AFi ISA User manual

User Manual

│Revision 1.0 │

English version

ISA CENTRIFUGE

Models

AFI-CI060R

AFI-CI060R-E

AFI-CI060V

AFI-CI060V-E

Operation Manual

(120 VAC, 60 Hz and 230 VAC, 50/60 Hz)

Designed & Manufactured by:

AFI Centrifuge

Rue N. Copernic

ZI Nord Bazouges

53200 CHATEAU-GONTIER

FRANCE

602348

This document has been prepared with the utmost care. However, AFI

Centrifuge refuses to accept any responsibility in the event of errors or

omissions. The same applies to any damage resulting from the use of

information contained in this manual.

AFI Centrifuge

3, Rue Nicolas Copernic

ZA Nord Bazouges

53200 CHATEAU-GONTIER

FRANCE

+33 (0) 2 43 06 66 76

Original Instructions Rev.1.0 User Manual –Isa 1/ 42

You have just purchased one of the finest Laboratory Centrifuges available. With proper care, maintenance and

laboratory procedure, this centrifuge will provide you years of productive service. Please read this manual carefully to

familiarize you with proper installation, and operation of the centrifuge. Other information are available on our website,

www.aficentrifuge.com .

Warranty

AFI Centrifuge. warrants AFI-CI060 Series ISA Centrifuge that it will repair F.O.B. its factory or furnish without charge F.O.B.

its factory a similar part to replace any material in its equipment within 24 months after the date of sale if proved to the

satisfaction of the company to have been defective at the time it was sold provided that all parts claimed defective shall

be returned, properly identified to the company at its factory, charges prepaid. Factory installed equipment or accessories

are warranted only to the extent guaranteed by the original manufacturer, and this warranty shall not apply to any portion

of the equipment modified by the user. Claims under this warranty should be directed to AFI Centrifuge. setting forth in

detail the nature of the defect, the date of the initial installation and the serial and model number of the equipment.

This warranty shall not apply to any AFI Centrifuge product or part thereof which has been subject to misuse, abuse,

accident, shipping damage, improper installation or service, or damage by fire, or flood. If the serial number of this product

is altered, removed or defaced as to be illegible, the Warranty shall be null and void in its entirety.

The warranty is for the sole benefit of the original purchaser and is not assignable or transferable. Prior to returning any

item, for any reason, contact AFI Centrifuge for a Return Authorization Number. This number must accompany all returns.

Any product shipped to AFI Centrifuge without this number will be returned refused shipment or collect freight.

Original Instructions Rev.1.0 User Manual –Isa 2/ 42

Explanation of Symbols

Safety alert symbol indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

Safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury.

Pinching: This warning symbol indicates the presence of a risk of

pinching when handling the lid.

Note:

Used for important information

Potential electrical hazard, only qualified person to access

Biohazard

Ground, Earth

Lead Free

Modification registration

Following modifications register updates of the manual.

Date

Revision

Modifications

Paragraph

Author

2018, october

1.0

Creation

All

F. LE CAM

CAUTION

!

CAUTION

WARNING

!

Original Instructions Rev.1.0 User Manual –Isa 3/ 42

Table of Contents

GENERAL INFORMATION ------------------------------------------------------------------------------------------------------ 5

DESCRIPTION.......................................................................................................................................................5

INTENDED USE .....................................................................................................................................................5

PROHIBITIONS: ....................................................................................................................................................5

SPECIFICATIONS AND ACCESSORIES ..........................................................................................................................6

1.4.1. SPECIFICATIONS ...................................................................................................................................................6

1.4.2. ACCESSORIES.......................................................................................................................................................7

SAFETY INSTRUCTIONS...........................................................................................................................................8

INFORMATION ON THE REFRIGERANT FLUID USED........................................................................................................8

INSTALLATION INSTRUCTIONS ------------------------------------------------------------------------------------------------ 9

SHIPMENT ..........................................................................................................................................................9

DAMAGED SHIPMENTS..........................................................................................................................................9

HANDLING AND TRANSPORT ...................................................................................................................................9

UNPACKING ........................................................................................................................................................9

PACKING LIST.......................................................................................................................................................9

MACHINE DESCRIPTION.......................................................................................................................................10

INTERFACE DESCRIPTION ......................................................................................................................................10

SITE PREPARATION..............................................................................................................................................10

ELECTRICAL &ENVIRONMENTAL REQUIREMENTS .....................................................................................................11

2.9.1. ELECTRICAL ENVIRONMENT ..................................................................................................................................11

2.9.2. ENVIRONMENTAL REQUIREMENTS .........................................................................................................................11

OPERATING THE ISA CENTRIFUGE -AFI-CI060--------------------------------------------------------------------------- 12

FIRST START ......................................................................................................................................................12

ROTOR ASSEMBLY...............................................................................................................................................12

POSITION THE BUCKETS .......................................................................................................................................13

FIRST POWERING................................................................................................................................................13

OPENING THE LID ...............................................................................................................................................13

ROTOR LOADING AND BALANCING .........................................................................................................................14

