3

TABLE OF CONTENTS

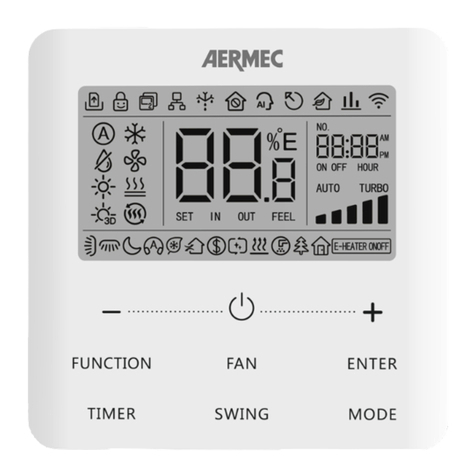

1. User interface .......................................................................................p.5

Main Page (Home) .................................................................................p.5

2. Structure of the menus...................................................................p.6

Functions...................................................................................................p.6

Parameters................................................................................................p.6

View.............................................................................................................p.6

Commission (Function)........................................................................p.7

Commission (Parameter).....................................................................p.7

General.......................................................................................................p.7

3. Basic functions.....................................................................................p.8

Switching the unit on and o (On/O)..........................................p.8

Selecting a menu....................................................................................p.8

4. Function menu ....................................................................................p.9

Navigating the menu............................................................................p.9

Setting the operating mode (Mode)...............................................p.9

Activating the function for fast domestic hot water

production (Fast hot water)................................................................p.9

Setting the priority between cooling and domestic hot

water production (Cool+hot water)................................................p.9

Set the priority between heating and domestic hot water

production (Heat+hot water) ......................................................... p.10

Setting the noise reduction function (Quiet mode)............... p.10

Setting the automatic setting compensation on the basis

of external air (Weather depend).................................................. p.10

Setting a timer for programmed switch-on and/or switch-

o (Weekly timer)................................................................................ p.11

Enabling the Holiday Program function used for the

weekly timer (Holiday release)....................................................... p.12

Enabling/disabling the anti-legionella cycle (Disinfection)

................................................................................................................... p.12

Setting a timed switch-on/switch-o (Clock timer) ............... p.12

Setting programmed setting changes on system water

delivery (Temp. timer) ....................................................................... p.13

Enabling emergency operation for heating or DHW

(Emergen. mode)................................................................................. p.14

Setting the winter period absence function (Holiday

mode) ...................................................................................................... p.14

Setting the daily timer programming (Preset mode)............. p.15

Deleting current errors (Error reset) ............................................. p.15

WiFi connection reset function (WiFi reset)............................... p.15

Loading the default settings (Reset)............................................ p.15

5. Parameter menu.............................................................................. p.16

Navigating the menu......................................................................... p.16

Setting the temperature set-points used by the unit in

the various modes (WOT-Cool~ ΔT-hot water)......................... p.16

6. View menu .......................................................................................... p.17

Navigating the menu......................................................................... p.17

Viewing the status of the unit components (Status).............. p.17

Viewing the status of the unit parameters (Parameter) ........ p.18

Viewing the active errors on the unit (Error)............................. p.18

Viewing the error log (Error log).................................................... p.18

Viewing software information (Version)..................................... p.18

7. Commission menu.......................................................................... p.19

Navigating the menu......................................................................... p.19

Setting the control logic (Ctrl.state) ............................................ p.19

Setting the status of the 2-way valve in cooling mode

(Cool 2-Way valve)............................................................................... p.19

Setting the status of the 2-way valve in heating mode

(Heat 2-Way valve) .............................................................................. p.20

Setting solar system integration (Solar setting)....................... p.20

Set the installation of a compatible Aermec accessory

tank (DHW tank) .................................................................................. p.20

Setting the use of an external thermostat (Thermostat)...... p.20

Setting an additional heat source (Other thermal)................. p.20

Setting an additional heater (Optional E-heater).................... p.21

Setting the installation of the remote room temperature