AFi KATRINA AFI-C600R-2P User manual

6 x 1000 mL / 12 x 500 mL

User Manual

│ Revision 1.1

│ English version

602325

This document has been prepared with the utmost care. However, AFI

Centrifuge refuses to accept any responsibility in the event of errors or

omissions. The same applies to any damage resulting from the use of

information contained in this manual.

AFI Centrifuge

3, Rue Nicolas Copernic

ZA Nord Bazouges

53200 CHATEAU-GONTIER

FRANCE

+33 (0) 2 43 06 66 76

Originale Notice - Rev.1.2 User Manual –Katrina p.1/ 55

KATRINA CENTRIFUGE

Models

AFI-C600R-2P

AFI-C600R-3P

Operation Manual

(230 VAC ±10%, 50 Hz)

Manufactured by:

AFI Centrifuge

Rue N. Copernic

ZI Nord Bazouges

53200 CHATEAU-GONTIER

FRANCE

Originale Notice - Rev.1.2 User Manual –Katrina p.2/ 55

You have just purchased one of the finest Laboratory Centrifuges available. With proper care,

maintenance and laboratory procedure, this centrifuge will provide you years of productive service. Please

read this manual carefully to familiarize you with proper installation, and operation of the centrifuge. Other

information are available on our website, www.aficentrifuge.com .

Warranty

AFI Centrifuge. warrants AFI-C600R Series KATRINA Centrifuge that it will repair F.O.B. its factory or furnish

without charge F.O.B. its factory a similar part to replace any material in its equipment within 24 months after

the date of sale if proved to the satisfaction of the company to have been defective at the time it was sold

provided that all parts claimed defective shall be returned, properly identified to the company at its factory,

charges prepaid. Factory installed equipment or accessories are warranted only to the extent guaranteed by

the original manufacturer, and this warranty shall not apply to any portion of the equipment modified by the

user. Claims under this warranty should be directed to AFI Centrifuge. setting forth in detail the nature of the

defect, the date of the initial installation and the serial and model number of the equipment.

This warranty shall not apply to any AFI Centrifuge product or part thereof which has been subject to misuse,

abuse, accident, shipping damage, improper installation or service, or damage by fire, or flood. If the serial

number of this product is altered, removed or defaced as to be illegible, the Warranty shall be null and void in

its entirety.

The warranty is for the sole benefit of the original purchaser and is not assignable or transferable. Prior to

returning any item, for any reason, contact AFI Centrifuge for a Return Authorization Number. This number

must accompany all returns. Any product shipped to AFI Centrifuge without this number will be returned

refused shipment or collect freight.

Explanation of Symbols

Safety alert symbol indicates a potentially hazardous

situation which, if not avoided, could result in death or

serious injury

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

Safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in minor or

moderate injury.

Pinching: This warning symbol indicates the presence of

a risk of pinching when handling the lid.

Note:

Used for important information

Potential electrical hazard, only qualified person to

access

Biohazard

Ground, Earth

Lead Free

CAUTION

!

CAUTION

WARNING

!

Originale Notice - Rev.1.2 User Manual –Katrina p.3/ 55

Modification registration

Following modifications register updates of the manual.

Date

Revision

Modifications

Paragraph

Author

2018, sept., 21th

1.0

Creation

All

F. LE CAM

2018, oct, 3rd

1.1

Levelling, Add spare parts

references.

3.1, 5.8

F. LE CAM

July 2020

1.2

Update according to 2020

catalogs

C. ROIDOT

Originale Notice - Rev.1.2 User Manual –Katrina p.4/ 55

Table of Contents

WARRANTY --------------------------------------------------------------------------------------------------------------------------- 2

1. GENERAL INFORMATION------------------------------------------------------------------------------------------------------ 7

1.1. DESCRIPTION.......................................................................................................................................................7

1.2. INTENDED USE..................................................................................................................................................... 7

1.3. PROHIBITIONS:.................................................................................................................................................... 8

1.4. MODELS,SPECIFICATIONS AND ACCESSORIES.............................................................................................................9

1.4.1. MODELS &SPECIFICATIONS ...................................................................................................................................9

1.4.2. ACCESSORIES.....................................................................................................................................................11

