3 4

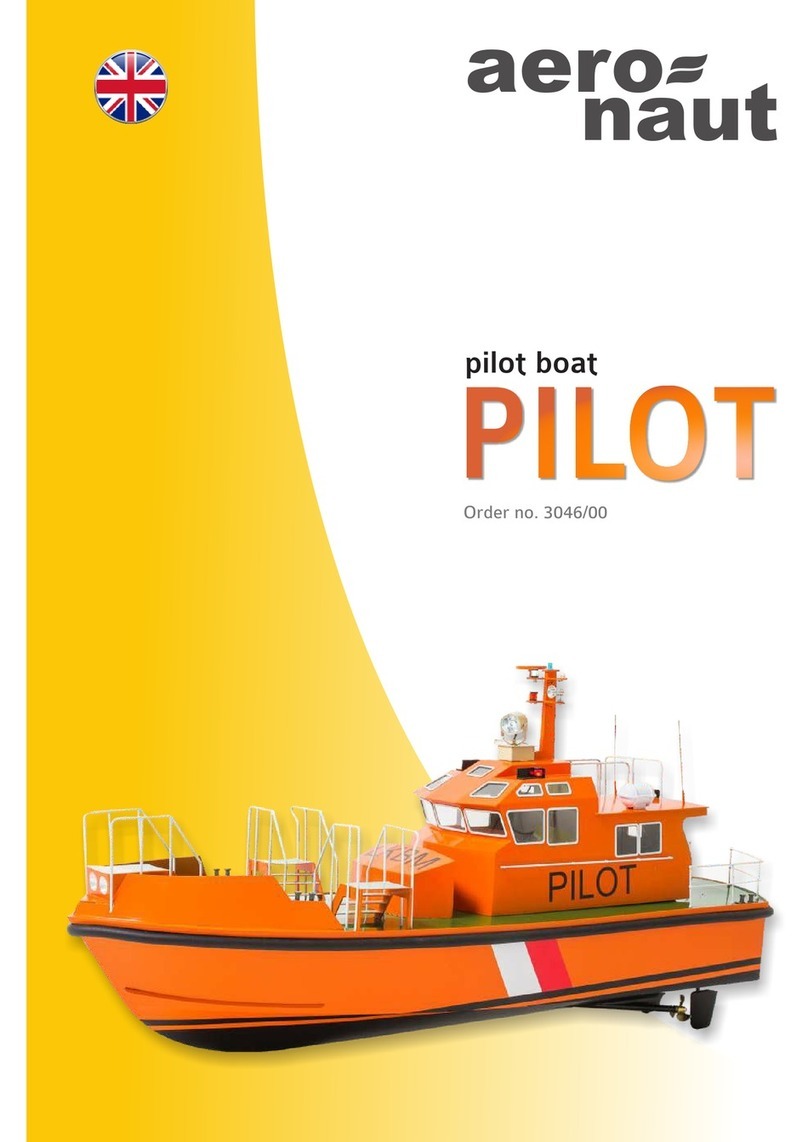

Fig. 8

26

25

24

27

16

Fig. 7

7. Drill holes in the brass brackets 25 exactly as shown in

the drawing alongside.

Fit the two 80 mm lengths of brass rod 26 through the holes.

8. Fit the two brass brackets 25 in the openings in the deck

from the underside.

The upper rod 26 should rest against the underside of the deck

33; the lower rod on the RC plate.

Glue the brass brackets to the rear sealing plate 24, taking

care to produce watertight joints (e.g. using Stabilit express -

not included in the kit).

9. Glue two spruce strips 16 to the underside of the deck to act as

stop-piece for the two stern plates 27.

Allow the glue to set hard, then glue the two stern plates 27 to the

sides of the brass brackets.

Glue the stern plates to the RC plate and the stop-pieces 16 on

the underside of the deck using two-pack adhesive (Stabilit

express). The two brass rods in the brackets should be fixed in

place using plenty of the same adhesive.

When the boat is operating, these glued joints absorb all the

forces exerted by the coupling.

Make sure that these joints are watertight.