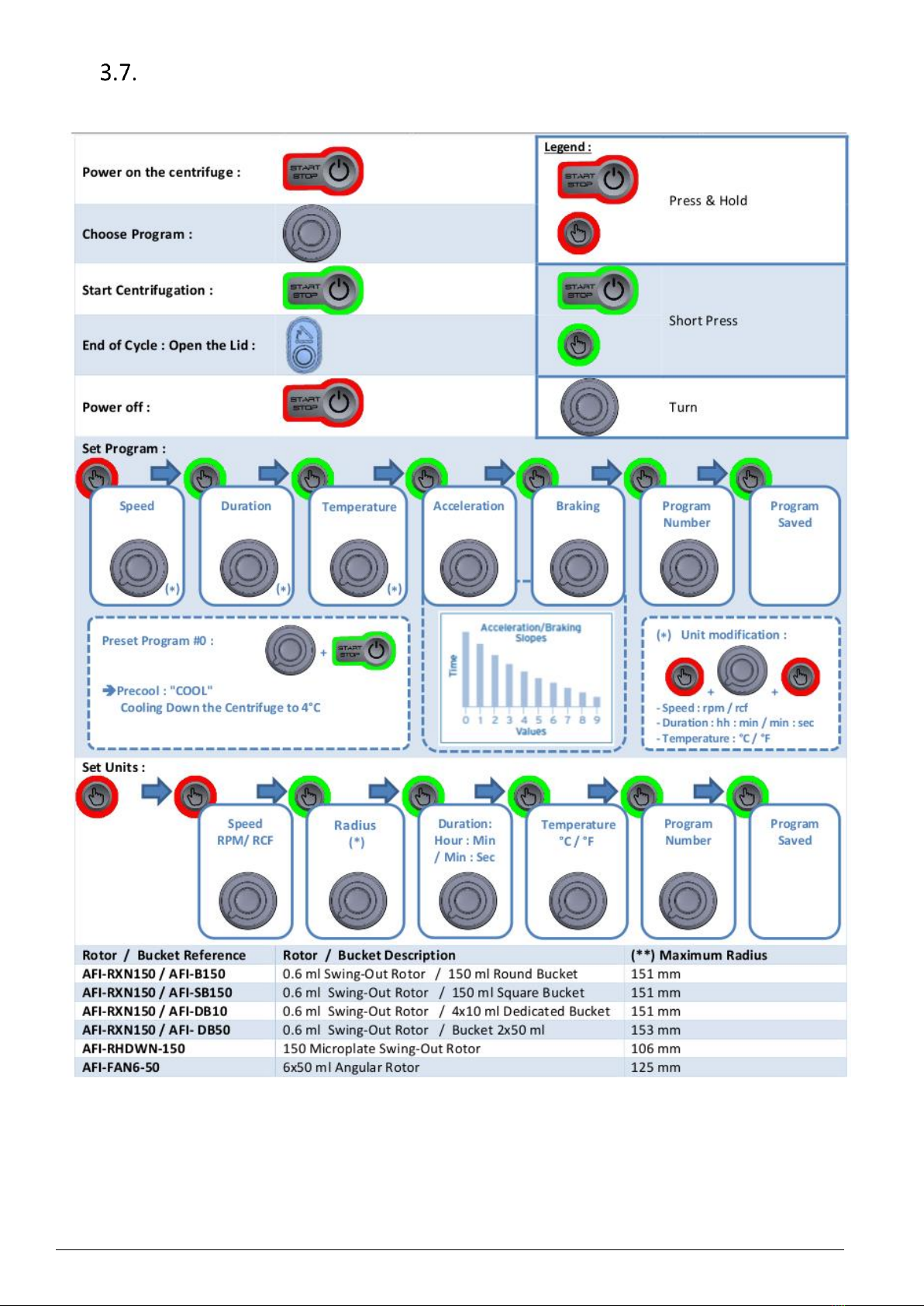

QUICK START-UP ................................................................................................................................................15

OPERATING ------------------------------------------------------------------------------------------------------------------ 16

SETTINGS..........................................................................................................................................................16

SET SPEED ........................................................................................................................................................16

SET DURATION...................................................................................................................................................16

SET TEMPERATURE (REFRIGERATING MODEL) ..........................................................................................................16

SET ACCELERATION SLOPE....................................................................................................................................17

SET BRAKING SLOPE ...........................................................................................................................................17

USE A PROGRAM TO CENTRIFUGE ..........................................................................................................................18

INTERRUPT CENTRIFUGATION................................................................................................................................18

OPEN AFTER AN ELECTRIC POWER FAILURE /EMERGENCY STOP ...................................................................................18

PRECOOLING .....................................................................................................................................................19

SETTING MODE .................................................................................................................................................19

4.11.1. SET SPEED UNIT /CENTRIFUGE FORCE ...................................................................................................................19

4.11.2. SET CENTRIFUGATION RADIUS ..............................................................................................................................20

4.11.3. SET TIME UNIT ..................................................................................................................................................20

4.11.4. SET TEMPERATURE UNIT (REFRIGERATING MODEL)...................................................................................................21

ADVANCED PARAMETERS .....................................................................................................................................21

SLEEP MODE......................................................................................................................................................22

CARE AND MAINTENANCE -------------------------------------------------------------------------------------------------- 23

CARE AND CLEANING ..........................................................................................................................................23

5.1.1. AUTHORIZED MAINTENANCE PRODUCTS..................................................................................................................23

5.1.2. CENTRIFUGE......................................................................................................................................................23

5.1.3. ROTOR &ACCESSORIES .......................................................................................................................................24

5.1.4. DISINFECTION /DECONTAMINATION......................................................................................................................24

DISMANTLING THE ROTOR....................................................................................................................................25

LIMITING THE DURATION OF OPERATION .................................................................................................................25

CHECKING AND TESTING ACCESSORIES ....................................................................................................................25

STORAGE OF ACCESSORIES....................................................................................................................................25

Original Instructions Rev.1.0 User Manual –Isa 4/ 42

ANNUAL MAINTENANCE.......................................................................................................................................25

ERROR MESSAGES,TROUBLESHOOTING,OPTION-DIAGNOSTICS..................................................................................26

REMINDER MESSAGES .........................................................................................................................................27

BACK TO MANUFACTURER....................................................................................................................................28

DISPOSAL AND RECYCLE----------------------------------------------------------------------------------------------------- 29

THEORETICAL BASICS OF CENTRIFUGATION ------------------------------------------------------------------------------- 30

BASICS .............................................................................................................................................................30

NOMOGRAM.....................................................................................................................................................31

LOGBOOK .........................................................................................................................................................31

RETURN COUPON ...............................................................................................................................................32

ANNEX 1: ACCESSORY SPECIFICATIONS------------------------------------------------------------------------------------ 33

AFI-RXN150 SWING-OUT ROTOR ........................................................................................................................33

NU-RHDWN-150 SWING-OUT ROTOR ................................................................................................................38

NU-FAN6-50 ANGLE ROTOR ..............................................................................................................................39

EC CONFORMITY DECLARATION-------------------------------------------------------------------------------------------- 41

Original Instructions Rev.1.0 User Manual –Isa 5/ 42

General Information

Description

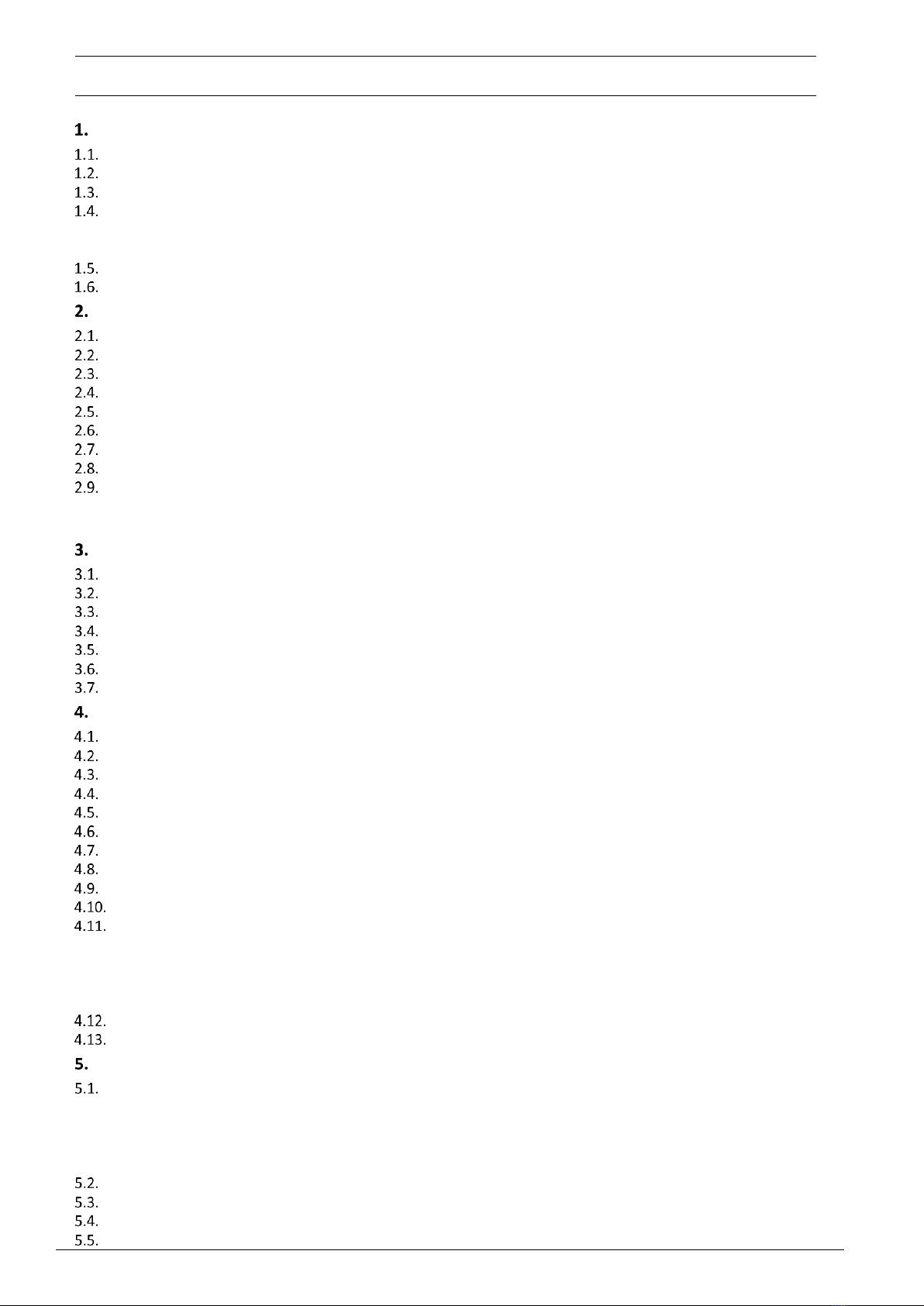

The ISA Centrifuge is a laboratory benchtop serie of centrifuges that maximizes productivity while minimizing laboratory

required bench space. The centrifuge functionality allows the separation of substances of different densities held in

suspension or emulsion in a liquid using centrifugal force.

The ISA Centrifuge is available in two models, one ventilated and the other refrigerated.

The ISA Centrifuge ventilated model has a unique ventilation system to maximize performance within laboratory ambient

temperature conditions.

The ISA Centrifuge refrigerated model adds precise temperature control to further maximize performance.

The refrigeration system refrigerant used is CFC-free to meet regulations of refrigerant use.

