AFi ISA AFI-CI060V Series User manual

Maintenance Manual -

Revision 1.1 - English version

602697

This document has been prepared with the utmost care. However, AFI

Centrifuge refuses to accept any responsibility in the event of errors or

omissions. The same applies to any damage arising from the use of

information contained in this manual.

AFI Centrifuge

3, Rue Nicolas Copernic

ZA Nord Bazouges

53200 CHATEAU-GONTIER

FRANCE

+33 (0) 2 43 06 66 76

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 2/ 27

You have just purchased one of the finest Laboratory Centrifuges available. With proper care, maintenance

and laboratory procedure, this centrifuge will provide you years of productive service. Please read this manual

carefully to familiarize you with proper installation, and operation of the centrifuge. ther information are

available on our website,

www.aficentrifuge.com

.

Warranty

AFI Centrifuge warrants ISA Centrifuges that it will repair F. .B. its factory or furnish without charge F. .B. its

factory a similar part to replace any material in its equipment within 24 months after the date of sale if proved

to the satisfaction of the company to have been defective at the time it was sold provided that all parts claimed

defective shall be returned, properly identified to the company at its factory, charges prepaid. Factory installed

equipment or accessories are warranted only to the extent guaranteed by the original manufacturer, and this

warranty shall not apply to any portion of the equipment modified by the user. Claims under this warranty

should be directed to AFI Centrifuge. Setting forth in detail the nature of the defect, the date of the initial

installation and the serial and model number of the equipment.

This warranty shall not apply to any AFI Centrifuge product or part thereof which has been subject to misuse,

abuse, accident, shipping damage, improper installation or service, or damage by fire, or flood. If the serial

number of this product is altered, removed or defaced as to be illegible, the Warranty shall be null and void in

its entirety.

The warranty is for the sole benefit of the original purchaser and is not assignable or transferable. Prior to

returning any item, for any reason, contact AFI Centrifuge for a Return Authorization Number. This number must

accompany all returns. Any product shipped to AFI Centrifuge without this number will be returned refused

shipment or collect freight.

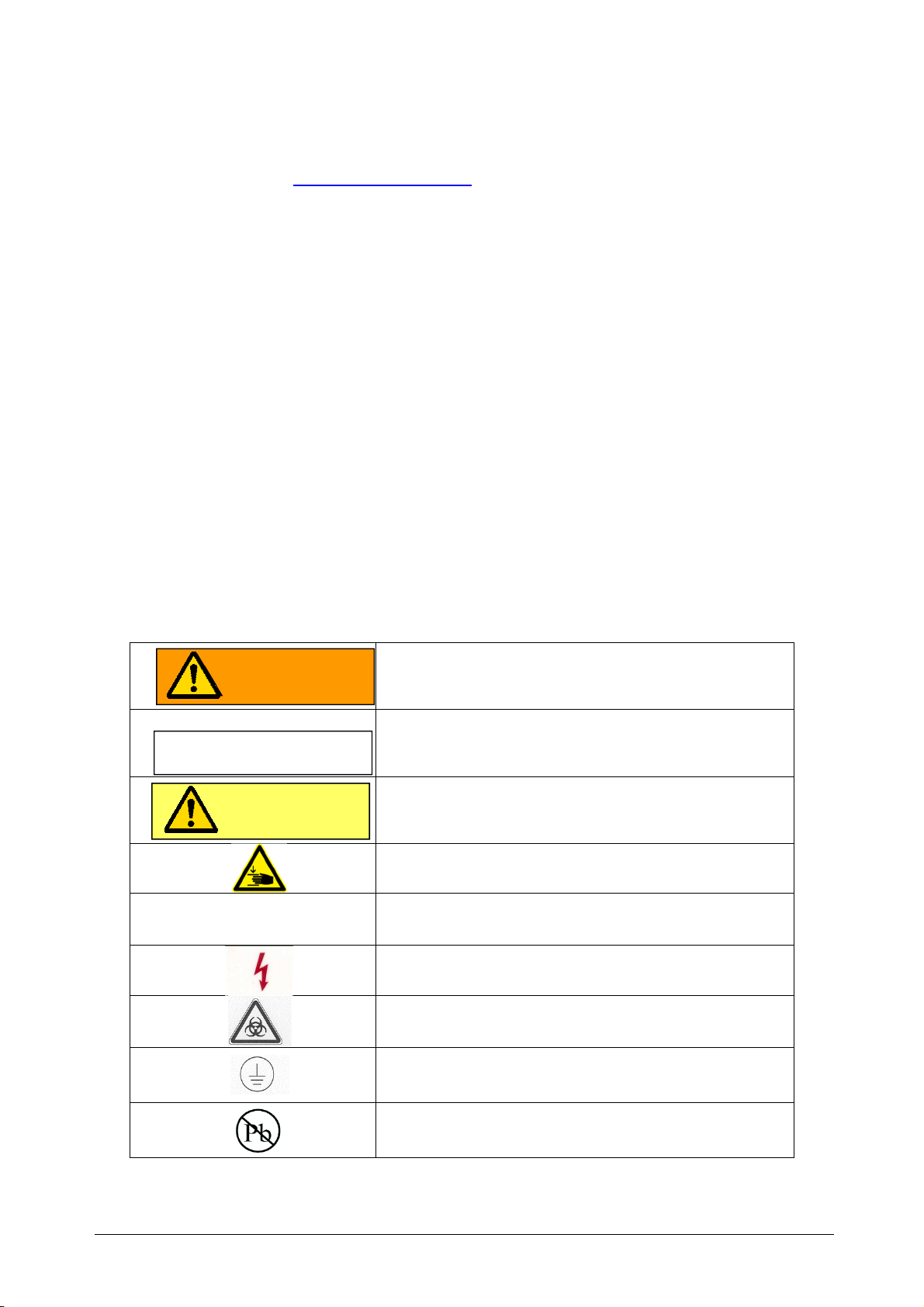

Explanation of Symbols

Safety alert symbol indicates a potentially hazardous

situation which, if not avoided, could result in death or

serious injury

CAUTI N used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

Safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in minor or

moderate injury.

Pinching: This warning symbol indicates the presence of

a risk of pinching when handling the lid.

