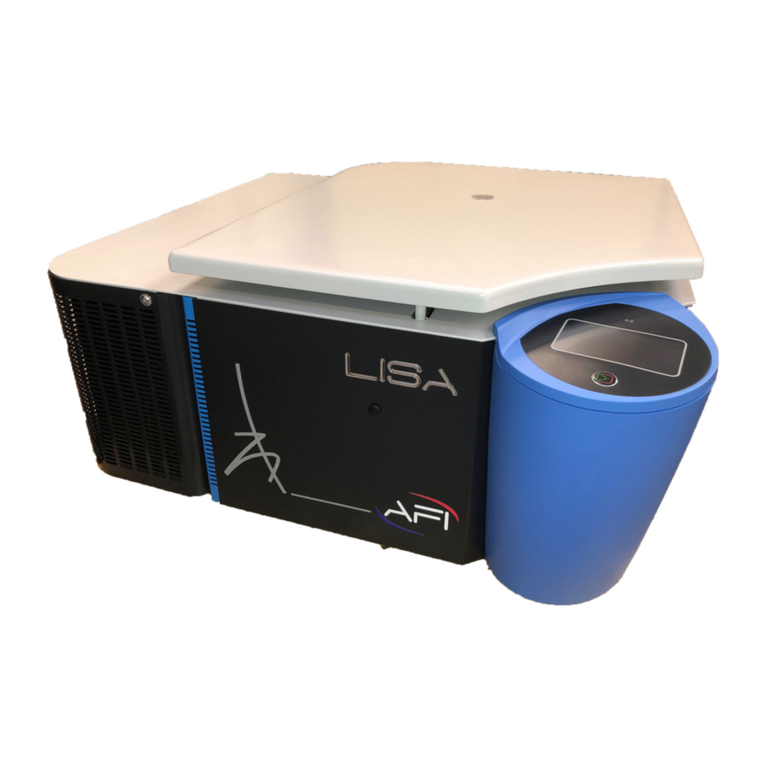

AFi Lisa AFI-C200 Series User manual

Maintenance Manual -

Revision 1.4 -

English version

602398

This document has been prepared with the utmost care. However, AFI

Centrifuge refuses to accept any responsibility in the event of errors or

omissions. The same applies to any damage arising from the use of

information contained in this manual.

AFI Centrifuge

3, Rue Nicolas Copernic

ZA Nord Bazouges

53200 CHATEAU-GONTIER

FRANCE

+33 (0) 2 43 06 66 76

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 2/ 41

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 3/ 41

You have just purchased one of the finest Laboratory Centrifuges available. With proper care, maintenance

and laboratory procedure, this centrifuge will provide you years of productive service. Please read this manual

carefully to familiarize you with proper installation, and operation of the centrifuge. Other information are

available on our website, www.aficentrifuge.com .

Warranty

AFI Centrifuge. warrants AFI-C200 Series LISA & AFI-C300 Series LOREENA Centrifuge that it will repair F.O.B. its

factory or furnish without charge F.O.B. its factory a similar part to replace any material in its equipment within

24 months after the date of sale if proved to the satisfaction of the company to have been defective at the time

it was sold provided that all parts claimed defective shall be returned, properly identified to the company at its

factory, charges prepaid. Factory installed equipment or accessories are warranted only to the extent

guaranteed by the original manufacturer, and this warranty shall not apply to any portion of the equipment

modified by the user. Claims under this warranty should be directed to AFI Centrifuge. setting forth in detail

the nature of the defect, the date of the initial installation and the serial and model number of the equipment.

This warranty shall not apply to any AFI Centrifuge product or part thereof which has been subject to misuse,

abuse, accident, shipping damage, improper installation or service, or damage by fire, or flood. If the serial

number of this product is altered, removed or defaced as to be illegible, the Warranty shall be null and void in

its entirety.

The warranty is for the sole benefit of the original purchaser and is not assignable or transferable. Prior to

returning any item, for any reason, contact AFI Centrifuge for a Return Authorization Number. This number

must accompany all returns. Any product shipped to AFI Centrifuge without this number will be returned

refused shipment or collect freight.

Explanation of Symbols

Safety alert symbol indicates a potentially hazardous

situation which, if not avoided, could result in death or

serious injury

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

Safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in minor or

moderate injury.

Pinching: This warning symbol indicates the presence of a

risk of pinching when handling the lid.

Note:

Used for important information

Potential electrical hazard, only qualified person to access

Biohazard

Ground, Earth

Lead Free

CAUTION

!

CAUTION

WARNING

!

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 4/ 41

Updates

Date

Revision

Modification

Paragraph

Author

11 Oct. 2016

1.2

Error3 detection, Add counter

modification menu &

overtemperature alarm. Reset.

Ogival control unit change procedure

2.2, 3.7, 3.8,

3.11

F. LE CAM

July, 4th, 2017

1.3

Missing rotor detection, Auto-

Diagnostic.

2.2, 3.5, Erreur !

Source du

renvoi

introuvable.

F. LE CAM

August, 28th, 2018

1.4

Add 3 Liter Loreena series,

Information menu changed.

1, 1.2.2, 3.4.2,

4.3.2, 6.3, 6.4,

7.4

F. LE CAM

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 5/ 41

Table of contents

1DESCRIPTION OF THE CENTRIFUGE .......................................................................................................... 7

1.1 ELECTRONIC CONTROL CENTER /BLOCK ................................................................................................................... 7

1.2 LOCK ................................................................................................................................................................. 9

1.3 MOTOR ........................................................................................................................................................... 10

1.4 SPEED SENSOR................................................................................................................................................... 10

1.5 TACHOMETER BOARD.......................................................................................................................................... 10

1.6 TEMPERATURE PROBE ......................................................................................................................................... 10

1.7 IMBALANCE SENSOR............................................................................................................................................ 10

1.8 GAS SPRING ...................................................................................................................................................... 10

1.9 ABSORPTION OF VIBRATIONS ................................................................................................................................ 11

1.10 VENTILATION SYSTEM:VENTILATED MODEL............................................................................................................ 11

1.11 REFRIGERATION SYSTEM:REFRIGERATING MODEL.................................................................................................... 11

