FIGURE 2

FIGURE 1

REMOVE

SPRAY

TIP

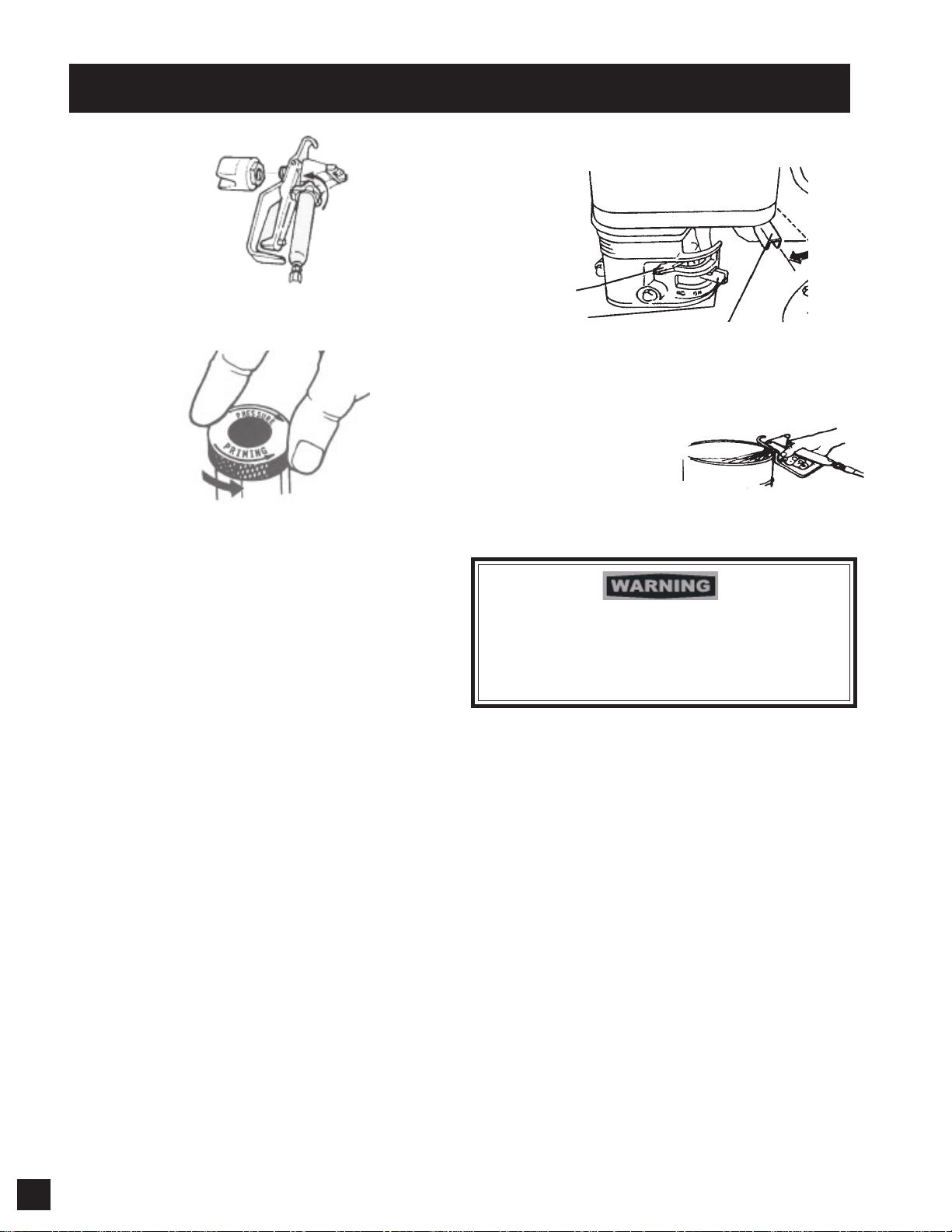

FIGURE 3

FIGURE 4

MAINTAINFIRM

METAL TO METAL

CONTACT BETWEEN

GUN AND CONTAINER

1. Be sure the gun safety latch is engaged and there is

no spray tip in the gun. Refer to Fig. 1. Refer to your

separate instruction manual provided with your gun

on its safety features and how to engage safety latch.

2. Pour enough clean, compatible solvent into a large,

empty metal pail to fill the pump and hoses.

3. Place the suction tube into the pail or place the pail

under the pump.

4. Turn the pressure control knob to low pressure. Refer

to Fig. 2.

5. Open the prime valve to the open - "Priming Position".

This will allow an easy start. Refer to Fig.2.

6. Turn the engine ON/OFF switch to ON.

7. Move the choke to the closed position as per Fig.3.

8. Move the throttle lever slightly to the left as per Fig.3.

9. Turn the fuel valve ON as per Fig. 3. Pull the start rope.

Pull the engine over against compression stroke and then

let the rope rewind slowly into the starter . Pull firmly and

rapidly to start the engine. Do NOT drop the rope. Hold

onto the handle while rewinding, or the rope may rewind

improperly and jam the assembly. If the engine does not

start, open the choke half way. If the engine floods, open

the choke all the way and continue cranking.

10.After the engine is warm, gradually open the choke

lever, increase the RPM of engine by moving throttle

all the way to the left. Close the prime valve. Refer to

Fig. 2

11. Point the gun into the metal pail and hold a metal part of

the gun firmly against the pail Refer to fig. 4 .

12. Disengage the gun safety latch and squeeze the gun

trigger. At the same time, slowly turn the pressure

control knob clockwise just enough to move liquid at

low pressure.

13. Allow the pump to operate until clean solvent comes

from the gun.

14. Release the trigger and engage the gun safety latch.

15. If you are going to start spraying, place the pump or

suction tube into the supply container . Release the

gun safety latch and trigger the gun into another

empty, metal container, holding a metal part of the gun

firmly against the metal pail (Fig. 4) and force the

solvent from the pump and hose. When paint starts

coming from the gun, turn pressure control knob to

minimum pressure, place prime valve in prime (open)

position and engage the gun safety latch.

16. If you are going to store the sprayer , remove the

suction tube or pump from the solvent pail force the

solvent from the pump and hose. Engage the gun

safety latch and refer to the "Storage" Procedure on

page 6. Step 5.

17. Whenever you shut off the sprayer follow the

Pressure Relief Procedure warning on page 11.

HOW TO FLUSH

To reduce the risk of static sparking, which can

cause fire or explosion, always hold a metal

part of the gun firmly against the metal pail

when flushing. This also reduces splashing.

Refer to Fig.4.

ChokeLever

FuelValve ThrottleLever

7

CONTROL

VALVE