

vacuum is located and close-by areas, thus eliminating the need to install

another inlet valve and tubing route.

Marking the Placement of the Inlet Valves

Mark the installation points of the inlet valves in the layout drawings using

wire of the same length as the actual vacuum hose. When using drawings

scaled 1:1000 the wire length is 3 1/4” (8 cm), and when using drawings

scaled 1:50 the wire length is 6 1/2” (16 cm). Suitable places for inlet

valves are entrance halls, hallways, etc.

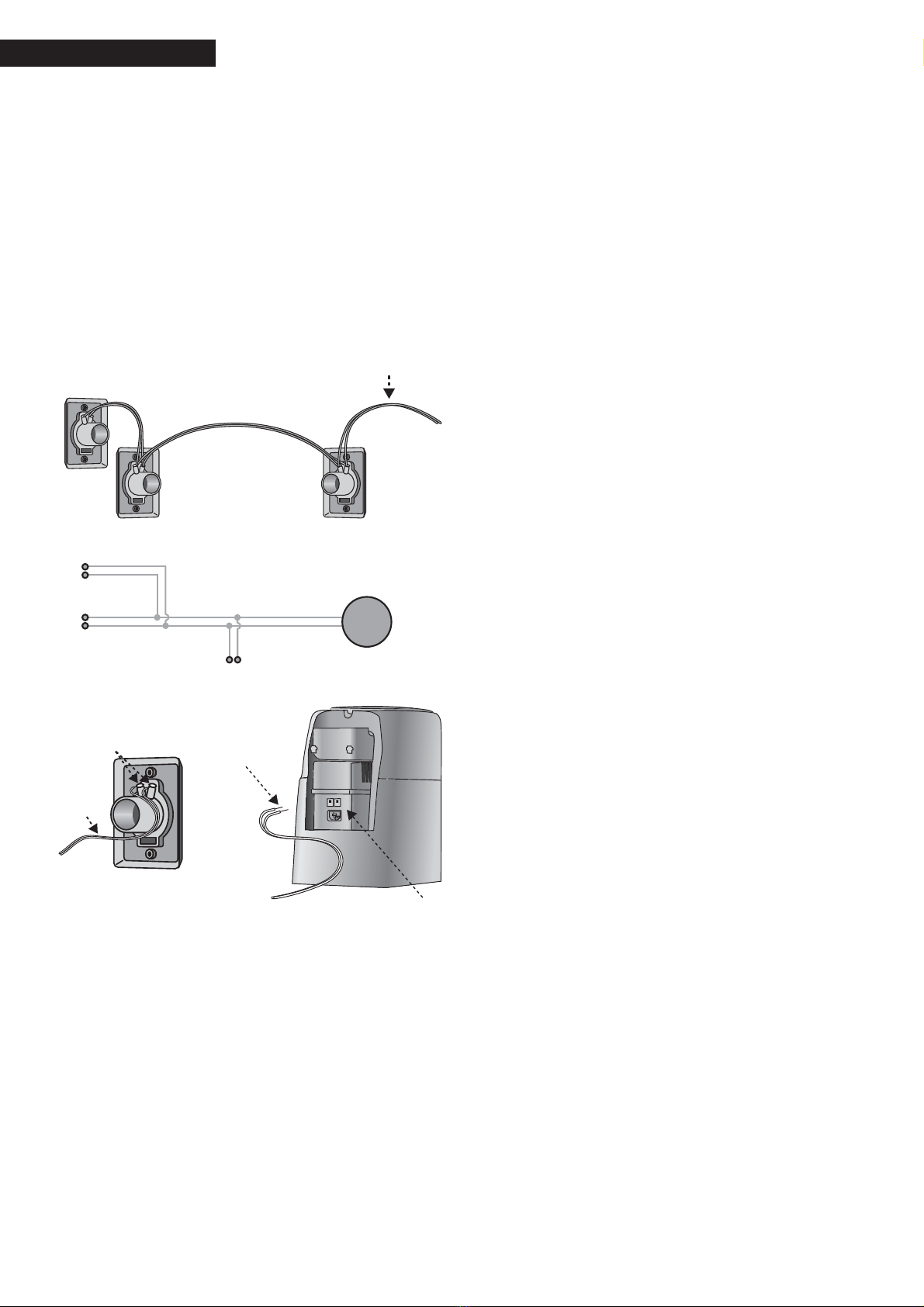

In a typical house only two inlet val-

ves are needed. In such cases, the

utility valve of the power unit can

be used for cleaning the basement

because it often covers the whole

basement area.

In this example, the main tube has

been routed under the house. Ho-

wever, the tube in the under-house

crawl space should be insulated to

avoid condensation.

The whole floor area can often be

vacuumed from one single inlet val-

ve. The light, broken line indicates

an alternative installation type.

In the house of the same size, the

power unit is in the garage, where

the utility valve serves as a third

inlet valve allowing you to clean

your car, for example.

wall

valve

door

Floor

valve

wall

valve

In this example, the simplest

solution is to route the tubing in

the attic. If the space is cold, the

main tube should be insulated.

It is recommended to place the

inlet valves in between different

levels. In such cases, you can ea-

sily clean two levels from one inlet

valve. The power unit is placed in

the storage room.