Note: Used for important information

Potential electrical hazard, only qualified person to

access

Biohazard

Ground, Earth

Lead Free

CAUTION

CAUTION

WARNING

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 3/ 27

Table of contents

1

DESCRIPTION OF THE CENTRIF GE .......................................................................................................... 5

1.1

E

LECTR NIC

C

NTR L

C

ENTER

/

B

L CK

................................................................................................................... 5

1.2

L

CK

................................................................................................................................................................. 7

1.3

M

T R

............................................................................................................................................................. 9

1.4

S

PEED SENS R

..................................................................................................................................................... 9

1.5

T

EMPERATURE PR BE

........................................................................................................................................... 9

1.6

I

MBALANCE SENS R

.............................................................................................................................................. 9

1.7

G

AS SPRING

........................................................................................................................................................ 9

1.8

A

BS RPTI N F VIBRATI NS

................................................................................................................................ 10

1.9

R

EFRIGERATI N

S

YSTEM

...................................................................................................................................... 10

2

TRO BLESHOOTING & MESSAGES ..........................................................................................................11

2.1

T

R UBLESH TING

............................................................................................................................................ 11

2.2

R

EMINDER MESSAGES

......................................................................................................................................... 13

3

SETTINGS ................................................................................................................................................14

3.1

A

CCESS T PARAMETERS

...................................................................................................................................... 14

3.2

U

NBALANCING

S

ENSITIVITY

S

ETTING

...................................................................................................................... 18

3.3

S

ETTING THE

T

IME

D

ELAY F THE L CK

................................................................................................................... 19

3.4

L

ADING THE FIRMWARE

..................................................................................................................................... 19

4

STANDARD EXCHANGE OF COMPONENTS ..............................................................................................19

4.1

S

AFETY

R

ULES

................................................................................................................................................... 19

4.2

T

ERMIN L GY

.................................................................................................................................................. 19

4.3

S

PARE PARTS

&

T LS

........................................................................................................................................ 20

4.4

S

ETTING F RM

.................................................................................................................................................. 21

5

F NCTIONAL CHECKS ..............................................................................................................................22

5.1

S

AFETY

............................................................................................................................................................. 22

5.2

S

PEED

C

HECK

.................................................................................................................................................... 23

5.3

C

HECKING THE

T

IMER

......................................................................................................................................... 23

5.4

C

HECKING THE

T

EMPERATURE

(R

EFRIGERATED M DEL

) ............................................................................................. 23

6

ELECTRICAL DIAGRAMS...........................................................................................................................24

6.1

0.6

L

ITER

V

ENTILATED

M

DEL

:

ISA

/

AFI-CI060V

&

AFI-CI060V-E

SERIES

............................................................... 24

6.2

0.6

L

ITER

R

EFRIGERATING

M

DEL

:

ISA

/

AFI-CI060R

&

AFI-CI060R-E

SERIES

.......................................................... 25

7

REFRIGERATING SYSTEM ........................................................................................................................26

7.1

0.6

L

ITER

120V

/

230V

M

DEL

/

ISA

–

AFI-CI060R-E .......................................................................................... 26

8

ANNEXES ................................................................................................................................................27

8.1

R

ETURN AUTH RIZATI N

..................................................................................................................................... 27

8.2

S

FTWARE UPDATE

.............................................................................................................................................. 1

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 4/ 27

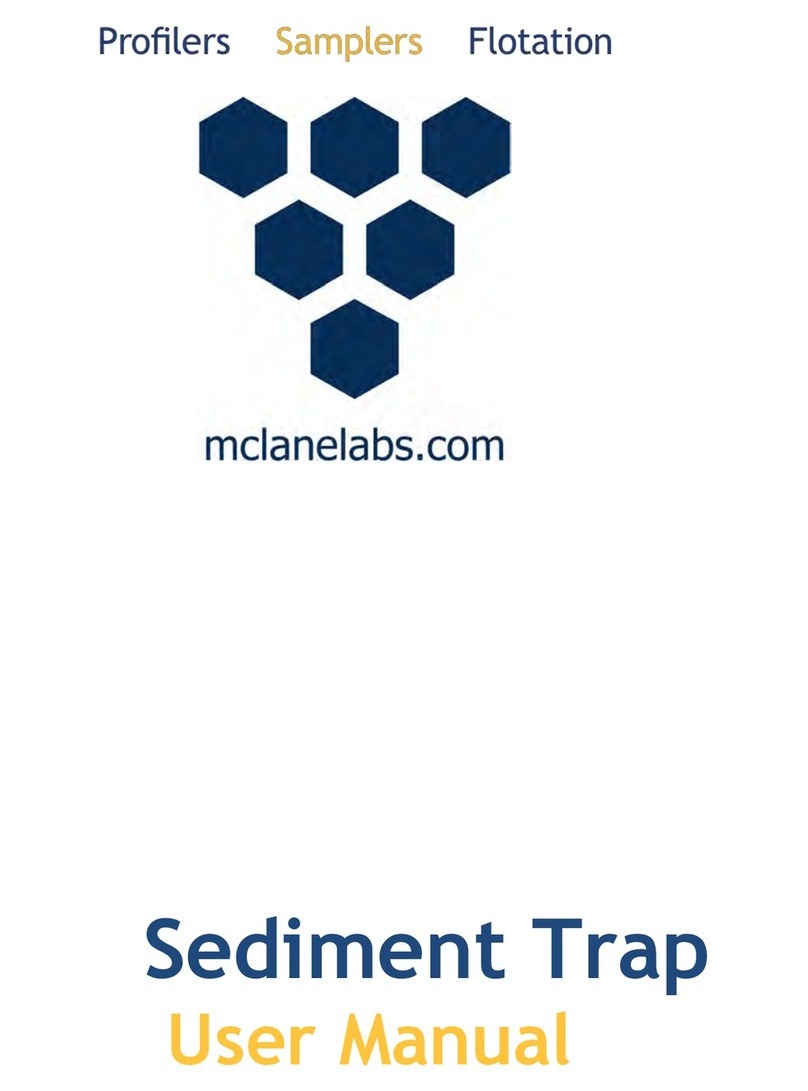

Updates

Date Revision Modification Paragraph Author

2019 August 27

th

2020 Jun 6th

1.0

1.1

Creation

Modification – Temperature Check

All

5.4

LS / FB

FB

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 5/ 27

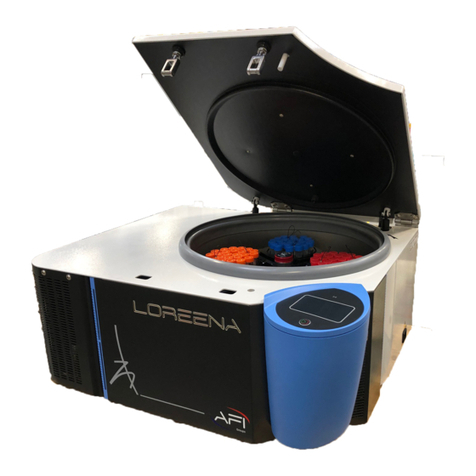

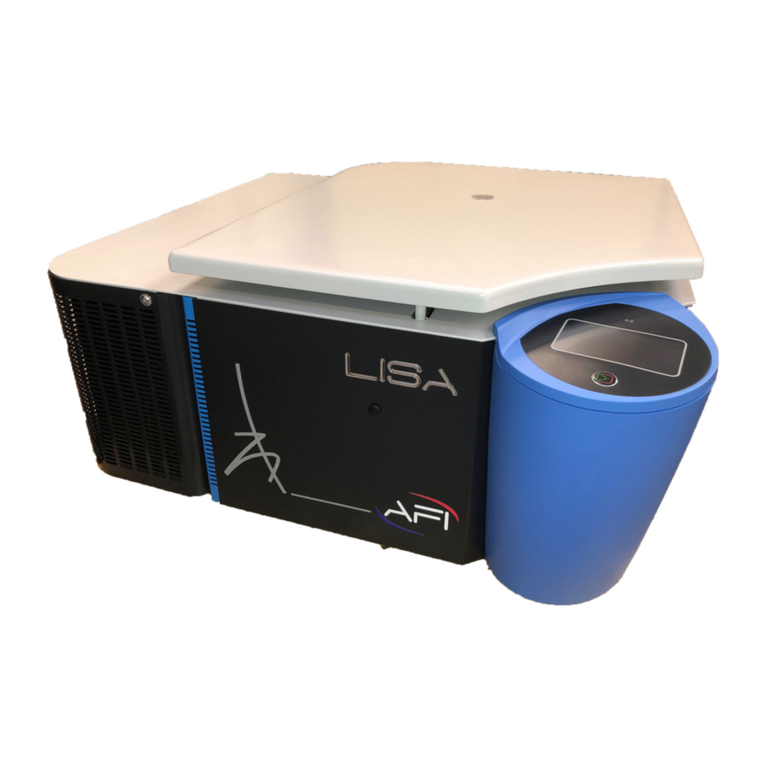

1Description of the Centrifuge

The centrifuge range is composed of:

References Model

AFI-CI060V Ventilated, 120V / 60Hz

AFI-CI060V-E Ventilated, 230V / 50-60Hz

AFI- CI060R Refrigerating, 120V / 60Hz

AFI- CI060R-E Refrigerating, 230V / 50Hz

The centrifuge is composed of:

•an electrical block, called Ogival Control Center

•a lock

•a motor

•a ventilation or refrigeration system (depending on the model)

•a lid

It is equipped with one or several rotors:

•Free or swing-out

•Angular

The free rotors are fitted with:

•Buckets

•Tube adapters or inserts

•Watertight lids

Some angular rotors are equipped with tight fitting lids.

1.1 Electronic Control Center / Block

Electronic control center is included in an ogival block.

It includes touch buttons, a knob, a lid opening button, as well as the microcontroller electronic board,

It is also equipped with RGB LED lighting for various color lighting.

There is no provision for changing the elements composing the Control. It is a complete separate part. In case of

defective element, a standard exchange of the complete Control Center must be considered, which facilitates the

restoration of the centrifuge.

The power electronic board is located inside the centrifuge body, on a power electronic “rack”. This can be ordered

independently for replacement.

Start/Stop Button

There is no main electrical switch on ISA centrifuges.

When connected to power supply through the power cord, the centrifuges turns ON.

To switch to stand-by mode, press & hold START/STOP button.

Logo Short press Press & hold

ISA series

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 6/ 27

Validation Button

validation button is the following one ,

Logo Short press Press & hold

ISA series

Setting controls

Values can be directly adjusted using the front panel Knob

Logo

ISA series

Lid Opening Button

The lid opening is controlled by the button on the right side of the Control Center.

Electronic microcontroller Board

The electronic microcontroller board is located under the display card. The data for controlling the various parts

are stored in this board, in the form of firmware.

The connection for the update of this firmware, via USB key, is described in 3.4 Loading the firmware

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 7/ 27

1.2 Lock

Description

ISA / AFI-CI060 series are equipped with an electric lid opening. Lid closing is a manual operation

Visual Description

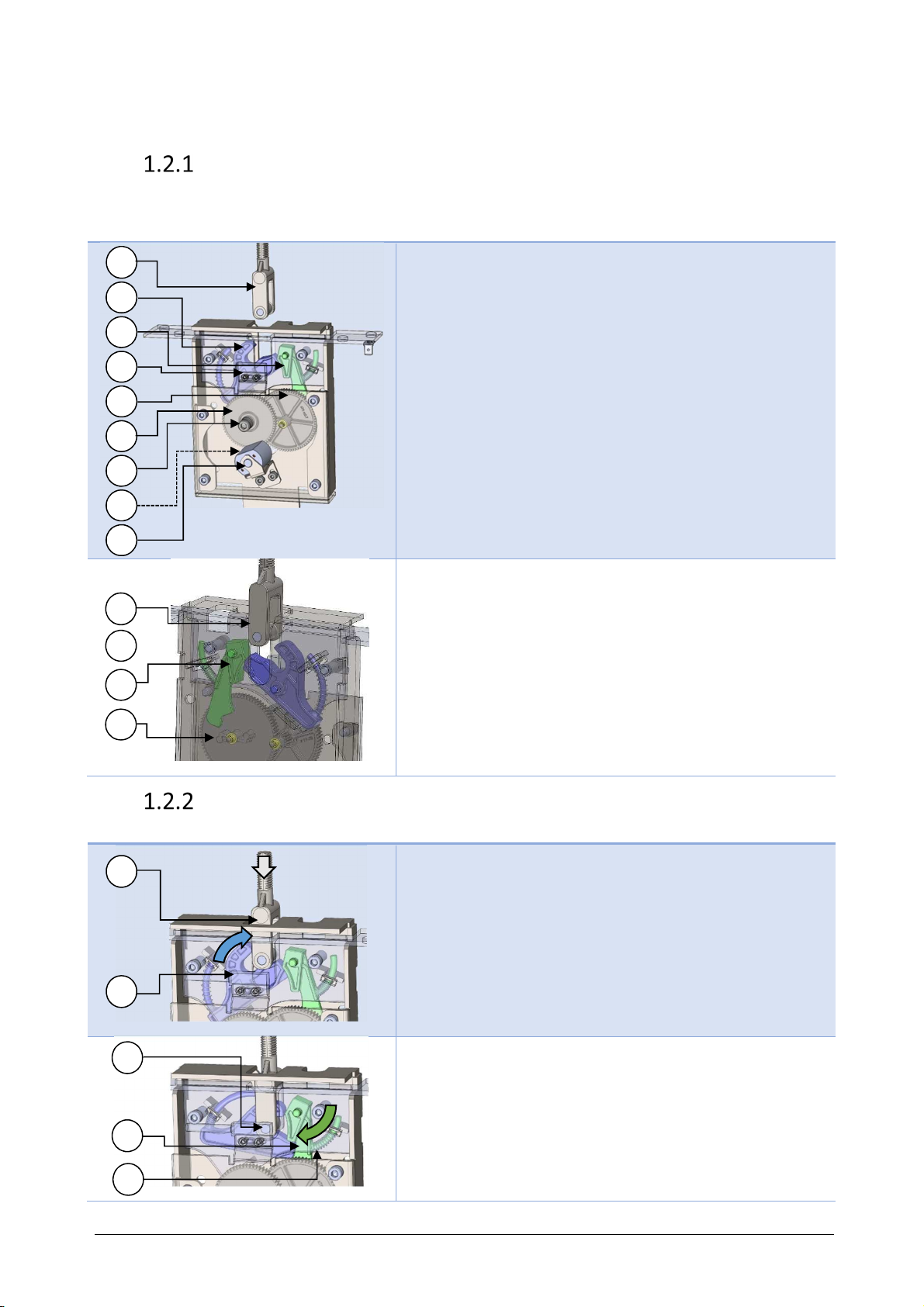

Fig. 1 Lock front view

(1) Lid latch, permanent magnet equipped.

(2) Hook.

(3) Pendulum.

(4) Microswitch contact (ILS sensor).

(5) Cogwheel (3x) :

(5a) Ratchet cogwheel

(5b) Intermediate cogwheel

(5c) Drive hole

(5d) Motor cogwheel (not visible here)

(6) Motor.

Fig. 2 Lock back view

(1) Lid latch.

(2) Hook.

(3) Pendulum.