1.12 FRAME............................................................................................................................................................. 11

1.13 LID :VENTILATED MODEL .................................................................................................................................... 11

1.14 LID :REFRIGERATING MODEL ............................................................................................................................... 11

2TROUBLESHOOTING................................................................................................................................12

2.1 TROUBLESHOOTING............................................................................................................................................ 12

2.2 ERROR MESSAGES.............................................................................................................................................. 12

3SETTINGS ................................................................................................................................................15

3.1 ACCESS TO THE TECHNICIAN MENU ....................................................................................................................... 15

3.2 SETTING THE TEMPERATURE PROBE........................................................................................................................ 16

3.3 UNBALANCING SENSITIVITY DETECTION .................................................................................................................. 16

3.4 SETTING THE LOCK.............................................................................................................................................. 18

3.5 AUTO-DIAGNOSTIC ............................................................................................................................................ 20

3.6 INFORMATION UPDATE........................................................................................................................................ 21

3.7 COUNTERS MODIFICATION ................................................................................................................................... 21

3.8 OVERTEMPERATURE ALARM MENU ........................................................................................................................ 22

3.9 LOADING THE FIRMWARE..................................................................................................................................... 22

3.10 SOFTWARE IDENTIFICATION: ................................................................................................................................ 22

3.11 FACTORY RESET ................................................................................................................................................. 23

3.12 CLEAR COUNTERS............................................................................................................................................... 23

4STANDARD EXCHANGE OF COMPONENTS ..............................................................................................24

4.1 SAFETY RULES ................................................................................................................................................... 24

4.2 TERMINOLOGY .................................................................................................................................................. 24

4.3 SPARE PARTS &TOOLS ........................................................................................................................................ 25

4.4 SETTING FORM .................................................................................................................................................. 27

5FUNCTIONAL CHECKS..............................................................................................................................29

5.1 SAFETY............................................................................................................................................................. 29

5.2 SPEED CHECK .................................................................................................................................................... 29

5.3 CHECKING THE TIMER ......................................................................................................................................... 30

5.4 CHECKING THE TEMPERATURE .............................................................................................................................. 30

6ELECTRICAL DIAGRAMS...........................................................................................................................31

6.1 2.0 LITER VENTILATED MODEL :LISA /C200V &C200VE SERIES.............................................................................. 31

6.2 2.0 LITER REFRIGERATING MODEL :LISA /C200R &C200RE SERIES ......................................................................... 32

6.3 3.0 LITER REFRIGERATING MODEL :LOREENA /C300V ............................................................................................ 33

6.4 3.0 LITER REFRIGERATING MODEL :LOREENA /C300R-C300RE-C300RF-C300RFE SERIES......................................... 34

7REFRIGERATING SYSTEM ........................................................................................................................35

7.1 2.0 LITER 115V MODEL ..................................................................................................................................... 35

7.2 2.0 LITER 230V MODEL ..................................................................................................................................... 36

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 6/ 41

7.3 3.0 LITER BENCHTOP MODEL............................................................................................................................... 37

7.4 3.0 LITER FLOOR STANDING MODEL...................................................................................................................... 38

8ANNEXES ................................................................................................................................................39

8.1 RETURN AUTHORIZATION..................................................................................................................................... 40

8.2 TECHNOTES ...................................................................................................................................................... 41

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 7/ 41

1Description of the Centrifuge

The centrifuge range is composed of :

2 Liter centrifuges, LISA series :

References

Model

AFI-C200V

Ventilated, 120V / 60Hz

AFI-C200VE

Ventilated, 230V / 50Hz

AFI-C200R

Refrigerating, 120V / 60Hz

AFI-C200RE

Refrigerating, 230V / 50Hz

3 Liter centrifuges, LOREENA series.

References

Model

AFI-C300V

Benchtop, Ventilated, 120V / 60Hz

AFI-C300VE

Benchtop, Ventilated, 230V / 50Hz

AFI-C300R

Benchtop, Refrigerating, 120V / 60Hz

AFI-C300R-E

Benchtop, Refrigerating, 230V / 50Hz

AFI-C300RF

Floor stand, Refrigerating, 120V / 60Hz

AFI-C300RF-E

Floor stand, Refrigerating, 230V / 50Hz

The centrifuge is composed of:

an electrical block, called Ogival Control Center.

a lock

a motor

a ventilation or refrigeration system (depending on the model)

a one-piece frame

a lid

It is equipped with one or several rotors:

Free or swing-out

Angular

The free rotors are fitted with:

Buckets

Tube adapters or inserts

Watertight lids

Some angular rotors are equipped with tight fitting lids.

1.1 Electronic Control Center / Block

The electrical block, or Control Center, includes a touch screen, a control button, the main switch, a lid opening

button, as well as the microcontroller electronic board, and the electrical power supply electronic board.

There is no provision for changing the elements composing the Control Center. It is a complete separate part. In

case of defective element, a standard exchange of the complete Control Center must be considered, which

facilitates the restoration of the centrifuge.

1.1.1 .Touch Screen

The display is based on a TFT type display its size is 4.3”. It offers 480X272 pixels, and 16 Million colors.

It is also equipped with LED lighting for bright background.

The screen is also touch, and resistive type. It provides access to many features when using the interface.

The display and display card unit is located in the upper part of the Control Center.

1.1.2 .Start/Stop Button

The control button placed under the screen allows for controlling the startup and interruption of a centrifugation

cycle.

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 8/ 41

1.1.3 .Main Switch

The main switch is located under the Control Center. It allows for completely shutting off power to the

centrifuge.

1.1.4 .Cover Opening Button

The lid opening is controlled by the button on the right side of the Control Center.

1.1.5 .Electronic microcontroller Board

The electronic microcontroller board is located under the display card. The data for controlling the various parts

are stored in this board, in the form of software, also marked “Display fw”

The connection for the update of this software is below the Control Center, via the connection kit

part no. 71122001.

The procedure is described in the technote AP2.002 Software programming, in annex.

This board communicates with:

•The tachometer board

•The various lid position sensors for detecting the lid position,

•The touch display card

•The programming connector

•The temperature probe

•The Start / Stop control button on the membrane

•The lid opening button on the right side of the Control Center.

