Table of Contents

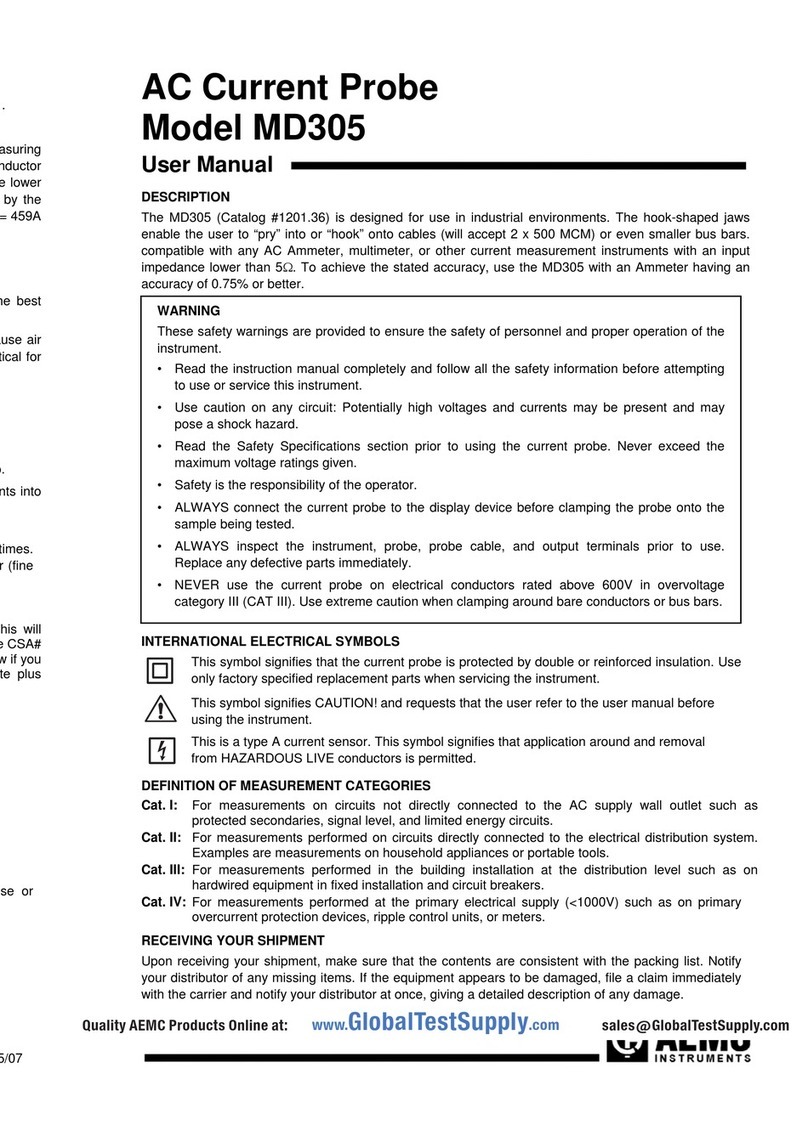

Warning.....................................................................................................4

International Electrical Symbols................................................................4

Definition of Measurement Categories......................................................5

Receiving Your Shipment..........................................................................5

Packaging..................................................................................................5

Accessories...............................................................................................5

Important Information - Proper Operation.................................................5

Description ................................................................................................6

Product Construction.............................................................................6

Jaw Design............................................................................................7

Body Design..........................................................................................7

Electrical Specifications ............................................................................8

Ground Resistance................................................................................8

Ground or Leakage Current...................................................................8

Mechanical Specifications.........................................................................8

Safety Specifications.................................................................................9

Model 3711 Controls...............................................................................10

Model 3731 Controls...............................................................................11

Digital Display Features..........................................................................12

Additional Features of the Model 3731................................................13

Function Controls....................................................................................14

On/Off..................................................................................................14

Auto-Off ...............................................................................................15

Hold .....................................................................................................15

Beeper Disable....................................................................................15

Resistance...........................................................................................15

Resistance...........................................................................................16

Current.................................................................................................17

Alarm ...................................................................................................18

Programming the Alarm Setpoint........................................................18

Changing the Alarm Trigger ................................................................19

Memory................................................................................................19

Memory................................................................................................20

Memory Recall.....................................................................................20

Clear Memory......................................................................................20

Function Access Summary .....................................................................21