(5a) Ratchet cogwheel

Locking the lid

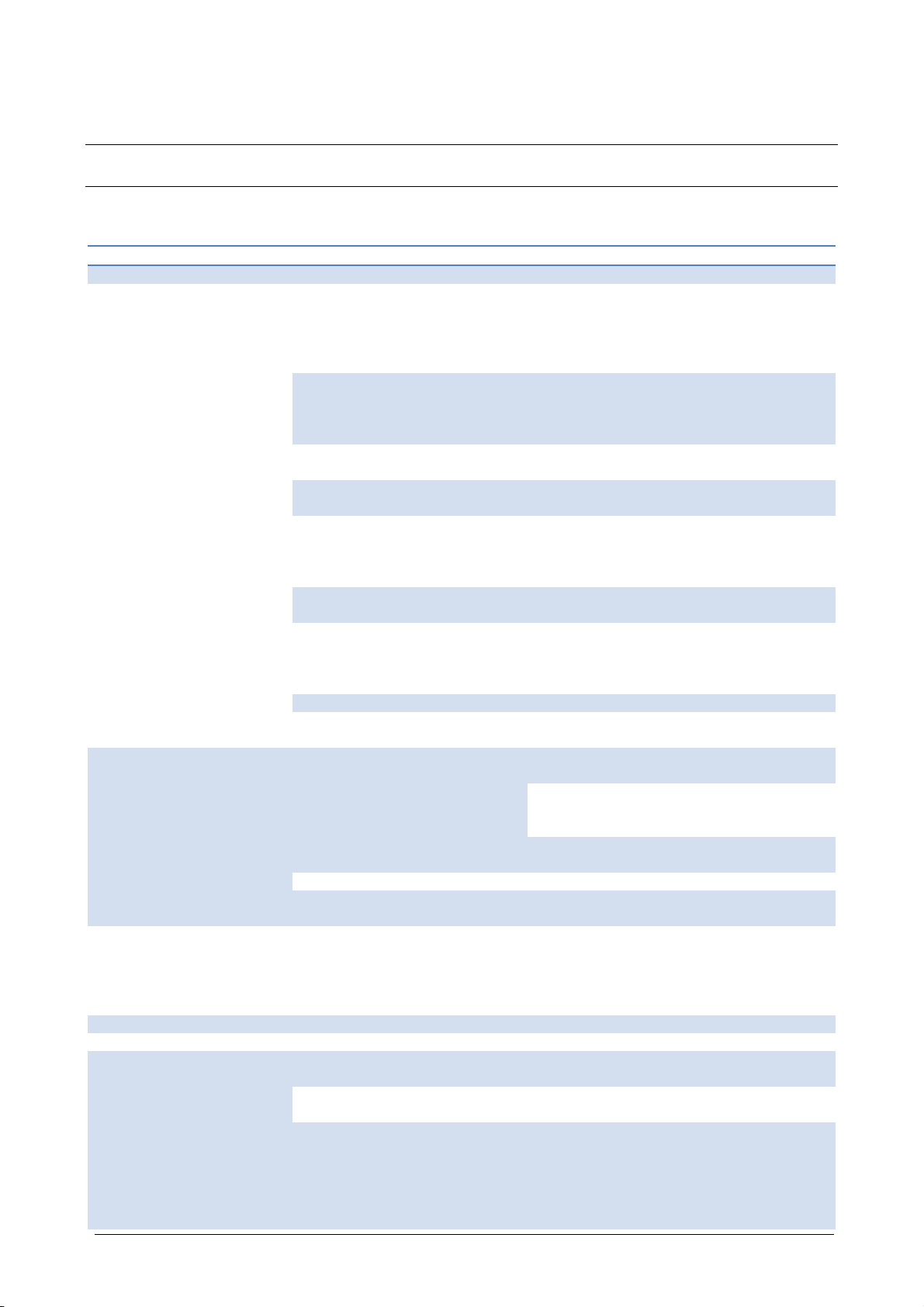

Visual Description

Fig. 3 Lock back view –locking kinematics start

1. The lid is manually lowered.

2. When lowered, the lid latch (1) pushes down the hook (2).

The hook (2) toggles to lock position

Fig. 4 Lock back view – Locked position

3. The pendulum (3) rotates, activated by a spring (3a).

It maintains the hook in locked position.

4. The permanent magnet (1a) on the latch switches on the

ILS sensor. The locked position is now electrically

detected.

2

1

3

5a

6

5d

1

2

3

3a

1a

4

2

1

3

5b

5c

5a

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 8/ 27

nlocking the lid

Visual Description

Fig. 5 Lock back view – Locked position

1. The lid is locked :

The pendulum (3) maintains the hook (2) in its position.

Fig. 6 Ratchet cogwheel pushing pendulum

2. When activated, the ratchet cogwheel (5a) pushes the

pendulum (3).

Fig. 7 Pendulum pushed

3. Pendulum (3) is completely pushed.

4. The hook (2) is now free to toggle.

Fig. 8 Rotation of the hook

5. The hook (2) toggles, activated by spring force

6. The lid latch (1) is now released.

Fig. 9 Released lid latch

7. The lid rises, helped by gas

2

3

2

3

3

5a

1

3

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 9/ 27

1.3 Motor

Three phases induction motor powered in variable voltage & frequency.

It has an integrated over temperature sensor. It measures the heating of the internal motor winding, and sends a

signal from 130 degrees Celsius. Centrifuge then display error code “# 04”.

1.4 Speed sensor

The speed sensor is a Hall Effect magnetic sensor, placed under the motor. Six (6) magnets with alternating poles

are placed on a rotating disc. The sensor measures the frequency of passage of the magnets, to determine the speed.

1.5 Temperature probe

It is located in the bowl gasket, and therefore in the rotor airflow when the rotor is in rotation.

The measurements are only taken when the rotor is rotating.

sensor is a PT500 class A probe.

At the beginning of a cycle the displayed temperature is the air temperature (air around the sensor), once target

temperature reached, the displayed temperature is that of the samples.

Before being centrifuged, the sample must be brought to the program setpoint temperature.

Use either an oven, or a refrigerator to bring it to the desired temperature.

The centrifuge is designed to maintain the temperature during a rotation cycle.

1.6 Imbalance sensor

In the case of a load presenting an imbalance, the oscillations caused will be higher than the centrifuge’s own

vibration.

The vibration sensor then intervenes to detect the movements of the centrifuge. This sensor is an electronic

accelerometer.

The systematic minimum threshold detection is: 9 gr. The detection results in an immediate shutdown of the power

supply to the motor, and a slowdown of the rotor free wheel.

This threshold is adjustable according to the media on which the centrifuge rests, in order for the imbalance sensor

to always be triggered with a minimum imbalance of 9 gr.

Cf. § 3.2Unbalancing Sensitivity Setting for the procedure to adjust the imbalance detection threshold.

1.7 Gas spring

A single cylinder allows the opening of the lid when it is released by the lock. It is a gas cylinder, fitted with a

spring. This spring allows a better relaxation at the opening start. The cylinder should open the lid without causing

rebound of the latter at the end of travel.