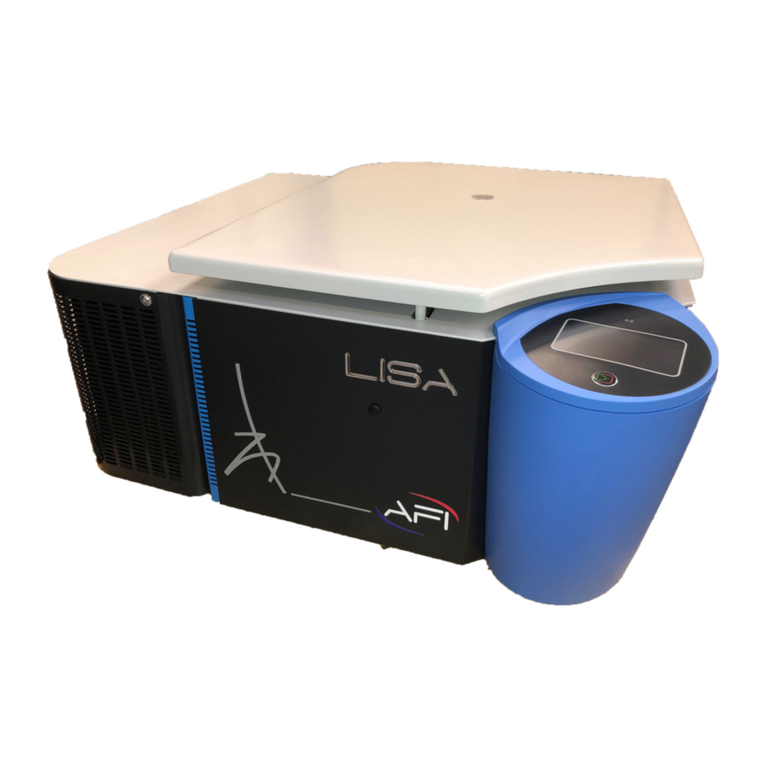

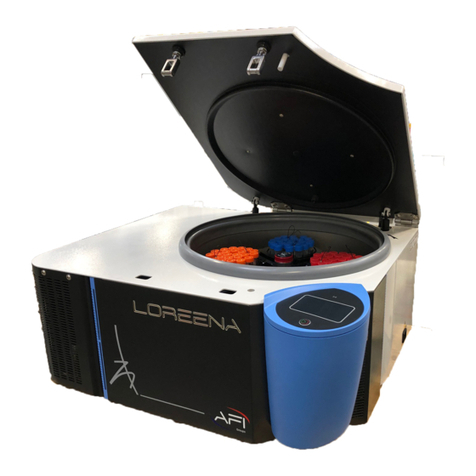

ISA Ventilated Centrifuge

ISA Refrigerated Centrifuge

Intended use

The centrifuge is designed and manufactured for use with rotating accessories supplied by AFI Centrifuge. It is suitable for

separating substances of different densities held in suspension, or emulsion in a liquid.

The maximum density of substances should be 1.2 g/cm3.

The centrifuge must be used in an optimal state of operation and maintenance. The non-observance of the rule of use may

threaten the health of users or third persons, but it may also cause damages to the unit and/or surrounding equipment.

Users of the equipment must be trained on good centrifugation practices, as well specific usage of the ISA Centrifuge

models and Accessories. Any use outside the framework defined above is considered non-compliant.

AFI Centrifuge assumes no responsibility for injury due to improper use.

Prohibitions:

This centrifuge is not designed for the following uses and environments.

The following items are prohibited:

Flammable, explosive, toxic and radioactive materials

Materials which may react, causing a hazard

Contaminated materials not contained in an aerosol-barrier container

Rotating rotors and accessories that have exceeded their maximum use.

Rotating rotors and accessories that are not maintained according to the instructions in this manual,

or showing signs of wear and/or corrosion.

Rotating rotors and accessories not supplied by AFI Centrifuge.

Explosive environments

Radioactive environments

Only operate a centrifuge after taking all necessary safety measures.

Rotors and buckets should be removed from use in case of mechanical fault, trace, or

corrosion. These elements have a life cycle duration, engraved on their visible part:

To maintain safe conditions, it is imperative to replace them when the recommended duration is reached.

CAUTION

!

CAUTION

!

Original Instructions Rev.1.0 User Manual –Isa 6/ 42

Specifications and Accessories

Specifications

Model

Ventilated

Refrigerating

Benchtop centrifuge

Reference

AFI-CI060V-E

AFI-CI060V

AFI-CI060R-E

AFI-CI060R

Electrical specifications

Nominal voltage (+/- 10%)

230 V

120 V

230 V

120 V

Frequency

50 / 60 Hz

60 Hz

50 Hz

60 Hz

Max. Current

2A

4A

5A

10A

Current phase

1

Max. Power

300 W

800 W

Dimensions & Weight

Dimensions (HxWxD)

34 x 38.9 x 50.8 cm

13.4 x 15 x 19.7 in

34.1 x 45.9 x 70.2 cm

13.4 x 17.7 x 27.6 in

Dimensions on benchtop (WxD)

36.6 x 45.1 cm

14.2 x 17.7 in

44.1 x 64.5 cm

17.3 x 25.2 in

Package dimension (HxWxD)

49 x 57 x 66 cm

19.3 x 22.4 x 26.0 in

50 x 65 x 93 cm

19.7 x 25.6 x 36.6 in

Opened lid height

74 cm

29.1 in

80 cm

31.5 in

Weight unpacked

40 kg

70 kg

Weight packed

50 kg

80 kg

Centrifuge description

4.7’’ hight contrast screen

Knob + Tactile Touch

Microprocessor control

Automatic rotor recognition

Imbalance detection

Working area auto-calibration - Continuous vibration measurement

Cycle duration

10 s to 99h : 59 min : 59 s / Continuous cycle / Pulse

Temperature units

°C / °F

Centrifugation chamber

Inox

Max. density

1.2 g / cm3

Brushless induction motor

Speed accuracy

± 0.5%

Programs number

99

99+1

Pulse (short run)

Acceleration & Braking slopes

10 & 10

Brakeless mode

Cooling system

Ventilation device

Without CFC

Range of setting temperature

N/A

-10°C +40°C

Precool function

N/A

Temperature accuracy

N/A

+/- 2°C

Heat dissipation

1364 BTU/h

2729 BTU/h

Max. noise

≤ 58 dB(A)

