AFL Noyes CSS1 Series User manual

CSS1 Contractor Series Light Sources and

CSM1 Contractor Series Optical Power Meters

User’s Guide

www.AFLglobal.com or (800) 321-5298, (603) 528-7780

Limited Warranty

All NOYES test equipment products are

warranted for a period of (1) one year from

the date of delivery to the end user. Extended

warranties start at the end of the standard (1)

one year warranty period.

1 year, 2 year, and 4 year extended warranties

are available for NOYES products with or

without annual calibration included. Please see

our website at www.AFLglobal.com for more

information.

Any product that is found defective within

the warranty period will, at the discretion of

AFL, be repaired or replaced. Warranty will

be voided if the product has been repaired or

altered by other than an authorized NOYES

product repair facility, if the void sticker has

been compromised, or which have been

subject to misuse, negligence, or accident. In

no case shall AFL liabilities exceed the original

purchase price.

CE Information

These instruments have been

designed and tested to comply

with the relevant sections of

any applicable specications including full

compliance with all essential requirements of

all applicable EU Directives.

Returning Equipment

To return equipment, please contact NOYES

to obtain additional information and a Service

Request (S.R.) number. To allow us to serve

you more efciently, please include a brief

description specifying the reasons for the

return of the equipment.

AFL

NOYES Test and Inspection

16 Eastgate Park Road

Belmont, NH 03220

Tel: 800-321-5298 or 603-528-7780

Fax: 603-528-2025

I

Contents

Safety Information

Important Safety Information.......................................... III

Section 1: General Information

Introduction ................................................................... 2

Contacting NOYES Customer Service .............................. 2

Unpacking and Inspection .............................................. 2

Recommended Accessories............................................. 3

Section 2: Functional Description

CSS1 Series Light Sources ............................................... 4

CSM1 Series Optical Power Meters ................................. 6

Front Panel Features................................................... 6

Display Readings ........................................................ 8

II

Section 3: Applications

Measuring Optical Power................................................ 10

Testing Fiber Links.......................................................... 12

Step I - Set the Reference (One Jumper Method) ......... 12

Step II - Verify Test Jumpers ....................................... 14

Step III - Measure Link Insertion Loss .......................... 16

Section 4: Maintenance

Battery Replacement ...................................................... 18

Cleaning Optical Ports .................................................... 18

To Clean CSS1 Optical Port ......................................... 20

III

Safety Information

Important Safety Information

WARNING! Use of controls or adjustments other than those specied herein may

result in hazardous radiation exposure.

The CSS1-MM light source is a CLASS I LED PRODUCT.

The CSS1-SM light source is a CLASS I LASER PRODUCT.

CAUTION! To avoid serious eye injury, never look directly into the optical outputs of

ber optic network equipment, test equipment, patch cords, or test jumpers. Always

assume that optical outputs are on.

NOTICE! NOYES power meters and light sources contain no user serviceable parts.

Except for changing batteries and cleaning optical ports, these units must be returned

to NOYES or authorized agents for repair and calibration.

IMPORTANT! Proper care in handling should be taken when using any precision

optical test equipment. Scratched or contaminated optical connectors can impact the

performance of the instrument. It is important to keep the dust caps in place when the

unit is not being used.

!

!

!

!

2

Section 1: General Information

Introduction

The purpose of this User’s Guide is to explain how to use and maintain NOYES test equipment.

Please check our web site at www.AFLglobal.com for updates to this manual, software

updates, and additional application information. If you have any questions about your

instruments and recommended accessories, or if you need technical or sales support, please

contact NOYES Customer Service.

Contacting NOYES Customer Service

You may call NOYES Customer Service between 8 a.m. and 5 p.m., United States Eastern Time, as

follows:

Phone: 800-321-5298 (North America)

603-528-7780

Fax: 603-528-2025

Email: NOYESTechSupport@AFLglobal.com

Unpacking and Inspection

These instruments have been carefully packed in accordance with standard shipping procedures.

Examine the equipment for damage that may have occurred during shipment. If you nd any

damage, please contact NOYES.

3

Recommended Accessories

You will need ber optic test jumpers to connect instruments to the ber optic system under test.

