Table of Contents

1. Specification -------------------------------------------------------------------------------------- 1-1

1.1 Specifications ----------------------------------------------------------------------------------------------------------- 1-1

1.2 Set Value ----------------------------------------------------------------------------------------------------------------- 1-2

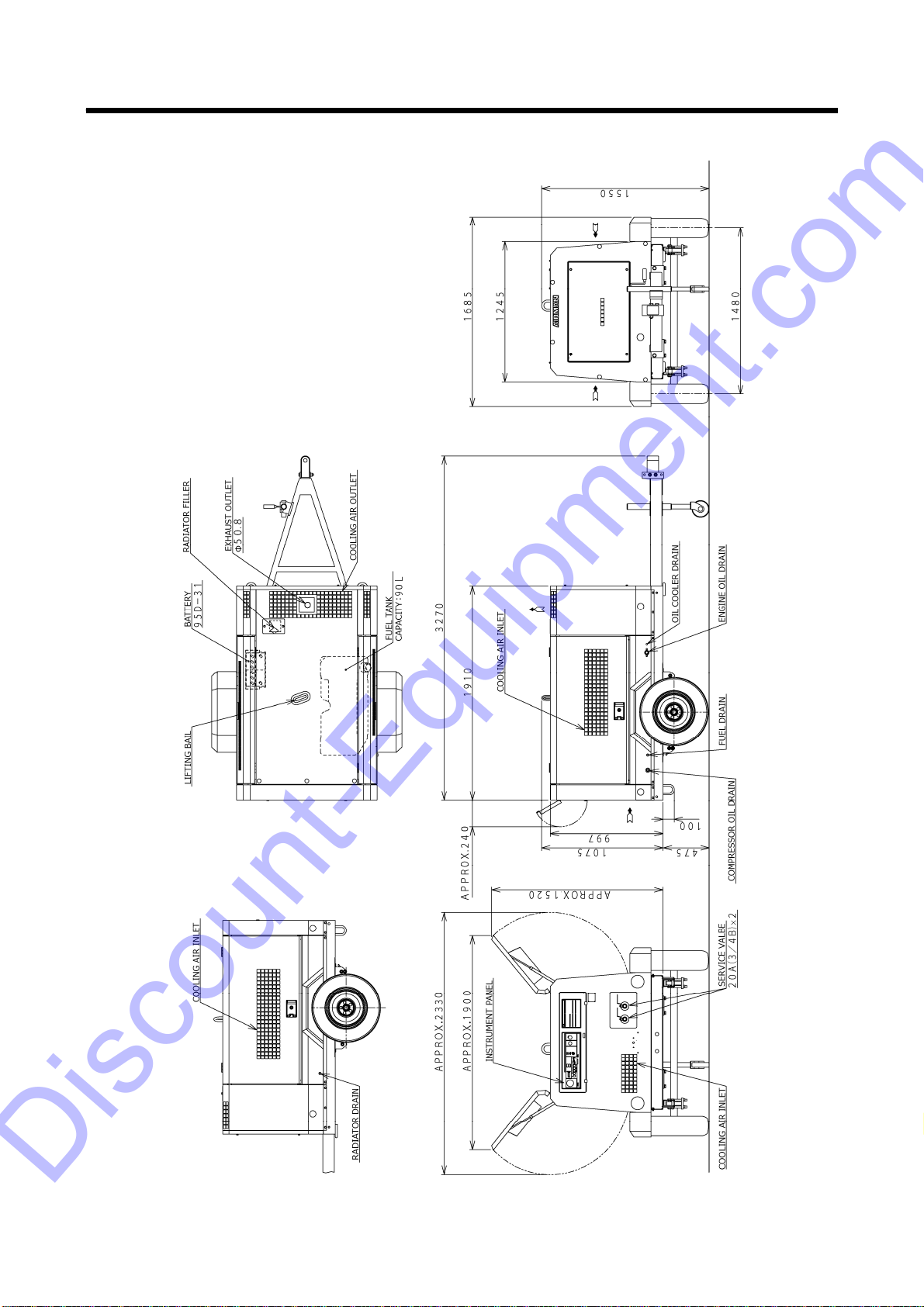

1.3 Outline Drawing -------------------------------------------------------------------------------------------------------- 1-3

