Page 5 of 12

Duct Cleaning with the Air-Care TruckMaster II

The Air-Care TruckMaster II has a unique dual function. The motorized brush on the end of the

vacuum hose assembly agitates the dust and debris in the air duct, while you’re Truck Mount Vacuum

functions as the debris collector. This method of cleaning only requires that the supply and return

grills be removed and the air system is turned off. Caution, some air systems may automatically cycle

in the OFF position on the Thermostat, so it is best to also shut off the main power breaker to the

furnace while cleaning.

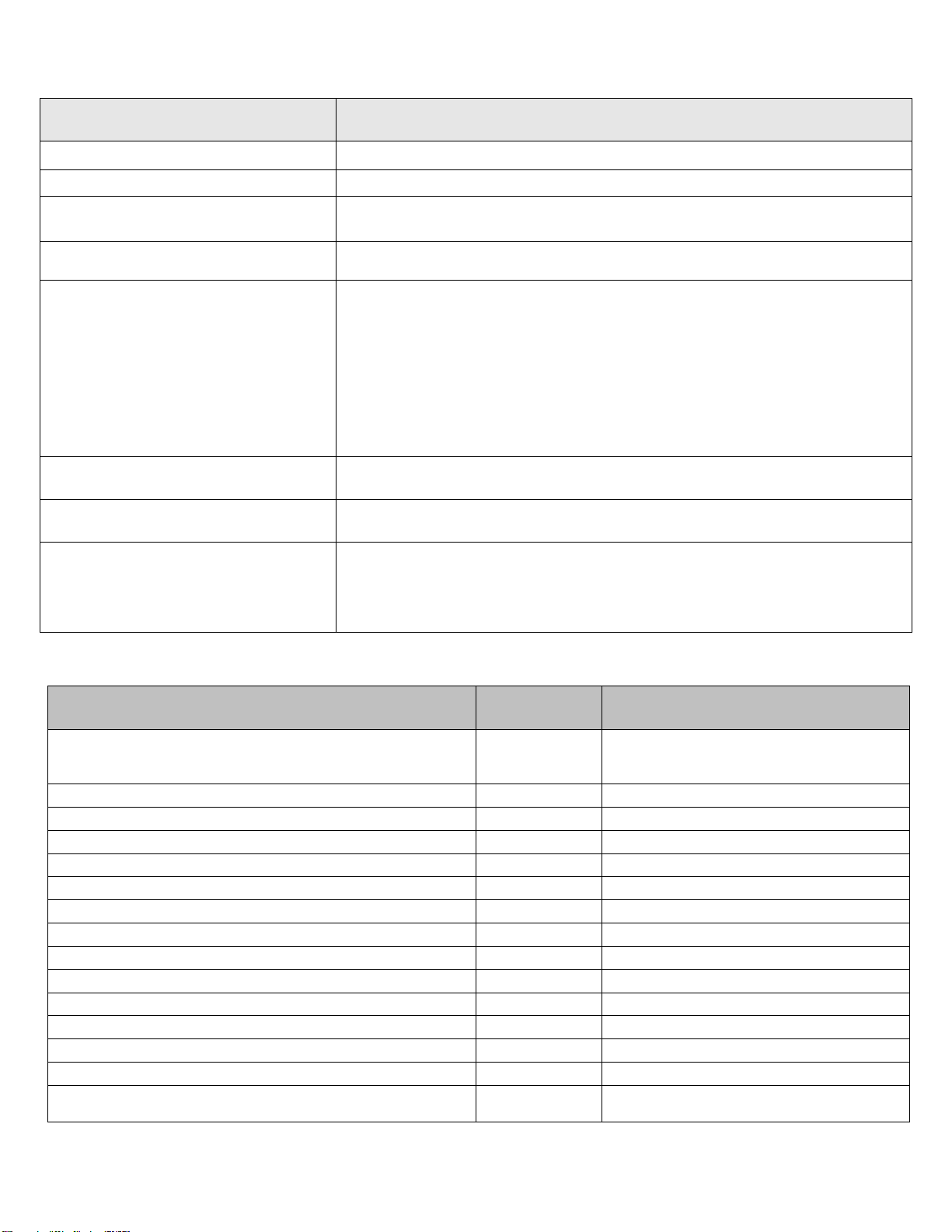

Before applying power, be sure that all 3 Switches on the Control Box are in the

OFF (0) position. After connecting the Air-Care TruckMaster to an extension cord

and a wall outlet, Turn on the Circuit Breaker on the Right, then the Motor can be

started after a few seconds. Connect the 1 ½” X 35’ hose assembly (or the

optional 2” X 35’ hose assembly) to your Vacuum Source Hose. The electrical

cord from the hose will plug in to the TruckMaster control panel socket. Unless

your truck vacuum has provision for “Dry Dust”, you should install the “Dust

Damper” between the Truck vacuum hose and the TruckMaster Hose and attach

the solution hose to the trucks solution hose. This wets the dust so it will not

damage the vacuum blower wheel. A low pressure setting can be used for the

Solution hose since it is only needed to “Dampen” the dust to prevent wear of the

Truck Mount Vacuum Blower Wheel.

The Remote uses an Infrared Light beam similar to a Television Remote. The

Remote Receivers are located on the control panel and on the back of the Power

Box. The operator can be across the room or up on a ladder and the remote will

often function with the IR beam reflecting off of light colored walls and ceilings even with obstructions

to visibility.

When using the Remote, BOTH Switches on the control box for the

brush MUST BE OFF (DOWN)! These switches can be used to

manually START/STOP or Change rotation direction of the brush if the

Handheld Remote Transmitter is lost or has a dead battery. When

these switches are ON (UP), it deactivates the Remote.

Once the technician inserts the brush into the duct, use the Remote’s

ON/OFF Button to start the brush and gently work the vacuum hose

and brush into the duct. STOP the brush before removing it from the

duct.

When the technician cannot push the vacuum hose in any further,

press the FWD/REV button on the remote to change the brush rotation

to allow it to go deeper into the ducts. Repeat this process for each supply and return duct. After a

Duct Run is clean, pull the hose partially out of the duct with the motor running, but stop it before

removing the brush from the duct opening.

Where you have long ducts, such as main trunk lines without access doors, you must make “cut-ins”,

to access the entire length of the duct. The cut-in must be covered with a metal plate and screwed in

place with sheet metal screws, then taped with Aluminum tape.