1.5. SAFETY INSTRUCTIONS ........................................................................................................................................12

1.6. INFORMATION ON THE REFRIGERANT FLUID USED...................................................................................................... 12

2. INSTALLATION INSTRUCTIONS ---------------------------------------------------------------------------------------------- 13

2.1. SHIPMENT ........................................................................................................................................................13

2.2. DAMAGED SHIPMENTS........................................................................................................................................13

2.3. HANDLING AND TRANSPORT.................................................................................................................................13

2.4. UNPACKING ......................................................................................................................................................13

2.5. PACKING LIST ....................................................................................................................................................14

2.6. MACHINE DESCRIPTION.......................................................................................................................................15

2.7. INTERFACE DESCRIPTION...................................................................................................................................... 15

2.8. LABEL ..............................................................................................................................................................16

2.9. SITE PREPARATION .............................................................................................................................................16

2.10. ELECTRICAL &ENVIRONMENTAL REQUIREMENTS .....................................................................................................17

2.10.1. ELECTRICAL ENVIRONMENT ..................................................................................................................................17

2.10.2. OPERATIONAL PERFORMANCE (FOR INDOOR USE ONLY).............................................................................................17

2.10.3. LIGHT EXPOSURE................................................................................................................................................17

2.10.4. POLLUTION DEGREE:2.0....................................................................................................................................17

2.10.5. CHEMICAL EXPOSURE .........................................................................................................................................17

2.10.6. EMC PERFORMANCE (CLASSIFIED FOR LIGHT INDUSTRIAL)..........................................................................................17

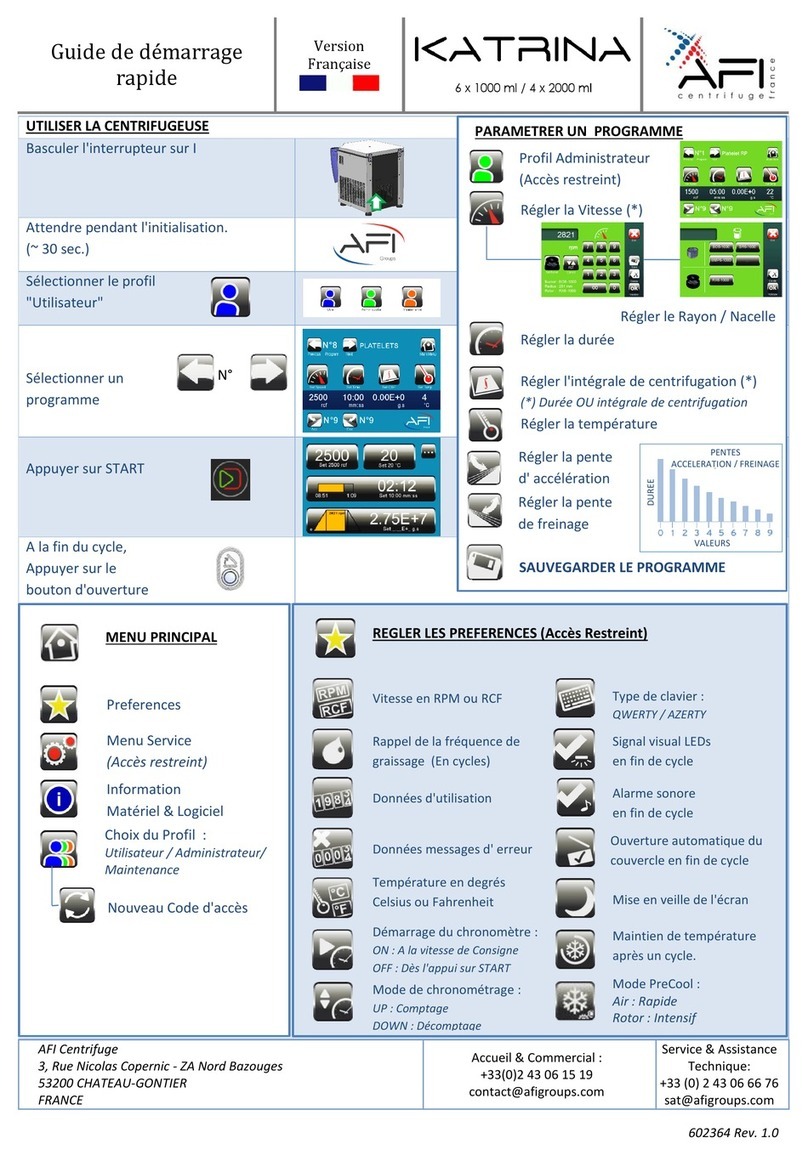

3. OPERATING THE KATRINA CENTRIFUGE -AFI-C600R------------------------------------------------------------------ 19

3.1. LEVELLING ........................................................................................................................................................19