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 10/ 27

1.8 Absorption of vibrations

Any system has its own resonance frequency, which will cause oscillations. The dissipative elements of these

oscillations, which translate into vibrations, are anti-vibration mounts, numbering 3. This set will allow for

absorbing parasitic movements whatever the rotor, its load, and its speed, providing that the load is balanced.

Those 3 shock absorbers are placed vertically between the motor and the stabilizer bed.

1.9 Refrigeration System

The refrigerating model allows the maintenance of a sample at its initial temperature, while undergoing a rotation.

Take care to let free space around the centrifuge for airflow renewing.

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 11/ 27

2Troubleshooting & Messages

2.1 Troubleshooting

Error Codes / Description Cause Solution

01

Reserved Not used code

02

IMBALANCE Buckets don't swing freely. Clean the rotor trunions and corresponding

areas on buckets. Apply a thin film of supplied

grease on these locations. Cf. § Erreur !

Source du renvoi introuvable. Erreur !

Source du renvoi introuvable..

The rotor buckets are not loaded

symmetrically. Wait until complete stop.

Open the lid.

Load the buckets as shown in manual.

Start a new cycle.

The centrifuge is installed on an

uneven bench. Install the centrifuge on a flat bench/table, as

described in manual.

The imbalance detector is not well

calibrated. Contact a Certified Technician.

03 BOWL

OVERTEMPERATURE The temperature in the bowl is

higher than 50 °C; the room

temperature is too high.

Wait until complete stop.

Turn the AC or Ventilation system on to

obtain an ideal ambient temperature as

described in manual.

The temperature set in the program

is not adapted. The settings for speed / temperature are not

compatible with a normal utilization.

The temperature of the samples is

too high. Make sure the samples can be cooled to down

to a temperature between 4 °C and 37 °C

during 1 hour before being introduced in the

centrifuge

The refrigeration doesn’t work. Contact a Certified Technician.

The temperature probe is

malfunctioning. Contact a Certified Technician.

04 MOTOR

OVERTEMPERATURE The motor temperature is too high. A « no-brakes / free wheel» stop is occurring.

Wait complete stop before opening the lid.

Turn the AC or Ventilation system on to

obtain an ideal ambient temperature as

described in manual.

The centrifuge is being used too

intensively (ventilated model). Let the centrifuge cool down between cycles.

The motor has been damaged Contact a Certified Technician.

The temperature sensor on the

motor has a bad connection. Contact a Certified Technician.

05 LID REED SENSOR

NOT RELEASED -

OPEN

The “Reed” contact doesn’t work.

The connection of the micro

contact is not good.

The locking device is

mechanically blocked.

The “Reed” sensor was seen as closed when it

should have been seen as open (released)

when the lid opened.

Contact a Certified Technician.

06

Reserved

07

Reserved

08 POWER BOARD

SECURITY DEFAULT The power board is working

improperly. Contact a Certified Technician.

The connection to this board parts

is not good. Contact a Certified Technician to check (P1,

P3, P4, P5 pins).

09 NO SPEED SIGNAL

AT START No speed measurement within 20s

after the start of the centrifuge

The speed sensor is defective.

The speed sensor or the connection of these

elements is defective

Contact an authorized technician.

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 12/ 27

Motor is diconnected / not

properly connected

The power board is not able to

feed the motor

Contact an authorized technician.

Contact an authorized technician

10 SPEED SIGNAL LOST The speed sensor is working

improperly.

The power board is working

improperly.

The connection to these parts is

not good.

The speed signal was lost more than 6s during

rotation.

Wait for the end of the displayed countdown

before opening the centrifuge. call a Certified

Technician

11 Reserved

12 OVERSPEED Major error, the centrifuge will

stop.

Speed control device is working

improperly.

The speed measured is higher than the

maximum speed allowed for this rotor.

Check the rotor is compatible with set speed.

Contact a Certified Technician.

13 Reserved

14 Reserved

15 LID OPEN DURING

ROTATION Manual lid opening during

centrifugation, with the supplied

opening key.

Wait for the rotor stop without trying to brake

it manually: Danger: Risk of injury.

Press the START / STOP key: The message

disappears.

Press the lid control button: The mechanism

initializes.

Wrong adjustment of locking

mechanism. The hook was slightly released during the

centrifugation (enough to release the Lid lock

“Reed” sensor).

Contact a Certified Technician.

16 TEMPERATURE

CONTROL ISSUE Temperature probe out of service. Verify that the temperature probe is properly

installed under the lid and replace it if

necessary.

Remove the probe and measure the resistance.

The value must be 500+ - 100 Ohm (Probe

PT500)

17 Reserved

/ NO DISPLAY No power.

Centrifuge entered “IDLE” mode

after 4h of inactivity. In this case a

short blue flash can be observed

(Knob backlight)

Verify the power plug is connected properly.

Check the power in the laboratory.

Turn the switch on.

A short press on any key allow to wke the

system up.

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 13/ 27

2.2 Reminder messages

According machine status, recall message are displayed.They are composed of a message number & a logo.

Message

# Logo Cause Solution Command

01

The rotor needs to be greased after

200 cycles runs. Dispense synthetic grease

following Erreur ! Source du

renvoi introuvable. Erreur !

Source du renvoi introuvable.,

To acknowledge the message,

press START/STOP.

02

When less than 2,000 cycles remain

before end of rotor life, this

message appears each time a cycle

is started. The number of cycles

remaining before the machine is

stopped is displayed.

Provide rotor replacement and

complete control of the machine

before putting it back into service.

03

The rotor and its buckets have

reached the end of their life. They

are obsolete. The centrifuge and its

rotor are no longer usable until the

rotating accessory has been

changed.

Contact a dealer to renew your

rotating accessories. An

authorized technician will

proceed with the return to service.

