3

QUICK REFERENCE............................................................................... 4

DESCRIPTION OF THE ACCESSORY .................................................... 5

RECOMMENDED SYSTEM DOUBLE RING WITH STORAGE TANK AND

CIRCUIT BREAKER.......................................................................................................5

INSTALLATION...................................................................................... 6

MULTICHILLEREVO GENERAL CONNECTION DIAGRAM............................6

NOTES REGARDING CONNECTION OF MULTICHILLEREVO PROBES.....6

NOTES ON THE SERIAL CONNECTION.................................................................8

MATERIAL SUPPLIED ..................................................................................................8

STRUCTURE OF THE MENUS ............................................................... 9

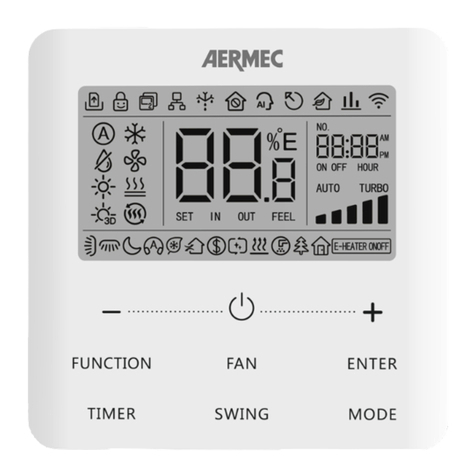

INTERACTING WITH THE GRAPHIC INTERFACE ...............................................10

NAVIGATING THE APPLICATION PAGES..............................................................10

MODIFYING THE VALUE OF A PARAMETER.......................................................11

SYSTEM LAYOUT MENU....................................................................... 12

SYSTEM LAYOUT CHILLER MAIN MONITOR HOME ..................................12

CHILLER SUBMENU:

SYSTEM LAYOUT CHILLER MAIN MONITOR CHILLER SUBMENU GENERAL STATUS.....13

SYSTEM LAYOUT CHILLER MAIN MONITOR CHILLER SUBMENU VA

LUES READ ON THE CHILLER PROBES/TRANSDUCERS ................................13

SYSTEM LAYOUT CHILLER MAIN MONITOR CHILLER SUBMENU

ALARM STATUS ON SELECTED CHILLER.............................................................14

SYSTEM LAYOUT CHILLER MAIN MONITOR CHILLER ENABLING AND

ACTIVE ALARMS RESET .............................................................................................14

ON/OFF MENU...................................................................................... 15

ON/OFF MAIN SYSTEM SIDE FUNCTIONING SETTINGS............................15

TIME PERIODS SUBMENU

ON/OFF MAIN FUNCTIONING SETTINGS TIME PERIODS SUBMENU

DAILY SETTING .............................................................................................................16

ON/OFF MAIN FUNCTIONING SETTINGS TIME PERIODS SUBMENU

COPY HOURLY PROGRAMS FUNCTION..............................................................17

ON/OFF MAIN 2/4PIPE SYSTEM RECOVERY SIDE FUNCTIONING SET

TINGS VISIBLE IF MULTIPURPOSE UNITS ARE PRESENT............................17

ON/OFF MAIN FUNCTIONING SETTINGS TIME PERIODS SUBMENU RECO

VERY SIDE DAILY SETTING IF MULTIPURPOSE UNITS ARE PRESENT .............18

ON/OFF MAIN FUNCTIONING SETTINGS TIME PERIODS SUBMENU

COPY HOURLY PROGRAMS FUNCTION ON RECOVERY SIDE IF MULTI

PURPOSE UNITS ARE PRESENT.............................................................................19

CLOCK MENU ........................................................................................ 19

CLOCK DATE AND TIME SETTINGS ON THE MAIN BOARD AND ON THE

TOUCH DISPLAY BOARD...........................................................................................19

CHARTS MENU...................................................................................... 20

CHARTS DISPLAYS REALTIME CHARTS OF THE VALUES READ BY THE

SYSTEM SIDE PROBES................................................................................................20

CHARTS DISPLAY CHARTS IN REAL TIME REGARDING VALUES READ BY

THE 2/4PIPE SYSTEM RECOVERY SIDE PROBES VISIBLE IF MULTIPURPO

SE UNITS ARE PRESENT............................................................................................20

LANGUAGE MENU................................................................................ 21

LANGUAGE SELECTION OF SYSTEM LANGUAGE.........................................21

INSTALLER MENU................................................................................. 22

INSTALLER ACCESS PASSWORD ENTERING....................................................22

INSTALLER SUBMENU SELECTING PAGE........................................................22

INPUTS/OUTPUTS SUBMENU:

INSTALLER INPUTS/OUTPUTS STATUS OF PCO5+ ANALOGUE INPUTS PAGE 1....... 23

INSTALLER INPUTS/OUTPUTS STATUS OF PCO5+ ANALOGUE INPUTS

PAGE 2 ...........................................................................................................................23

INSTALLER INPUTS/OUTPUTS STATUS OF PCO5+ DIGITAL OUTPUTS 24

INSTALLER INPUTS/OUTPUTS STATUS OF PCO5+ ANALOGUE OU

TPUTS ..............................................................................................................................24

INSTALLER INPUTS/OUTPUTS STATUS OF PCOE ANALOGUE INPUTS ..... 25

INSTALLER INPUTS/OUTPUTS STATUS OF PCOE DIGITAL INPUTS ....25

INSTALLER INPUTS/OUTPUTS STATUS OF PCOE DIGITAL OUTPUTS 26

INSTALLER INPUTS/OUTPUTS STATUS OF PCOE ANALOGUE OUTPUTS ....26

THRESHOLD AND TIMES SUBMENU:

INSTALLER THRESHOLDS AND TIMINGS CHILLER ON/OFF MANAGEMENT.....27

INSTALLER THRESHOLDS AND TIMING FIXED THRESHOLD LOGIC SETTINGS......28

INSTALLER THRESHOLDS AND TIMING OPTIMISATION LOGIC SETTINGS......28

INSTALLER THRESHOLDS AND TIMING CHILLER IGNITION PRIORITY/

ORDER SETTINGS FOR FIXED THRESHOLD MANAGEMENT.......................29

INSTALLER THRESHOLDS AND TIMING BACKUP CHILLER SETTINGS ....... 29

REMOTE CONTROL SUBMENU:

INSTALLER REMOTE CONTROL CONNECTION WITH BMS SETTINGS...... 30

INSTALLER REMOTE CONTROL CHANGEOVER MANAGEMENT...........30

INSTALLER REMOTE CONTROL ENABLE ON/OFF FROM DIGITAL INPUT.......31

INSTALLER REMOTE CONTROL ENABLE ON/OFF FROM DIGITAL INPUT.......31

INSTALLER REMOTE CONTROL MULTIFUNCTION INPUT MANAGEMENT .....32

INSTALLER REMOTE CONTROL CLIMATIC CURVE SETTINGS U2 SET AS

NTC FOR OUTDOOR AIR PROBE...........................................................................33

INSTALLER REMOTE CONTROL CLIMATIC CURVE SETTINGS U2 SET AS

VOLTAGE OR CURRENT VALUE..............................................................................33

INSTALLER REMOTE CONTROL POWER DEMAND/LIMITATION SET

TINGS U2 SET AS NTC PROBE...............................................................................34

INSTALLER REMOTE CONTROL POWER DEMAND/LIMITATION SET

TINGS U2 SET AS VOLTAGE OR CURRENT VALUE.........................................34

INSTALLER REMOTE CONTROL RECOVERY SIDE SET POINT COMPENSATION SETTINGS ......35

INSTALLER REMOTE CONTROL POWER DEMAND/LIMITATION SET

TINGS ON RECOVERY SIDE.......................................................................................35

PASSWORD SUBMENU:

INSTALLER PASSWORD PASSWORD SETTING ............................................36

INFO SUBMENU:

INSTALLER INFO SOFTWARE VERSIONS DISPLAY .....................................36

GRAPHS SUBMENU

INSTALLER CHARTS TEMPERATURE PROBE SETTING FOR CHARTS VALUES........37

CHILLER NETWORK SUBMENU:

INSTALLER CHILLERS NETWORK SET OF THE CONNECTED CHILLERS PAGE 1.....37

INSTALLER CHILLERS NETWORK SET OF THE CONNECTED CHILLERS PAGE 2.....38

DISPLAY SUBMENU:

INSTALLER DISPLAYS ENABLES PROBE READING FOR NRL/NRP........39

INSTALLER DISPLAYS ENABLES PROBE READING FOR NSM.................39

INSTALLER DISPLAYS ENABLES DEBUG MENU...........................................40

MANUFACTURER MENU ...................................................................... 41

MANUFACTURER ACCESS PASSWORD ENTERING.......................................41

ALARMS MENU..................................................................................... 42

ALARMS DISPLAYS ACTIVE ALARMS.................................................................42

ALARMS DISPLAYS ALARMS LOG.......................................................................42

MULTICHILLEREVO LIST OF ALARMS............................................... 43

INDEX