3.2. FIRST START /POWERING.................................................................................................................................... 19

3.3. ROTOR ASSEMBLY .............................................................................................................................................. 20

3.4. POSITION THE BUCKETS .......................................................................................................................................20

3.5. FIRST POWERING................................................................................................................................................20

3.6. OPENING THE LID...............................................................................................................................................21

3.7. ROTOR LOADING AND BALANCING .........................................................................................................................21

3.8. QUICK START-UP................................................................................................................................................ 22

4. OPERATING ------------------------------------------------------------------------------------------------------------------ 23

4.1. PICTOGRAMS EXPLANATIONS................................................................................................................................23

4.2. DIFFERENT PROFILES........................................................................................................................................... 23

4.3. ACCESS ADMINISTRATOR &SERVICE PROFILE ..........................................................................................................23

4.4. MODIFY PROFILE CODE.......................................................................................................................................24

4.5. CREATE A PROGRAM...........................................................................................................................................24

4.6. MODIFY A PARAMETER........................................................................................................................................ 25

4.7. SET SPEED /CENTRIFUGAL FORCE..........................................................................................................................26

4.8. CONVERT RPM /CGF FORCE .................................................................................................................................26

4.9. SET TIME CYCLE .................................................................................................................................................27

4.10. SET INTEGRAL OF CENTRIFUGATION .......................................................................................................................27

4.11. SET TEMPERATURE.............................................................................................................................................27

4.12. CONVERT TEMPERATURE.....................................................................................................................................28

4.13. SET ACCELERATION SLOPE ...................................................................................................................................28

4.14. SET DECELERATION SLOPE ...................................................................................................................................29

4.15. USE A PROGRAM TO CENTRIFUGE .......................................................................................................................... 29

Originale Notice - Rev.1.2 User Manual –Katrina p.5/ 55

4.16. INTERRUPT CENTRIFUGATION ...............................................................................................................................29

4.17. OPEN AFTER AN ELECTRIC POWER FAILURE /EMERGENCY STOP...................................................................................30

4.18. PRECOOLING..................................................................................................................................................... 31

4.19. PREWARMING................................................................................................................................................... 31

4.20. PREFERENCES MENU ..........................................................................................................................................32

4.20.1. SPEED CONVERSION............................................................................................................................................33

4.20.2. FREQUENCY OF LUBRICATION................................................................................................................................34

4.20.3. ACCESS TO LOGBOOK.......................................................................................................................................... 34

4.20.4. ACCESS TO ERROR LOGBOOK................................................................................................................................. 34

4.20.5. TEMPERATURE MODE ......................................................................................................................................... 35

4.20.6. TIMER MODE.....................................................................................................................................................35

4.20.7. COUNTING MODE...............................................................................................................................................35

4.20.8. KEYBOARD TYPE.................................................................................................................................................36

4.20.9. END OF CYCLE ALARM.........................................................................................................................................36

4.20.10. ERROR MESSAGE ALARM.....................................................................................................................................37

4.20.11. AUTOMATIC LID OPENING ....................................................................................................................................37

4.20.12. SLEEP MODE ..................................................................................................................................................... 37

4.20.13. POST COOL.......................................................................................................................................................37

4.20.14. PRE COOL FUNCTION..........................................................................................................................................39

4.20.15. TEMPERATURE DISPLAY MODE .............................................................................................................................39

4.20.16. END OF CYCLE LIGHTING SIGNAL ............................................................................................................................39

4.21. SERVICE MENU.................................................................................................................................................. 40

4.22. INFORMATION................................................................................................................................................... 40

