BEAMEX MB140 User manual

Metrology

Temperature Block series

Beamex® MB140, MB155, MB425, MB700

User Guide

MBTB____tgeng0000

i

Table of Contents

1 Before You Start .......................................................................1

1.1 Introduction ............................................................................................... 1

1.2 Symbols Used ........................................................................................... 1

1.3 Safety Information ..................................................................................... 2

1.3.1 Warnings .........................................................................................................2

1.3.2 Cautions ..........................................................................................................4

1.4 CE Comments ........................................................................................... 5

1.4.1 EMC Directive .................................................................................................5

1.4.2 Immunity Testing .............................................................................................5

1.4.3 Emission Testing ..............................................................................................6

1.4.4 Low Voltage Directive (Safety) ........................................................................6

1.5 Authorized Service Centers ...................................................................... 6

2 Specications and Environmental Conditions ......................7

2.1 Specifications ........................................................................................... 7

2.2 Environmental Conditions ......................................................................... 8

3 Quick start .............................................................................. 11

3.1 Unpacking .............................................................................................. 11

3.2 Setup ....................................................................................................... 12

3.3 System Setup .......................................................................................... 13

3.4 Display .................................................................................................... 13

3.4.1 Measure ........................................................................................................13

3.5 Setting the Temperature .......................................................................... 14

3.5.1 Set-point Setup ..............................................................................................14

3.6 Reference Probe (-R models only).......................................................... 14

3.6.1 Probe Connection .........................................................................................15

3.6.2 Measure Temperature ...................................................................................16

4 Parts and controls .................................................................17

4.1 Back panel .............................................................................................. 17

4.2 Front panel .............................................................................................. 18

4.3 Front Panel Display ................................................................................. 20

4.4 Front Panel Buttons ................................................................................. 20

4.5 Accessories ............................................................................................ 22

MBXXX Series Metrology Temperature Block

ii

5 Controller operation...............................................................23

5.1 Main Screen ............................................................................................ 23

5.2 Main Menu .............................................................................................. 25

5.2.1 Temp Menu ....................................................................................................25

5.2.1.1 Set ........................................................................................................................ 26

5.2.1.2 Preset ................................................................................................................... 27

5.2.1.3 Setup .................................................................................................................... 28

5.2.1.4 Cutout ................................................................................................................... 28

5.2.2 Ref Menu (-R instruments only) .....................................................................30

5.2.2.1 Select .................................................................................................................... 30

5.2.2.2 Setup .................................................................................................................... 31

5.2.2.3 Test ....................................................................................................................... 34

5.2.2.4 Focus (-R instruments only) .................................................................................. 35

5.2.3 Prog Menu .....................................................................................................36

5.2.3.1 Select .................................................................................................................... 36

5.2.3.2 Setup .................................................................................................................... 37

5.2.3.3 Run ....................................................................................................................... 38

5.2.4 System Menu .................................................................................................39

5.2.4.1 Setup menu .......................................................................................................... 40

5.2.4.2 Cal Menu .............................................................................................................. 44

5.2.4.3 Pass ...................................................................................................................... 50

5.2.4.4 Info (view only) ..................................................................................................... 51

5.3 Menu Structure ....................................................................................... 52

6 Digital communication interface...........................................57

6.1 Wiring ...................................................................................................... 57

6.1.1 Setup .............................................................................................................58

6.1.2 Serial Operation ............................................................................................58

6.2 Command Syntax ................................................................................... 58

6.3 Commands by Function or Group .......................................................... 59

6.4 Serial Commands - Alphabetic Listing ................................................... 61

6.5 Non-SCPI Process Commands ............................................................... 77

6.6 Non-SCPI Command by Function or Group ........................................... 78

7 Maintenance ...........................................................................83

7.1 Regular Metrology Temperature Block performance analysis ................ 83

8 Troubleshooting .....................................................................85

8.1 Troubleshooting ...................................................................................... 85

iii

Figures

Figure 1 Probe connector wiring...................................................................... 15

Figure 2 Metrology Temperature Block back panel view ................................. 17

Figure 3 Metrology Temperature Block front panel view ................................. 19

Figure 4 Metrology Temperature Block insert options. ................................... 22

Figure 5 Main screen display........................................................................... 23

Figure 6 MAIN MENU ...................................................................................... 25

Figure 7 TEMPERATURE MENU .............................................................................25

Figure 8 CONTROL SETPOINT menu ......................................................................26

Figure 9 SELECT POINT menu ........................................................................ 27

Figure 10 PRESETS SETUP menu .............................................................................28

Figure 11 CUTOUT SETTINGS menu .............................................................. 28

Figure 12 REFERENCE MENU ......................................................................... 30

Figure 13 PROBE SELECT menu ..................................................................... 30

Figure 14 SETUP PROBE menu ...................................................................... 31

Figure 15 PROBE TEST menu ......................................................................... 34

Figure 16 FOCUS SELECT menu .................................................................... 35

Figure 17 PROGRAM MENU ........................................................................... 36

Figure 18 PROGRAM SELECT menu ............................................................... 36

Figure 19 PROGRAM SETUP menu ................................................................. 37

Figure 20 PROGRAM RUN menu .................................................................... 38

Figure 21 SYSTEM MENU ................................................................................ 39

Figure 22 SETUP MENU .................................................................................. 40

Figure 23 DISPLAY SETTINGS menu............................................................... 40

Figure 24 MEASUREMENT SETTINGS menu .................................................. 41

Figure 25 OPERATION SETTINGS menu ......................................................... 42

Figure 26 COMMUNICATION SETUP menu .................................................... 43

Figure 27 CALIBRATION MENU ...................................................................... 44

Figure 28 SETUP CONTROLLER menu ........................................................... 45

Figure 29 SENSOR SETTINGS menu .............................................................. 46

Figure 30 CUTOUT CALIBRATION menu ........................................................ 48

Figure 31 REFERENCE CALIBRATION menu .................................................. 49

Figure 32 PASSWORD SETUP ......................................................................... 50

Figure 33 SYSTEM INFO menu ........................................................................ 51

Figure 34 RS-232 Wiring .................................................................................. 57

MBXXX Series Metrology Temperature Block

iv

Tables

Table 1 Symbols ................................................................................................. 1

Table 2 Metrology Temperature Block Specifications ........................................ 7

Table 3 Built-in Readout Specifications ............................................................. 8

Table 4 Matching Certificate Values to MBXXX ITS-90 Coefficients ................ 32

Table 5 Setting Coefficients Rtpw, a8, b8, a4, and b4 ..................................... 32

Table 6 Commands by function or group ........................................................ 59

1

Before You Start

Symbols Used

1 Before You Start

1.1 Introduction

Beamex Metrology Temperature Blocks (MB140, MB155, MB425, and MB700) are

designed to be stable heat sources that can be used in a laboratory or eld environ-

ment. With a calibrated display and an optional built-in reference thermometer input

(designated with “-R”), Metrology Temperature Blocks may also be used as a refer-

ence standard.

Metrology Temperature Blocks feature interchangeable probe inserts that t various

sized diameter probes.

The Metrology Temperature Blocks’ controller uses a PRT sensor and thermoelectric

modules or heaters to achieve stable, uniform temperatures throughout the block.

The LCD display continuously shows many useful operating parameters including the

block temperature, block stability, heating and cooling status, and current set-point.

The temperature may be easily set with the control buttons to any desired temperature

within the temperature block’s specied range.

Metrology Temperature Blocks are designed for laboratory performance that can

be used anywhere. With proper use, the instrument will provide continued accurate

calibration of temperature sensors and devices. Before use, the user should be familiar

with the warnings, cautions, and operating procedures of the block as described in the

users manuals.

1.2 Symbols Used

Table 1 lists the symbols that may be used on the instrument or in this manual.

Table 1 Symbols

Symbol Description Symbol Description

AC (Alternating Current) PE Ground

AC-DC Hot Surface (Burn Hazard)

Battery Read the User’s Guide (Important

Information)

Complies with European Union

directives Off

DC On

Double Insulated Canadian Standards Association

MBXXX Series Metrology Temperature Block

Safety Information

2

Symbol Description Symbol Description

Electric Shock C-TICK Australian EMC mark

Fuse

The European Waste Electrical

and Electronic Equipment (WEEE)

Directive (2002/96/EC) mark.

OVERVOLTAGE (Installation)

CATEGORY II, Pollution Degree 2

per IEC1010-1 refers to the level

of Impulse Withstand Voltage

protection provided. Equipment of

OVERVOLTAGE CATEGORY II is

energy-consuming equipment to be

supplied from the xed installation.

Examples include household, office,

and laboratory appliances.

