Operation

10 3A0413B

Spraying

1. Unlock trigger lock.

2. Be sure the arrow shaped tip faces

forward (spray).

3. Hold gun perpendicular and

approximately 12-inches (30 cm) from

surface. Move gun first, then pull gun

trigger to spray a test pattern.

4. Slowly increase pump pressure until

coverage is uniform and even (see

sprayerinstructionmanualforadditional

information).

Aligning Spray

1. Perform Pressure Relief Procedure,

page 8.

2. Loosen tip guard retaining nut.

3. Align tip guard horizontally to spray a

horizontal pattern.

4. Align tip guard vertically to spray a

vertical pattern.

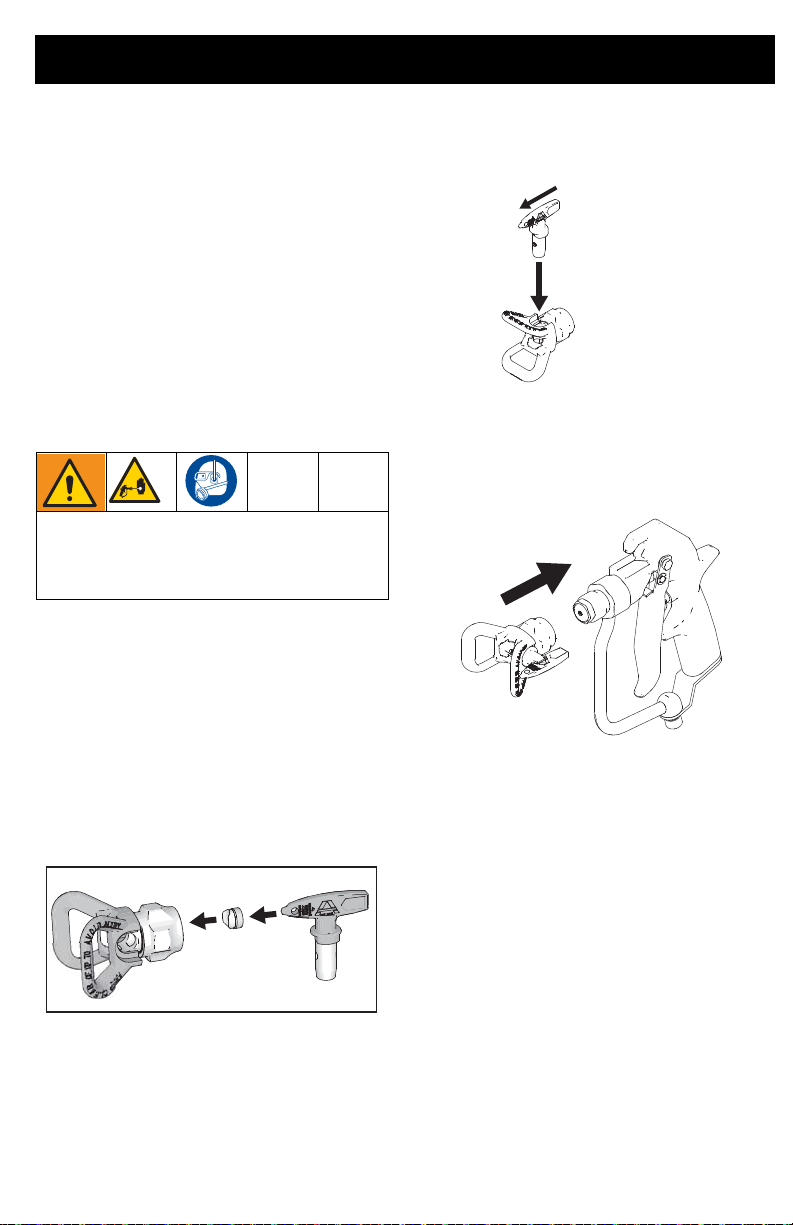

Clear Tip Clog

In the event that particles or debris clog the

spray tip, this sprayer is designed with a

reversible spray tip that quickly and easily

clearstheparticleswithoutdisassemblingthe

sprayer.

1. Engage trigger lock. Rotate spray tip to

unclog position. Disengage trigger lock.

Trigger gun at waste area to clear clog.

NOTE: If spray tip is difficult to rotate when

turning to the unclog position, perform

Pressure Relief Procedure, page 8, then

turn Prime/Spray valve to spray position and

repeat step 1.

2. Engage trigger lock. Rotate spray tip

back to spray position. Disengage

trigger lock and continue spraying.

Cleanup

Flush gun after each work shift and store in a

drylocation.Donotleavethegunoranyparts

in water or cleaning solvents.

Maintenance

To avoid personal injury, always read all

warnings in this manual, and the

equipment manual, before performing any

maintenance on the gun.

ti29221a