5. CARE AND MAINTENANCE -------------------------------------------------------------------------------------------------- 41

5.1. CARE AND CLEANING ..........................................................................................................................................41

5.1.1. AUTHORIZED MAINTENANCE PRODUCTS..................................................................................................................41

5.1.2. CENTRIFUGE .....................................................................................................................................................41

5.1.3. ROTOR &ACCESSORIES.......................................................................................................................................42

5.1.4. DISINFECTION /DECONTAMINATION .....................................................................................................................42

5.2. DISMANTLING THE ROTOR.................................................................................................................................... 43

5.3. LIMITING THE DURATION OF OPERATION .................................................................................................................43

5.4. CHECKING AND TESTING ACCESSORIES ....................................................................................................................44

5.5. STORAGE OF ACCESSORIES ...................................................................................................................................44

5.6. ANNUAL MAINTENANCE ...................................................................................................................................... 44

5.7. ERROR MESSAGES,TROUBLESHOOTING,OPTION-DIAGNOSTICS..................................................................................45

5.8. WEARING PARTS &CONSUMMABLE.......................................................................................................................48

5.9. BACK TO MANUFACTURER.................................................................................................................................... 48

5.10. DISPOSAL AND RECYCLE ......................................................................................................................................48

6.1. BASICS.............................................................................................................................................................49

6.2. NOMOGRAM.....................................................................................................................................................50

6.3. LOGBOOK .........................................................................................................................................................51

6.4. RETURN COUPON............................................................................................................................................... 52

7. ANNEX 1: ACCESSORY SPECIFICATIONS------------------------------------------------------------------------------------ 53

7.1. SWING-OUT ROTOR AFI-RX6-1000..................................................................................................................... 53

Originale Notice - Rev.1.2 User Manual –Katrina p.6/ 55

Objectives of this Manual

This manual is part of the documentation belonging to the device and is, as a result, an integral part of the

device. It includes all the technical specifications of the Katrina device as well as all the necessary information

to assist the operator. Before use, the operator must have followed the training course provided by AFI

Centrifuge about using the machine and how to achieve optimal results.

The machine can only be used by people who have received training about the correct use and manipulation of

the equipment. The user manual must also by studied carefully before using the equipment.

Information in this document is liable to be modified without notice, for improvement to reliability, design and

operation. It does not represent an engagement by the manufacturer.

Assembly, extensions, adjustments, modifications and repairs can only be made by AFI Centrifuge or authorized

personnel.

AFI Centrifuge produced this user manual to provide simple and precise information. To this end, AFI

Centrifuge declines all responsibility in the case of incorrect interpretation. While the best care possible has

been given to provide a manual as correct as possible, typing mistakes are possible.

The owner of the equipment is responsible for the preservation of this manual as long as the device is in usage.

Recommendations regarding and the range of application are also included in this manual.

Any information or modification linked with this manual should be addressed to AFI Centrifuge.

Who is the manual for ?

This manual is for any professional wanting to use the equipment concerned in this document.

Originale Notice - Rev.1.2 User Manual –Katrina p.7/ 55

1.General Information

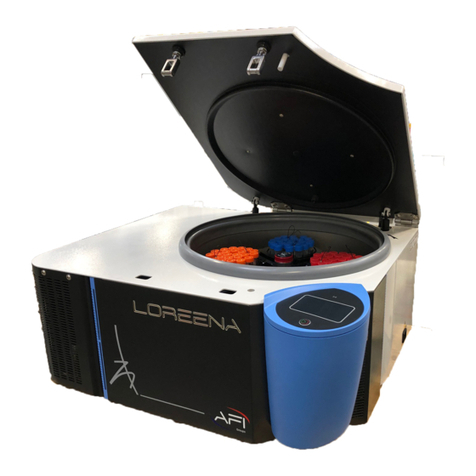

1.1. Description

The KATRINA Centrifuge is a laboratory benchtop series of centrifuges that maximizes productivity while

minimizing laboratory required bench space. The centrifuge functionality allows the separation of substances

of different densities held in suspension or emulsion in a liquid using centrifugal force.

The KATRINA Centrifuge adds precise temperature control to further maximize performance.

KATRINA Refrigerated Centrifuge

The refrigeration system refrigerant used is CFC-free to meet regulations of refrigerant use.