1.3 Safety Information

Use this instrument only as specied in this guide. Otherwise, the protection provided

by the instrument may be impaired. Refer to the safety information in the Warnings

and Cautions sections below.

The following denitions apply to the terms “Warning” and “Caution”.

“Warning” identies conditions and actions that may pose hazards to the user.

“Caution” identies conditions and actions that may damage the instrument

being used.

1.3.1 Warnings

To avoid personal injury, follow these guidelines.

GENERAL

DO NOT use this instrument in environments other than those listed in the User’s

Guide.

Inspect the instrument for damage before each use. DO NOT use the instrument if it

appears damaged or operates abnormally.

Follow all safety guidelines listed in this guide.

Calibration equipment should only be used by trained personnel.

If this equipment is used in a manner not specied by the manufacturer, the protection

provided by the equipment may be impaired.

Before initial use, or after transport, or after storage in humid or semi-humid environ-

ments, or anytime the Metrology Temperature Block has not been energized for more

than 10 days, the instrument needs to be energized for a “dry-out” period of 2 hours

before it can be assumed to meet all of the safety requirements of the IEC 1010-1. If

3

Before You Start

Safety Information

the product is wet or has been in a wet environment, take necessary measures to re-

move moisture prior to applying power such as storage in a low humidity temperature

chamber operating at 50°C for 4 hours or more.

DO NOT use this instrument for any application other than calibration work. The

instrument was designed for temperature calibration. Any other use of the instrument

may cause unknown hazards to the user.

Completely unattended operation is not recommended.

DO NOT place the instrument under a cabinet or other structure. Overhead clearance

is required. Always leave enough clearance to allow for safe and easy insertion and

removal of probes.

Use of this instrument at HIGH TEMPERATURES for extended periods of time

requires caution.

Completely unattended high temperature operation is not recommended due to safety

hazards that can arise.

If the instrument is used in a manner not in accordance with the equipment design, the

operation of the Metrology Temperature Block may be impaired or safety hazards may

arise.

This instrument is intended for indoor use only.

BURN HAZARD

Each Metrology Temperature Block is equipped with a Block Temperature Indica-

tor (front panel LED HOT indicator – Patent Pending) even when the instrument

is unplugged. When the indicator is ashing, the instrument is not powered and the

temperature of the block is above 50°C. When the indicator is illuminated, always on,

the instrument is powered and the block temperature is above 50°C.

DO NOT turn the instrument upside down with the inserts in place; the inserts will

fall out.

DO NOT operate instrument in any orientation other than vertical (block opening face

up). Risk of re or burn hazard may result due to excessive heat build up.

DO NOT operate on a ammable surface or near ammable materials.

DO NOT touch the block access surface of the instrument.

The block vent may be very hot due to the fan blowing across the heater block of the

Metrology Temperature Block.

The calibration block temperature of the Metrology Temperature Block is the same as

the actual display temperature, for example, if the instrument is set to 700°C and the

display reads 700°C, the block is at 700°C.

The air over the block can reach temperatures greater that 200°C for high temperature

(400°C and higher) Metrology Temperature Blocks.

Probes and inserts may be hot and should only be inserted and removed from the

instrument when the instrument is operating at temperatures below 50°C.

MBXXX Series Metrology Temperature Block

Safety Information

4

DO NOT turn off the instrument at temperatures higher than 100°C. This could create

a hazardous situation. Select a set-point less than 100°C and allow the instrument to

cool before turning it off.

The high temperatures present in Metrology Temperature Blocks designed for opera-

tion at 300°C and higher may result in res and severe burns if safety precautions are

not observed.

ELECTRICAL HAZARD

These guidelines must be followed to ensure that the safety mechanisms in this instru-

ment will operate properly. This instrument must be plugged into a 230 VAC (115

VAC optional), AC only electric outlet. The power cord of the instrument is equipped

with a grounding plug for your protection against electrical shock hazards. It must be

plugged directly into a properly grounded receptacle. The receptacle must be installed

in accordance with local codes and ordinances. Consult a qualied electrician. DO

NOT use an extension cord or adapter plug.

If supplied with user accessible fuses, always replace the fuse with one of the same

rating, voltage, and type.

Always replace the power cord with an approved cord of the correct rating and type.

HIGH VOLTAGE is used in the operation of this equipment. SEVERE INJURY or

DEATH may result if personnel fail to observe safety precautions. Before working

inside the equipment, turn power off and disconnect power cord.