A test jumper must have the same core and cladding size as the ber under test. The connector at

one end of the test jumper must mate with the optical port on each instrument. The connector on

the other end must mate with the ber optic system under test.

A Connector adapter is required to mate ber optic test jumpers.

Optical ports and connector end faces must be kept free from dirt or other contaminates to

ensure accurate measurements and operation.

For cleaning connector end faces on light sources, test jumpers, and in ber frames or adapters,

use optical quality cleaning uid such as AFL FCC2 connector cleaning uid and AFL CCT molded

cleaning tips.

For cleaning an optical power meter port and adapter caps, use lint-free optical cleaning wipes

such as AFL FiberWipes and optical quality cleaning uid such as AFL FCC2 connector cleaning

uid (or IPA - Reagent Grade Isopropyl Alcohol 99% or better) and a can of ltered compressed

air.

Visit our web at www.AFLglobal.com for more information.

4

-.0.0.00

-00.00

nm

dBm

uW

Ref

λ IDCWTone

nm

dBmHz

Tone

CSS 1

[Tone/CW] key [l]- wavelengths key

4

[Power] key

1

6

3

Output port

2

Display

[Backlight] key

5

Section 2: Functional Description

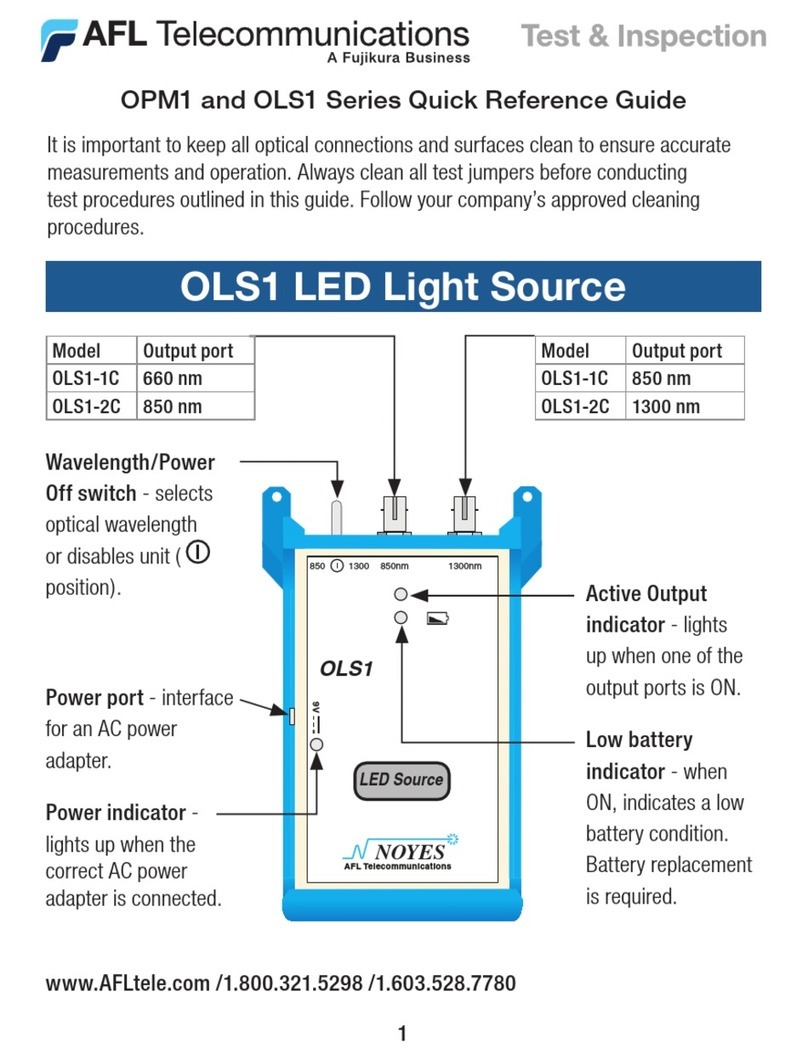

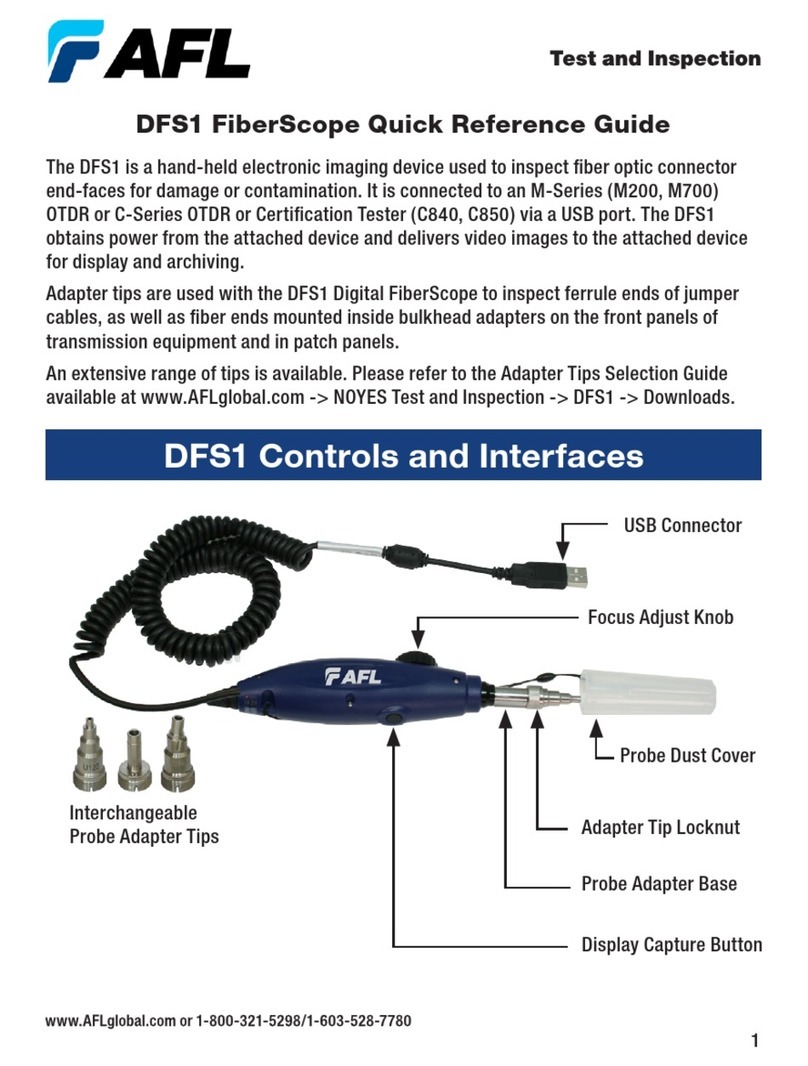