1.2. Intended use

The centrifuge is designed and manufactured for use with rotating accessories supplied by AFI Centrifuge. It is

suitable for separating substances of different densities held in suspension, or emulsion in a liquid.

The maximum density of substances should be 1.2 g/cm3.

The centrifuge must be used in an optimal state of operation and maintenance. The non-observance of the rule

of use may threaten the health of users or third persons, but it may also cause damages to the unit and/or

surrounding equipment.

Users of the equipment must be trained on good centrifugation practices, as well specific usage of the KATRINA

Centrifuge models and Accessories. Any use outside the framework defined above is considered non-

compliant.

AFI Centrifuge assumes no responsibility for injury due to improper use.

CAUTION

!

Originale Notice - Rev.1.2 User Manual –Katrina p.8/ 55

1.3. Prohibitions:

This centrifuge is not designed for the following uses and environments.

The following items are prohibited:

•Flammable, explosive, toxic and radioactive materials

•Materials which may react, causing a hazard

•Contaminated materials not contained in an aerosol-barrier container

•Rotating rotors and accessories that have exceeded their maximum use.

•Rotating rotors and accessories that are not maintained according to the instructions in this manual,

•or showing signs of wear and/or corrosion.

•Rotating rotors and accessories not supplied by AFI Centrifuge.

•Explosive environments

•Radioactive environments

Only operate a centrifuge after taking all necessary safety measures.

Rotors and buckets should be removed from use in case of mechanical fault, trace, or corrosion. These

elements have a life cycle duration, engraved on their visible part: To maintain safe conditions, it is imperative

to replace them when the recommended duration is reached.

CAUTION

!

Originale Notice - Rev.1.2 User Manual –Katrina p.9/ 55

1.4. Models, Specifications and Accessories

Spécifications / Specifications

Modèle / Model

Réfrigéré / Refrigerating

Centrifugeuse de sol /

Floor stand centrifuge

Référence / Reference

AFI-C600R-2P

Tension nominale / Nominal voltage (+/- 10%)

200, 208, 220, 230, 240V - Single phase

Fréquence / Frequency

50 Hz

Puissance alimentation max. / Power max.

4000 W

Conformité aux directives Européennes / Compliance with European directives

98/79/CE : Dispositifs medicaux de diagnostic in vitro / In vitro

diagnostic medical devices

✓

2006/42/CE : Directive machine / Machinery directive

✓

2014/30/UE : Directive CEM / EMC directive

✓

2012/19/CE : Directive DEEE / WEEE directive

✓

2011/65/CE : Directive ROHS / ROHS Directive

✓

IEC / EN61010-1 (2010) : Sécurité / Safety

✓

IEC / EN61010-2-020 (2006) : Sécurité / Safety

✓

IEC / EN61010-2-101 (2015) : Sécurité / Safety

✓

EN61326-1(2013) : Compatib. électromagn. / EMC compatibility

✓

EN55011 2009/A1 (2010) Classe A : Perturbations / Emissions

✓

EN ISO 14971 (2012) : Gestion des risques / Risk management

✓

ISO 9001 (2015) : Gestion des risques / Risk management

✓

ISO 13485 (2016): Gestion des risques / Risk management

✓

93/42/CE : Dispositifs medicaux / Medical device

✓

Caractéristiques principales (voir brochure) / Main specifications (see brochure for full specification)

Rotors Swing-out

with windshield /

Swing-out rotors

avec carenage

AFI-RX6-1000

Capacité max. /

Max. capacity

6x500ml qiun/quad bags (oval) /

6x1000ml (round sealed) /

RPM max.

4300rpm

ACR max /

Max. RCF

5809xg

Rotors Swing-out

with windshield /

Swing-out rotors

avec carenage

AFI-RX4-2000

Capacité max. /

Max. capacity

4x2000ml (round)

4x4 microplates sealed (rectangular dedicated)

RPM max.

4400rpm

ACR max /

Max. RCF

5931xg

H Rotors Swing-out /

Swing-out rotors H

AFI-RH-EK

Capacité max. /

Max. capacity

192x5ml / 32 Microplates

RPM max.