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 14/ 27

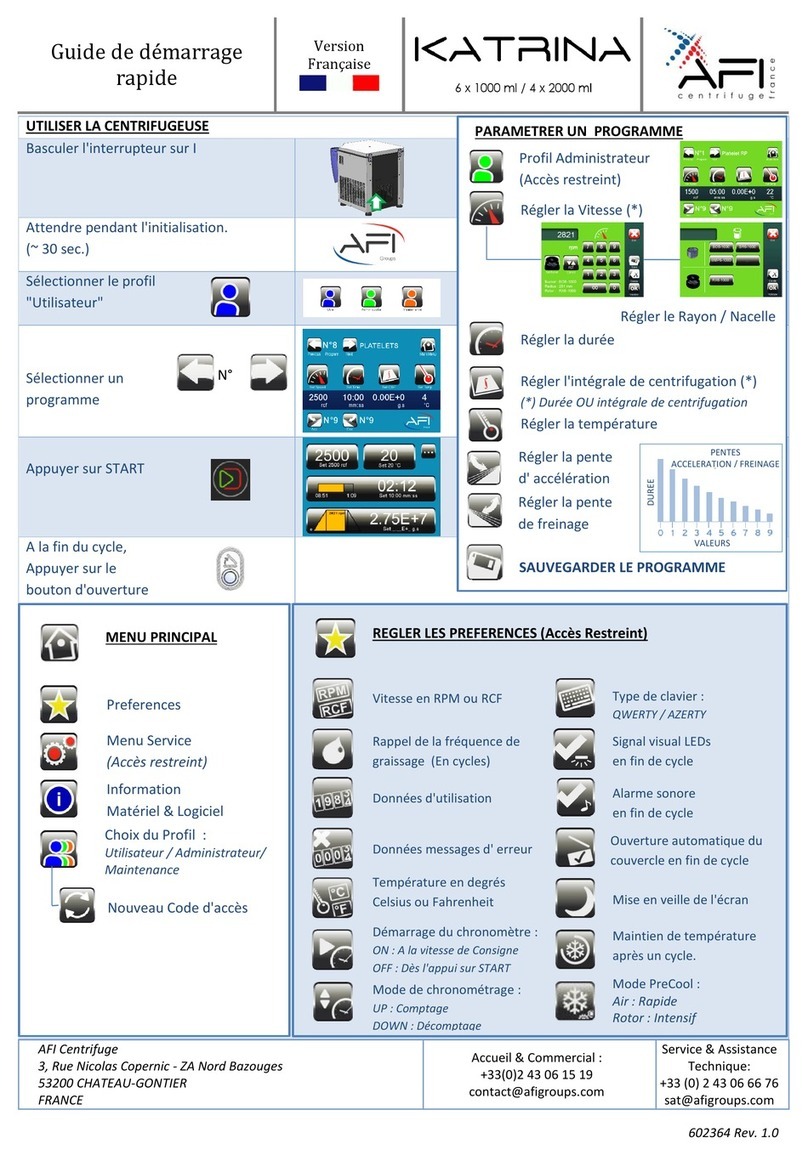

3Settings

3.1 Access to parameters

Advanced parameters

To access to advanced parameters menu, follow instructions:

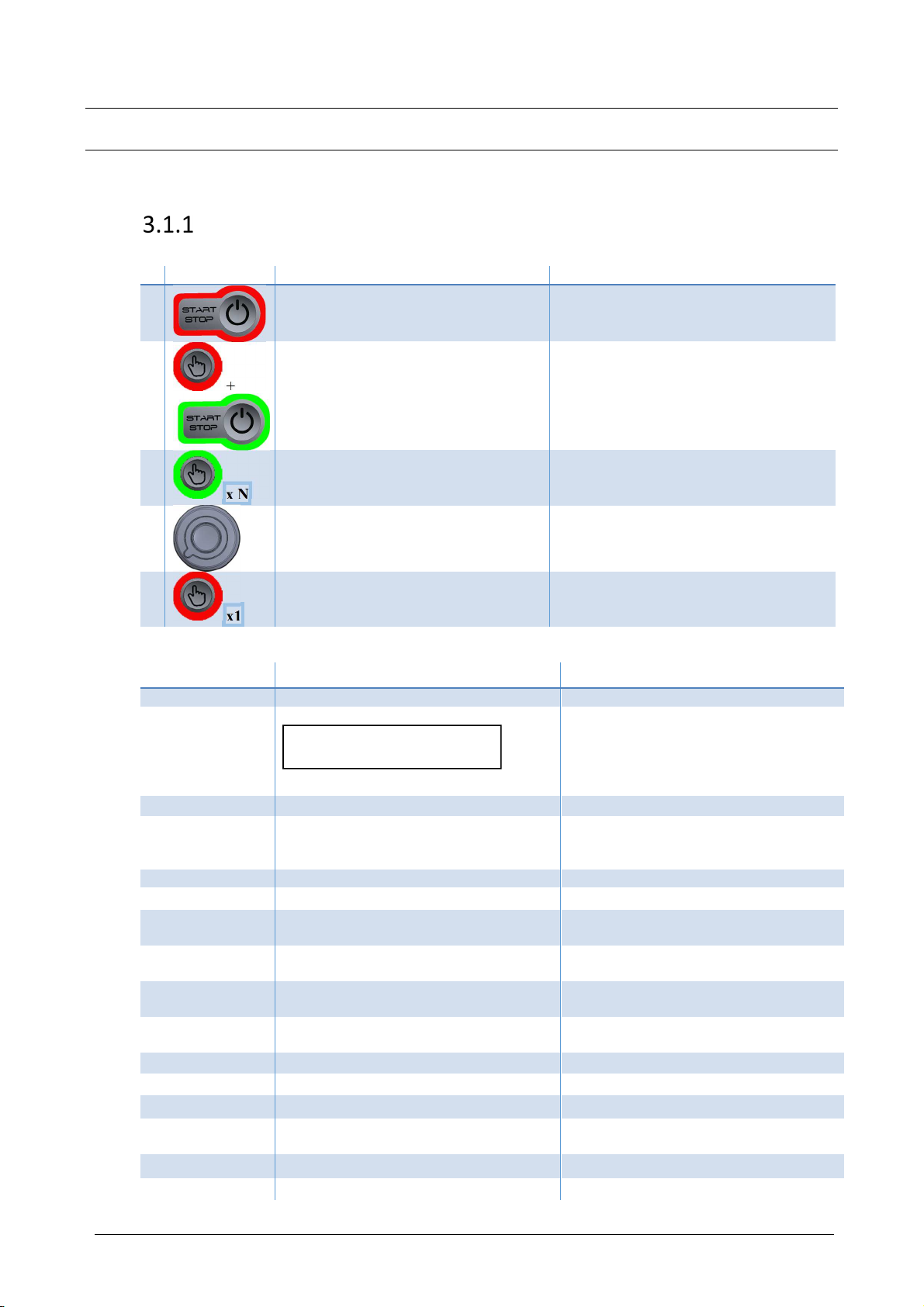

# Action on ISA

Instruction

Effect

1

Press & hold START/STOP button to

switch to sleep mode.

2

+

Press & hold validation button & press

START button to access to advanced

parameters.

The software revision is displayed.

3

x N

Press validation button as many times as

necessary to access following

parameters.

4

Modify value spinning the Advanced parameter setting is modified.

5

x1

Press & hold validation button to save &

exit advanced parameters mode. The modification of the selected

parameter is saved.

Advanced parameters are listed bellow :

Displayed codes Description Details

SOFT Microcontroller software release

A1 Imbalance setting

The higher the value, the bigger imbalance

is tolerated. (Default value : 350)

Only certified technicians are

authorized to adjust this value. Any

damage can occur if not followed).

A2 Temperature offset (± 5 degrees) Refrigerating model only

A3 Countdown starting at speed (On/Off) On : Timer starts at set speed reached.

Off : Timer starts as soon as rotor begins

spinning (default value).

A4 End of cycle sound signal (On/Off) Default value : On

A5 Alarm sound signal (On/Off) Default value : On

A6 Available program number setting

(20 or 40 or 99) Default value : 20

A7 Speed adjusting step setting

(50 or 100 rpm) Default value : 100 rpm

A8 RCF adjusting step setting

(50 or 100 rcf) Default value : 100 rcf

A9 Time adjusting step setting

(15 or 30 min/sec) Default value : 15 min/sec

L1 Total number of cycles

L2 Total number of high speed cycles*

L3 Running hours counter – all cycles

L4 Running hours of high speed cycles

counter*

L5 Cooling unit starts counter Refrigerating Model

L6 Cooling unit running hours Refrigerating Model

CAUTION

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 15/ 27

L7 Number of lid openings (lid motor

activation)

L8 Last error code Last detected error

(*) high speed means: > 4500 RPM

Service parameters

To access to service parameters, follow instructions:

When reaching L7 code in advanced parameters (cf. previous paragraph), press & hold validation button.

