9

Specications and Need-to-Know Information

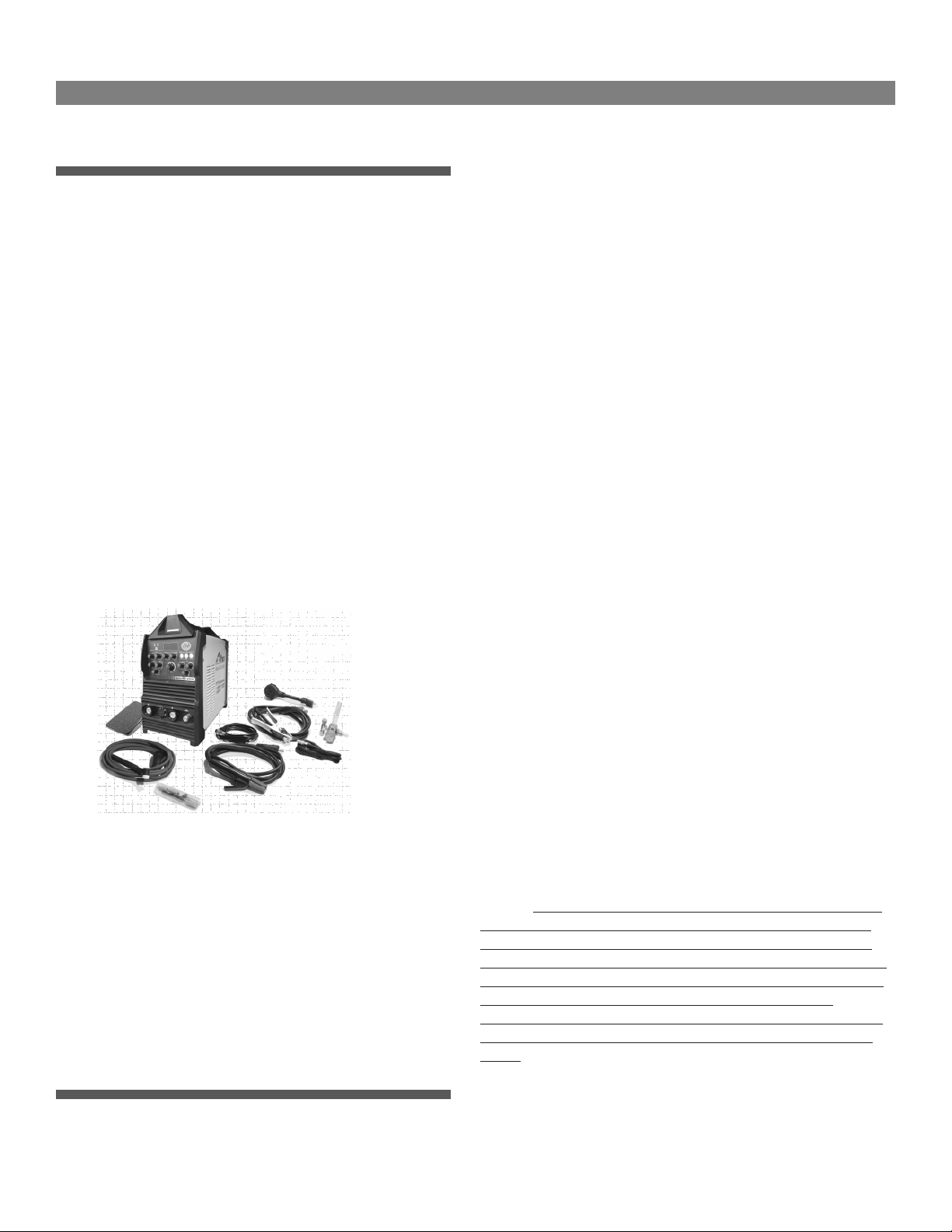

alphaTIG 225Xi

About the AlphaTIG 225Xi

The AlphaTIG 225Xi is the latest evolution of the long running Al-

phaTIG series. It utilizes the latest in digitally controlled IGBT invert-

er welding technology, while providing the user with a mostly manual

interface. This unit is great for users who tend to use a few different

settings and like to be able to see and determine their settings at a

glance, but who still desire the simplicity and reliability of a internal

digital design.