CSS1 Series Light Sources

Figure 2-1: Front Panel Features.

5

270

1300 nm

Hz

Tone

Enabled wavelength

Tone frequency

Low battery indicator

CSS1 Model Features

Figure 2-1 illustrates the CSS1 model features described below.

1 Output port - Emits either continuous (CW) or modulated with one of four tone frequencies

(270, 330, 1000, 2000 Hz) light. This output port is equipped with a UCI base and adapter.

2 Display - Shows the enabled Wavelength [nm] and Tone frequency [Hz]. Also, the [Low

battery] indicator will be displayed to identify a low battery condition.

3 [Tone] key - Tone select key. Press this key to cycle through the available tone frequencies

or switch to the CW mode.

4 [Power] key - Press and hold for 2 sec. to turn the CSS1 on, press again to turn it off. Press

and hold during power up until the letter [AP] is displayed to enable the Auto-off feature.

5 [Backlight] key - Press this key to toggle the Backlight on or off.

6 [l - Wavelength] key - Press this key to toggle between two wavelengths.

6

Ref

dB

dBm

µW

Set Ref

CSM 1

-.0.0.00

-00.00

nm

dBm

uW

Ref

λ IDCWTone

nm

dBmHz

2

5

3

Optical input -

adapter cap mount

Display

[Wavelength/

Backlight] key

[Set Reference] key

[dB/dBm/µW] key

[Power] key

Adapter cap

1

7

6

4

Figure 2-2: Front Panel Features.

