Originale Instructions- Rev.1.3 User Maunal–Loreena 4/ 68

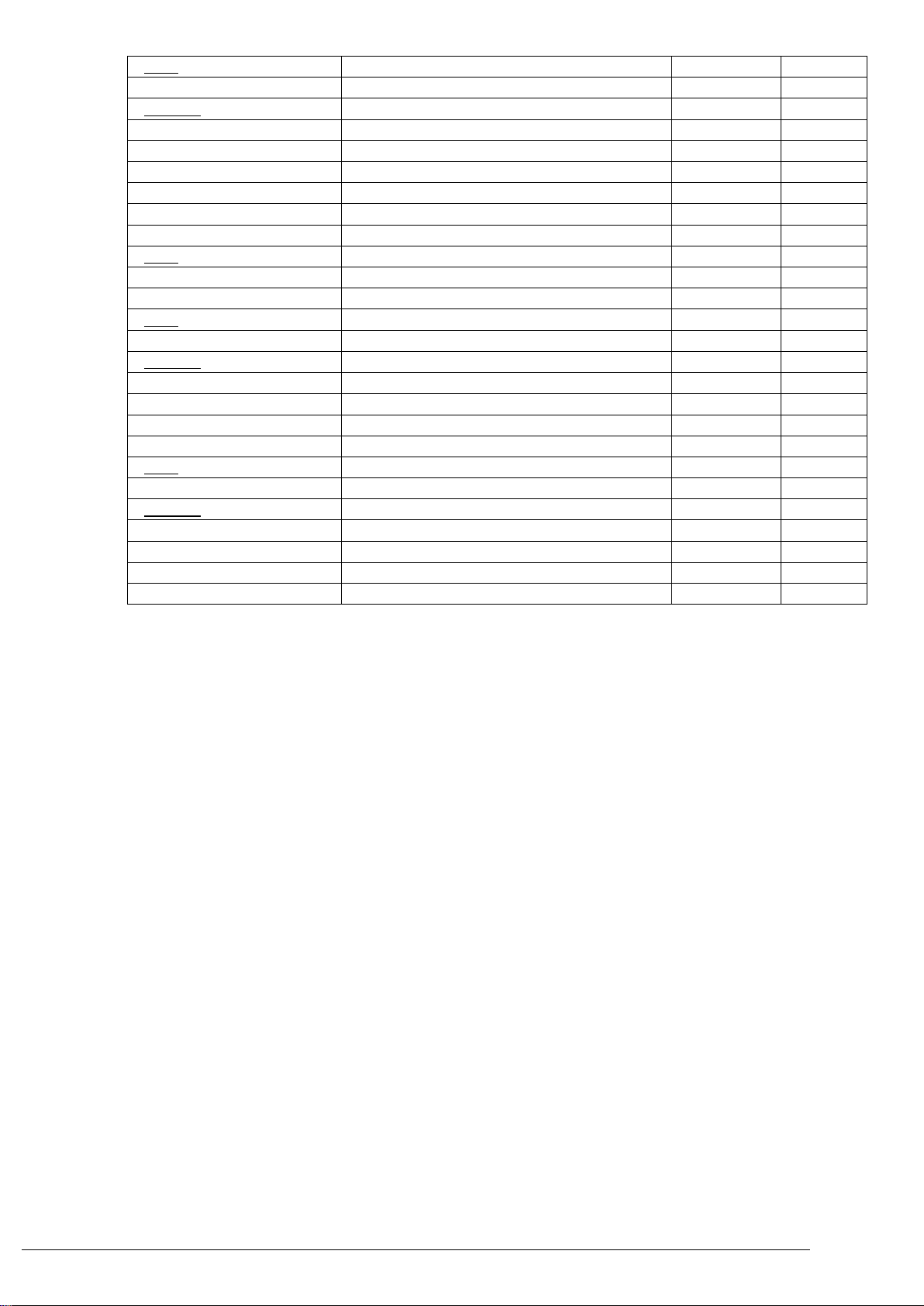

Table of Contents

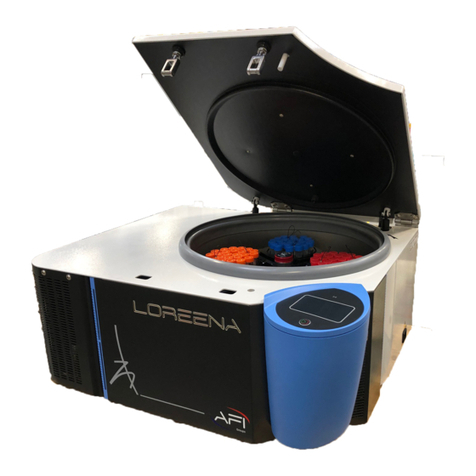

1. GENERAL INFORMATION ------------------------------------------------------------------------------------------------------ 6

