Page 3of 92

MAN177 rev_08_21_2018

4.5.4.3 Serial...............................................................................................................................................................35

String Format Options ...............................................................................................................................................35

Pset Changed String Format:...................................................................................................................................39

4.5.4.4 Anybus ...........................................................................................................................................................39

4.5.5 Front Panel Buttons ..........................................................................................................................................40

4.5.6 Power Up...........................................................................................................................................................40

4.5.7 Bar Code Setup................................................................................................................................................41

4.5.8 Set Time.............................................................................................................................................................42

4.5.9 Remote Connections ......................................................................................................................................43

4.5.10 Languages......................................................................................................................................................43

4.6 Diagnostics...................................................................................................................................................................... 44

4.6.1 Controller Overview.........................................................................................................................................44

....................................................................................................................................................................................44

4.6.2 Controller Status check voltages..................................................................................................................45

4.6.3 Live Tool Features.............................................................................................................................................45

4.6.4 Tool Communications update image.........................................................................................................46

4.6.5 Identify Controller.............................................................................................................................................46

4.6.6 Record Logs......................................................................................................................................................46

4.6.7 System Status....................................................................................................................................................47

4.6.8 I/O Diagnostics................................................................................................................................................47

4.7 Login................................................................................................................................................................................. 48

4.8 Advanced....................................................................................................................................................................... 48

4.9.1 Login Setup.......................................................................................................................................................49

4.9.2 Results Archive..................................................................................................................................................49

4.9.3 Import Settings................................................................................................................................................50

4.9.4 Export Controller.............................................................................................................................................51

4.9.5 Update Controller ............................................................................................................................................51

4.9.6 Backup Restore ................................................................................................................................................52

4.9.7 Restore Factory Defaults .................................................................................................................................52

4.9.8 Calibrate Touch Screen...................................................................................................................................53

4.9.9 Soft Reboot.......................................................................................................................................................54

5.) Barcode Reader Details................................................................................................................................................................ 55

6.) Icons Defined ................................................................................................................................................................................. 58

6.1 Stop Codes ..................................................................................................................................................................... 59

7.) Error Codes ..................................................................................................................................................................................... 61

8.) 24 Volt I/O....................................................................................................................................................................................... 63

9.) Assignable I/O ............................................................................................................................................................................... 66

10.) Controller supported MIDs ......................................................................................................................................................... 84

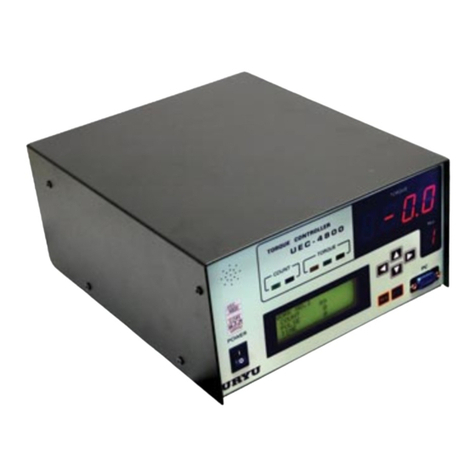

11.) Dimensions ................................................................................................................................................................................... 87

12.)

Specifications

............................................................................................................................................................................. 88

13.) Trouble Shooting .......................................................................................................................................................................... 88

14.) AIMCO Warranty.......................................................................................................................................................................... 91