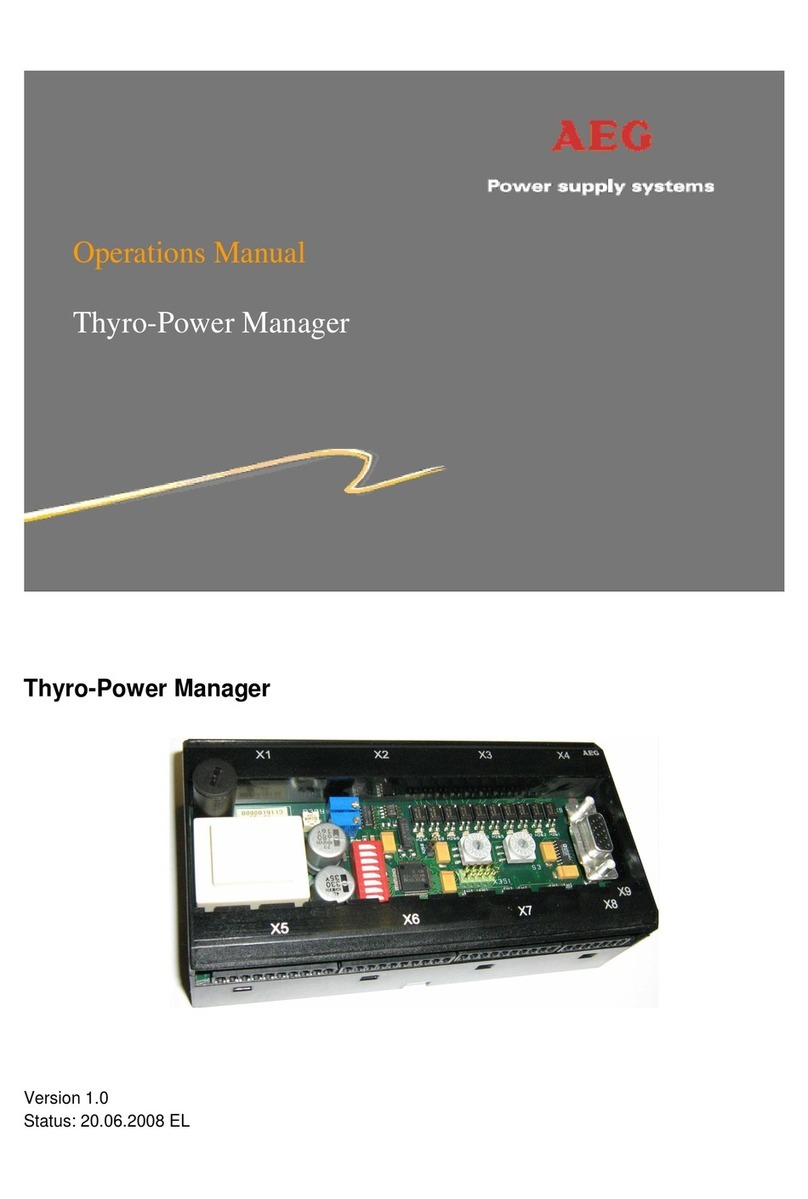

Notes to this Operations Manual Operations Manual Thyro Power Manager

Page 6 of 6 Version: 1.7.2009 8000022632 BAL, EN

4.5.5 Adaptation to the Lamp Type ...........................................................................22

4.5.6 Adaptation to Local Conditions ........................................................................23

5Shut-Down, Dis-Assembly.............................................................................................24

5.1 Safety Notes...........................................................................................................24

5.2 Electric Terminals...................................................................................................24

5.3 Separation..............................................................................................................24

5.4 Disposal .................................................................................................................24

5.4.1 Legal Regulations ............................................................................................24

5.4.2 Type of Disposal ..............................................................................................24

6Technical Data ..............................................................................................................25

6.1 Type Plate ..............................................................................................................25

6.2 Technical Data .......................................................................................................25

6.3 Dimensions and Weights .......................................................................................27

6.4 Power loss/ efficiency.............................................................................................27

7Functional Description...................................................................................................28

7.1 General ..................................................................................................................28

7.2 Functional Description............................................................................................29

7.2.1 Description of the General Procedures ............................................................30

7.2.2 Control via Internal Timer .................................................................................30

7.2.3 Control via Binary Inputs ..................................................................................31

7.2.4 Pulse Inhibitor ..................................................................................................31

7.3 Messages...............................................................................................................31

7.3.1 Messages with Bypass Contactor ....................................................................32

7.3.2 Default Settings for Messages .........................................................................32

7.3.3 Other Messages...............................................................................................32

7.3.4 Fuse Triggering ................................................................................................32

8Display and Operating Elements...................................................................................32

8.1 Power Controller ....................................................................................................32

8.1.1 Switch S1 .........................................................................................................33

8.1.2 Potentiometer ...................................................................................................33

8.1.3 Analogue Output ..............................................................................................34

8.1.4 LEDs ................................................................................................................34

8.2 Timer ......................................................................................................................36

8.3 Thyro-Tool E ..........................................................................................................37

9Commissioning..............................................................................................................40

9.1 Safety Notes...........................................................................................................40

9.2 Process of Commissioning.....................................................................................40