Table of Contents

1. Safety .......................................................................................................................................................

1-1

1.1 Caution before Operation ................................................................................................................

1-2

1.2 Caution during Operation ................................................................................................................

1-4

1.3 Caution during Inspection and Maintenance ...................................................................................

1-6

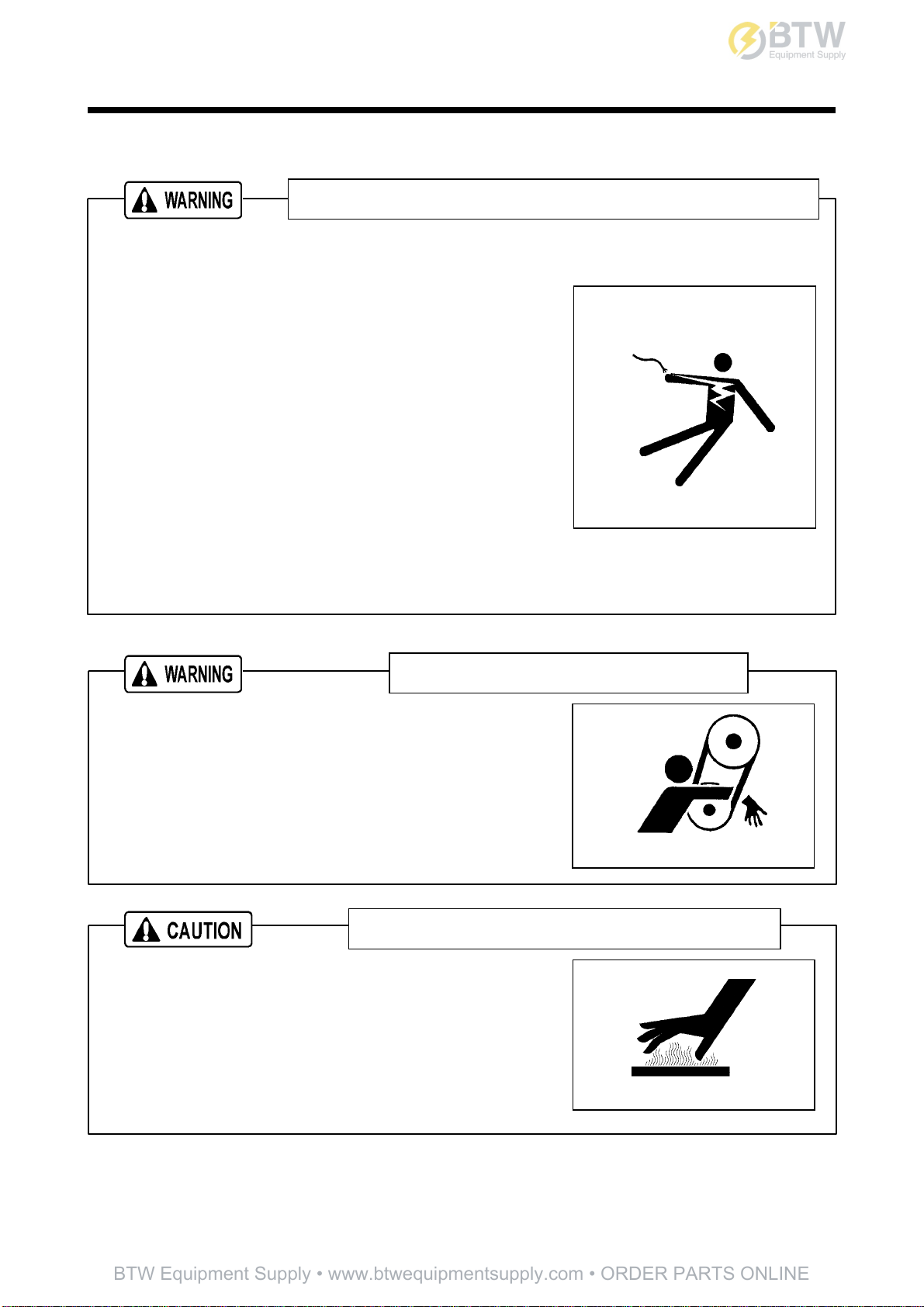

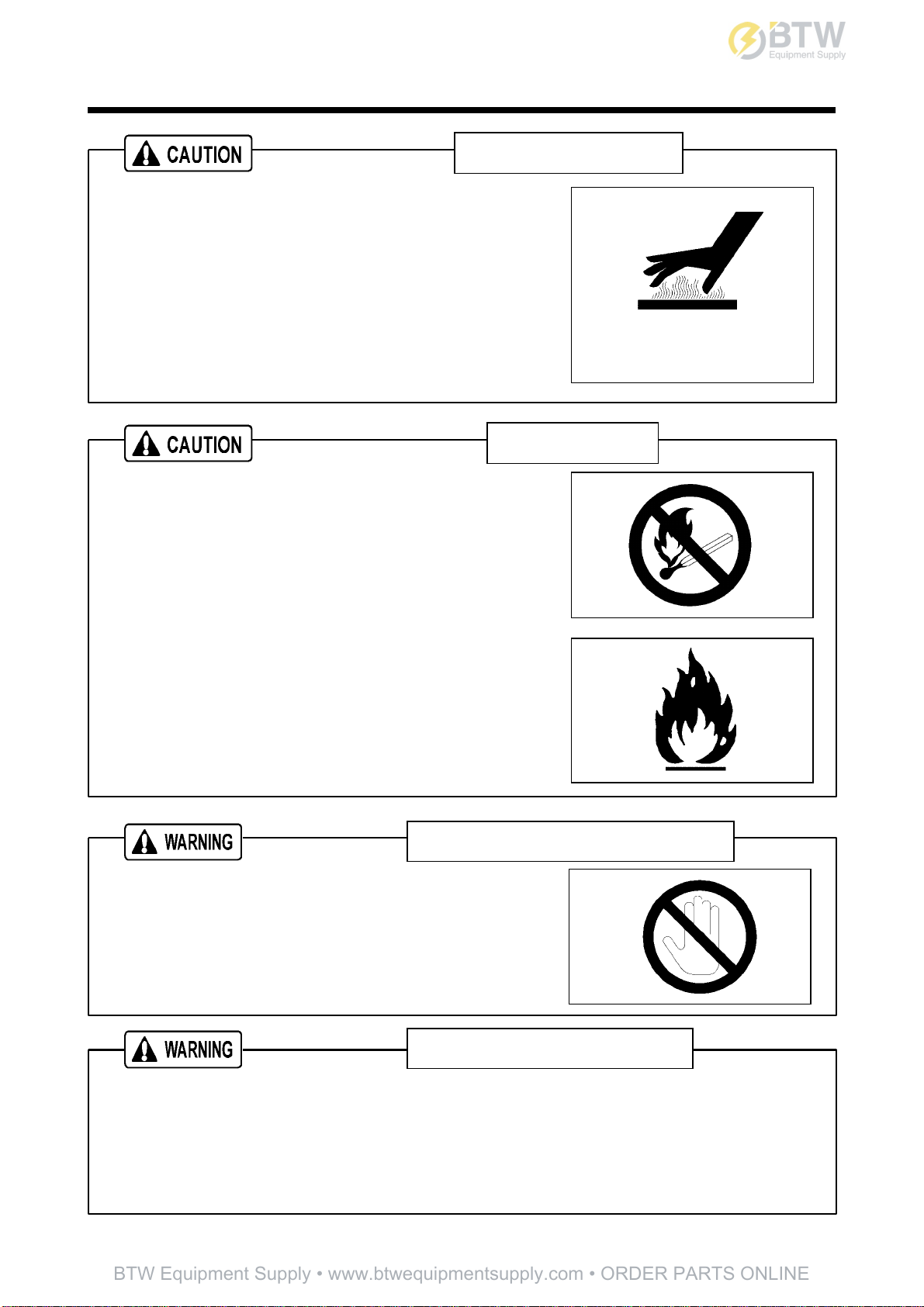

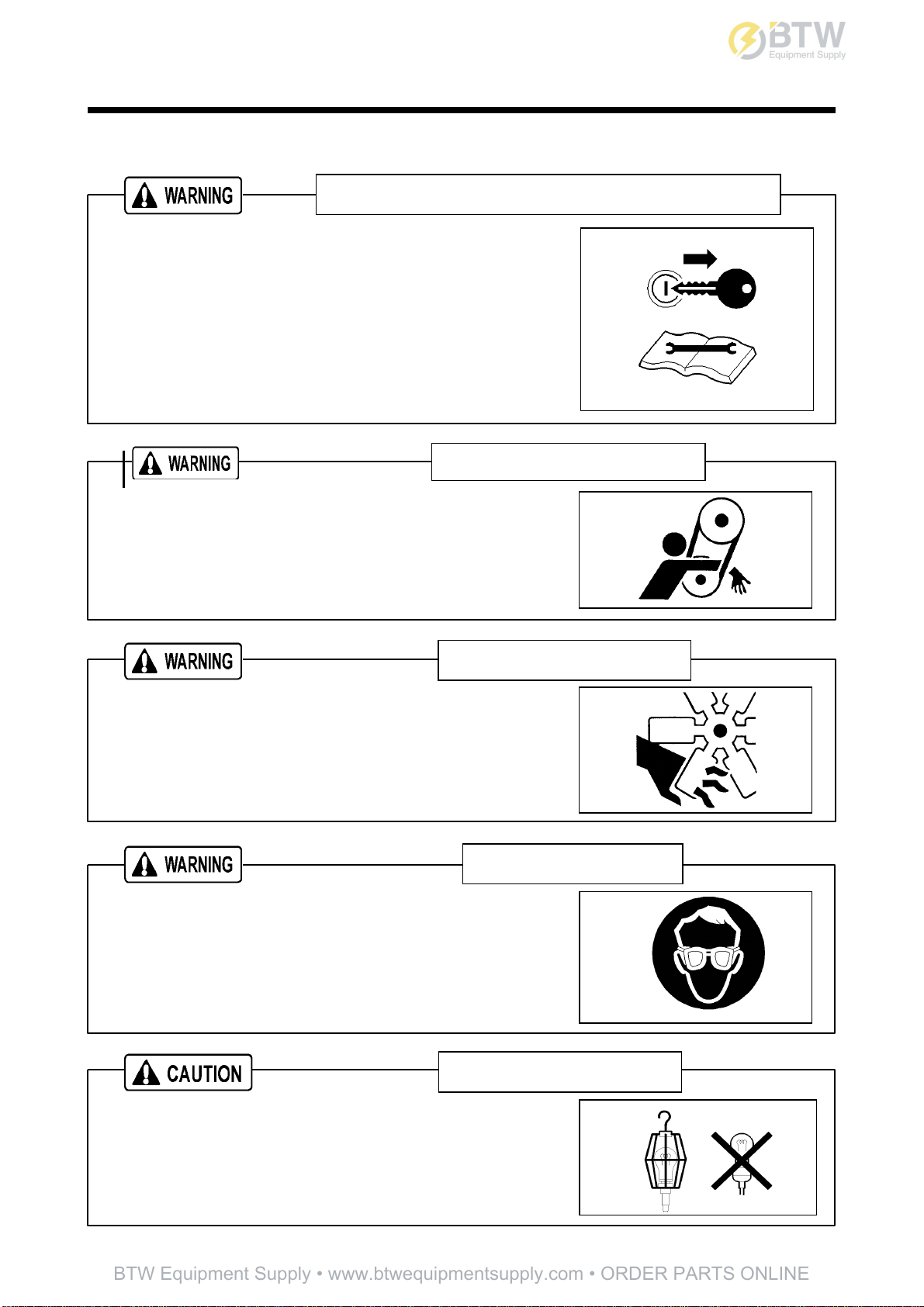

1.4 Safety Warning Labels ....................................................................................................................

1-8

2. Part Names ..............................................................................................................................................

2-1

2.1 Unit Appearance and Part Names ...................................................................................................

2-1

2.2

Internal Components

.......................................................................................................................

2-2

3. Installation ...............................................................................................................................................

3-1

3.1

Transporting Unit

...........................................................................................................................

3-1

3.2

Place and Conditions of Unit Installation

...................................................................................

3-2

3.3 Selecting Cable ...............................................................................................................................

3-3

3.4 Connecting load................................................................................................................................

3-4

