10

Specications and Need-to-Know Information

alphaCUT 825i

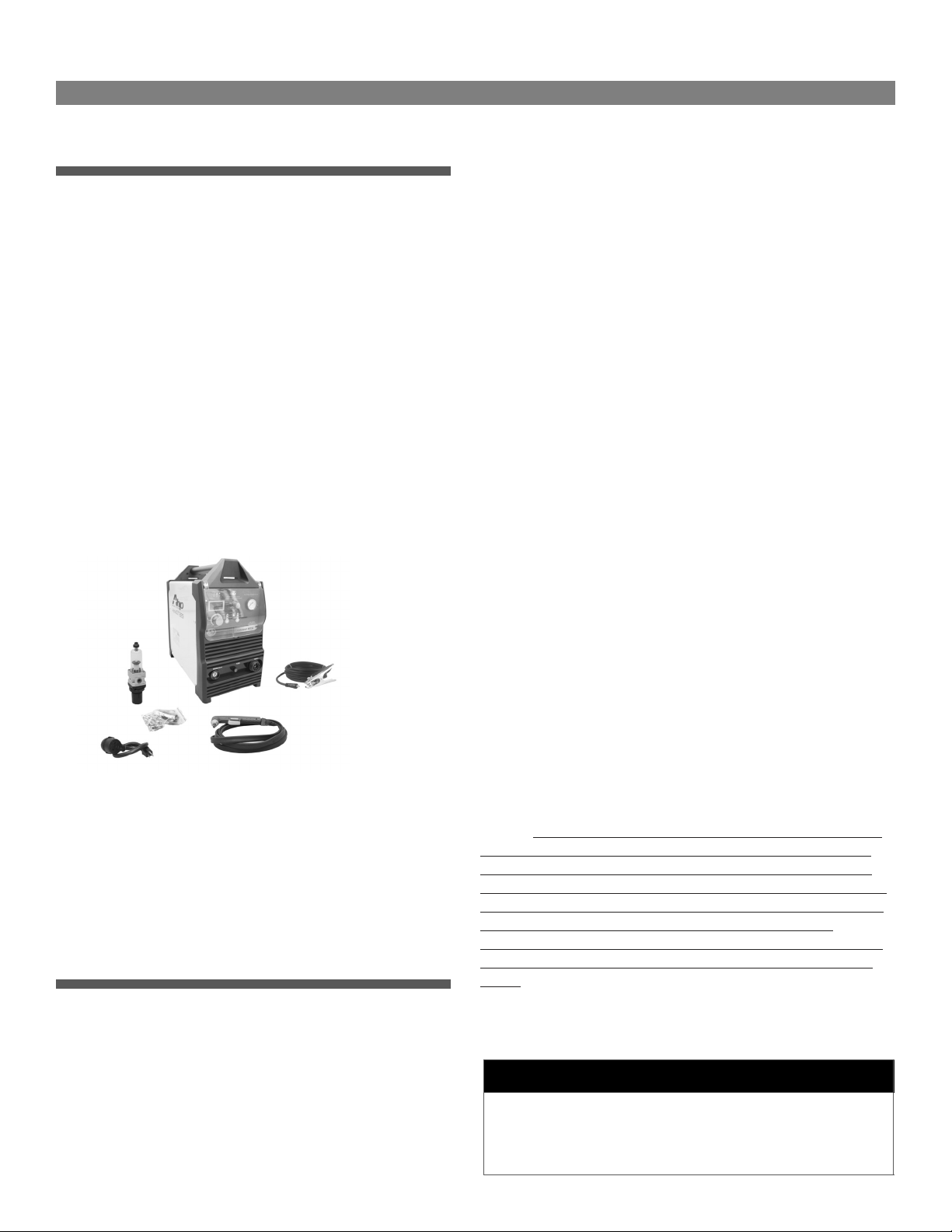

About the AlphaCUT 825i

The AlphaCUT 825i is well-suited for day to day cutting tasks in the

small shop and home garage. The duty cycle of the machine (35% at

60A) offers more than enough duty cycle to handle regular, daily

cutting chores. The design is simple and intuitive, lending itself to

perform well in situations where there are multiple or beginning us-

ers.

