.

SPL user manual Page 4 of 24 0412-6180459 –rev.00

2 PURPOSE

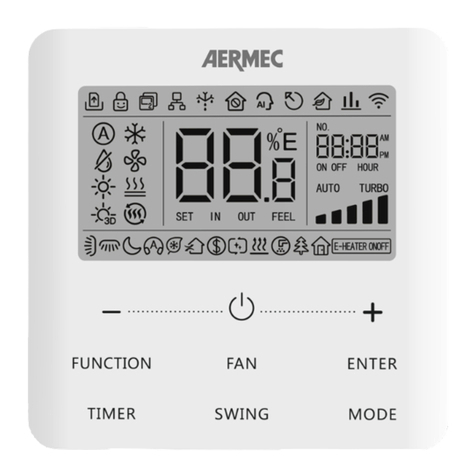

- The purpose of this manual is to provide all the basic information needed to run a SPL UNIT equipped

with EXTK PRO keyboard (see Fig. 1 page 6).

- The recipients of this manual include those involved in the basic operation of the UNIT.

3 USE OF THE DEVICE

Permitted use

This product is used for the control of the SPL unit. For safety reasons, the control device must be installed

and used according to the instructions provided and in particular, under normal conditions, live parts must not

be accessible.

The device must be protected from water and dust according to the application, and should only be accessible

with the use of tools.

Unintended use

Any use other than that expressly permitted is prohibited. Please note that the relay contacts supplied are

functional and are subject to failure, (since they are managed by an electronic component they can short or

remain open). Any protection devices required by product standards or dictated by common sense for obvious

safety reasons should therefore be made outside of the instrument.

4 RESPONSABILITIES AND RESIDUAL RISKS

Aermec SpA are not liable for any damages arising from:

• installation/use other than that prescribed and, in particular, that does not comply with safety requirements

laid down by regulations and/or specified in the present;

• use on equipment that do not provide adequate protection against electric shock, water and dust following

the assembly;

• use of devices that allow access to hazardous parts without the use of tools;

• installation/use on equipment not conforming to regulations and provisions in force.

5 WEEE DIRECTIVE (FOR EU ONLY)

WEEE Directive (for EU only)

All materials must be recovered or disposed of in accordance with national regulations.

• The WEEE Directive requires that the disposal and recycling of electrical and electronic

equipment must be managed through a special collection, in appropriate centres, separate

from the one adopted for the disposal of mixed municipal waste.

• The user is obliged not to dispose of equipment at the end of its useful life as municipal

waste, but to dispose of it in a special collection centres.

• The units covered by the WEEE Directive are marked with the above symbol.

• Potential effects on the environment and human health are presented in this manual.

• Additional information may be obtained from the manufacturer.