≤ 54 dB(A)

Refrigerant fluid / Global Warming Potential (GWP)

N/A

R452A / 2141

Original Instructions Rev.1.0 User Manual –Isa 7/ 42

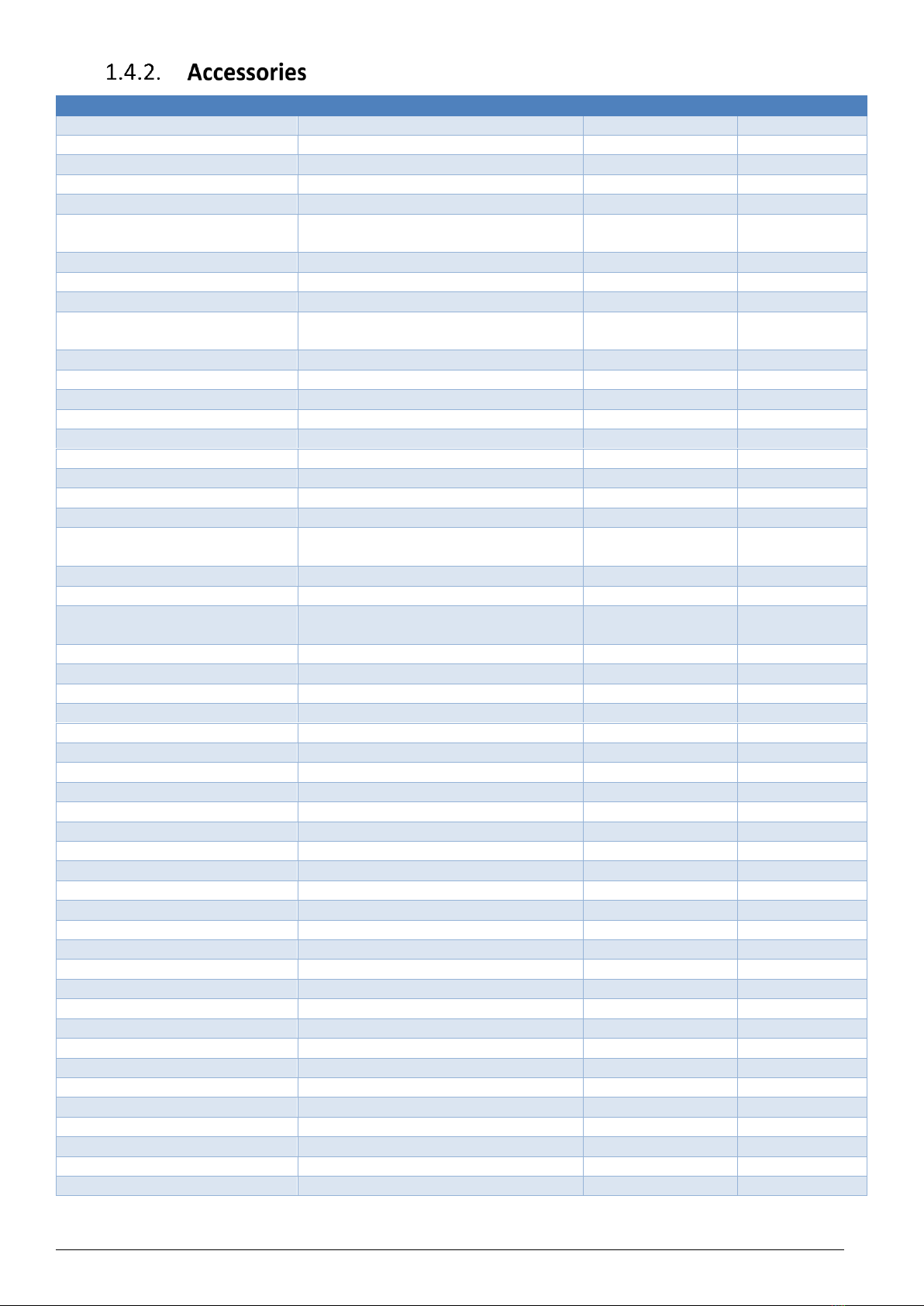

References

Description

Capacity

Lot

Swing-out Rotors, Buckets & Lids

AFI-RXN150

Swing-Out rotor 4x 150 ml

4x 150 ml

One unit

AFI-CPI150

Clinical Pack

36 x 5 ml

One unit

AFI-B150

150 ml Round Buckets

24 x 5 ml

Set of 4

AFI-SB150

150 ml Square Buckets

36 x 5 ml

Set of 4

AFI-DB50

Dedicated Buckets for 50/10 ml Conical

Tube

8 x 50 ml

Set of 4

AFI-L150

Biosafety secured lid for AFI-B150

-

Set of 4

AFI-LSB150

Biosafety secured lid for AFI-SB150

-

Set of 4

NU-RHDW-N150

Swinging Bucket Rotor

2 microplate carriers

One unit

NU-BHDW-N150

Microplate Carrier

2 x 3 Microplates

2 x 1 Deep-Weel

Set of 2

Adapters for Square buckets

-

AFI-06T50C-SB

50 ml Conical Tube

4 x 50 ml

AFI-06T50AOR-SB

50ml AOR* Round Tube

4 x 50 ml

AFI-06T50S-SB

50 ml Skirted Conical Tube

4 x 50 ml

AFI-06T30-SB

30 ml Conical Tube

4 x 30 ml

AFI-06T30S-SB

30 ml Skirted Conical Tube

4 x 30 ml

AFI-06T15C-SB

15ml Conical Tube

8 x 15 ml

AFI-06T10C-SB

10ml Conical Tube

16 x 10 ml

AFI-06T10-SB

10 ml Blood Collection Tube

14ml Urine Tube

16 x 10 ml / 14 ml

AFI-06T5-SB

5-7ml Blood Collection Tube

36 x 5 ml

AFI-06T2-SB

1,5 - 2ml MicroTube

72 x 2 ml

Adapters for Round buckets

(possibility set of 2)

