36

Impianti aspirapolvere centralizzati

Zentralstaubsauganlagen

Central vacuum systems

Système d’aspiration centralisée

4. STARTING

It is recommended to use the system

only for vacuuming household dust.

To avoid possible damages use only

DISAN accessories. Please pay atten-

tion to the following security advices:

4.1 Static shock

In very rare circumstances it may be

possible for some people to feel a sta-

tic shock from the flexible suction

hose. These are not caused by the

vacuum cleaner but the most likely

causes are:

-Very dry air

-Statically loaded carpet (usually

synthetic)

-Any person that finds themselves

suffering from this problem whilst

vacuuming could use rubber shoes

or woolen socks to help avoid static

shock

4.2 Electrical security

-Use the machine only in accordan-

ce to the voltage stated on the spe-

cification label - see page 33.

-Ensure electrical appliance is instal-

led into an electrical circuit with cor-

rect earthing.

-The security of the electrical instal-

lation is provided by a current pro-

tective switch that corresponds with

all current regulations.

4.3 Security of the system

-Ensure correct installation of the

complete system before switching

on for the first time.

-The central vacuum systems are

not designed for vacuuming up

cement dust or other building mate-

rials therefore it is advisable to

clean the system after using it for

this purpose.

-Do not expose the system directly

to outdoor conditions (e.g. rain,

snow, etc)

-Do not vacuum any large materials

that are likely to obstruct or damage

the flexible pipe.

-Do not vacuum liquids except when

using liquid separators.

-Only use original DISAN accesso-

ries.

-Do not start the machine if it is

damaged in any way.

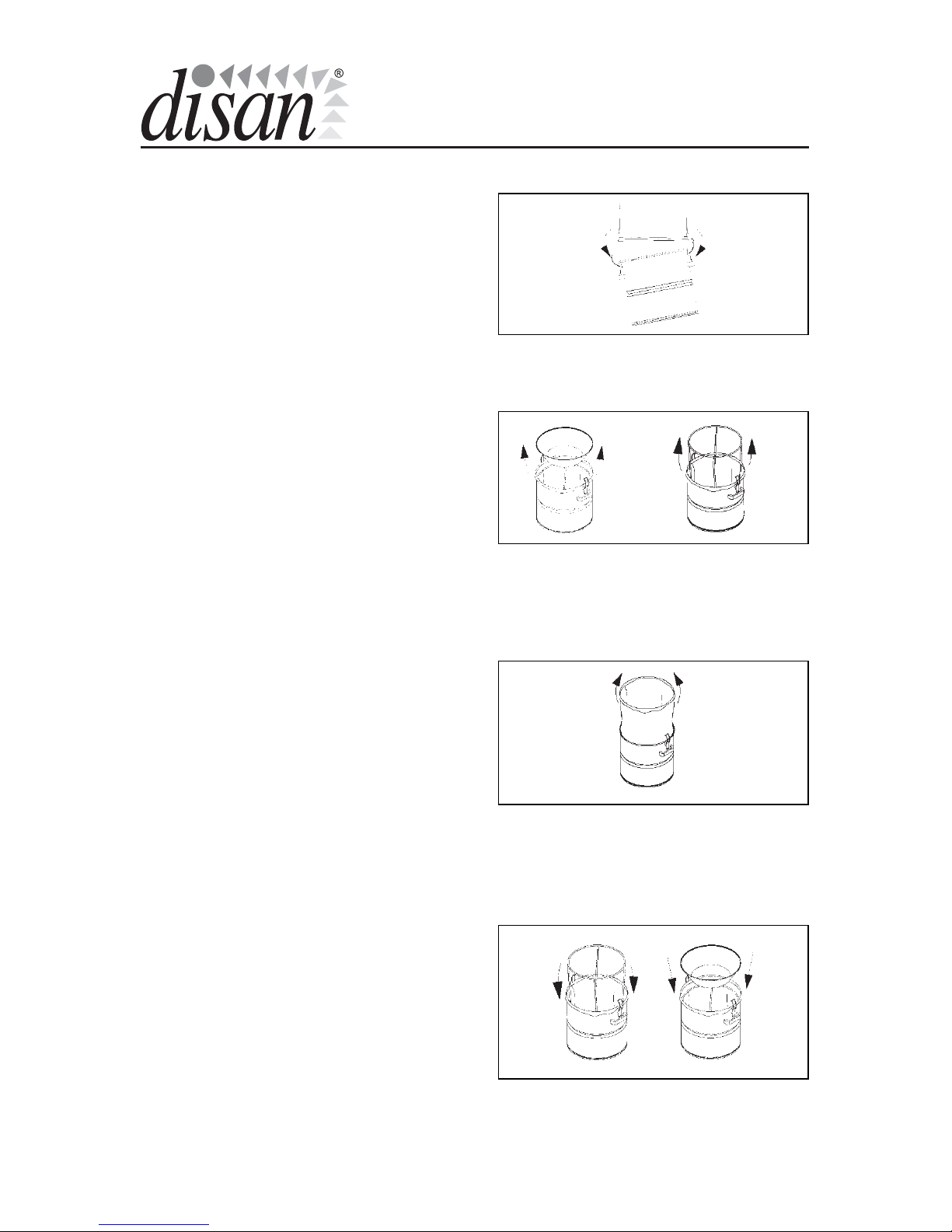

-Periodically check the condition of

the waste bag and the filter, particu-

larly after a long time with the clea-

ner out of work.

-Never run the machine without a fil-

ter and always use a genuine

DISAN part.

ATTENTION! ALWAYS USE THE

MACHINE IN ACCORDANCE WITH

THESE INSTRUCTIONS AND

NEVER MISHANDLE OR MODIFY

THE SECURITIES

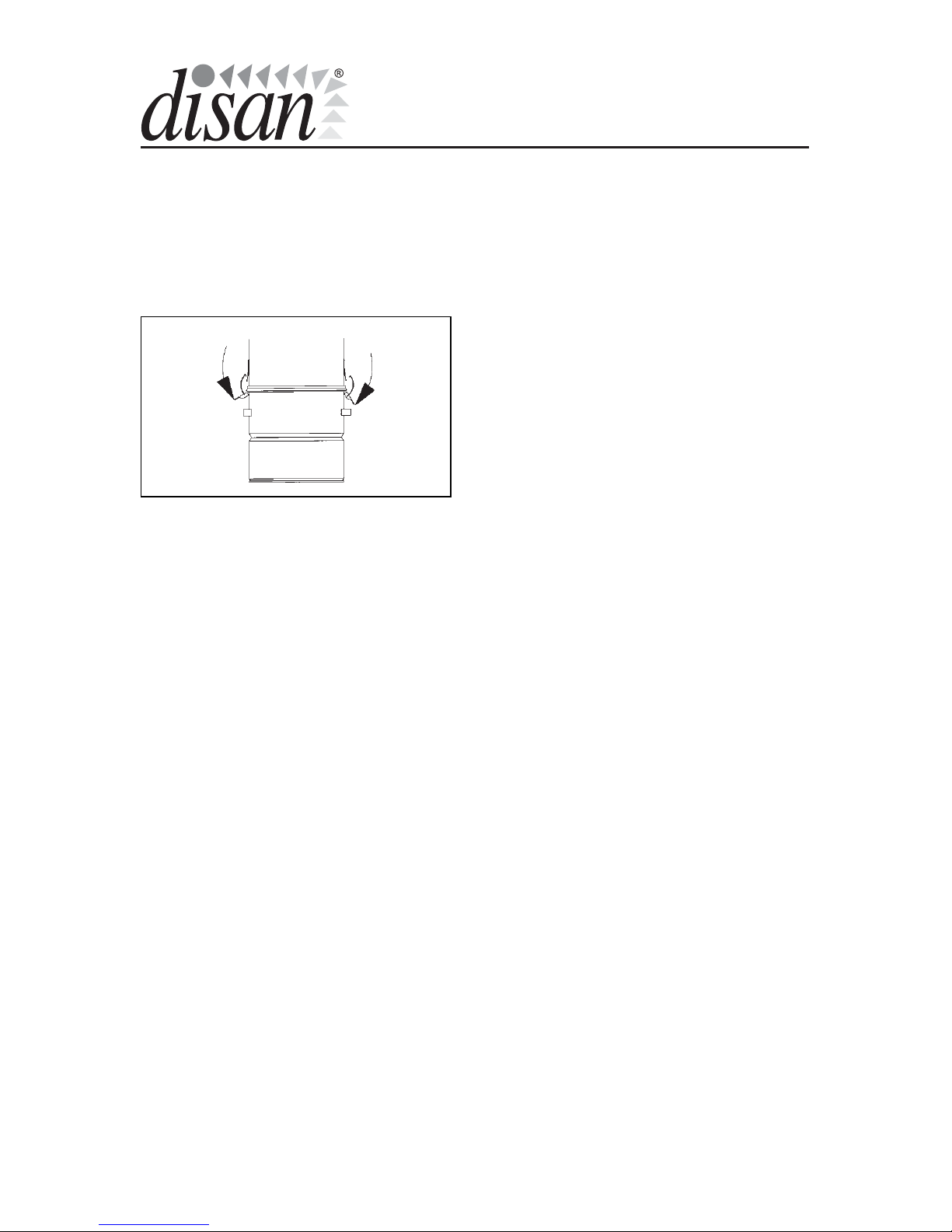

Do not open the cover, do not mani-

pulate or prevent in any case the tu-

ning or the protections of the clean-

ers, or the sealing of the cables.

If should it happen accidentally please

contact immediately an authorized