The unit comes standard with the following features:

• Dual Voltage 120/240V operation capability

• 60A max output for cutting nearly all metals

• 2T/4T Torch switch operation capability

• Adjustable post-flow timer

• Auto restart pilot arc or Tip Saver Pilot Arc

• Gas purge function

• Modern Blow-back type arc starting

• 20 Amp minimum operation

• Air Pressure Gauge

The unit comes standard with the following accessories:

• Innotect iPT 60 Plasma Torch, 14 ft.

• Work clamp and cable, 9 ft.

• Combination air pressure regulator/water trap

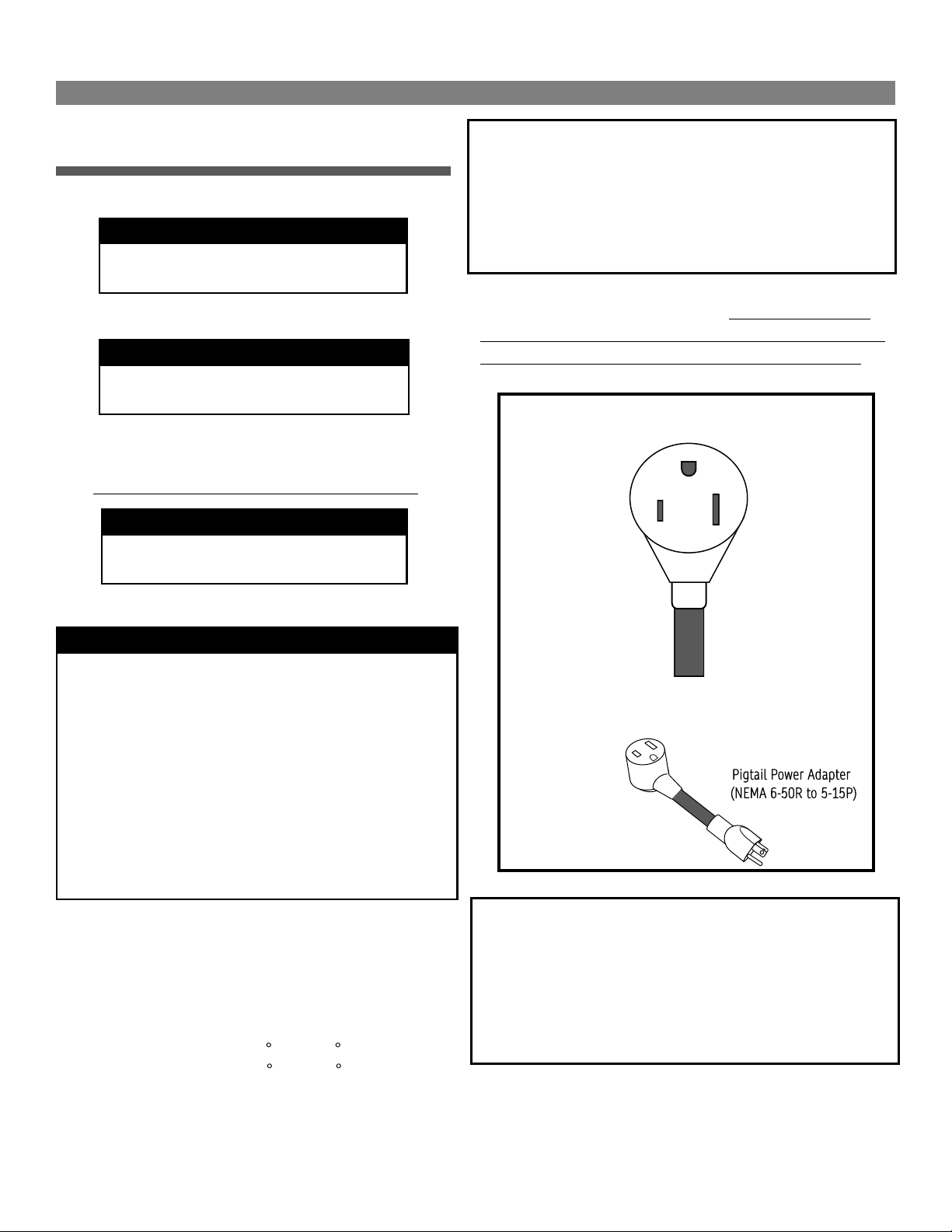

• 240 to 120V pigtail adapter

• 60A consumable starter kit

Ahp Warranty Statement

WARRANTY ONLY APPLIES TO UNITS WITH PROOF OF PURCHASE

FROM AN AUTHORIZED DEALER. NO EXCEPTIONS. PLEASE FEEL FREE

TO REQUEST A LIST OF AUTHORIZED DEALERS.

All new AHP welders and plasma cutters, shall be warrantied to the

original owner for a period to extend for 3 years from date of pur-

chase against breakage, malfunction, or other unit failure resulting

from manufacturing defect. The faulty unit will either be repaired or

an exchange will be made for a new or factory reconditioned unit at

AHP Welds discretion. The customer must contact the technical sup-

port team to review unit failure so that the warranty claim can be

established. Items such as electrodes, contact tips, nozzles, cups,

shields, liners etc, considered to be consumable items, are NOT cov-

ered under warranty. Torches, foot pedals and spool guns are warran-

tied for a period of 6 months. Additionally, certain items such as

torches, foot pedals and easily serviced parts may be individually

exchanged without returning the entire unit assembly should a fail-

ure with these items occur, at AHP Welds discretion. AHP Welds will

not be responsible for time/contract loss from unit failure, damages

occurring from improper or unskilled operation, damages resulting

from improper maintenance, improper wiring, poor quality power

sources, abuse or neglect. Nor will AHP assume responsibility for the

customer's failure to heed/read safety instructions, to read and un-

derstand operator's manual, obey occupational laws or to ensure the

unit's safe operation complies with state or local laws, personal injury