CSM1 Series Optical Power Meters

Front Panel Features

7

Front Panel Features

Figure 2-2 illustrates the CSM1 model features described below.

1 Optical input (adapter cap mount) - Accepts NOYES thread-on adapter caps.

2 Adapter cap - The CSM1 must be equipped with an adapter cap. Caps for different

connector styles are available from NOYES.

3 Display - Shows measured power [dBm or µW] or insertion loss [dB], enabled wavelength,

and tone frequency [Hz] if detected. Also, the [Low battery] indicator will be displayed to

identify a low battery condition.

4 [dB/dBm/µW] key - Provides two functions as follows:

• Pressthekeytotoggletestreadingsbetweeninsertionlossin[dB]andpowerin[dBm].

• Pressandholdthekeyuntiltheword[HELD]isdisplayedtoviewpowerin[µW].

5 [Power] key - Provides two functions as follows:

• Pressandholdthekeyfor2sec.toturntheCSM1on.Pressagaintoturnitoff.Theunit

will turn off automatically ve minutes after the last key press.

• Pressandholdthekeyduringpowerupuntiltheletter[P]isdisplayedtodisablethe

[Auto Off] feature.

6 [l - Wavelength/ Backlight] key - Provides two functions as follows:

8

• Pressthekeytocyclethroughthecalibratedwavelengths.

• Pressandholdthekeyuntiltheword[HELD]isdisplayedtotoggletheBacklightonor

off.

7 [Ref/Set Ref] key - Provides two functions as follows:

• Pressandreleasethekeytodisplaythestoredreferencelevelforthecurrentlyselected

wavelength.

• Press and hold the key until the word [HELD] is displayed to store the currently measured

level as the new reference level. Once the new reference is set, the CSM1 switches to the

loss [dB] measurement mode.

Display Readings

Figures 2-3 illustrates the CSM1 display readings described below.

1 Test measurements eld - This eld displays various test measurements as follows:

• Displays measured power [dBm or µW] or insertion loss [dB]. If power or loss is too high

or low for the CSM1 to measure, this eld will display [HI] or [LO].

• Ifthereferencepowerlevelissetforthe currently enabled wavelength, this eld will

display the reference value. To see the reference value, press and release the [Ref] key.

Reference value will be displayed briey (for about 3 seconds), and then Display will

revert to test readings.

2 Wavelength/frequency eld - This eld displays the currently enabled wavelength,

9

-88.88

-.8.8.88 dB (dBm)

µW

Hz

nm

Tone CW

1

2

3

which will alternate with modulation frequency if detected.

3 Tone/CW/Battery status eld - This eld displays [Tone] label to indicate the presence of

one of the 4 modulation frequencies, [CW] label to indicate no tone, and a battery icon used

to indicate the Low battery state - battery requires replacement.

Figure 2-3: Display Readings.

10

!

Section 3: Applications

It is important to keep all optical connections and surfaces free from dirt, oils, or

other contaminants to ensure proper operation. Always clean all test jumpers before

conducting the test procedures outlined in this Guide (see Section titled “Maintenance”

for details).

Measuring Optical Power

Figure 3-1 illustrates the following procedures.

1 Turn on the CSM1 optical power meter.

2 Select the appropriate ber optic test jumper. The ber type of this jumper must be the same

as the ber type normally connected to the output being measured.

3 Mount the appropriate adapter cap on the CSM1 optical input. This adapter cap must match

the connector on the end of the test jumper you will connect to the CSM1.

4 Connect one end of the test jumper to the CSM1 adapter cap and the other end to the

optical output to be measured.

5 Press the [l] key to select the calibrated wavelength that matches the nominal wavelength

of the source being measured.

6If the CSM1 is presently measuring loss [dB], press and release the [dB/dBm] key to display

power in [dBm], or press and hold to display power in [µW].

11

Output Input

Ref

dB

dBm

µW

Set Ref

CSM 1

-.0.0.00

-00.00

nm

dBm

uW

Ref

λ IDCWTone

nm

dBmHz

Figure 3-1: Measuring Optical Power

Adapter cap

Test jumper

Fiber optic equipment

1

2

3

4

4

5

6

12

Testing Fiber Links

Step I - Set the Reference (One Jumper Method)

Figure 3-2 illustrates the following procedures.