1.1. DESCRIPTION.......................................................................................................................................................6

1.2. INTENDED USE .....................................................................................................................................................6

1.3. PROHIBITIONS: ....................................................................................................................................................7

1.4. MODELS,SPECIFICATIONS AND ACCESSORIES.............................................................................................................8

1.4.1. MODELS &SPECIFICATIONS ...................................................................................................................................8

1.4.2. ACCESSORIES.......................................................................................................................................................9

1.5. SAFETY INSTRUCTIONS.........................................................................................................................................12

1.6. INFORMATION ON THE REFRIGERANT FLUID USED......................................................................................................12

2. INSTALLATION INSTRUCTIONS ---------------------------------------------------------------------------------------------- 13

2.1. SHIPMENT ........................................................................................................................................................13

2.1.1. DAMAGED SHIPMENTS........................................................................................................................................13

2.1.2. HANDLING AND TRANSPORT .................................................................................................................................13

2.2. SITE PREPARATION..............................................................................................................................................13

2.3. ELECTRICAL ENVIRONMENT ..................................................................................................................................14

2.4. UNPACKING ......................................................................................................................................................14

2.5. PACKING LIST.....................................................................................................................................................14

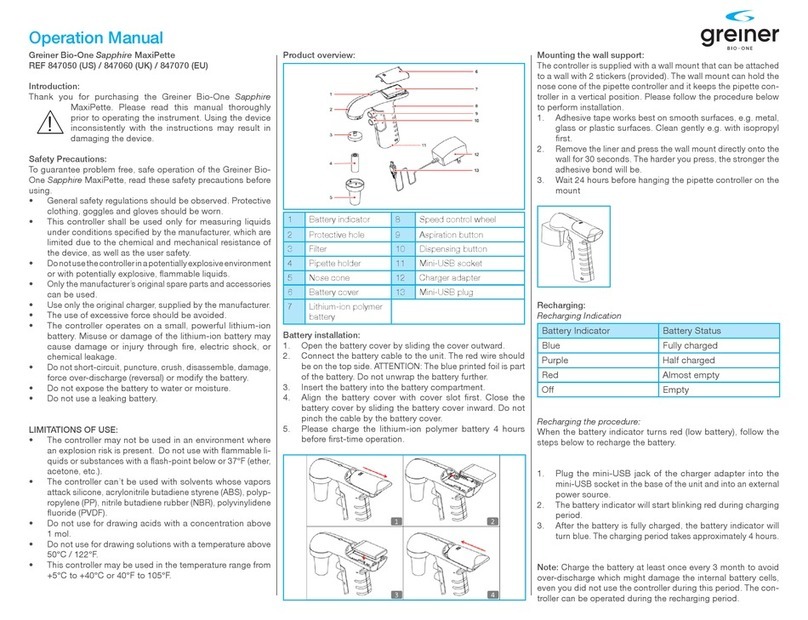

2.6. DESCRIPTION.....................................................................................................................................................15

3. OPERATING THE LOREENA CENTRIFUGE -AFI-C300 ------------------------------------------------------------------- 16

3.1. FIRST START /POWERING....................................................................................................................................16