arising from the inherent risks involved with welding, including

burns, electric shock or death. Warranty extends only to the machine,

its accessories and parts contained inside as stated above. No other

warranty is expressed or implied.

In the event of unit failure or malfunction, the customer must contact

AHP to obtain a location of a designated return/repair facility. The

replacement unit will then be returned to the customer. AHP will

cover the shipping charges both ways for domestic customers that

have units in need of warranty within the first 30 days from the pur-

chase date. After the 30 days from the purchase date, the customer

shall be responsible for all shipping and handling costs both ways of

non-functioning units for repair or replacement. Customers located

outside of the USA lower 48 states will have to pay shipping and han-

dling charges both ways from the purchase date. It is the customer's

responsibility to adequately insure the unit, as AHP is not responsible

for lost or damaged returns. Labor coverage only applies if the unit is

serviced at our facility or one of our authorized dealers. We will not

reimburse the labor if the customer decides to have a third-party or

unauthorized repair technicians work on the unit.

NOTICE:

Ahp’s TIG products are designed for use by individuals with

a professional knowledge base in TIG and Stick welding and is de-

signed with commercial operation in mind. Ahp cannot be held ac-

countable for instruction and training of inexperienced users or dam-

age or malfunctions that may result from use by inexperienced users

or improper installation. If you do not have the skill level or

knowledge base to properly operate and install this machine, do not

use this machine until proper training and instruction has been re-

ceived.

View full warranty, terms of sale and shipping details here:

https://ahpwelds.com/

NOTICE:

Output on 120V will be limited to 30A. This unit is supplied with 60A consuma-

bles. To operate on 120V, you’ll need to purchase 20 or 30A rated consumables.

With a 60A consumable installed while operating on 120V, arc operation will be

erratic and unstable.. See torch page for Amp ranges of consumables.