1.1.6 .Electronic Power Board

This board is powered by the transformer.

The electronic tachometer board controls:

•The microcontroller board

•The display card

•The centrifuge motor

•The refrigeration group

•The lock motor

It also transmits the power accumulated during rotor braking to the load shedding resistance.

1.1.7 .Transformer

The transformer generates 3 voltages identified by the following colors:

Tension

26V

16V

10V

18.5 V

Colour

Green

Yellow

Red

Black

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 9/ 41

1.2 Lock

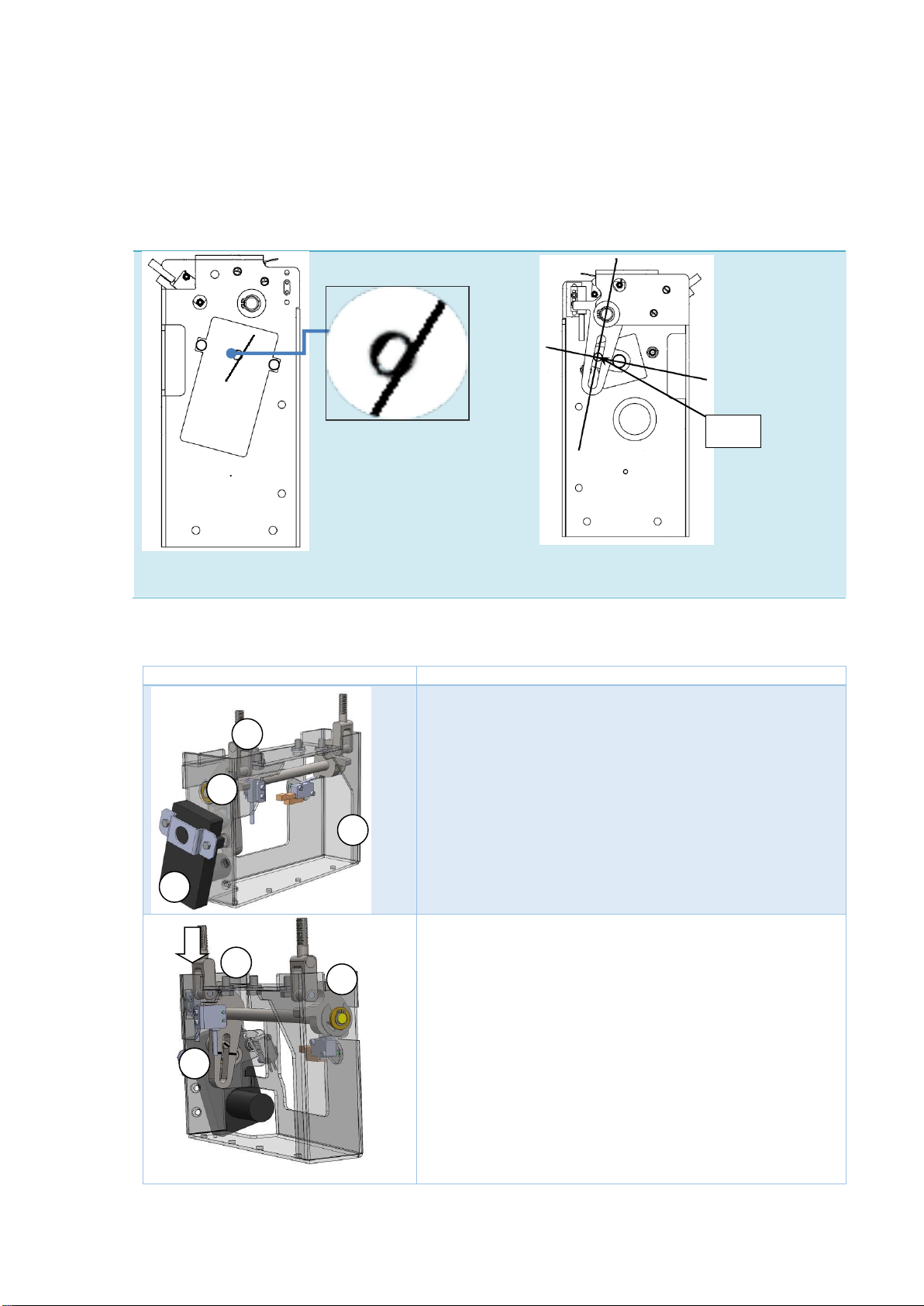

1.2.1 .LISA Model

The lock consists of a media on which the following are assembled:

Description

1) Micro contact / Micro switch No. 1:

It detects the open position of the lock.

The deadbolt presses on the micro switch blade when

the lid strike plate is completely released.

2) Micro contact / Micro switch No. 2:

It detects the closed position of the lid.

The guide finger comes in contact with the micro switch

blade when the lid is closed.

This signal stops the gear motor command.

A “Lid lock tempo” timer allows for adjusting the stop for

proper locking.

3) Magnetic sensor:

It detects the approach of the lid. The integrated magnet

in the lid strike plate allows for starting the gear motor

command.

4) Deadbolt:

It pivots to mechanically immobilize the lid.

5) Crankshaft:

It actuates the deadbolt through the motor reducer.

The locking position is obtained when the crankshaft and

the deadbolt form a 90 degree angle.

This position is marked by the trace on the visible face.

6) Trace from the locked position

7) Motor reducer:

It rotates counter-clockwise to close and clockwise to

open. It is supplied with a voltage of 24 V.

1.2.2 .LOREENA Model

Description :

1) Lid latches. Both of them is equipped with 2 magnets.

2) Latch approach sensor (Magnetic switch).

3) Closed position sensor (Magnetic switch). It detects the

latch postion.

4) Crankshaft: This is the moving part driven by the motor

reducer.

5) Locked position sensor (microswitch contact). It detects

the deadbolt when the device is locked.

6) Motor reducer. It turns counter-clockwise for closing,

and clockwise for opening. (Viewed from outside the

machine)

7) Hook. They are part of the "welded shaft" & deadbolt.

This welded shaft is moved through the crankshaft,

which moves in the oblong guide zone of the deadbolt.

8) Open position sensor. (microswitch contact). It detects

the hook when the device is unlocked.