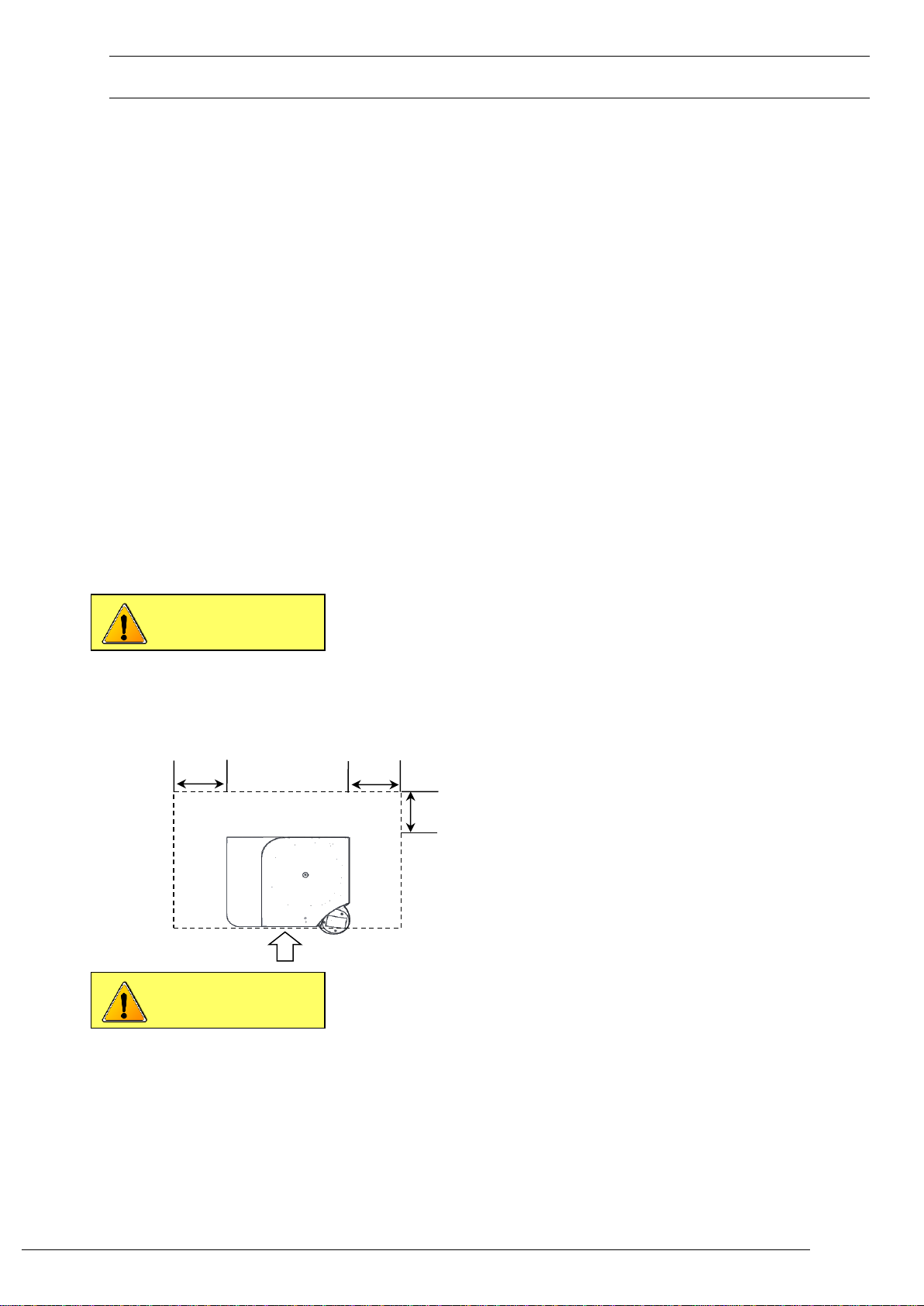

3.2. LEVELLING (FLOOR MODEL)..................................................................................................................................17

3.3. ROTOR ASSEMBLY...............................................................................................................................................17