Typical Installation Examples

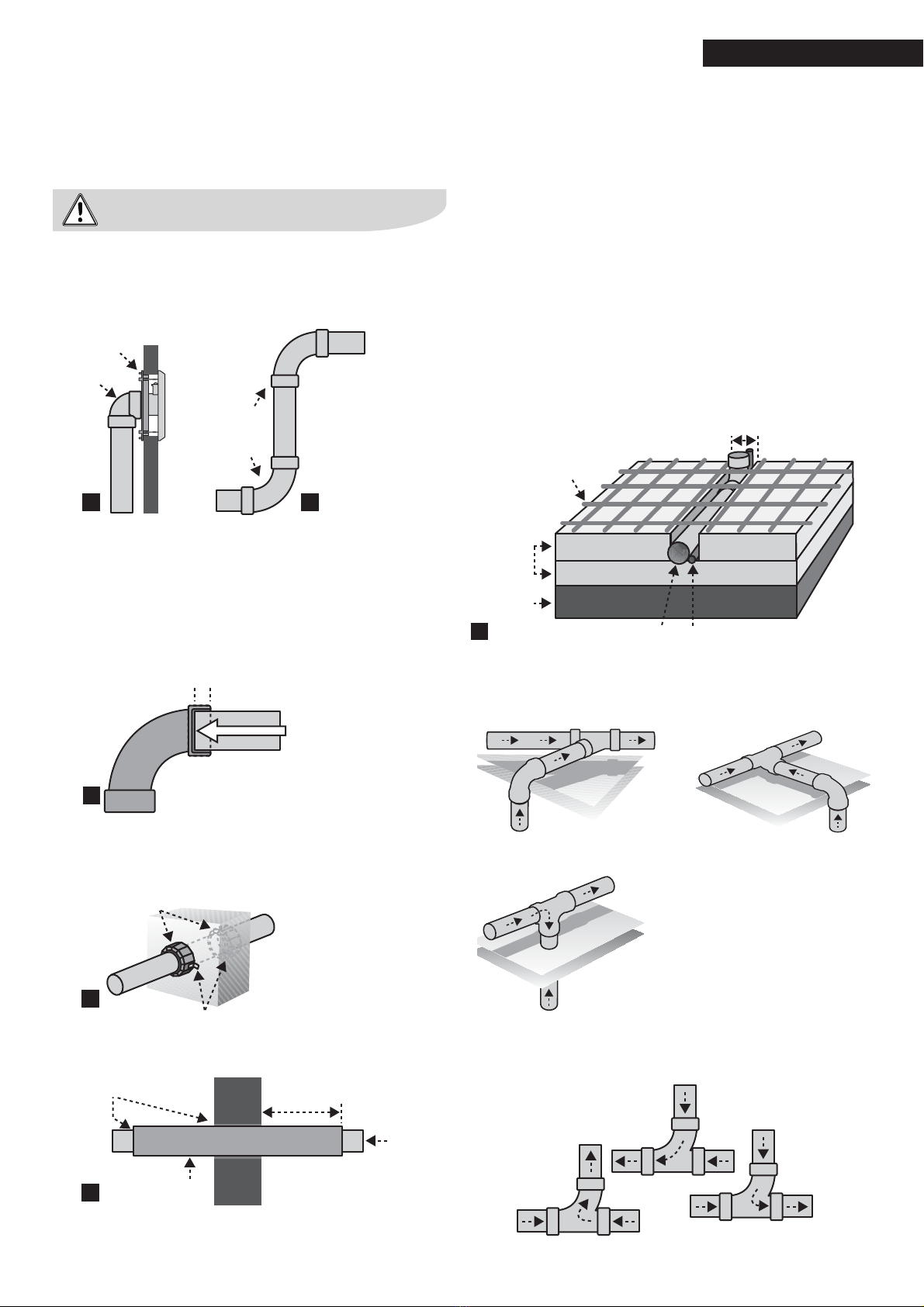

Tubing System Design

The main principle for designing the layout of the tubing system is to

keep it as short as possible. This will give the highest possible vacuum

performance. However, the main tube can be routed in different ways.

The outside diameter of the tubing system is 2” (50.08mm) and is 2 1/8”

(56mm) at the extension. The through-holes in the walls must be 2 3/16”

to 2 1/2” (55mm to 60mm) in diameter so that the extension and the low-

voltage cable can also go through the opening. The minimum diameter of

the exhaust tube is 2 1/8” (56mm).

New One-Story Houses

The horizontal main tube is placed in the under-house crawl space or in

the attic. In the under-house crawl space, the tubing should be insulated.

Tubes to the inlet valves are routed in the partition walls or between

secondary spaces, such as closets. In a cold attic, the tubes should be

covered with insulation in order to avoid condensation.

Two- or Multi-Story Houses

The main tube is placed in the under-house crawl space, attic, closet,

between walls, etc.

Existing Houses

The main tube can be installed on the surface in existing secondary

spaces, such as a garage or storage room. The tube can also be routed

through the attic and then vertically inside the partition walls and closets

all the way to the inlet valves. A lowered ceiling and closet footings can

also be used for routing of the tubes.

Read these instructions carefully. Installation of the central vacuum

system is easy and can be performed with regular hand tools. The

system can be installed both in new and existing buildings. When

using a central vacuum system, it is important to make sure there is

a sufficient compensation air supply. Normal ventilation ensures that

there is enough compensation air. This central vacuum system is very

useful, and you can enjoy it for years to come.