1.3.2 Cautions

To avoid possible damage to the instrument, follow these guidelines:

To properly calibrate the Metrology Temperature Block, the “Fan Limit” must be set

to “Auto.”

DO NOT leave the insert(s) in the instrument for prolonged periods. Due to the high

operating temperatures of the instrument, the inserts should be removed after each use

and buffed with a Scotch-Brite® pad or emery cloth (see the Maintenance section of

the Users Guide).

Always operate this instrument at room temperature between 5°C and 50°C (41°F and

122°F). Allow sufcient air circulation by leaving at least 15 cm (6 in) of clearance

around the instrument. Overhead clearance is required. DO NOT place the instrument

under any structure.

DO NOT interchange inserts between Metrology Temperature Block models. The in-

serts provided with the instrument as well as any additional inserts ordered are model

specic.

Component lifetime can be shortened by continuous high temperature operation.

DO NOT use uids to clean out the block. Fluids could leak into electronics and dam-

age the instrument.

5

Before You Start

CE Comments

DO NOT introduce any foreign material into the probe hole of the insert. Fluids, etc.

can leak into the instrument causing damage.

DO NOT change the values of the calibration constants from the factory set values.

The correct setting of these parameters is important to the safety and proper operation

of the block.

DO NOT slam the probe sheath or inserts into the block. This type of action can cause

a shock to the sensor and affect the calibration.

The instrument and any thermometer probes used with it are sensitive instruments that

can be easily damaged. Always handle these devices with care. DO NOT allow them

to be dropped, struck, stressed, or overheated.

DO NOT operate this instrument in an excessively wet, oily, dusty, or dirty environ-

ment. Always keep the block and inserts clean and clear of foreign material.

The Metrology Temperature Block is a precision instrument. Although it has been de-

signed for optimum durability and trouble free operation, it must be handled with care.

Always carry the instrument in an upright position to prevent the probe inserts from

dropping out. The convenient handle allows for hand carrying the instrument.

If a mains supply power uctuation occurs, immediately turn off the instrument.

Power bumps from brown-outs could damage the instrument. Wait until the power has

stabilized before re-energizing the instrument.

The probe and the block may expand at different rates. Allow for probe expansion in-

side the block as the block heats. Otherwise, the probe may become stuck in the block.

Most probes have handle temperature limits. Be sure the air temperature above the

Metrology Temperature Block does not exceed the probe handle’s temperature limit. If

the probe handle limits are exceeded, the probe may be permanently damaged.

1.4 CE Comments

1.4.1 EMC Directive

Beamex’s equipment has been tested to meet the European Electromagnetic Compat-

ibility Directive (EMC Directive, 89/336/EEC). The Declaration of Conformity for

your instrument lists the specic standards to which the instrument was tested.

This instrument was designed specically as a test and measurement device. Compli-

ance to the EMC directive is through IEC 61326-1 Electrical equipment for measure-

ment, control and laboratory use - EMC (1998).

As noted in the IEC 61326-1, the instrument can have varying congurations. The

instrument was tested in a typical conguration with shielded RS-232 cables.

1.4.2 Immunity Testing

This instrument has been designed and tested to meet electromagnetic compatibility

(EMC) requirements for electrical equipment for measurements, control, and laborato-

ry use (IEC 61326-1). However, the reference thermometer input of models MB140R

MBXXX Series Metrology Temperature Block

Authorized Service Centers

6

and MB155R may show some susceptibility to a strong electromagnetic eld having a

frequency of approximately 194 MHz.

1.4.3 Emission Testing

The instrument fullls the limit requirements for Class A equipment but does not fulll

the limit requirements for Class B equipment. The instrument was not designed to be

used in domestic establishments.

1.4.4 Low Voltage Directive (Safety)

In order to comply with the European Low Voltage Directive (73/23/EEC), Beamex’s

equipment has been designed to meet the IEC 1010-1 (EN 61010-1) and the IEC

1010-2-010 (EN 61010-2-010) standards.

1.5 Authorized Service Centers

Please contact Beamex to coordinate service on your product:

7

Specications and Environmental Conditions

Specications

2 Specications and Environmental Conditions

2.1 Specications

Table 2 Metrology Temperature Block Specifications

Specication MB140 MB155 MB425 MB700

Range –45°C to 140°C

(–49°F to 284°F)

–30°C to 155°C

(–22°F to 311°F)

35°C to 425°C

(95°F to 797°F)

50°C to 700°C

(122°F to 1292°F)

Display Accuracy2±0.1°C full range ±0.1°C: 35°C to 100°C

±0.15°C: 100°C to 225°C

±0.2°C: 225°C to 425°C

±0.2°C: 50°C to 425°C

±0.25°C: 425°C to 660°C

Stability1±0.005°C full range ±0.005°C: 35°C to 100°C

±0.008°C: 100°C to

225°C

±0.01°C: 225°C to 425°C

±0.005°C: 50°C to 100°C

±0.01°C: 100°C to 425°C

±0.03°C: 425°C to 700°C

Axial Uniformity2

(40 mm [1.6 in])

±0.08°C: –45°C to –35°C

±0.04°C: –35°C to 0°C

±0.02°C: 0°C to 50°C

±0.07°C: 50°C to 140°C

±0.025°C: –30°C to 0°C

±0.02°C: 0°C to 50°C

±0.05°C: 50°C to 155°C

±0.05°C: 35°C to 100°C

±0.09°C: 100°C to 225°C

±0.17°C: 225°C to 425°C

±0.09°C: 50°C to 100°C

±0.22°C: 100°C to 425°C

±0.35°C: 425°C to 700°C

Axial Uniformity2

(60 mm [2.3 in])

±0.1°C: –45°C to –35°C

±0.04°C: –35°C to 0°C

±0.02°C: 0°C to 50°C

±0.07°C: 50°C to 140°C

±0.025°C: –30°C to 0°C

±0.02°C: 0°C to 50°C

±0.07°C: 50°C to 155°C

±0.05°C: 35°C to 100°C

±0.1°C: 100°C to 225°C

±0.2°C: 225°C to 425°C

±0.1°C: 50°C to 100°C

±0.25°C: 100°C to 425°C

±0.4°C: 425°C to 700°C

Axial Uniformity2

(80 mm [3.15 in])

N/A ±0.05°C: –30°C to 0°C

±0.04°C: 0°C to 50°C

±0.15°C: 50°C to 155°C

±0.06°C: 35°C to 100°C

±0.12°C: 100°C to 225°C

±0.23°C: 225°C to 425°C

±0.15°C: 50°C to 100°C

±0.30°C: 100°C to 425°C

±0.45°C: 425°C to 700°C

Radial Uniformity ±0.01°C full range ±0.01°C: 35°C to 100°C

±0.02°C: 100°C to 225°C

±0.025°C: 225°C to

425°C

±0.01°C: 50°C to 100°C

±0.025°C: 100°C to

425°C

±0.04°C: 425°C to 700°C

Loading Effect

(with reference

thermometer)

±0.02°C: –45°C to –35°C

±0.005°C: –35°C to

100°C

±0.01°C: 100°C to 140°C

±0.005°C: –30°C to 0°C

±0.005°C: 0°C to 100°C

±0.01°C: 100°C to 155°C

±0.01°C full range ±0.02°C: 50°C to 425°C

±0.04°C: 425°C to 700°C

Hysteresis ±0.025°C ±0.04°C ±0.07°C

Operating Range1 5°C to 40°C (41°F to 104°F)

Block Depth 160 mm (6.3 in) 203 mm (8 in)

Resolution 0.001° C/F

Display LCD, °C or °F user–selectable

Key Pad Ten key with decimal and +/– key. Function keys, menu key, and °C/°F key.

Cooling Time 44 min: 23°C to –45°C

19 min: 23°C to –30°C

19 min: 140°C to 23°C

30 min: 23°C to –30°C

25 min: 155°C to 23°C

220 min: 425°C to 35°C

100 min: 425°C to 100°C

235 min: 700°C to 50°C

153 min: 700°C to 100°C

Heating Time 32 min: 23°C to 140°C

45 min: –45°C to 140°C

44 min: 23°C to 155°C

56 min: –30°C to 155°C

27 min: 35°C to 425°C 46 min: 50°C to 700°C

Size 366 x 203 x 323 mm (14.4 x 8 x 12.7 in) [height x width x depth]

Weight 14.2 kg (31.5 lb) 14.6 kg (32 lb) 12.2 kg (27 lb) 14.2 kg (31 lb)

MBXXX Series Metrology Temperature Block

Environmental Conditions

8

Specication MB140 MB155 MB425 MB700

Power 115 V (±10%), 50/60 Hz, 550 W

230 V (±10%), 50/60 Hz, 550 W

115 V (±10%), 50/60 Hz, 1025 W

230 V (±10%), 50/60 Hz, 1025 W

System Fuse

Ratings

115 V: 6.3 A 250 V

230 V: 3.15 A 250 V

115 V: 10 A 250 V

230 V: 5 A 250 V

Internal Fuse

Ratings

F1: 8 A 250 V

F2: 1 A 250 V

F4: 4 A 250 V

n/a

Computer Interface RS-232 Interface

Safety OVERVOLTAGE (Installation) CATEGORY II, Pollution Degree 2 per IEC–61010–1:2001

1Specifications are given with an ambient temperature of 23°C (73.4°F). Range, display accuracy, axial uniformity, loading effect, cooling time, and heating time are subject to the ambient

temperature and may be affected outside the “Full Accuracy” temperature range

2Refer to the Maintenance section in the User’s Guide regarding maintaining the accuracy of the instrument.

Table 3 Built-in Readout Specifications

Specications Built-in Reference Input

Temperature Range1–200°C to 962°C

(–328°F to 1764°F)

Resistance Range 0Ω to 400Ω, auto-ranging

Characterizations ITS-90 subranges 4, 6, 7, 8, 9, 10, and

11

Callendar-Van Dusen (CVD): R0,

ALPHA, DELTA, BETA

Resistance Accuracy10Ω to 20Ω: 0.0005Ω

20Ω to 400Ω: 25 ppm (0.0025%)

Temperature Accuracy1, 2 10Ω PRTs:

±0.013°C at 0°C

±0.013°C at 50°C

±0.014°C at 155°C

±0.014°C at 225°C

±0.019°C at 425°C

±0.028°C at 700°C

25Ω and 100Ω PRTs:

±0.005°C at –100°C

±0.007°C at 0°C

±0.011°C at 155°C

±0.013°C at 225°C

±0.019°C at 425°C

±0.027°C at 661°C

Temperature Resolution 0.001° C/F

Operating Range 5°C to 40°C (41°F to 104°F)

1Specifications are given with an ambient temperature of 23°C (73.4°F). Resistance accuracy and temperature accuracy are subject to the ambient temperature and may be affected outside

the “Full Accuracy” temperature range.

2The temperature range may be limited by the reference probe connected to the external “Probe” connection of the Metrology Temperature Block. Does not include sensor probe accuracy. It

does not include probe uncertainty or probe characterization errors.

2.2 Environmental Conditions

Although the instrument has been designed for optimum durability and trouble-free

operation, it must be handled with care. The instrument should not be operated in an

excessively dusty or dirty environment. Maintenance and cleaning recommendations

can be found in the Maintenance section.

The instrument operates safely under the following environmental conditions:

temperature range: 5-40°C (41-104°F)

ambient relative humidity: maximum 80% for temperature <31°C, decreasing

linearly to 50% at 40°C

9

Specications and Environmental Conditions

Environmental Conditions

pressure: 75kPa-106kPa

mains voltage: within ±10% of nominal

vibrations in the calibration environment should be minimized

altitude: less than 2,000 meters

indoor use only

11

Quick start

Unpacking

3 Quick start

3.1 Unpacking

Unpack the instrument carefully and inspect it for any damage that may have occurred

during shipment. If there is shipping damage, notify the carrier immediately.

Verify that the following components are present:

MB140

MB140 Metrology Temperature Block

Insert: MB140-MH2, MB140-MH1, or MB140-B

Power Cord

RS-232 Cable

User’s Guide

Technical Guide

Calibration Certicate

LEMO Connector (-R units only)

Block Insulator

Tongs (insert removal tool)

MB155

MB155 Metrology Temperature Block

Insert: MB155-MH2, MB155-MH1, or MB155-B

Power Cord

RS-232 Cable

User’s Guide

Technical Guide

Calibration Certicate

LEMO Connector (-R units only)

Block Insulator

Tongs (insert removal tool)

MB425

MB425 Metrology Temperature Block

Insert: MB425-MH2, MB425-MH1, or MB425-B

Power Cord

RS-232 Cable

User’s Guide

Technical Guide

MBXXX Series Metrology Temperature Block

Setup

12

Calibration Certicate

LEMO Connector (-R units only)

Block Insulator

Tongs (insert removal tool)

MB700

MB700 Metrology Temperature Block

Insert: MB700-MH2, MB700-MH1, or MB700-B

Power Cord

RS-232 Cable

User’s Guide

Technical Guide

Calibration Certicate

LEMO Connector (-R units only)

Tongs (insert removal tool)

If all items are not present, contact an Authorized Service Center.

3.2 Setup

NOTE: The instrument will not heat, cool, or control until the “CONT

ENABLE” parameter is set to “On.” Refer to Set-Point Setup on page 16 to set

this parameter.

Place the block on a at surface with at least 15 cm of free space around the instru-

ment. Overhead clearance is required. DO NOT place under a cabinet or structure.

Plug the Metrology Temperature Block power cord into a mains outlet of the proper

voltage, frequency, and current capability (see Specications for power details). Ob-

serve that the nominal voltage corresponds to that indicated on the back of the block.

Carefully place the probe insert into the block. Probe inserts should be of the small-

est hole diameter possible still allowing the probe to slide in and out easily. Inserts

of various sizes are available from Beamex. The block must be clear of any foreign

objects, dirt and grit before the insert is installed. The insert is installed with the two

small tong holes positioned upward.

Turn on the power to the temperature block by toggling the switch on the power entry

module. After a brief self-test, the controller should begin normal operation. The main

screen will appear within 30 seconds. If the instrument fails to operate, please check

the power connection.

The display will show the block temperature, and wait for user input before heating or

cooling to current set-point.

13

Quick start

Display

3.3 System Setup

Before using the instrument, the parameters in this section need to be setup (Main

Menu: SYSTEM|SETUP MENU).

3.4 Display

Language

English, French, and Chinese are the only languages supported by the instrument.

Select the preferred language using the right/left arrow keys and press “ENTER” to

accept the selection.

Decimal

The decimal of the numbers in the instrument can be either a comma or decimal.

Select the desired decimal type using the right/left arrow keys and press “ENTER” to

accept the selection.

3.4.1 Measure

Stability Limit

NOTE: Metrology Temperature Blocks should not be expected to operate better

than the stability limit specification set forth in the Specifications section of this

guide. Therefore, the minimum setting of the stability limit should not be less

than the stability specification set forth in the Specifications section.

The stability limit of the instrument is the parameter which allows the instrument to

notify the user when it has achieved the stability limit set in this parameter. There are

two notications: visual and audible. The visual notication is always active. When

the instrument is operating within the stability limit, the stability parameter on the

main screen will remain highlighted as long as the instrument is within the given

specication, otherwise the parameter will not be highlighted. The audible, if enabled,

alerts the user once per set-point when the instrument achieves the set stability limit.

Use the numeric keys to set the desired stability limit and press “ENTER” to accept

the new stability limit.

Example:

A specic calibration process requires the instrument be operating within ±0.1°C.

“0.1” would be entered into the stability limit parameter. When the instrument is

within ±0.1°C, “STAB: X.XXX°C” will be highlighted and the audible alarm (if

enabled) will notify the user that the instrument is operating within ±0.1°C. Use the

numeric keys to set the desired stability limit and press “ENTER” to accept the new

stability limit.

MBXXX Series Metrology Temperature Block

Setting the Temperature

14

Stability Alarm (STAB ALARM)

The audible alarm described in “Stability Limit” is turned on or off using this param-

eter. Select either “On” or “Off” using the right/left arrow keys and press “ENTER” to

accept the selection.

3.5 Setting the Temperature

The users guide explains in detail how to set the temperature set-point of the tempera-

ture block using the front panel keys. The procedure is summarized here.

3.5.1 Set-point Setup

1. From the main screen, press “ENTER” once to access the “SETUP SET

POINT” menu.

2. Press +/- to set a positive or negative temperature. If the “-” symbol is not

present, the temperature is assumed to be positive. Use the number keys to set

the desired temperature. Press “ENTER” to set the temperature and continue

setting up the set-point information. If the other information in the set-point

menu does not need to be edited at this point, press “EXIT” to return to the

main screen

NOTE: Each time the instrument is turned off and back on, the “CONT

ENABLE” parameter is set to “Off”.

3. The “CONT ENABLE” parameter enables or disables active heating or cooling

of the instrument. This parameter must be set to “On” for the instrument to heat

or cool. Using the right/left arrow keys, select “On” to allow the instrument to

heat or cool or select “Off” to disable heating and cooling.

4. The scan rate of the instrument can be set from 0.1 to 99°C/min, however

the actual scan rate is limited by the natural heating or cooling rate of the

instrument. Use the number keys to set the desired scan rate and press

“ENTER”.

When the set-point temperature is changed the controller will switch the thermoelec-

tric modules or heater on or off to raise or lower the temperature. The displayed block

temperature will gradually change until it reaches the set-point temperature. The block

may require 5 to 10 minutes to reach the set-point depending on the span. Another 5 to

10 minutes is required to stabilize with ±0.1°C of the set-point. Ultimate stability may

take 15 to 20 minutes more of stabilization time.

3.6 Reference Probe (-R models only)

The reference probe section of the user manual explains in detail how to set up the

reference probe of the temperature block using the front panel keys. The procedure is

summarized here.

This manual suits for next models

3

Table of contents

Other BEAMEX Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Gima

Gima BC401 user manual

UE Systems

UE Systems UE ECM-586 instruction manual

Halma

Halma Alicat Scientific CODA KM quick start guide

NVision

NVision TIRE PRESSURE MONITORING SYSTEM owner's manual

Endress+Hauser

Endress+Hauser Prothermo NMT 539 technical information

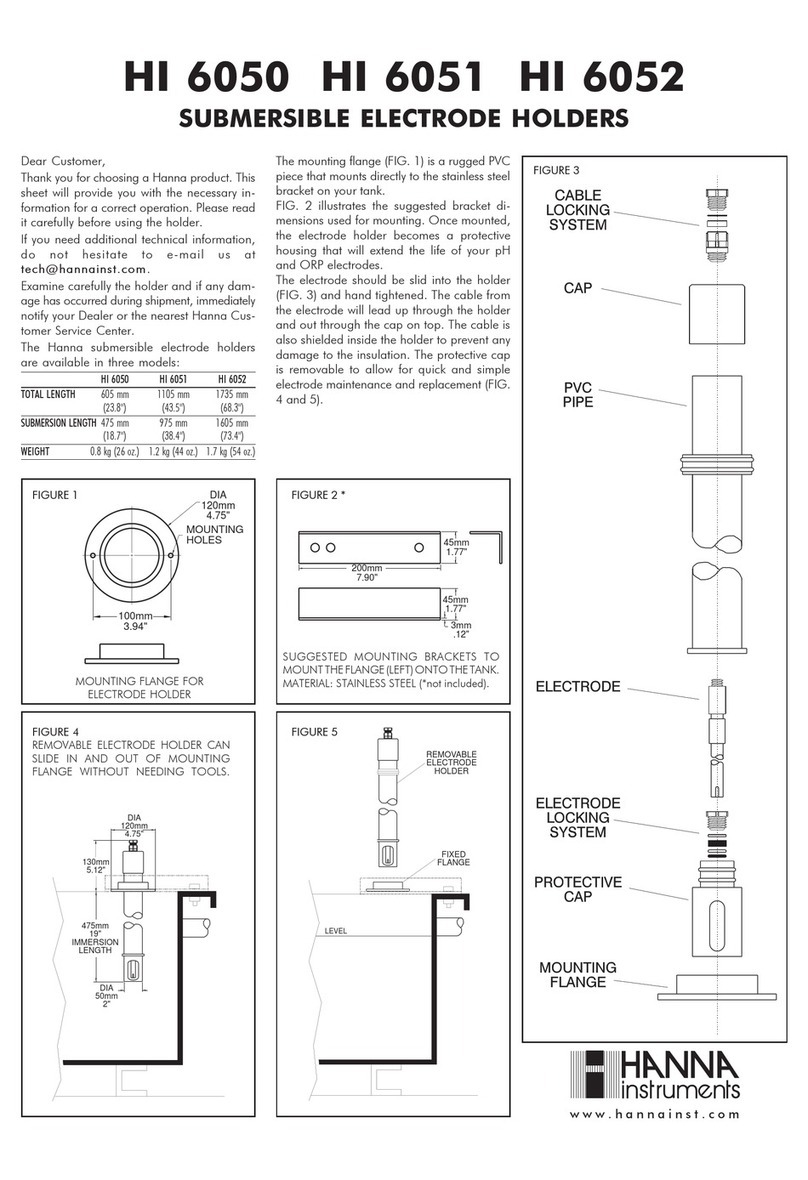

Hanna Instruments

Hanna Instruments HI 6052 instruction manual