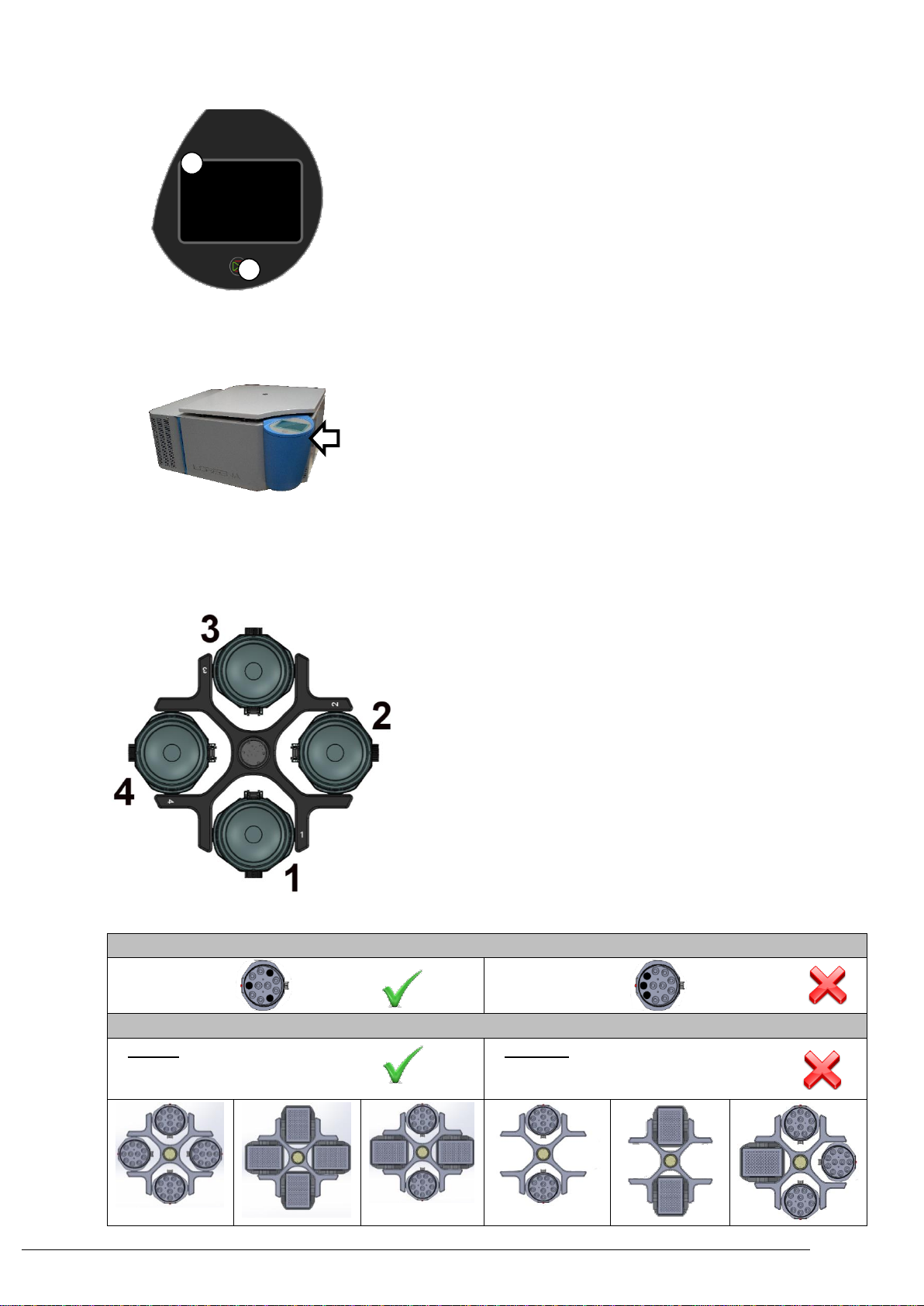

3.4. POSITION THE BUCKETS .......................................................................................................................................17

3.5. FIRST POWERING................................................................................................................................................17

3.6. USING THE INTERFACE .........................................................................................................................................18

3.7. OPENING THE LID ...............................................................................................................................................18

3.8. ROTOR LOADING AND BALANCING .........................................................................................................................18