3.5 Grounding Method ............................................................................................................................

3-8

3.6

Selector Valve of Fuel Pipe

..........................................................................................................

3-9

4. Operation .................................................................................................................................................

4-1

4.1

Instrument panel

............................................................................................................................

4-1

4.2

Protection device

...........................................................................................................................

4-2

4.3

Check before Starting the Unit

....................................................................................................

4-6

4.4

Unit Operation

................................................................................................................................

4-8

4.5

Stopping Procedures

.....................................................................................................................

4-12

4.6

Adjustment of frequency

.................................................................................................................

4-12

4.7

Emergency Stop

..............................................................................................................................

4-13

4.8

Air Bleeding

......................................................................................................................................

4-13

5. Periodic Inspection/Maintenance ..........................................................................................................

5-1

5.1 Important items as Periodic and Maintenance or after Maintenance ..............................................

5-1

5.2 Daily Inspection and keeping Operation Log ...................................................................................

5-2

5.3 Periodic Inspection List ...................................................................................................................

5-3

5.4 Periodic Replacement of Parts .........................................................................................................

5-4

5.5 Maintenance .....................................................................................................................................

5-5

6. Maintenance/Adjustment .......................................................................................................................

6-1

6.1 Maintenance of Battery.....................................................................................................................

6-1

6.2 Troubleshooting ................................................................................................................................

6-3

7. Storage of the Unit .................................................................................................................................

7-1

7.1 Preparation for Long-term Storage .................................................................................................

7-1

8. Specifications .........................................................................................................................................

8-1

8.1 Specifications....................................................................................................................................

8-1

8.2 Outline

drawing ..............................................................................................................................

8-5

9. Wiring Diagram .......................................................................................................................................

1

9-1

9.1 Generator Wiring Diagram................................................................................................................

.

9-1

9.2 Engine Wiring Diagram.....................................................................................................................

.

9-4

BTW Equipment Supply • www.btwequipmentsupply.com • ORDER PARTS ONLINE