9) Alignment marks of deadbolt and crankshaft. When

aligned, the device is in locked position.

1

2

3

4

5

6

Visible face - when

the front panel is

removed

Internal Face - after

extraction of the

lock unit

7

1

3

8

6

4

5

7

2

9

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 10/ 41

1.3 Motor

It is a three phase induction motor powered in variable frequency.

It has an integrated over temperature sensor. It measures the heating of the internal motor winding, and sends a

signal from 130 degrees Celsius. It then sends the message “ERROR 04”.

1.4 Speed sensor

The speed sensor is a Hall Effect magnetic sensor, placed under the motor. Six (6) magnets with alternating

poles are placed on a rotating disc. The sensor measures the frequency of passage of the magnets, to

determine the speed.

1.5 Tachometer board

The tachometer board is composed of:

1) The connection to the tachometer sensor

2) The connection to the Control Center

3) The accelerometer: It detects the vibrations emitted by the

centrifuge. The triggering threshold is set by the menu for

setting the sensitivity to the imbalance: see §. 3.3

4) The accelerometer is perfectly maintained by the 5 mounting

points.

1.6 Temperature probe

It is located under the lid, and therefore nearest to the samples when the lid is closed and the rotor is in rotation.

The measurements are only taken when the rotor is rotating.

It is a PT500 class A probe.

During a centrifugation cycle, the temperature displayed on screen is that of the sample.

Before being centrifuged, the sample must be brought to the program setpoint temperature.

Use either an oven, or a refrigerator to bring it to the desired temperature.

The centrifuge is designed to maintain the temperature during a rotation cycle.

1.7 Imbalance sensor

In the case of a load presenting an imbalance, the oscillations caused will be higher than the centrifuge’s own

vibration.

The vibration sensor then intervenes to detect the movements of the centrifuge. This sensor is an electronic

accelerometer. It is placed at the level of the tachometer board, located to the side of the shield, and sends the

information to the microcontroller board.

The systematic minimum threshold detection is: 25 gr. The detection results in an immediate shutdown of the

power supply to the motor, and a slowdown of the rotor free wheel.

This threshold is adjustable according to the media on which the centrifuge rests, in order for the imbalance

sensor to always be triggered with a minimum imbalance of 25 gr see Section 3.3 for the procedure to adjust the

imbalance detection threshold.

1.8 Gas spring

A single cylinder (Lisa model), or double (Loreena model) allows the opening of the lid when it is released by

the lock. It is a gas cylinder, fitted with a spring. This spring allows a better relaxation at the opening start. The

cylinder should open the lid without causing rebound of the latter at the end of travel.

1

2

3

4

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 11/ 41

1.9 Absorption of vibrations

Any system has its own resonance frequency, which will cause oscillations. The dissipative elements of these

oscillations, which translate into vibrations, are anti-vibration mounts, numbering 4, coupled by an absorbent

foam. This set will allow for absorbing parasitic movements whatever the rotor, its load, and its speed, providing

that the load is balanced.

Three (3) of these mounts are placed vertically between the motor and the stabilizer bed.

The 4th mount acts horizontally. It is located under the machine frame.

1.10 Ventilation System: Ventilated Model

The ventilated model allows for heat exchange between the inside of the centrifugation bowl and the ambient air.

The air inlets are installed in the lower part of the lid. This ambient air is sucked in and enters the bowl by the

central part of the lid.

During rotation, the friction between the rotor and the air causes overheating. The hot air is expelled by the

circular part under the lid. A circuit allows this air to descend through the centrifuge body, by the duct located on

the right, near the hinge. A silencer allows you to evacuate the air from the rear, under the unit. The heat caused

by motor rotation is also evacuated by this conduit.

1.11 Refrigeration System: Refrigerating Model

The Refrigerating model allows the maintenance of a sample at its initial temperature, while undergoing a

rotation. It is possible to maintain a temperature from -10°C to 40°C.

Maximum performance for an ambient temperature of 20+ /- 2°C, with the RX625 rotor (equivalent to RX500

rotor) and the BX625 bucket (equivalent to BX500 bucket):

2. 0 Liter: continuous maintenance of 4°C at 4200 rpm,

3. 0 Liter: continuous maintenance of 4°C at 3600 rpm,

1.12 Frame

It is a one-piece frame: The safety shield allowing for absorbing the energy deployed by the rotor in the event of

an accident is directly visible from outside the machine. This allows you to limit the parts, and the sources of

vibration.

1.13 Lid : Ventilated Model

The lid is fitted with an anti-vibration mount in anterior position, allowing for stabilizing it in the closed

position.

A single strike plate allows the lock to close the lid, immobilizing it with a motorized deadbolt.

A guide finger provides additional safety when closing the lid.Lid : Refrigetaring Model

A guide finger provides additional safety when closing the lid.

The lid of the ventilated model has a fresh air inlet circuit, and a hot air outlet circuit.

1.14 Lid : Refrigerating Model

The lid is fitted with an anti-vibration mount in anterior position, allowing for stabilizing it in the closed

position.

A single strike plate allows the lock to close the lid, immobilizing it with a motorized hook.

A guide finger provides additional safety when closing the lid.

The lid of the Refrigerating model allows you to maintain the sealing of the bowl when the latter is closed.

It is fitted with a removable temperature sensor.

A porthole in the central part allows the tachometer control of the rotor using an optical tachometer.

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 12/ 41

2Troubleshooting

2.1 Troubleshooting

Problem

Cause

Solution

No display: the screen

remains black.

No voltage

Operate the switch under the Control Center.

Connect the mains power cable.

Check the electrical supply of the laboratory and restore it.

The lid does not close:

the mechanism does not

start.

The lid has been opened with

the manual opening key

Press the control button to open the lid:

The mechanism starts.

The lid can then be closed.

The speed goes down,

speed value is blinking.

After a short power off while

centrifuging, the cycle is

interrupted. The rotor slows

down in free wheel.

Wait for the complete stop of the rotor. Switch off and on

the power .

2.2 Error Messages

Error /

Message No.

Cause

Solution

01

LOCK FAIL

The lid is open at startup

Press Start / Stop: The message disappears.

Close the lid.

Wait for the complete closure of the lid before

starting a cycle.

The locked position detector is

faulty.

Check that the micro contact 2 blade is present

and not folded.

Check that this micro contact 2 is wired

correctly.

Check the operation of this micro contact, and

change it if necessary.

02

IMBALANCE

The rotor is non-symmetrically

loaded.

Wait until the end of automatic shutdown.

Open the lid by pressing the button.

Press Start/Stop: The message disappears.

Balance the rotor loads

Restart the spin cycle

The centrifuge is installed on a

wrong type of media.

Place the centrifuge on a compliant media.

Despite a weight gap < 15 gr, the

detection threshold is set

incorrectly.

Carry out a calibration of the imbalance sensitivity

threshold.

03

BOWL

OVERTEMPER

ATURE

The temperature in the bowl has

exceeded 43°C, the temperature

of the room being too high.

Wait until the end of the automatic shutdown of the

rotor.

Activate the air conditioning system for an ambient

temperature under the conditions described in the

user’s manual.

The programmed temperature

setpoint is inappropriate

Change speed / temperature pair of the program,

which is not compatible with normal use.

The initial loading temperature is

too high.

Place the samples before centrifugation in an

environment between 4 and 37°C, for 1h.

The chiller no longer works.

Check the operation of the chiller with the menu

“Auto-Diagnostic “ (Startup and performance)

The temperature probe is

defective

In the probe calibration menu, the value displayed is

different from the value measured by the probe, with

a gap > 2°C.

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 13/ 41

The difference between the air

temperature and the over

temperature alarm set point is

greater than the set value.

Check the value of the temperature alarm threshold.

Change program settings: speed and/or temperature.

04

MOTOR

OVERTEMPER

ATURE

The motor temperature is too

high.

A stop in “freewheel” mode occurs.

Wait 30 minutes (software reset) before opening the

lid.

Activate the air conditioning system of the room to

obtain a lower ambient temperature.

The frequency of use of the

centrifuge is too intensive

(ventilated model)

Spacing the periods of use.

The motor is damaged

Change the motor.

Motor temperature sensor

connection malfunction

Change the motor.

05

ERROR

MICROCONT

ACTOR ON

LOCKING

MECHANISM

One of the micro contacts is

damaged or non-working.

There is a bad connection to the

micro contacts.

Contact a Certified Technician.

06

MICROCONT

ACT NOT

SEEN - OPEN

The micro contact doesn’t work.

The auxiliary micro contact is not

working.

The connection of the auxiliary

micro contact is not good.

The micro contact was seen as closed when it should

have been seen as open when the centrifuge started.

Contact a Certified Technician.

07

MICROCONT

ACT NOT

SEEN –

CLOSED

The power contactor doesn’t

work.

The open position switch was

released after the lid closed.

The micro contact doesn’t receive

a command.

The coil of the micro contactor is

not working properly.

The micro contact was seen as open when it should

have been seen as closed.

Contact a Certified Technician.

08

ERROR LID

SAFETY

The board with tachometer /

accelerometer is working

improperly.

The connection to these parts is

not good.

The sensor for the closed lid

position was released after the

centrifugation started.

The lid slightly opened during the security auto test

when the cycle started.

09

NO SPEED

SIGNAL AT

START

The speed sensor is working

improperly.

The board with tachometer /

accelerometer is working

improperly.

The connection to these parts is

not good.

The speed cannot be read within the first 5s of the

cycle.

10

SPEED

SIGNAL LOST

The speed sensor is working

improperly.

The board with tachometer /

accelerometer is working

improperly.

The connection to these parts is

not good.

The speed signal was lost during rotation.

11

WRONG

SPEED

SIGNAL

The speed sensor is not working

properly.

The board with tachometer /

The speed signal is not correct.

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 14/ 41

accelerometer is working

improperly.

The connection to these parts is

not good.

Magnets from the tachometer

might have been lost.

12

OVERSPEED

Major error, the centrifuge will

stop.

The speed measured is higher than the maximum

speed allowed for this rotor.

Contact a Certified Technician.

13

Bus I²C

Acceleromete

r

The board with tachometer /

accelerometer is working

improperly.

The connection to these parts is

not good.

The microcontroller board is

working improperly.

Problem of communication with the accelerometer.

14

Bus I²C

Temperature

probe

The microcontroller board is

working improperly.

Problem of communication with the temperature

measurement.

15

LID OPEN

DURING

ROTATION

Manual lid opening during

centrifugation.

Wrong calibration of locking

mechanism.

The lid was manually opened or the hook was released

during the centrifugation.

Contact a Certified Technician.

NO DISPLAY

No power.

Verify the power plug is connected properly.

Check the power in the laboratory.

Turn the switch on.

16

TEMPERATUR

E CONTROL

ISSUE

Temperature probe out of

service.

Verify that the temperature probe is properly installed

under the lid and replace it if necessary.

Remove the probe and measure the resistance.

The value must be 500+ - 100 Ohm (Probe PT500)

17

ERROR

OVERSPEED

SAFETY

The startup test of the overspeed

safety has failed.

Microcontrol board is defaulting: Replace the control

center.

18

/

/

/

19

Missing rotor

A cycle was started without rotor

inside the bowl.

Switch the power off & on.

Assemble a rotor.

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 15/ 41

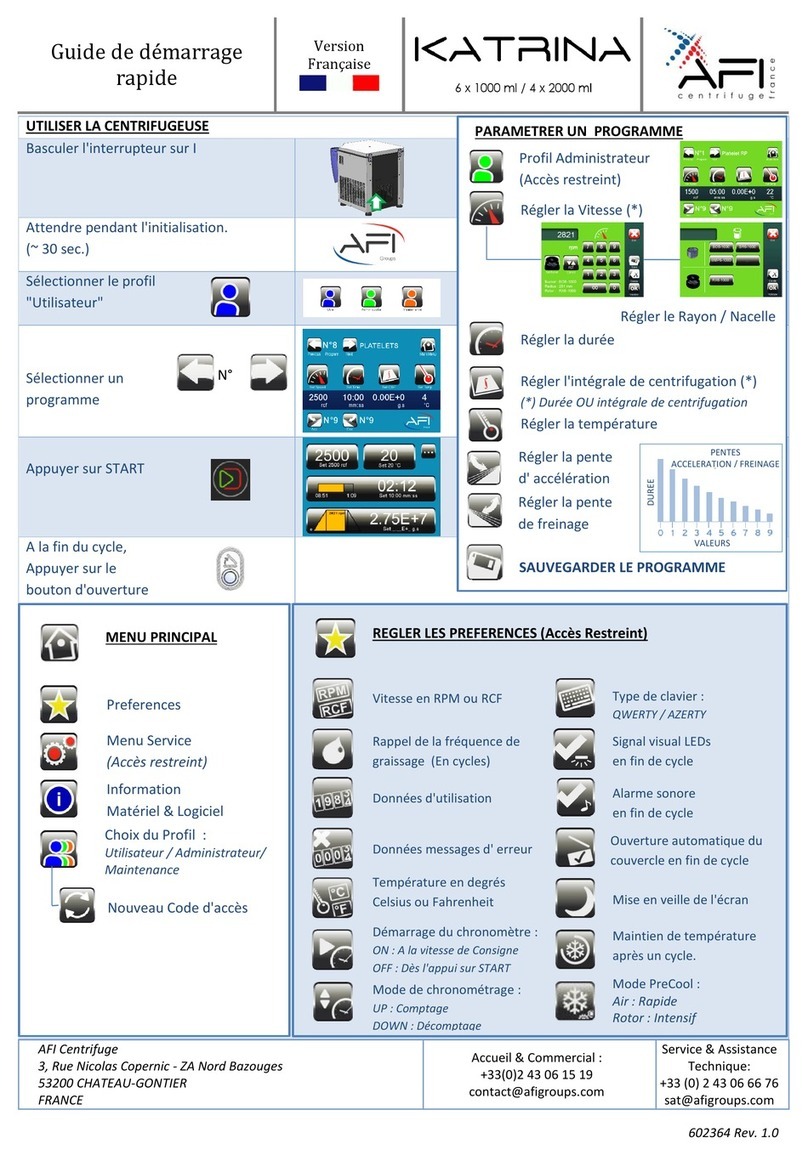

3Settings

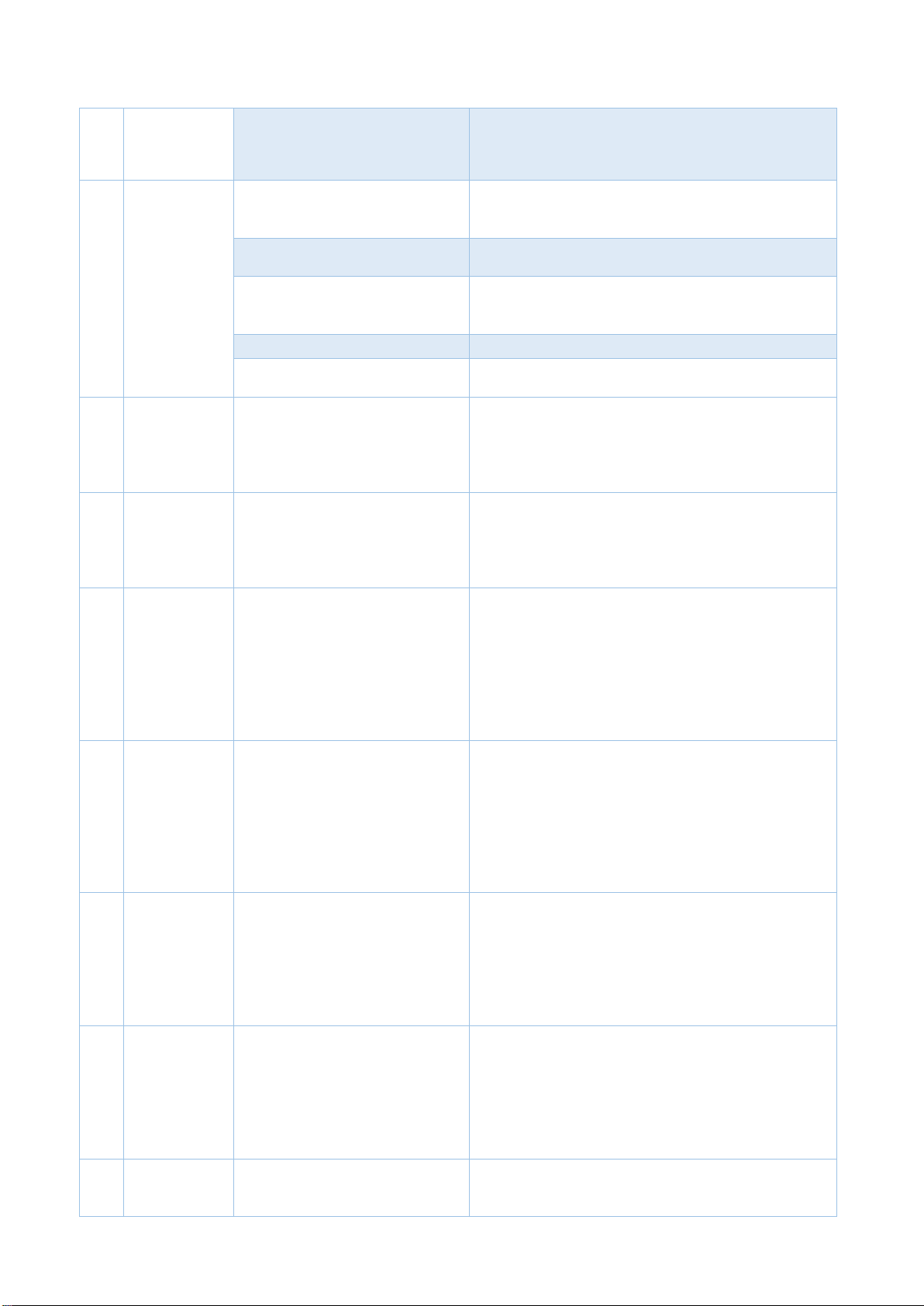

3.1 Access to the Technician Menu

Access the “Settings” menu using the following

keys:

This menu is reserved for authorized technicians.