44

chamfer on the outside

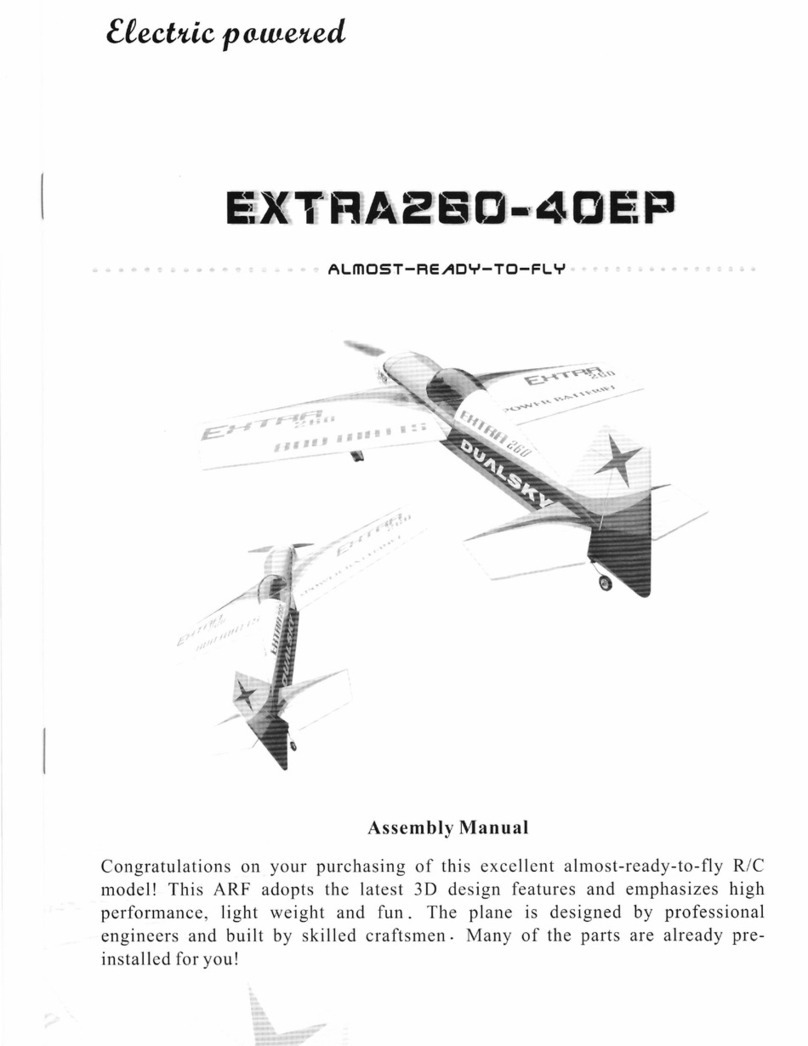

Fig. 14

46

47 12

43

Fig. 12

BSR

34

13

Fig. 13

22 23 21

Carriageway deck 45 not shown !

34

23

22

12

10. Glue parts 22 and 23 together as shown.

Glue these assemblies to the outside of the inner hull walls

12.

Glue these assemblies to the deck, applying adhesive on

both sides.

11. Insert the swivel bushes 46 in the holes in parts 22; note that the tubes must

not project on the inside. Slip the shaft 47 through the tubes to ensure correct

alignment. Glue the bushes to parts 22, and leave the shaft in place while the

glue hardens.

12. Open up the bow thruster stubs (BSR).

Slide the extension tubes 43 through the holes in the bow thruster

box from the outside.

Working inside the box, fit the extension tubes 43 on the bow

thruster stubs. The glued joints between these parts must be

watertight.

Apply the adhesive to the joint surfaces of the stubs before pushing

the extension tubes onto the housing.

Don't glue the bow thruster to the hull at this stage, as it has to be

aligned correctly with the deck later.

Thread the two cable guide tubes 34a through the frames, and glue

them in place. Insert the tubes 34b through the deck and the stop-

pieces 23. Heat them gently using a heat-gun so that they curve

smoothly, without any kinks. The tubes 34a and 34b are joined

using an outer sleeve 34c; glue these parts together.

Seal the openings in the deck and the stop-pieces 23 carefully; they

must be watertight.

13. Glue the bow plate 13 to the hull, the deck 33, the inner bearing

plates 22 and the stop-pieces 23.

Allow the glue to set hard, then temporarily slide the carriageway deck

45 into the hull to aid alignment of the forward sealing plate 21.

Fit the forward sealing plate 21 through the bow plate 13 from the

underside, then through the slots in the carriageway deck 45.

Permanently glue the sealing plate to the bow plate and parts 22 and

23.

When the glue has set hard, remove the carriageway deck 45 again.

