3

Technical Support

1-800-248-0892

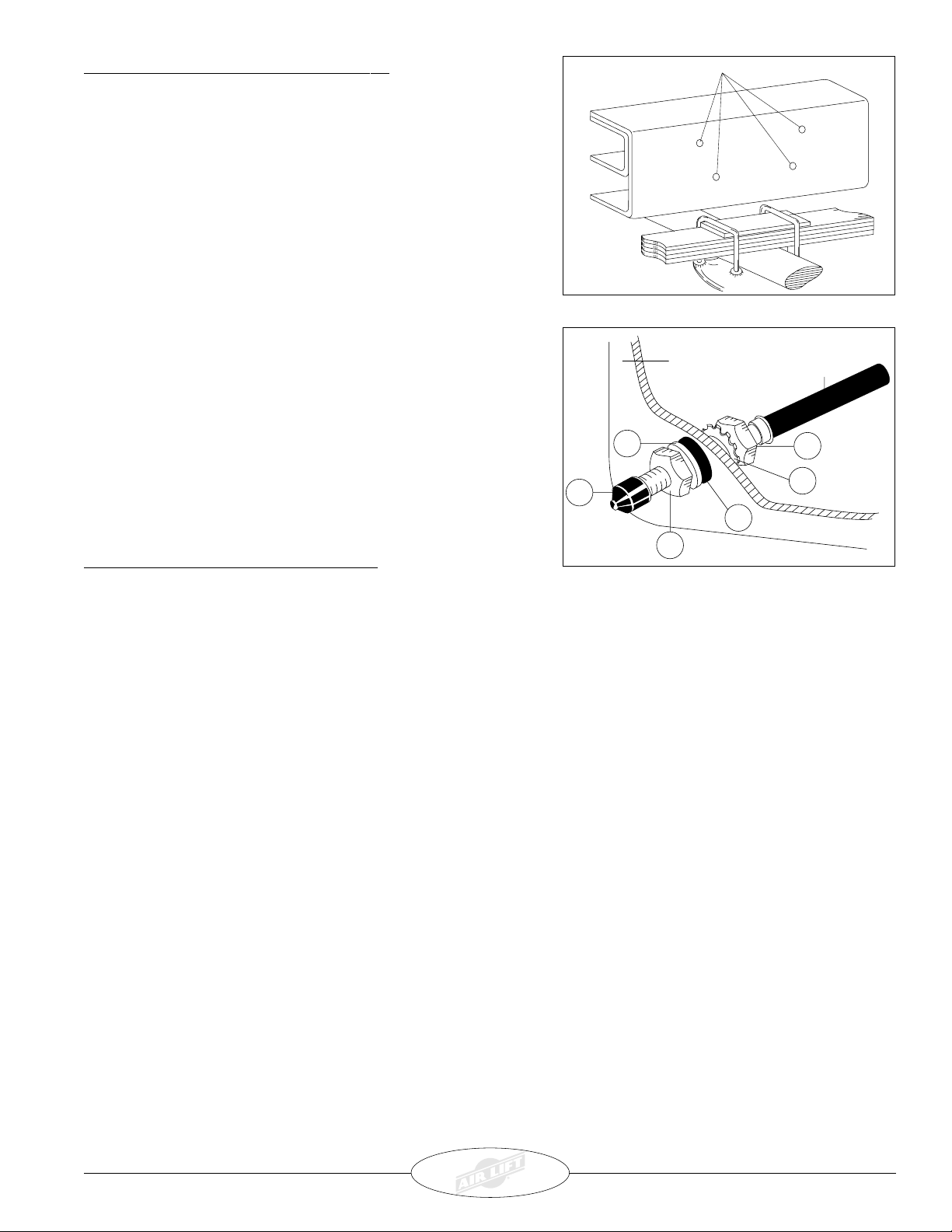

III. Installing the Assembly

1. Set the assembly on the leaf spring and insert two 1/2" carriage

bolts (L) through the bottom holes in the upper bracket and then

through the frame. Install a flat washer (M) and nylon lock nut

(N) to each bolt. Refer to Figure 1. Leave loose for

adjustment.

2. Insert two 3/8" frame bolts (I) through the top holes in the

upper bracket and frame. Secure using two flat washers (H)

and two nylon lock nuts (K) to the inside of the frame (Fig. 1).

3. Tighten all upper bracket mounting hardware at this time.

4. Insert four 3/8" bolts (J) and four flat washers (H) into the

holes on the lower bracket (Figure 1).

5. Slide two clamp bars (O) onto the bolts hanging from the lower

bracket and attach using four flat washers (H) and four nylon

lock nuts (N). Refer to Figure 1.

6. The lower bracket is slotted for in and out alignment of the air

spring. Align the air spring so that it is parallel and perpendicular

to the top and bottom. When aligned, tighten all mounting

hardware, including the lower air spring hardware to the specified

torque value found on page 5.

IV.Installing the Air Lines

1. Choose a convenient location for mounting the inflation valves

and drill a 5/16" hole to install the inflation valves. Popular

locations for the inflation valve are: the wheel well flanges, license

plate recess in bumper, under the gas cap access door, or

through license plate itself. NOTE: What ever the chosen

location is, make sure there is enough clearance around the

inflation valves for an air chuck.

2. Cut the air line assembly (AA) in two equal lengths. CAUTION: When cutting or trimming the air line, use a hose

cutter (Air Lift P/N 10530), a razor blade or a sharp knife. A clean, square cut will ensure against leaks. Do not use

wire cutters or scissors to cut the air line. These tools may flatten or crimp the air line, causing it to leak around the

O-

ring seal inside the elbow fitting.

3. Place a 5/16" nut (GG) and a star washer (FF) on the air valve. Leave enough of the inflation valve in front of the

nut to extend through the hole and have room for the rubber washer (EE), flat washer (DD), and 5/16" nut (GG) and

cap (CC). There should be enough valve exposed after installation - approximately 1/2" (13mm) - to easily

apply a pressure gauge or an air chuck (Figure 5).

4. Push the inflation valve through the hole and use the rubber washer (EE), flat washer (DD), and another 5/16"

nut (GG) to secure it in place. Tighten the nuts to secure the assembly in place (Figure 5).

5. Route the air line along the frame to the air fitting on the air spring. Keep at least 6" (150mm) of clearance

between the air line and heat sources, such as the exhaust pipes, muffler, or catalytic converter. Avoid sharp

bends and edges. Use the plastic zip ties (BB) to secure the air line to fixed, non-moving points along the chassis.

Be sure that the zip ties are tight, but do not pinch the air line. Leave at least 2" (50mm) of slack to allow for any

movement that might pull on the air line.

6. Cut off air line leaving approximately 12" (300mm) of extra air line. A clean square cut will ensure against leaks.

Insert the air line into the air fitting. This is a push to connect fitting. Simply push the air line into the 90 degree

swivel fitting until it bottoms out (9/16" of air line should be in the fitting).

Figure 4

Air Line to

Bellows

FF

Vehicle body

or bumper

GG

GG

EE

DD

CC

Figure 5