-

Set of 4

AFI-06T80AOR

80ml AOR* Round Tube

4 x 80 ml

AFI-06T50C

50 ml Conical Tube

4 x 50 ml

AFI-06T50AOR

50ml AOR* Round Tube

4 x 50 ml

AFI-06T50S

50 ml Skirted Conical Tube

4 x 50 ml

AFI-06T30

30 ml Conical Tube

4 x 30 ml

AFI-06T30S

30 ml Skirted Conical Tube

4 x 30 ml

AFI-06T15C

15ml Conical Tube

8 x 15 ml

AFI-06T10C

10ml Conical Tube

12 x 10 ml

AFI-06T10

14ml Urine Tube

16 x 14 ml

AFI-06T10

10ml Blood Collection Tube

16 x 10 ml

AFI-06T5

5-7ml Blood Collection Tube

24 x 5 ml

AFI-06T2

1,5 - 2ml MicroTube

48 x 2 ml

Fixed Angled Rotor

NU-FAN6-50

6 x 50 ml Angular Rotor

6 x 50 ml

One unit

Adapters for Fixed Angled Rotor

AFI-50R50-OAK

50ml AOR* Round Tube

6 x 50 ml

AFI-50R30-C

30 ml Conical Tube

AFI-50R30-OAK

30ml AOR* Round Tube

6 x 30 ml

AFI-50R15-C

30ml AOR* Round Tube

6 x 30 ml

AFI-50R10-OAK

10ml AOR* Round Tube

6 x 10 ml

AFI-50R10

10ml Blood Collection Tube

Accessories Kits

71199003

Cleaner / Disinfectant

71199012

Tube of Grease 20 gr

71199020

Replacement Kit AFI-LS150 O-rings for lids

Set of 4

Original Instructions Rev.1.0 User Manual –Isa 8/ 42

Safety Instructions

The operator must observe the following precautions when using the

centrifuge:

Ensure stability and perfect levelling of the centrifuge.

Check the correct mounting of the rotor and its accessories before starting a centrifugation cycle.

Check tube resistance at maximum applied centrifugal force: chemical resistance to centrifuged products and

mechanical strength at the centrifugal force applied thereto.

Check the condition of the tubes and remove damaged tubes.

Use only the rotors and accessories authorized by the manufacturer AFI Centrifuge.

Swing-out rotors: install four (or two) buckets; never perform any cycle with missing buckets.

Maintain and control accessories.

Balance the load of the rotor around the axis of rotation.

Respect the maximum density of 1.2 g / cm3,in particular in case of a cycle at full speed.

Limit volume in case of excess density.

Install the centrifuge in a ventilated area, on a horizontal rigid support to absorb the vibrations generated by the

centrifuge.

During operation, the centrifuge must not be moved or be subject to impact.

Do not attempt to open the lid while the rotor is spinning.

Do not attempt to neutralize the motorized lid lock

Do not lean over the centrifuge during the spin cycle.

Do not stay within a space of 10 inch around the centrifuge longer than necessary.

Do not leave potentially dangerous materials inside the free space.

Use aerosol-barrier accessories when centrifuging bio hazardous material.

Condensation may form inside the centrifuge when it is moved from a cold environment to a warm environment.

Allow the centrifuge to warm up for two hours before use.

Information on the refrigerant fluid used

The "refrigerant" type apparatus contains fluorinated greenhouse gases under the Kyoto Protocol. They should therefore

not be released into the atmosphere. Repairs or disassembly of this appliance should only be carried out by qualified

personnel.

The data corresponding to the type of refrigerant, the Global Warming Potential (GWP) value, and the load are detailed in

§ 1.4.1.Specifications.

CAUTION

!

Original Instructions Rev.1.0 User Manual –Isa 9/ 42

Installation Instructions

Shipment

AFI Centrifuge takes every reasonable precaution to assure that your ISA Centrifuge arrives without damage. Motor carriers

are carefully selected and shipping cartons have been specially designed to insure your purchase. However, damage can

occur in any shipment and the following outlines the steps you should take on receipt of a ISA Centrifuge to be sure that if

damage has occurred, the proper claims and actions are taken immediately.

Damaged Shipments

Terms are factory, unless stated otherwise. Therefore, it is important to check each shipment before acceptance.

If there is visible damage, the material can be accepted after the driver makes a notation on the consignee's copy of the

freight bill. Then an inspection must be made to verify the claim against the carrier. This inspection is the basis of your

filing the claim against the carrier.

If concealed damage is found it is absolutely necessary to NOTIFY THE FREIGHT AGENT AT ONCE and request an inspection.

Without this inspection, the transportation company may not accept a claim for loss or damage. If the carrier will not

perform the inspection, an affidavit must be prepared stating that he was contacted on a certain date and that he failed to

comply with the request. This along with other papers in the customer's possession will support the claim.

Handling and transport

The package containing the centrifuge needs to be handled by suitable means (pallet truck, etc.).

Please ensure that the people in charge of handling are qualified to handle the lifting equipment.

Maintain the following conditions during transport:

Temperature: -20 to 50 ° C

Relative humidity: <90%, under the dew point

Unpacking

Remove the cardboard packaging made of 2 parts (a lid and a bottom).

The ISA Centrifuge was packed with great care to prevent transport hazards. Before disposing of the packaging of the

centrifuge, and its spinning accessories, please make sure you are in possession of the following:

Packing list

ISA CENTRIFUGE

Compliance Certificate

User Manual

Power Cord

Rotor Fixing Wrench

Manual release key

Food grade grease

CAUTION

!

Original Instructions Rev.1.0 User Manual –Isa 10/ 42

Machine Description

Fig. 1 ¾ Front View

1. Lid

2. Window

3. Control panel

4. Opening lid button

5. Cooling unit

6. Electrical outlet

Interface description

1. Power ON-OFF, START-STOP, & cycle interruption button.

Can be activated through single press or press & hold action.

2. Display screen.

3. Validation button: Can be activated through single press or

press & hold action.

4. Setting knob. It is a lighting knob, giving information

concerning the centrifuge status, corresponding to colors changes.

5. Program number / Error number

6. Service key logo

7. Speed parameters : unit (rpm or xg), radius (mm)

8. Time unit : Hour / Minute or Minute / Second

9. Temperature unit (Celsius or Fahrenheit degree)

10. Slope parameters : Acceleration or Braking slope

Site preparation

Prepare a stable, clean and levelled support (e.g. laboratory bench). This support must be able to support the weight of the

centrifuge and its use, and be firm enough so as not to generate or maintain

vibration. Such vibrations would degrade the results of the centrifugation, and

may result in an unbalanced error.

A clearance envelope of 30 cm (11.8 inch) around the centrifuge should be

arranged according to IEC 61010-2-020: No potentially hazardous material,

nobody or no object shall be deposited within the free space.

Fig. 2 Open space around the centrifuge

It is recommended that no less than two people are present to manually lift the

centrifuge onto the laboratory bench.

CAUTION

!

2

1

3

5

4

6

2

1

3

4

4

5

8

7

6

9

30 cm

30 cm

Front Access

30 cm

Original Instructions Rev.1.0 User Manual –Isa 11/ 42

Electrical & Environmental Requirements

The centrifuge requires must be 230V/50Hz or 115V/60Hz, single phase, (current rating varies per centrifuge model, refer

to § 1.4.1 Specifications) according to the manufacturer sheet on the back of the unit.

The centrifuge must be plugged into an outlet with protective earthing connection with the standard power cord.

The electrical outlet into which the centrifuge is connected should be readily accessible for maintenance purposes.

The power cord plug serves as the main disconnect device and should remain readily accessible. The electrical outlet should

be on its own branch circuit, protected with a circuit breaker at the distribution panel near the centrifuge.

The centrifuge is designed for use under the following ambient conditions (according to EN 61010-1)

• Indoor use

• Maximum altitude: 2000 m

• Ambient temperature range of 5 to 40 ° C

• Maximum relative humidity of 80% for temperatures up to 22 ° C,

• Supply voltage fluctuation <± 10% of rated voltage.

• Overvoltage on the Category II power supply network (IEC 60364-4-44 standard)

• Maximum degree of pollution of the room: 2.0

• Walls less than 1m away must be able to stop the centrifuge from moving in the event of a major accident.

Maximum performance is ensured in the following ambient temperature range: 15 ° C to 25 ° C.

Original Instructions Rev.1.0 User Manual –Isa 12/ 42

Operating the ISA centrifuge - AFI-CI060

First Start

The first start must fulfill the conditions of the IEC 61010-2-020 safety standard

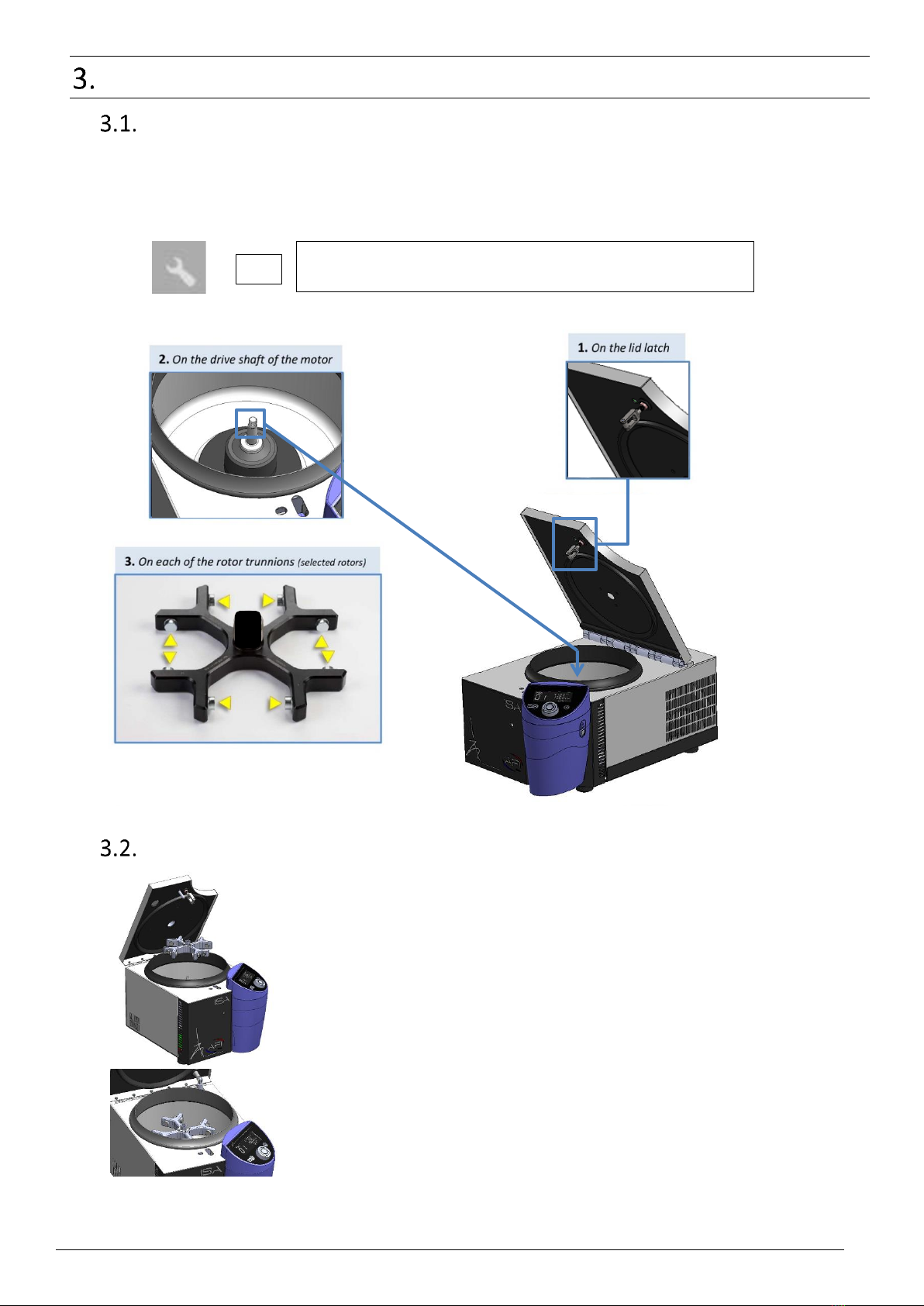

HOW TO GREASE A ISA CENTRIFUGE

Rotor assembly

Clean and lubricate the motor shaft by depositing a thin film of the

food grade grease supplied.

Place the rotor above the drive shaft.

Slide the rotor on the drive shaft.

Use the provided wrench to tighten the rotor nut onto the motor

shaft.

Remove the wrench

Clean and lubricate the pins by depositing a thin film of the food

grease supplied.

+

Grab the synthetic grease container provided with your centrifuge.

Dispense a small amount of grease on each of the following locations:

01

Original Instructions Rev.1.0 User Manual –Isa 13/ 42

Position the buckets

Swing-out rotors are used with round and square buckets or

microplate buckets.

Place the buckets & lids in the corresponding numbered locations.

First powering

After transport, wait at least 2 hours before putting the appliance

into operation so that the refrigerant circuit is fully efficient. Connect

the power cord to the mains.

Press & maintain the START-STOP button onto the control panel,

until display powering.

An animation starts during the initialization phase.

The parameters of a program appear.

Note: To enter the standby mode, press and hold the START / STOP

key: Only the knob remains illuminated.

Opening the lid

On the first start, the lid may not open right away due to a long storage in a cold

environment.

In this case, warm-up the hinge spring by repeated manual shifting of the lid

downwards.

To open the lid, press the button on the right side.

During a first start, it is possible that the lid does not open frankly after prolonged storage. In this case, activate the spring

hinges by manually manipulating the cover from top to bottom.

To close the lid, lower the lid and press until click.

CAUTION

Original Instructions Rev.1.0 User Manual –Isa 14/ 42

Rotor loading and balancing

Position the 4 numbered buckets in their corresponding positions on the rotor. Each

bucket should pivot freely in its slot.

Place the inserts corresponding to the tubes to be centrifuged in the four buckets.

The buckets must be symmetrically distributed.

For better balance, each numbered bucket must be placed in the corresponding position

marked on the rotor.

Each position on the rotor must be equipped with its bucket.

Do not use a rotor without its complete set of four buckets.

Maximum loads according to the type of rotor are specified in the annex.

The centrifuge tolerates an imbalance of 8 grams.

If the imbalance is higher than the tolerated threshold, an imbalance detection system

stops the centrifuge automatically.

Key logo and error message "02" appear. The rotor stops in free wheel mode without

braking system.

Excessive imbalance is likely to damage the turning components and/or the centrifuge.

Follow loading instructions referring to corresponding rotor description in § 9 Annex 1:

Accessory Specifications.

Original Instructions Rev.1.0 User Manual –Isa 15/ 42

Quick start-up

Before using the centrifuge, make sure it has been properly installed.

Original Instructions Rev.1.0 User Manual –Isa 16/ 42

Operating

Settings

Program setting is done adjusting successively following parameters:

Speed

Cycle Duration

Temperature

Acceleration Slope

Braking slope

Set Speed

#

Action

Instruction

Effect

1

Select the program number spinning

the knob.

The program number is displayed under

"Prog".

2

Press & hold validation button.

The selected program is now in

Modification mode.

Speed value is now blinking.

3

Modify blinking value spinning the

knob.

The speed value is modified.

Default setting unit is rotation per

minute (rpm).

To modify the unit, refer to § 4.11.1 Set

Speed Unit / Centrifuge Force

4

x6 (on

refrigerating

model)

Press validation button 6 x to validate.

(On ventilated model, press 5x)

The modification of the selected

program is saved.

Set duration

#

Action

Instruction

Effect

1

Select the program number spinning

the knob.

The program number is displayed under

"Prog".

2

Press & hold validation button.

The selected program is now in

Modification mode.

Speed value is now blinking.

3

x1

Press 1x to access to duration

parameter.

Duration value is blinking.

4

Modify blinking value spinning the

knob.

The duration value is modified.

Default setting unit is minutes : seconds

(min:sec).

5

x5 (on

refrigerating

model)

Press 5 x to validate.

(On ventilated model, press 4x)

The modification of the selected

program is saved.

Set Temperature (Refrigerating model)

#

Action

Instruction

Effect

1

Select the program number spinning

the knob.

The program number is displayed under

"Prog".

2

Press & hold validation button.

The selected program is now in

Modification mode.

Speed value is now blinking.

3

x2

Press 2x to access to temperature

parameter.

Duration value is blinking.

Table of contents

Other AFi Laboratory Equipment manuals