The unit comes standard with the following features:

• Dual Voltage 120/240V operation capability

• 225A AC and DC TIG output for welding all metals

• 185A AC and DC Stick output

• TIG AC Frequency adjustment

• TIG AC Balance adjustment

• 2T/4T Torch switch operation capability

• Foot Pedal operation

• HF or Lift Start Modes for TIG arc starting

• AC and DC Pulse in TIG mode

• 10 Amp DC minimum start

• 20 Amp AC minimum start

• Water Cooler Plug in the rear

The unit comes standard with the following accessories:

• Nova Long Life Foot Pedal (Low Profile)

• 26 Series Gas-Cooled TIG torch,12.5 ft cable, 35-70 DINSE style

adapter

• Basic consumable kit for TIG torch (Tungsten not included)

• Billet Brass Floating Ball type regulator

• Stick Electrode holder, 9 ft cable, 35-70 DINSE style adapter

• 2T/4T torch switch

• 250A Work Clamp, 6 ft cable, 35-70 DINSE style adapter

• 240V to 120V step down power cord pig-tail adapter

Ahp Warranty Statement

WARRANTY ONLY APPLIES TO UNITS WITH PROOF OF PURCHASE

FROM AN AUTHORIZED DEALER. NO EXCEPTIONS. PLEASE FEEL FREE

TO REQUEST A LIST OF AUTHORIZED DEALERS.

All new AHP welders, shall be warrantied to the original owner for a

period to extend for 3 years from date of purchase against breakage,

malfunction, or other unit failure resulting from manufacturing de-

fect. The faulty unit will either be repaired or an exchange will be

made for a new or factory reconditioned unit at AHP Welds discretion.

The customer must contact the technical support team to review unit

failure so that the warranty claim can be established. Items such as

electrodes, contact tips, nozzles, cups, shields, liners etc, considered

to be consumable items, are NOT covered under warranty. Torches,

foot pedals and spool guns are warrantied for a period of 6 months.

Additionally, certain items such as torches, foot pedals and easily

serviced parts may be individually exchanged without returning the

entire unit assembly should a failure with these items occur, at AHP

Welds discretion. AHP Welds will not be responsible for time/contract

loss from unit failure, damages occurring from improper or unskilled

operation, damages resulting from improper maintenance, improper

wiring, poor quality power sources, abuse or neglect. Nor will AHP

assume responsibility for the customer's failure to heed/read safety

instructions, to read and understand operator's manual, obey occupa-

tional laws or to ensure the unit's safe operation complies with state

or local laws, personal injury arising from the inherent risks involved

with welding, including burns, electric shock or death. Warranty ex-

tends only to the machine, its accessories and parts contained inside

as stated above. No other warranty is expressed or implied.

In the event of unit failure or malfunction, the customer must contact

AHP to obtain a location of a designated return/repair facility. The

replacement unit will then be returned to the customer. AHP will

cover the shipping charges both ways for domestic customers that

have units in need of warranty within the first 30 days from the pur-

chase date. After the 30 days from the purchase date, the customer

shall be responsible for all shipping and handling costs both ways of

non-functioning units for repair or replacement. Customers located

outside of the USA lower 48 states will have to pay shipping and han-

dling charges both ways from the purchase date. It is the customer's

responsibility to adequately insure the unit, as AHP is not responsible

for lost or damaged returns. Labor coverage only applies if the unit is

serviced at our facility or one of our authorized dealers. We will not

reimburse the labor if the customer decides to have a third-party or

unauthorized repair technicians work on the unit.

NOTICE:

Ahp’s TIG products are designed for use by individuals with

a professional knowledge base in TIG and Stick welding and is de-

signed with commercial operation in mind. Ahp cannot be held ac-

countable for instruction and training of inexperienced users or dam-

age or malfunctions that may result from use by inexperienced users

or improper installation. If you do not have the skill level or

knowledge base to properly operate and install this machine, do not

use this machine until proper training and instruction has been re-

ceived.

View full warranty, terms of sale and shipping details here:

https://ahpwelds.com/