3300rpm

ACR max /

Max. RCF

2313xg

Couvercle / Lid

✓

Originale Notice - Rev.1.2 User Manual –Katrina p.10/ 55

Dimensions & poids / Dimensions & Weight

Dimensions (HxlxL) / Dimensions (HxWxD)

960 x 800 x 960 mm

Dimensions emballage (HxlxL) /

Package dimension (HxWxD)

1170 x 900 x 1020 mm

Hauteur couvercle ouvert / Opened lid height

1690 mm

Poids net hors rotor / Weight unpacked without

rotor

352 Kg

Poids rotor & nacelles ovales / Rotor weight & oval

buckets

31 kg

Poids emballé / Weight packed

380 kg

Ecran graphique tactile 5.7’’, couleur

5.7’’ graphic color screen

✓

Commandes /

Commands

Touches et écran tactile

Buttons and touchscreen

Contrôle par microprocesseur /

Microprocessor control

✓

Reconnaissance automatique du rotor /

Automatic rotor recognition

✓

Tolerance de déséquilibre /

Imbalance tolerance

100 gr dans des nacelles opposées

/ 100 gr in opposite loads

Fermeture motorisée du couvercle / Motorized lid closing

✓

Programation par calcul d’integral / Accumulated

Centrifugal Effect

✓

Modes

Au démarrage, au démarrage vitesse/durée / At start, at speed,

time start

Durées de cycle /

Cycle duration

10 s à 99h : 59 min : 59 s / Cycle continu / Impulsion

10 s to 99h : 59 min : 59 s / Continuous cycle / Pulse

Unités de température / Temperature units

°C / °F

Matière & Taille Chambre de centrifugation

/Centrifugation chamber material & size

Inox Ø 640

Chambre de centrifugation /Centrifugation chamber

Inox

Densité max. / Max. density

1.2 g / cm3

Moteur à induction sans charbon /

Brushless induction motor

✓

Précision de vitesse / Speed accuracy

± 0.5%

Nombre de programmes / Programs number

99

Pentes d'accélération & de freinage

Acceleration & Braking slopes

10 & 10

Décélération libre / Brakeless mode

✓

Système de réfrigération / Cooling system

Sans CFC / Without CFC

Plage de réglage en température /

Range of setting temperature

-10°C →+40°C

Fonction de pré-refroidissement / Precool function

✓

Précision en temperature /Temperature accuracy

+/- 1°C

Dissipation de chaleur maximale / Heat dissipation

13648 BTU/h

Niveau sonore max. / Max. noise

≤ 61 dB(A)

Originale Notice - Rev.1.2 User Manual –Katrina p.11/ 55

References

Description

Capacity

Lot

Swing-out Rotors, Buckets

AFI-RX6-1000

Swing-Out rotor 6x 1000 ml

6x 1000 ml

One unit

AFI-BO6-1000

1000 ml Oval Buckets

1x 1000 ml

Set of 6

AFI-BR6-1000

1000 ml Round Buckets

1x 1000 ml

Set of 6

AFI-LI6-1000

1 Cavity liner

1 x 1000mL

Set of 6

AFI-LIS6-1000

2 Cavity liner

2 x 500 mL

Set of 6

AFI-BXDW6

1000 ml Microplate Buckets

48 Microplates

Set of 6

AFI-RX4-2000

Swing-Out rotor 4x 2000 ml

4x 2000 ml

One unit

AFI-BO4-2000

2000 ml Oval Buckets

4x 2000 ml

Set of 4

AFI-BR4-2000

2000 ml Round Buckets

4x 2000 ml

Set of 4

AFI-RHD6

Microplate Swing-Out rotor

One unit

AFI-BHD6

Microplate Buckets

Set of 2

Accessories Kits

71199012

Tube of Grease 20 gr

One unit

Only equipment listed here or supplied exclusively by AFI Centrifuge can be used. The use of accessories

and other cables than those specified can cause malfunction.

Originale Notice - Rev.1.2 User Manual –Katrina p.12/ 55

1.5. Safety Instructions

The operator must observe the following precautions when using the centrifuge:

•Ensure stability and perfect levelling of the centrifuge.

•Check the correct mounting of the rotor and its accessories before starting a centrifugation cycle.