Dial access code :

It is 4 last figures of serial number.

Ex : Serial number : 18C200RE1234

Access code : 1234

1st page of settings :

Next page

Setting the temperature probe

Setting the imbalance sensitivity

Setting the time delay of the lock

Auto-Diagnostic

Reset to factory settings

Clear the counters

2nd settings page

Previous page

Changing the internal numbers

Changing the counters

Over Temperature Alarm

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 16/ 41

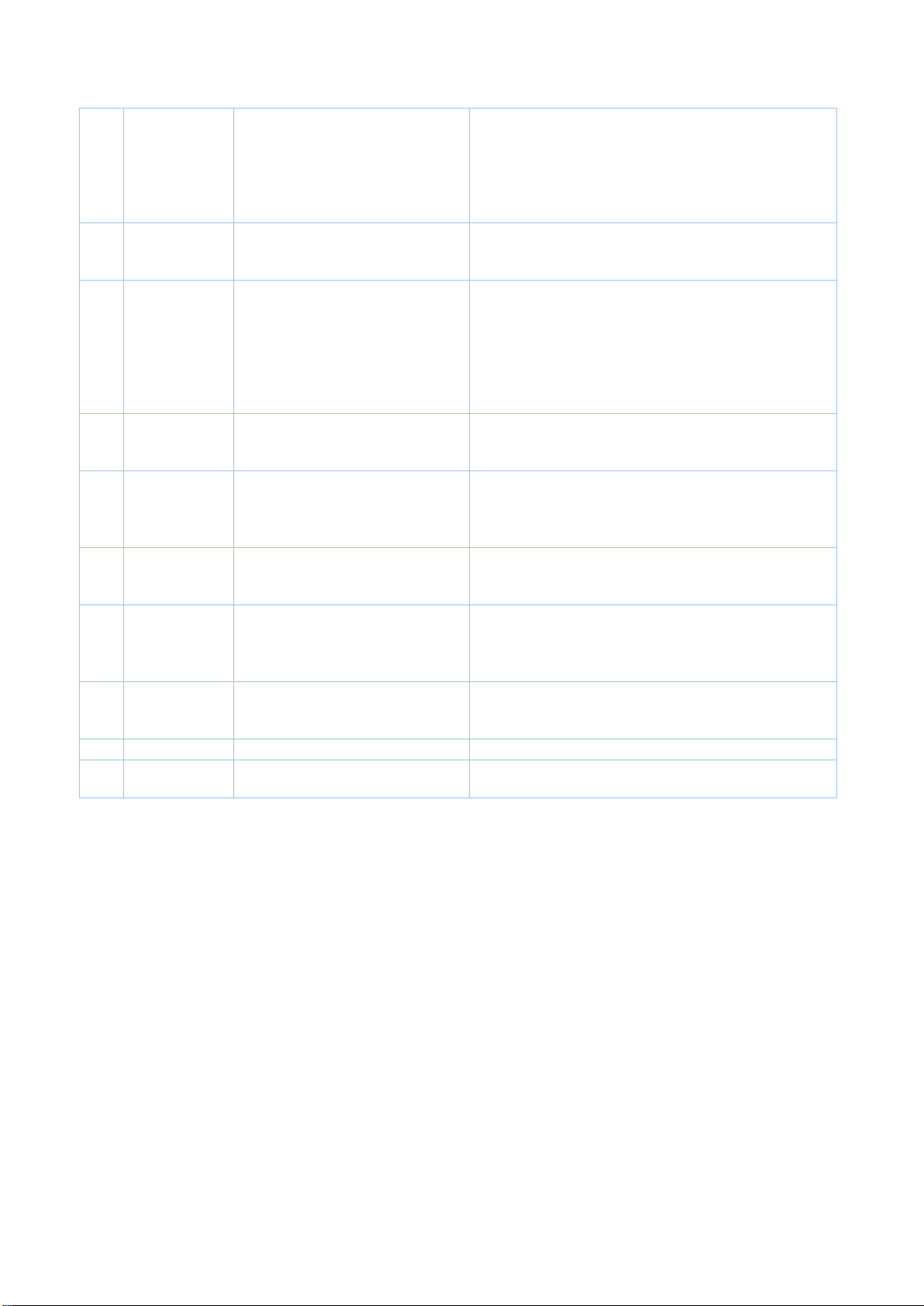

3.2 Setting the temperature probe

Access the temperature probe calibration

menu.

The upper value “Probe Temp.”

corresponds to the physical value measured

by the temperature sensor, located in the

lid.

The lower value “Displayed Temp.” is the

value displayed on the screen. This is the

temperature value of the samples in the

buckets, during a centrifugation cycle.

A correction of + /- 2°C is possible in the

case of deviation with the temperature of

the sample in the buckets.

Press the “-” or “+” keys to adjust the value.

Confirm by pressing ok.