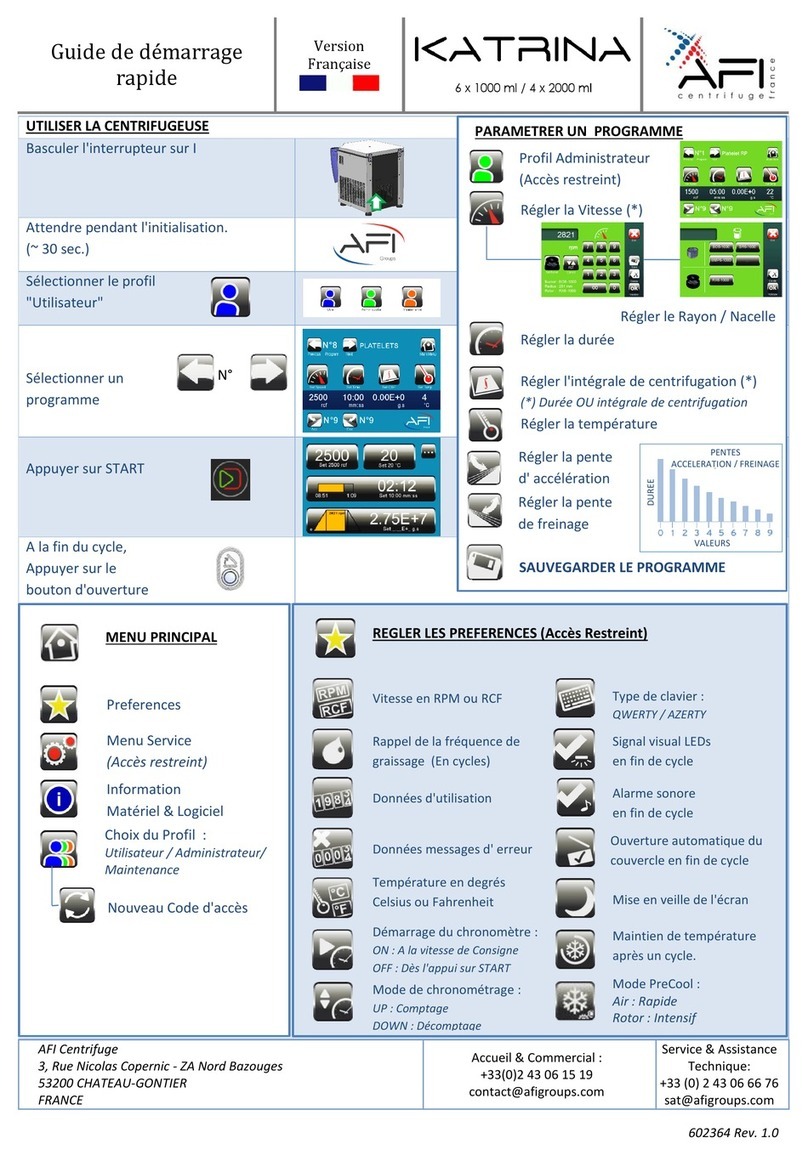

3.9. QUICK START-UP ................................................................................................................................................19

4. OPERATING ------------------------------------------------------------------------------------------------------------------ 20

4.1. SETTINGS..........................................................................................................................................................20

4.2. CREATE /EDIT A PROGRAM NAME .........................................................................................................................20

4.3. SET PROGRAM SETTINGS ......................................................................................................................................21

4.4. SET SPEED IN RPM OR RCF .................................................................................................................................22

4.5. PROTECT THE SETTINGS OF A PROGRAM ..................................................................................................................23

4.6. CENTRIFUGE:USE A PROGRAM .............................................................................................................................23

4.7. INTERRUPT CENTRIFUGATION................................................................................................................................24

4.8. OPEN AFTER AN ELECTRIC POWER FAILURE /EMERGENCY STOP ...................................................................................24

4.9. PRECOOLING .....................................................................................................................................................25

4.10. PREWARMING ...................................................................................................................................................25

4.11. ROUTINE MENU.................................................................................................................................................26

4.12. OTHER MENUS...................................................................................................................................................26

4.12.1. USER PREFERENCES ............................................................................................................................................28

4.12.2. TYPE OF SPEED DISPLAYED (RPM OR RCF) .............................................................................................................29