•Check tube resistance at maximum applied centrifugal force: chemical resistance to centrifuged

products and mechanical strength at the centrifugal force applied thereto.

•Check the condition of the tubes and remove damaged tubes.

•Use only the rotors and accessories authorized by the manufacturer AFI Centrifuge.

•Swing-out rotors: install four (or two) buckets; never perform any cycle with missing buckets.

•Maintain and control accessories.

•Balance the load of the rotor around the axis of rotation.

•Respect the maximum density of 1.2 g / cm3,in particular in case of a cycle at full speed.

•Limit volume in case of excess density.

•Install the centrifuge in a ventilated area, on a horizontal rigid support to absorb the vibrations

generated by the centrifuge.

•During operation, the centrifuge must not be moved or be subject to impact.

•Do not attempt to open the lid while the rotor is spinning.

•Do not attempt to neutralize the motorized lid lock

•Do not lean over the centrifuge during the spin cycle.

•Do not stay within a space of 10 inch around the centrifuge longer than necessary.

•Do not leave potentially dangerous materials inside the free space.

•Use aerosol-barrier accessories when centrifuging bio hazardous material.

•Condensation may form inside the centrifuge when it is moved from a cold environment to a warm

environment. Allow the centrifuge to warm up for two hours before use.

1.6. Information on the refrigerant fluid used

The "refrigerant" type apparatus contains fluorinated greenhouse gases under the Kyoto Protocol. They should

therefore not be released into the atmosphere. Repairs or disassembly of this appliance should only be carried

out by qualified personnel.

The data corresponding to the type of refrigerant, the Global Warming Potential (GWP) value, and the load are

detailed in § 1.4.1.Models & Specifications.

Originale Notice - Rev.1.2 User Manual –Katrina p.13/ 55

2.Installation Instructions

2.1. Shipment

AFI Centrifuge takes every reasonable precaution to assure that your KATRINA Centrifuge arrives without damage.

Motor carriers are carefully selected and shipping cartons have been specially designed to insure your purchase.

However, damage can occur in any shipment and the following outlines the steps you should take on receipt of a

KATRINA Centrifuge to be sure that if damage has occurred, the proper claims and actions are taken immediately.

2.2. Damaged Shipments

Terms are factory, unless stated otherwise. Therefore, it is important to check each shipment before acceptance.

If there is visible damage, the material can be accepted after the driver makes a notation on the consignee's copy of the

freight bill. Then an inspection must be made to verify the claim against the carrier. This inspection is the basis of your

filing the claim against the carrier.

If concealed damage is found it is absolutely necessary to NOTIFY THE FREIGHT AGENT AT ONCE and request an

inspection. Without this inspection, the transportation company may not accept a claim for loss or damage. If the

carrier will not perform the inspection, an affidavit must be prepared stating that he was contacted on a certain date and

that he failed to comply with the request. This along with other papers in the customer's possession will support the

claim.

2.3. Handling and transport

The package containing the centrifuge needs to be handled by suitable means (pallet truck, etc.).

Please ensure that the people in charge of handling are qualified to handle the lifting equipment.

Maintain the following conditions during transport:

Temperature: -20 to 50 ° C

Relative humidity: <90%, under the dew point

2.4. Unpacking

On reception, check the external packaging is undamaged.

Unpacking must take place in a sufficiently spacious area: a clearance area of 3 meters in front of the pallet is needed

to remove the machine from its packaging. 2 people authorized by AFI Centrifuge are needed to remove the

centrifuge from its pallet.

A label on the carton indicates which side to leave clear for removal of the centrifuge.

The Katrina is packaged with great care to avoid possible damage during transport. Before removing the packaging

from the centrifuge and the rotating accessories, check that all the items are present (see next paragraph).

If moving the machine means climbing steps it is recommended to put the machine back on its pallet.

The wheels are only to be used for removal from the pallet and short distances.

CAUTION

!