1 Turn on the CSM1 optical power meter and CSS1 light source. Allow the CSS1 light source to

stabilize (minimum of 2 minutes).

2 Set both instruments to the desired test wavelength.

3 Select the appropriate ber optic transmit and receive test jumpers. The ber type of these

jumpers must match the ber type of the link to be tested.

4 Wrap and secure the transmit jumper ve times around the appropriate diameter mandrel.

Note: Clean both ends of the transmit jumper.

5 Connect the transmit jumper to the CSS1 output port.

6 Mount an adapter cap on the CSM1 that matches the free connector on the transmit jumper.

7 Connect the free end of the transmit jumper to the CSM1. If necessary, press the [dB/dBm]

key to display optical power in [dBm].

8 If measured output power is outside of the normal range (specied by manufacturer), clean

all ber connections or replace the transmit jumper. Repeat steps 5 - 7.

9 To set the reference level at the current wavelength perform the following steps:

13

Figure 3-2: Set the Reference.

transmit jumper

CSS1 CSM1

0 dB

mandrel wrap

4

56

7

• OntheCSM1,pressandholdthe[Ref/SetRef]keyuntil the word [HELD] is displayed to

store the currently measured level as the new reference level.

• Oncethenewreferenceisset,theCSM1switchestotheloss[dB]measurementmode.

The CSM1 should display [0 dB] ± 0.05 dB.

Note: You may press the [Ref/Set Ref] key to display the stored reference level for the

currently selected wavelength.

14

Step II - Verify Test Jumpers

Figure 3-3 illustrates the following procedures.

10 Disconnect the transmit jumper from the CSM1.

Note: Do not disturb the transmit jumper at the CSS1 end.

11 If necessary, change the CSM1 adapter cap to match the connector on the receive jumper

that will be connected to the CSM1.

Note: Clean both ends of the receive jumper.

12 Connect the receive jumper to the CSM1.

13 Mate the free ends of the transmit and receive jumpers using the appropriate adapter.

14 Verify that the insertion loss of this mated connector pair is under 0.75 dB, the maximum

allowed by the TIA (NOYES recommends 0.4 - 0.5 dB typical), as follows:

• Observe the displayed power level. This is the mated connector pair insertion loss of the

test jumpers in [dB].

15 If the insertion loss is not acceptable, disconnect the transmit and receive jumpers at the

adapter.

• Cleanthefreeendsofbothtestjumpers

• Repeat steps 13 & 14.

• If the insertion loss is still not acceptable, replace test jumpers and repeat steps 1-14.

15

CSM1

0.4 dB

CSS1

Figure 3-3: Verify Test Jumpers.

New adapter cap

(if necessary)

Transmit jumper

Do NOT disturb

this connection

Adapter

Receive jumper

Mandrel wrap

11

12

13

16 If the insertion loss is acceptable, disconnect the transmit and receive jumpers at the

adapter.

17 Move the CSM1 and CSS1 to opposite ends of the link to be tested.

16

Step III - Measure Link Insertion Loss

Figure 3-4 illustrates the following procedures.

18 Connect the free ends of the transmit and receive jumpers to the link under test.

Note: Clean jumper end that connects to patch panel prior to every test.

19 CSM1 will measure and display the insertion loss of the link under test.

20 Record link insertion loss at the current test wavelength.

21 Repeat steps 18-20 for all links to be tested at the current wavelength.

This manual suits for next models

1

Table of contents

Other AFL Measuring Instrument manuals

AFL

AFL Noyes OFS 300 User manual

AFL

AFL OFL280 FlexTester User manual

AFL

AFL DFS1 User manual

AFL

AFL NOYES OFL280-10x User manual

AFL

AFL VFI2 User manual

AFL

AFL FS300-325 User manual

AFL

AFL FOCIS Flex User manual

AFL

AFL FlexScan FS300 User manual

AFL

AFL Noyes OPM 4 OLS 2D User manual

AFL

AFL NOYES OPM Series User manual