1.4 Internal Components and Part Names ---------------------------------------------------------------------------- 1-5

1.5 Instrument Panel ------------------------------------------------------------------------------------------------------- 1-7

1.5.1 Indicator lamp ------------------------------------------------------------------------------------------------------- 1-8

1.6 Capacity Control Device ---------------------------------------------------------------------------------------------- 1-9

1.6.1 Auto idle control (purge control) -------------------------------------------------------------------------------- 1-10

1.6.2 Adjustment of auto idle control (purge control) and correction of engine speed -------------------- 1-11

1.7 Piping Diagram --------------------------------------------------------------------------------------------------------- 1-12

1.8 Fuel Piping --------------------------------------------------------------------------------------------------------------- 1-13

2. Maintenance --------------------------------------------------------------------------------------- 2-1

2.1 Cautions for Overhauling --------------------------------------------------------------------------------------------- 2-1

2.1.1 Precautions before starting work ------------------------------------------------------------------------------- 2-1

2.1.2 Disassembly and reassembly ----------------------------------------------------------------------------------- 2-1

2.2 Tightening Torque ----------------------------------------------------------------------------------------------------- 2-2

2.2.1 General bolts and nuts tightening torque --------------------------------------------------------------------- 2-2

2.2.2 Tightening torque of such important quality parts as bolts and nuts ----------------------------------- 2-3

2.3 How to Adjust Regulator --------------------------------------------------------------------------------------------- 2-6

2.4 Change of Element in Fuel Pre-filter ------------------------------------------------------------------------------ 2-7

2.5 Change Oil Separator ------------------------------------------------------------------------------------------------- 2-8

2.6 Change O-ring of Unloader ------------------------------------------------------------------------------------------ 2-9

2.7 Change O-ring of Auto-relief Valve and Vacuum Relief Valve ---------------------------------------------- 2-11

2.8 Maintenance and Adjustment of Pressure Control Valve ---------------------------------------------------- 2-12

2.9 Change of Pellet assembly of By-pass Valve ------------------------------------------------------------------- 2-13

2.10 Air Bleeding in Fuel Line --------------------------------------------------------------------------------------------- 2-14

2.11 Clean Inside of Fuel Tank -------------------------------------------------------------------------------------------- 2-14

2.12 Clean Drain Separator (Option: With aftercooler only) -------------------------------------------------------- 2-15

2.13 Values of Various Adjustments of Engine ------------------------------------------------------------------------ 2-15

3. Electric System ----------------------------------------------------------------------------------- 3-1

3.1 Electronic Control System of Engine ------------------------------------------------------------------------------ 3-1

3.1.1 Electronic control system ---------------------------------------------------------------------------------------- 3-1

3.1.2 Acceleration control ----------------------------------------------------------------------------------------------- 3-2

3.1.3 Diesel particulate filter (DPF) ----------------------------------------------------------------------------------- 3-3

3.1.4 DPF regeneration control ---------------------------------------------------------------------------------------- 3-4

3.1.5 Preheating control ------------------------------------------------------------------------------------------------- 3-7

3.2 Emergency Controller ------------------------------------------------------------------------------------------------- 3-8

3.2.1 Emergency controller --------------------------------------------------------------------------------------------- 3-13

3.3 Engine Controller (ECU) --------------------------------------------------------------------------------------------- 3-17

3.4 Alternator ----------------------------------------------------------------------------------------------------------------- 3-24

3.5 Starter --------------------------------------------------------------------------------------------------------------------- 3-26

3.6 Starter / Glow Plug Relay -------------------------------------------------------------------------------------------- 3-27

3.7 EGR Valve Relay ------------------------------------------------------------------------------------------------------ 3-28

3.8 Solenoid Valve (SV1) for Starting Unloader and Purge /

Solenoid Valve (SV2) for Aftercooler Drain: Option ----------------------------------------------------------- 3-29

3.9 Engine Oil Pressure Switch (for emergency stops) ------------------------------------------------------------ 3-29

3.10 Fuel Air-bleeding Electromagnetic Pump ------------------------------------------------------------------------ 3-30

3.11 Discharge Temperature Sensor / Water temperature Sensor ----------------------------------------------- 3-30