Assemble the bollards by gluing together parts 71 and 72 (see Fig. 15).

Fit the bollards in the holes in the deck, and apply glue inside and out to

secure and seal them.

14. Chamfer the holes in the outside of the outer hull sides to a

depth of half the material thickness.

Turn the hull on one side, and apply glue to all the frames and rails.

Fix one hull side in place using strips of adhesive tape.

Turn the hull onto the opposite side.

This prevents the adhesive running out of the joints.

Don't glue the bow thruster in place at this stage.

glue

Fig. 15

don‘t glue

71

72

15. Use two-pack adhesive to glue the swivel bushes 46 in the hull

sides 44. Remove the flap shaft 47.

Sand off excess adhesive flush with the outside of the hull wall.

55

50

51

52

53

54

48

49

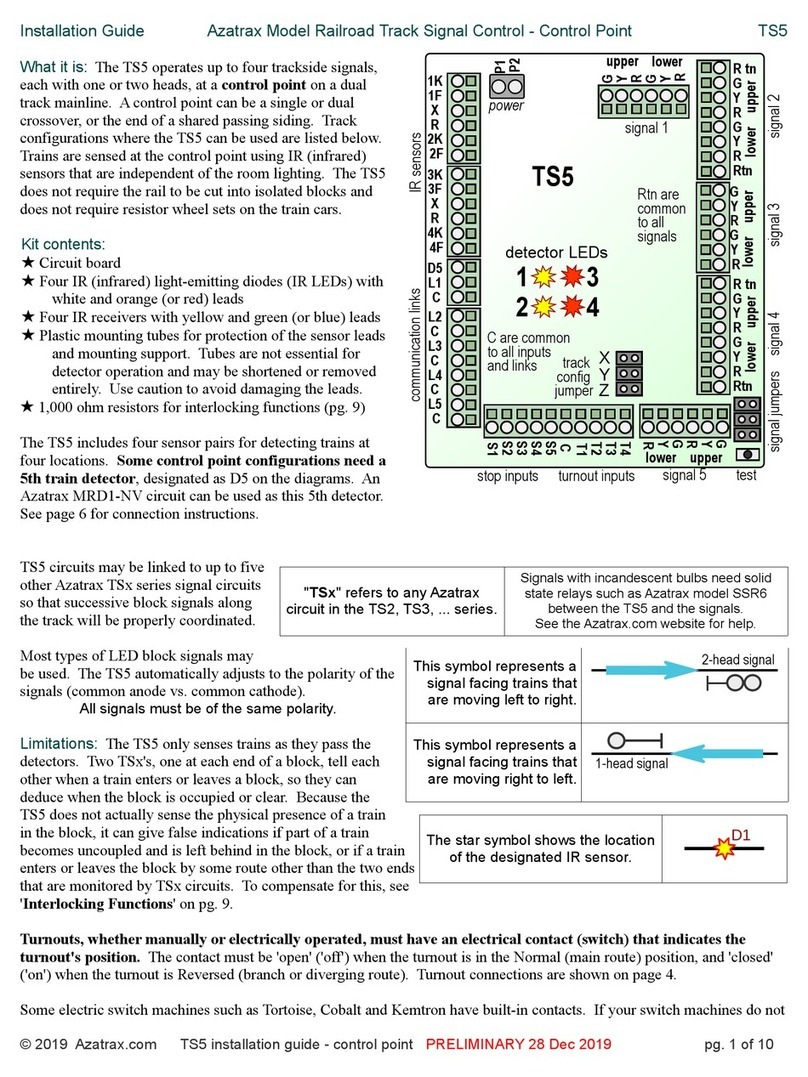

Fig. 16

16. Thread the five frames 53 onto the tube 48 and the rod 49, and space

them out evenly.

Position this assembly on the bottom plate 50, and glue the parts together.

Glue the six rails 54 to the rounded end of frames 53, taking care to

produce watertight joints. Leave this assembly on a flat surface until the

glue has set hard.

Glue the two upper flap panels 51 and 52 to the frames.

Sand the rails 54 to form a rounded face. If there are gaps between them,

fill them with more glue. Glue the two cable guide tubes 55 in the flap.

Install the flap, and check that it swivels smoothly.

If there are points where it rubs, sand them back.

The flap must rotate freely.

It does not need to be watertight.

Any water which gets inside the load bay can escape again under the flap.