# Action on ISA

Instruction

Effect

1

Press & hold validation button & press

START button to access to service

parameters.

2

x N

Press validation button as many times as

necessary to access following parameters.

3

Modify value spinning the Advanced parameter setting is modified.

4

x1

Press & hold validation button to save &

exit advanced parameters mode. The modification of the selected

parameter is saved.

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 16/ 27

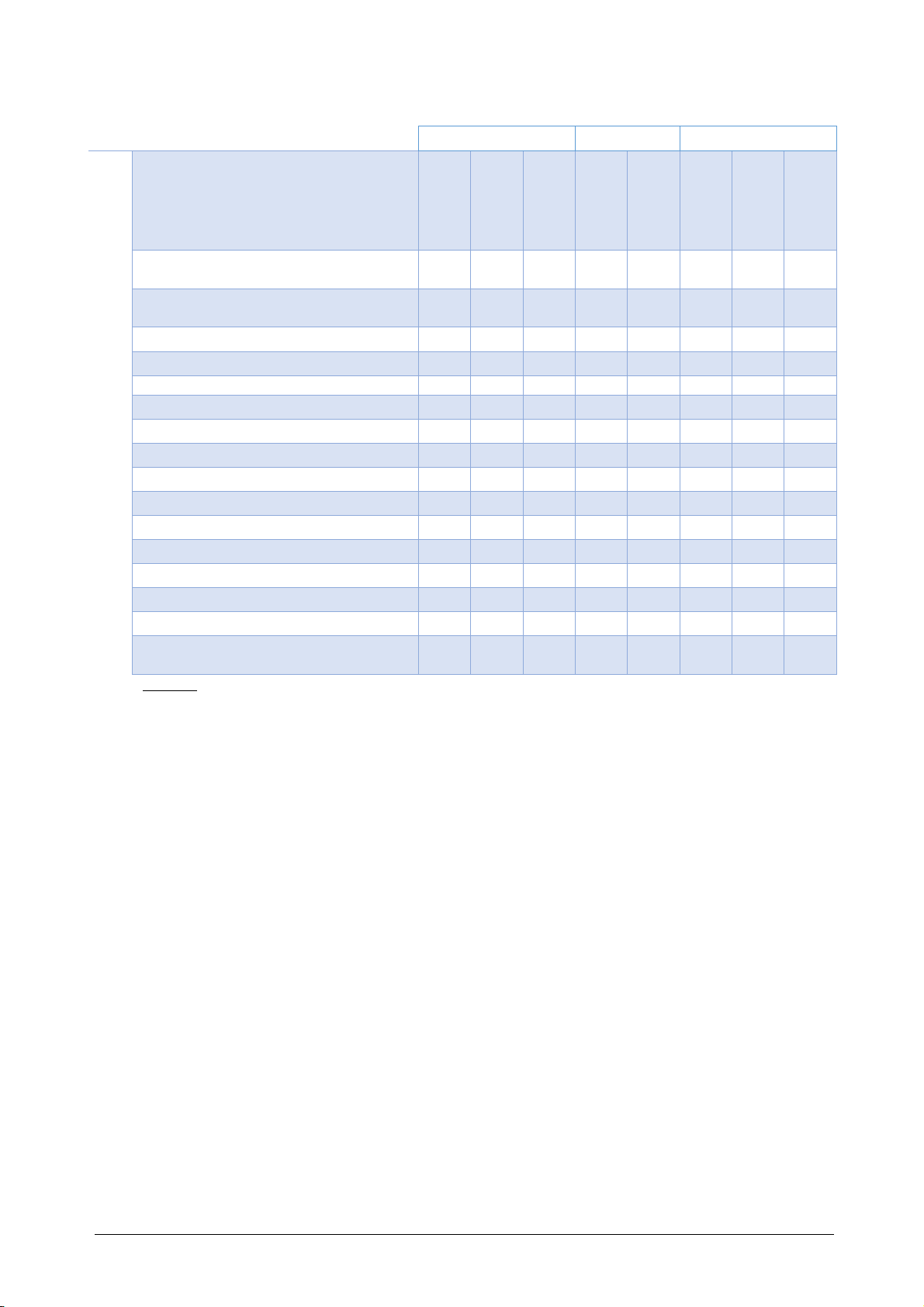

Service parameters

Availability Value range Default values

Ventilated

Refrigerting

min

max

Default ISA

V

Default ISA

R

b1 Buttons sensitivity (START / ST P &

Validation button)

Y Y 4 10 10 10

b5 Speed sensor feedback Y Y 0 6553

5

N/A N/A

b6 Lid locked sensor feedback Y Y 0 1

b7 pen button feedback Y Y 0 1

b8 PFC Feedback Y Y 0 1

b9 Lid motor test Y Y b F

b10 Motor over temperature Y Y 0 1

b11 Compressor starting test N Y n ff

b12 Potentiometer on knob angle Y Y 0 270

b13 Power driver temp / fault feedback Y Y 0 5000

b14 Power driver current feedback Y Y 0 5000

b17 Lock temporization Y Y 0 900 100 100

b18 Factory Reset Y Y n ff ff ff

b19 Motor voltage Y Y 180 230 180 180

b20 Last imballance measurement Y Y 0 999

b21 Potentiometer adjust (CAN value for max

rotation)

Y Y 3400

4000 3810 3810

Legend : Y : Yes / N : No

b :

backward / F : Forward)

N/A : Not Affected

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 17/ 27

Operating Service parameters

b1 (Setting) Sensitivity of START/STOP & validation buttons, the higher the value, the more the

sensibility of the button increases

b5 (Diagnostic) :

Tachometer diagnostic Open the lid.

With b5 parameter displayed, turn manually the rotor. The speed is displayed on the

screen.

b6 (Diagnostic) Open the lid.

With b6 parameter displayed, lower the lid.

When the magnetic hinge is detected, the lid status changes to 1.

b7 (Diagnostic) With b7 parameter displayed, press onto the lid opening button.

When pressed button is detected, the lid button status changes to 1.

b8 (Autotest) With b8 parameter displayed, the PFC voltage should deliver 400 V voltage: The

status is 1.

b9 (Diagnostic) With b9 parameter displayed, select "b" value (backward) : The lock motor turns

clockwise.

Select "F" value (Forward) : The lock motor turns counterclockwise. It is the only

direction used by the centrifuge in normal operation.

After this test, in stand-by mode, close the lid & press lid button for lock

initialization.

b10

(Autotest)

With b10 parameter displayed, the motor over temperature is tested.

The status is 1 in case of motor over temperature (or disconnected sensor).

b11 (Diagnostic) With b11 parameter displayed, select "On".

The cooling compressor & fans start.

b12 (Diagnostic) With b12 parameter displayed, turn the knob. The knob angle value is displayed.

b13 (AutoTest) With b13 parameter displayed, the value indicated IGBT temperature proportional

value (Insulated Gate Bipolar Transistor)

b14 (AutoTest) With b14 parameter displayed, the value indicated IGBT voltage proportional value

(Insulated Gate Bipolar Transistor)

b17 (Setting) Open the lid.

With b17 parameter displayed, the higher the value is set, the later the lid lock stops

after lid releasing detection.

b18 (Factory Reset) With b18 parameter displayed, to reset data, select "On" to set bck to Factory

settings.

The Factory reset sets default values on Program parameters, and advanced

parameters (A1 to A9 parameters). Once validated, wait for 10 seconds before STOP

& re-START the centrifuge.

b19 (Setting) Motor voltage can be selected, 2 values are possible: 180V and 230V. This settings

shall correspond to the motor characteristics

b20 (Diagnostic) Maximum vibration level measured during last centrifugation cycle

b21 (Setting) Value starting from which software shall identify potentiometer max rotation 270°C.

( potentiometer deviation compensation)

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 18/ 27

3.2 nbalancing Sensitivity Setting

The centrifuge has a reaction to the load balancing faults which may be different depending on the media on which the

centrifuge is placed. Check following items before any setting adjustment:

-Balanced bucket loadings,

-Installation instructions, conform to User Manual,

-Visual inspection,

-Cleaning rotor trunions & buckets for proper bucket balancing,

-Lubricating rotor trunions.

Required material:

7 grams weight

10 grams weight

Operating:

1. Place a 7 grams weight into a bucket, as unique load of the swing-out rotor.

When processing a 2000 rpm set speed cycle, no error code must appear.

2. Place a 10 grams weight into a bucket, as unique load of the swing-out rotor.

When processing a 2000 rpm set speed cycle, the error code #02 must appear.

3. Then, reproduce 2x each of previous test: the result must be unchanged.

If the tests are not conform, adjust A1 advanced parameter as following:

The higher the value, the bigger imbalance is tolerated. (Default value: 350).

Caution

Always check a 10 grams imbalance is detected.

An excess imbalance tolerance could deteriorate the centrifuge.

Remark:

Along this adjustment process, Parameter b20 can be used to check the measured vibration level (last centrifugation

cycle). This can help optimizing the threshold setting.

Original Instructions - Rev.1.0 Service Manual– ISA Centrifuges 19/ 27

3.3 Setting the Time Delay of the lock

See Tech note, attached with lid lock service kit.

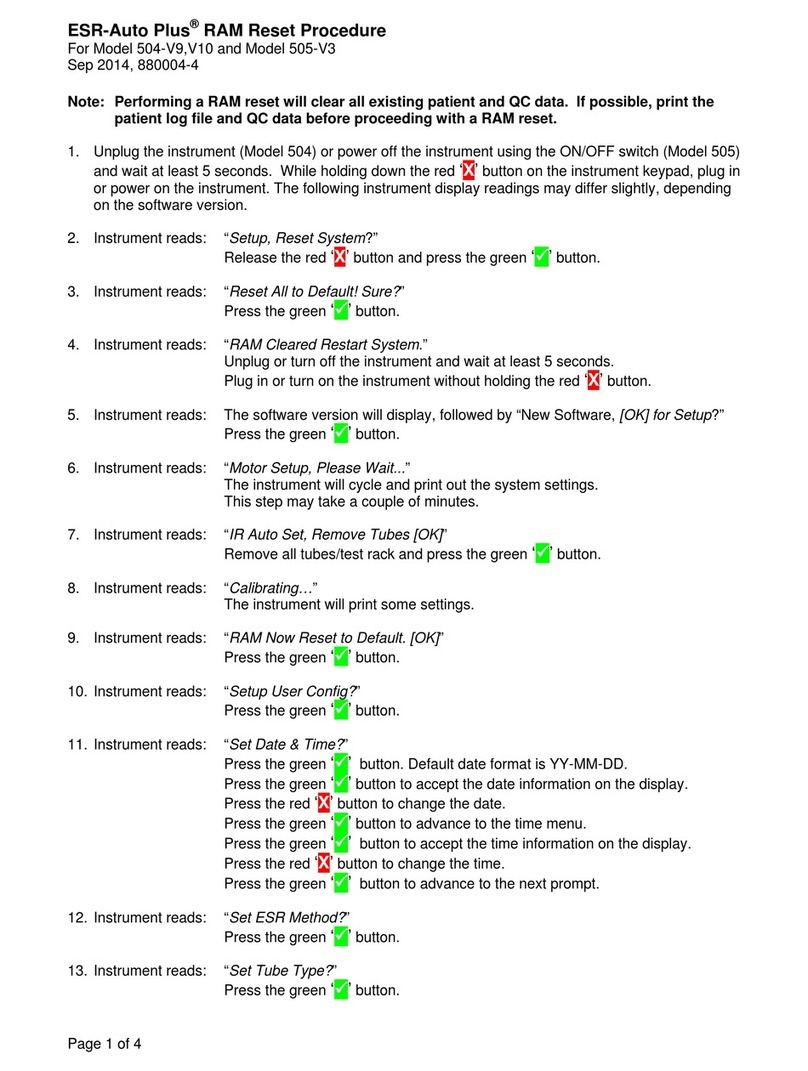

3.4 Loading the firmware

Required material :

-USB flash drive / stick, in FAT 32 format. Max. size : 32 GB.

-1 firmware file in *.bin format

Note : Take care to let the firmware file as unique file on root directory of USB drive.

Note 2 : Before loading firmware, note current version. Cf. following step 9.

Operating :

1. Unplug the centrifuge from power supply.

2. Connect USB drive to the centrifuge

3. Connect the centrifuge to power supply

USB key is being detected during 5 seconds.

The firmware is being loaded : A red spinning circular light while processing.

When successfully loaded, the light turns to solid green.

4. Unplug the centrifuge from power supply

5. Disconnect the USB drive

6. Connect the centrifuge to power supply

7. Check firmware revision through Advanced parameters :

7.1. Press & hold START/STOP button for Sleep mode access.

7.2. Press & hold Validation button & press START/STOP button for Advanced parameters access.

7.3. The firmware release is displayed.

4Standard Exchange of Components

4.1 Safety Rules

Before any repair intervention, observe the safety rules by turning off and unplugging the centrifuge.

In the event of non-compliance with these instructions, there is a risk of electrical shock.

4.2 Terminology

The kits and spare parts are specific to specific appliance models.

The crosses in the right part of the table allow you to define the part corresponding to the device concerned.

Symbol Description

V Ventilated Models

R Refrigerating Models

120V Models 120V / 60 Hz

230V Models 230V / 50 Hz

Wear Parts.

The figure corresponds to an estimated life in years, before change, for preventive maintenance,

in the case of use, maintenance and care consistent with the user manual.

In the contrary case, or for intensive uses, these life cycle durations may be decreased.

Kit The spare part is delivered with a set of parts required for its implementation,

as well as the procedure or Technote.

This manual suits for next models

3

Table of contents

Other AFi Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Fritsch

Fritsch PULVERISETTE 7 premium line operating instructions

Dynamica

Dynamica VELOCITY 14 Pro instruction manual

Opsytec Dr. Grobel

Opsytec Dr. Grobel BS-02 manual

Renfert

Renfert Catalyser 2300-0001 instruction manual

Matec

Matec CHDF 2000 Hardware manual

McLane Research Laboratories

McLane Research Laboratories Mark 78H-21 user manual