Originale Notice - Rev.1.2 User Manual –Katrina p.14/ 55

2.5. Packing list

KATRINA Centrifuge

Compliance Certificate

User Manual

N°6 key

(Rotor Fixing & Manual release)

Pad

(Quantity :4)

Pad clip

(Quantity :4)

Rotor & Rotor Cover

Rotor Fixing Nut

Food grade grease

1 of the following buckets set :

Round bucket

(Set of 6)

Oval bucket

(Set of 6)

Microplate bucket

(Set of 6)

Originale Notice - Rev.1.2 User Manual –Katrina p.15/ 55

2.6. Machine Description

Fig. 1 ¾ Front View

1. Lid

2. Window for metrological speed measurement.

3. Control panel

4. Opening lid button

5. Power switch

Fig. 2 Vue de face

6. Wheels (x4)

7. Ajustable feet (x4)

8.

2.7. Interface description

1. Touch-sensitive control-display.

2. START-STOP, PULSE & cycle interruption button.

2

1

3

5

4

2

1

10

9

Originale Notice - Rev.1.2 User Manual –Katrina p.16/ 55

CAUTION

!

2.8. Label

2.9. Site preparation

Doorway: 810 mm

The location of the centrifuge must be able to resist

twice the machine's weight in use (approximately 480

kg) i.e. 960 kg and be able to operate without vibrating.

Vibrations can diminish the results of the

centrifugation.

The floor must be horizontal and clean.

Allow an area of 860 x 1020mm for the centrifuge. Be

sure to create a clearance area of 30 cm around the

centrifuge. The clearance area must remain free of any

objects. In the event of a major accident, this clearance

area allows the centrifuge to absorb the kinetic energy

without interfering with any other object. Furthermore,

this empty space allows for a renewal of fresh air for

optimal operation of the refrigeration system.

Fig. 3 Free space around the centrifuge

Allow minimum of 60 cm between 2 adjacent centrifuges. This space ensures the required clearance area for

each machine and sufficient ventilation between them.

1020

860

Access areas

Originale Notice - Rev.1.2 User Manual –Katrina p.17/ 55

It is recommended that no less than two people are present to manually lift the centrifuge onto the laboratory

bench.

2.10. Electrical & Environmental Requirements

The KATRINA centrifuge must be connected directly to the switchboard, in 230V 50Hz single-phase or in a cable

outlet junction box.

The centrifuge is equipped with about 4 metres of 3G4 cable.

The protective earth conductor of the machine must be connected to the earth of the installation.

The centrifuge's power supply must be protected by a safety device that automatically cuts off the power

supply in the event of an insulation fault,

This will typically be a 30mA earth leakage circuit breaker upstream of the connection.

Dedicated power supply line :

- The power line must be capable of carrying at least 17A and must be dedicated to the appliance.

- It must be protected against overloads by its own protective device, e.g. a two-pole thermal magnetic circuit

breaker.

•in general it will be a 20A line, protected by its 20A circuit breaker. In all cases the calibre of the circuit

breaker must be adapted to the line to be protected.

•The circuit breaker must be identified as the centrifuge disconnecting device and easily accessible

nearby.

The electrical installation must comply with all regulations in force at the place of installation.

Environment Temperature Range: 60⁰F - 85⁰F (15⁰C - 30⁰C)

Environment Humidity: Maximum relative humidity 80% for temperatures up to 31⁰C decreasing linearly to

50% relative humidity at 40⁰C

Environment Altitude: Maximum of 6562 Feet (2000 meters) above sea level

Standard Fluorescent Lighting @ 150 ft. candles (1614 LUX) maximum intensity.

Pollution degree describes the amount of conductive pollution present in the operating environment.

Pollution degree 2 assumes that normally only non-conductive pollution such as dust occurs with the

exception of occasional conductivity caused by condensation.

Chemical exposure should be limited to antibacterial materials used for cleaning and disinfecting.

CHLORINATED AND HALOGEN MATERIALS ARE NOT RECOMMENDED FOR USE ON STAINLESS STEEL

SURFACES.

Originale Notice - Rev.1.2 User Manual –Katrina p.18/ 55

WARNING

!

Emissions: EN61326

Immunity: EN61326

Class A equipment is intended for use in an industrial environment.

In the documentation for the user, a statement shall be included drawing

attention to the fact that there may be potential difficulties in ensuring

electromagnetic compatibility in other environments, due to conducted

as well as radiated disturbances.

This manual suits for next models

1

Table of contents

Other AFi Laboratory Equipment manuals