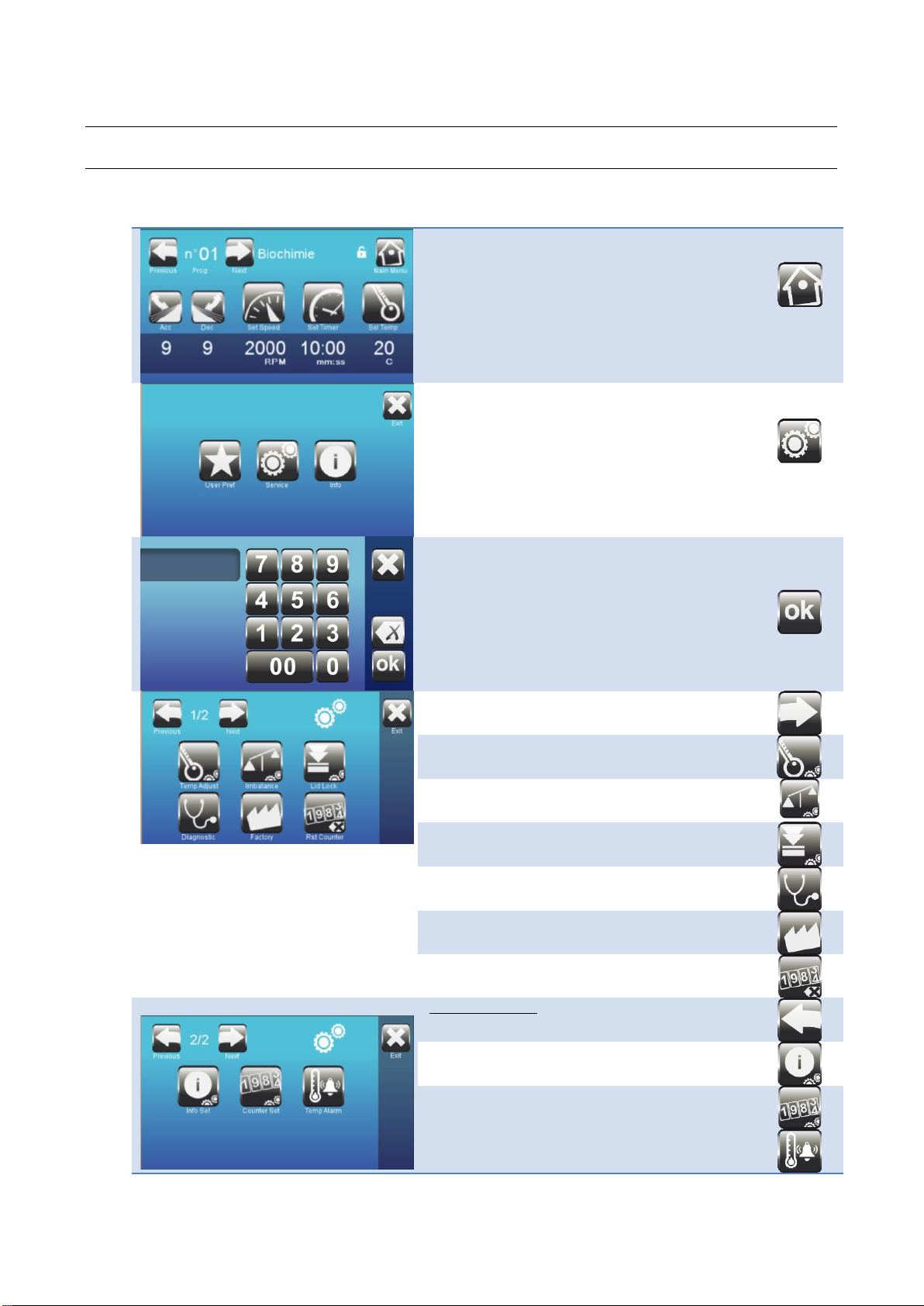

3.3 Unbalancing Sensitivity Detection

The centrifuge has a reaction to the load balancing faults which may be different depending on the media on

which the centrifuge is placed. A calibration of the imbalance sensitivity is therefore necessary during

installation.

Required equipment: Use the reference balancing kit 71122002.

Access the unbalance sensitivity calibration

menu.

Equip a rotor swing-out and its 4 buckets in

the centrifuge.

Remove the inserts of the buckets.

Low threshold

1. Place the round 15 gram weight in one

of the buckets and close the lid,

2. Press the button “15gr”

3. The rotor accelerates until it stabilizes.

4. The centrifuge shakes, then the rotor

slows down.

5. The low threshold is then determined. It

appears under the button “15 gr”. (e.g.

480)

6. Open the lid and remove the 15 gram

weight.

High threshold

7. Place the 25 gram weight in the same

bucket.

8. Proceed in the same way as for the 15

gram weight.

9. The low threshold is then determined.

(e.g. “520”)

10.Open the lid and remove the 25 gram

weight.

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 17/ 41

Average

11. Press on the Next button to average the

setting.

(e.g. [480+520]/2 = 500 )

The average value is displayed.

By default, the factory setting value is

500.

Check

The following steps are compulsory.

High threshold:

Do not adjust this threshold with a weight

greater than 25 gr. This would cause a breach

of warranty. The appliance has been

dimensioned for a maximum threshold of

25gr.

12.Place the 15 gr + 10 gr weights in a

bucket.

13. Start the cycle. 2000 rpm / 1 minute / 9

Acceleration / Braking 9

14. The centrifuge must stop during the

acceleration, and display the message

ERROR1:

The 25 gr imbalance is not tolerated.

Repeat the High threshold check 3 times:

ERROR1 must appear each time.

Low threshold:

15. Leave only a weight of 15 gr in a bucket.

16. Start the cycle. 2000 rpm / 1 minute / 9

Acceleration / Braking 9

17. The centrifuge should achieve the

desired speed and then slow down and

stop without the following error message

appearing: The 15 gr imbalance must be

tolerated.

Repeat the Low threshold check 3 times:

Each cycle should take place normally.

Note : This setting value is viewable in

HOME -> INFORMATION menu, at

SETTINGS paragraph.

Original Instructions - Rev.1.4 Service Manual–Lisa / Loreena Centrifuges 18/ 41

3.4 Setting the lock

3.4.1 .Lock Operation : LISA Model

The lock is in the locked position when the axis of the crankshaft and the oblong hole of the bolt are

perpendicular. A marking is carried out on the visible face, corresponding to this position.

Visible face - when the front panel is removed

Locked position identification marking

Internal face - after lock unit extraction.

Perpendicular position of the 2 axes

3.4.2 .Lock Operation : LOREENA Model

Locking steps : :

The lid is lowered manually.

The left strike of the cover (1) is detected by the approach sensor

(2).

The motor reducer (6) starts.

The open position sensor (8) changes to state 0.

The hooks (7) drive the 2 latches down.

When the left strike is detected, the closed position sensor of the

strike (3) goes to state 1.

90°

6

2

1

8

7

3

7

This manual suits for next models

12

Table of contents

Other AFi Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Nakanishi

Nakanishi PRESTO II Operation manual

Elmi

Elmi MS-01 user manual

Tuttnauer

Tuttnauer T-Top 10 Operation and maintenance manual

Endress+Hauser

Endress+Hauser Liquistation CSF48 operating instructions

Waters

Waters Vion IMS QTof Overview and maintenance guide

cytiva

cytiva Ettan IPGphor Cup Loading Manifold user manual