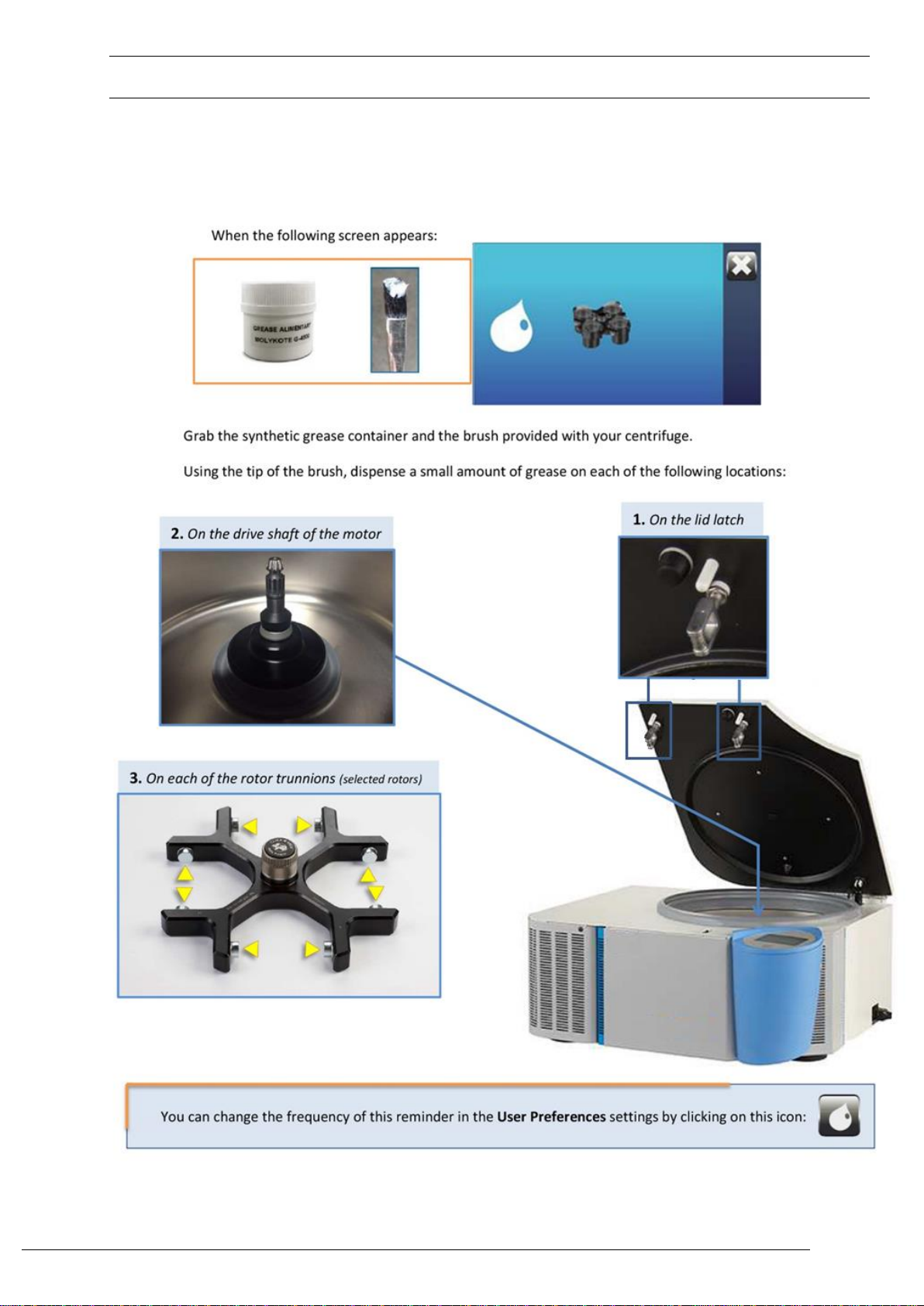

4.12.3. FREQUENCY OF LUBRICATION................................................................................................................................30

4.12.4. ACCESS TO LOGBOOK ..........................................................................................................................................30

4.12.5. ACCESS TO ERROR LOGBOOK.................................................................................................................................30

4.12.6. TYPE OF TEMPERATURE DISPLAYED ........................................................................................................................31

4.12.7. TIMER MODE.....................................................................................................................................................31

4.12.8. COUNTING MODE...............................................................................................................................................32

4.12.9. KEYBOARD TYPE .................................................................................................................................................32

4.12.10. CHANGE BACKGROUND COLOR..............................................................................................................................33

4.12.11. END OF CYCLE ALARM.........................................................................................................................................33

4.12.12. ERROR MESSAGE ALARM.....................................................................................................................................33

4.12.13. AUTOMATIC LID OPENING ....................................................................................................................................33

4.12.14. SLEEP MODE......................................................................................................................................................34

4.12.15. POST COOL .......................................................................................................................................................34

4.12.16. PRE COOL FUNCTION ..........................................................................................................................................35

4.12.17. TEMPERATURE DISPLAY MODE .............................................................................................................................35