Air Lift Ride Control 59544 User manual

Other Air Lift Automobile Accessories manuals

Air Lift

Air Lift SureSET 25004 User manual

Air Lift

Air Lift LoadLifter 5000 Series User manual

Air Lift

Air Lift loadlifter 5000 User manual

Air Lift

Air Lift 60819 User manual

Air Lift

Air Lift LoadLifter 5000 88216 User manual

Air Lift

Air Lift LoadLifter 5000 Ultimate User manual

Air Lift

Air Lift WirelessAIR 74100EZ User manual

Air Lift

Air Lift 75670 User manual

Air Lift

Air Lift 60823 User manual

Air Lift

Air Lift RideControl 59516 User manual

Air Lift

Air Lift LoadLifter 5000 Ultimate User manual

Air Lift

Air Lift LoadLifter 7500 XL User manual

Air Lift

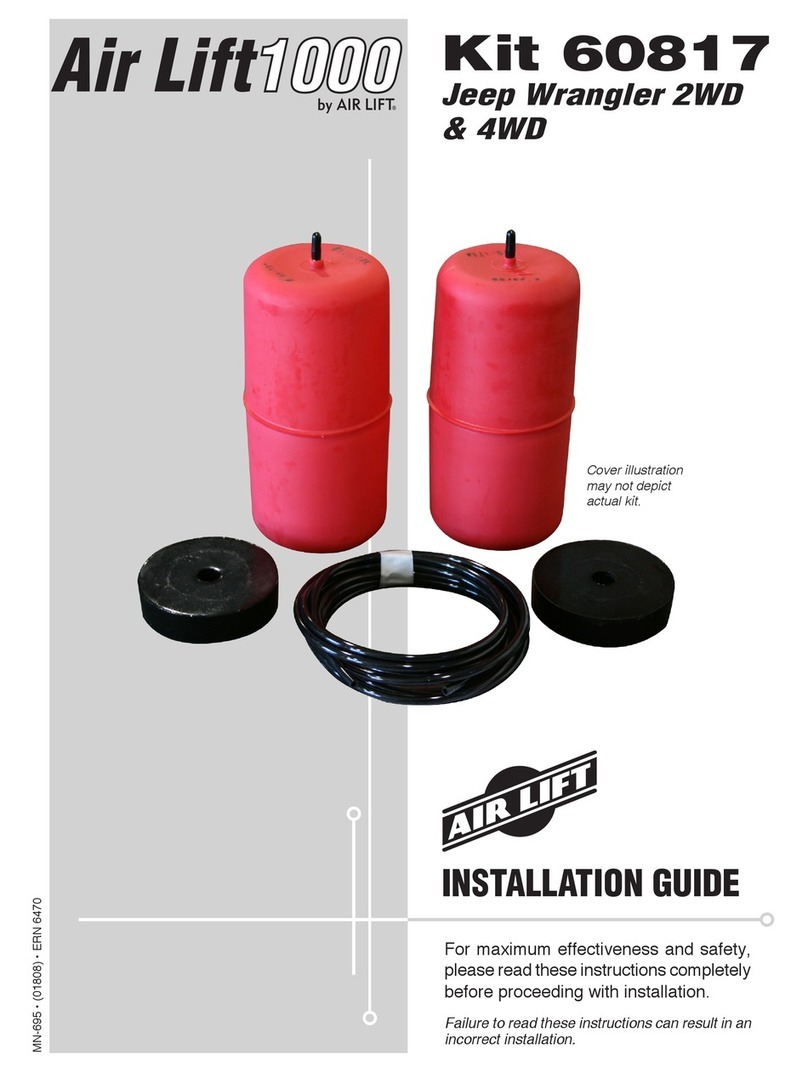

Air Lift 60817 User manual

Air Lift

Air Lift 1000 User manual

Air Lift

Air Lift AirCELL 52205 User manual

Air Lift

Air Lift RoadTamer 25325 User manual

Air Lift

Air Lift Slam Air 59111 User manual

Air Lift

Air Lift loadlifter 5000 User manual

Air Lift

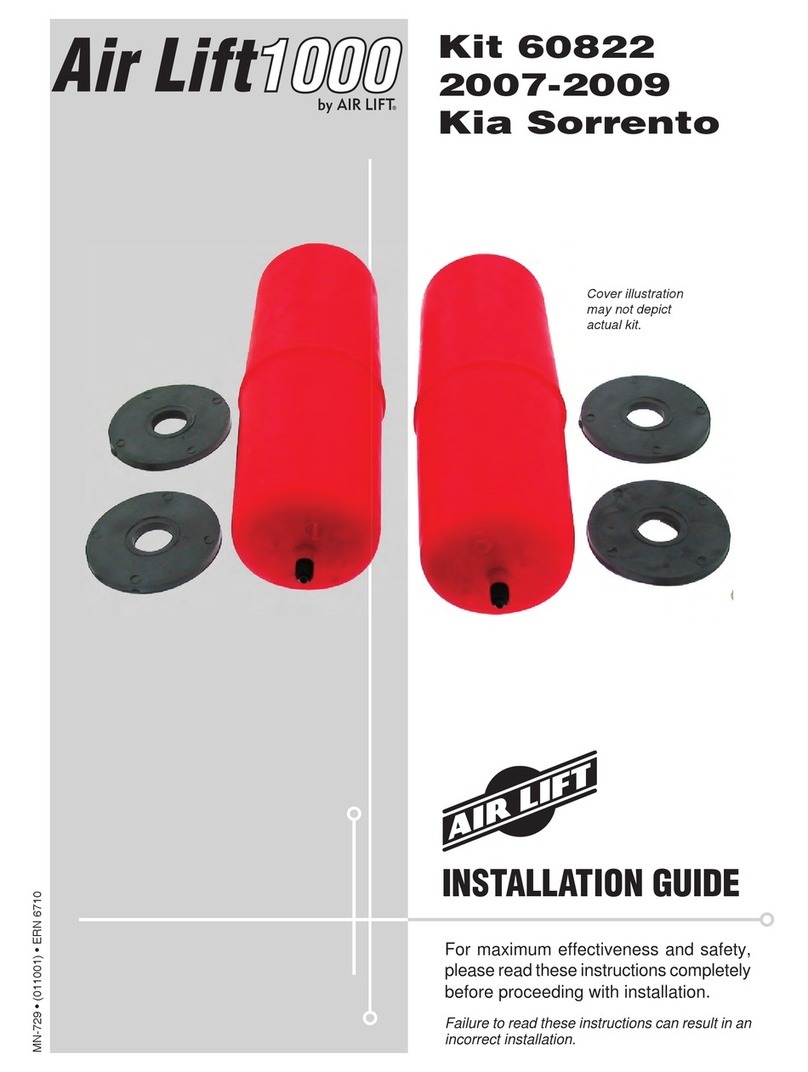

Air Lift 60822 User manual

Air Lift

Air Lift Load Controller I User manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction