PAGE 2 OF 2 0915 IH-5334

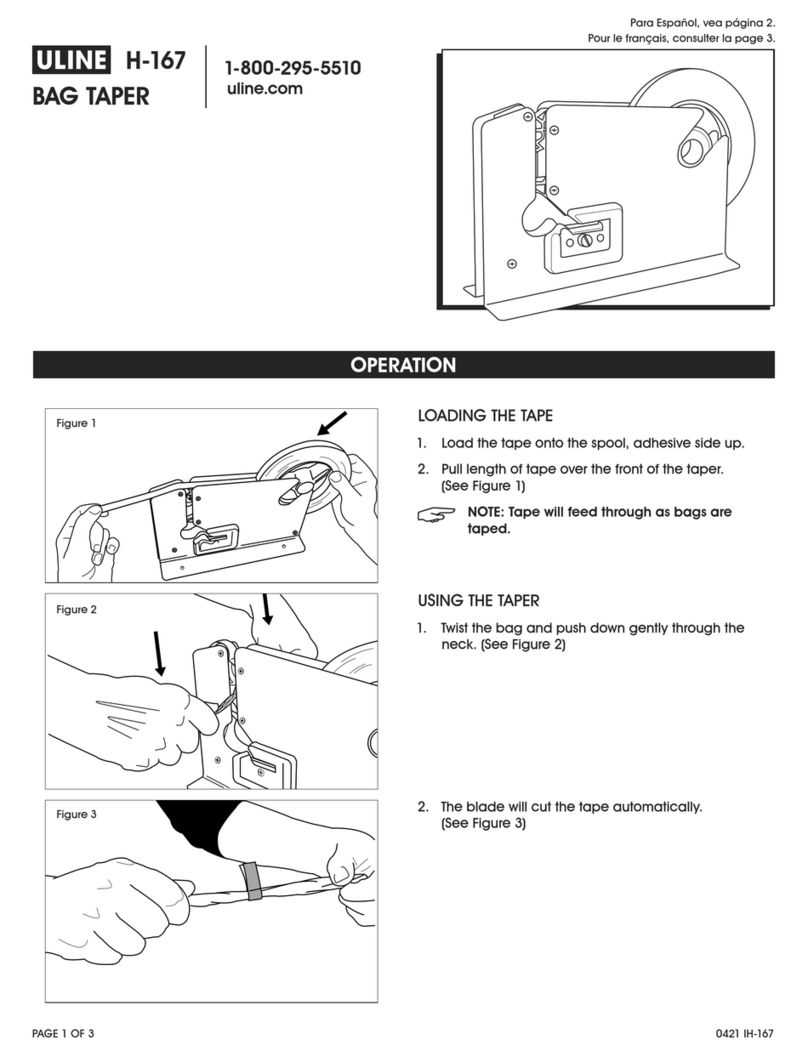

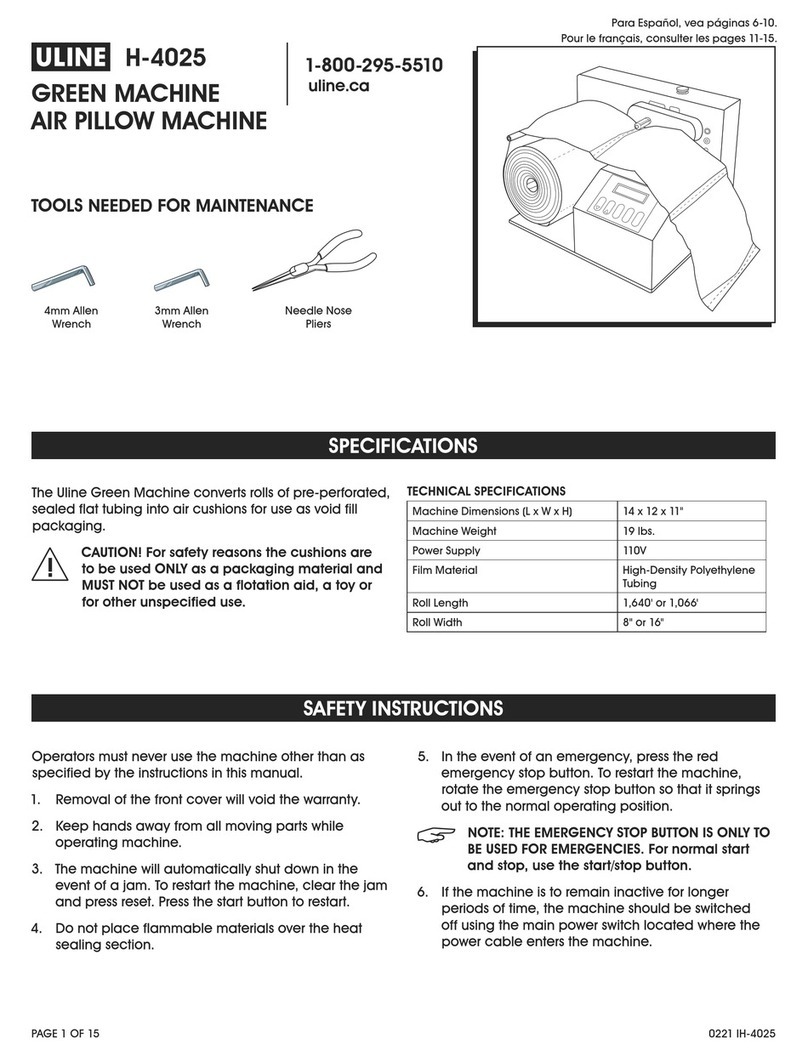

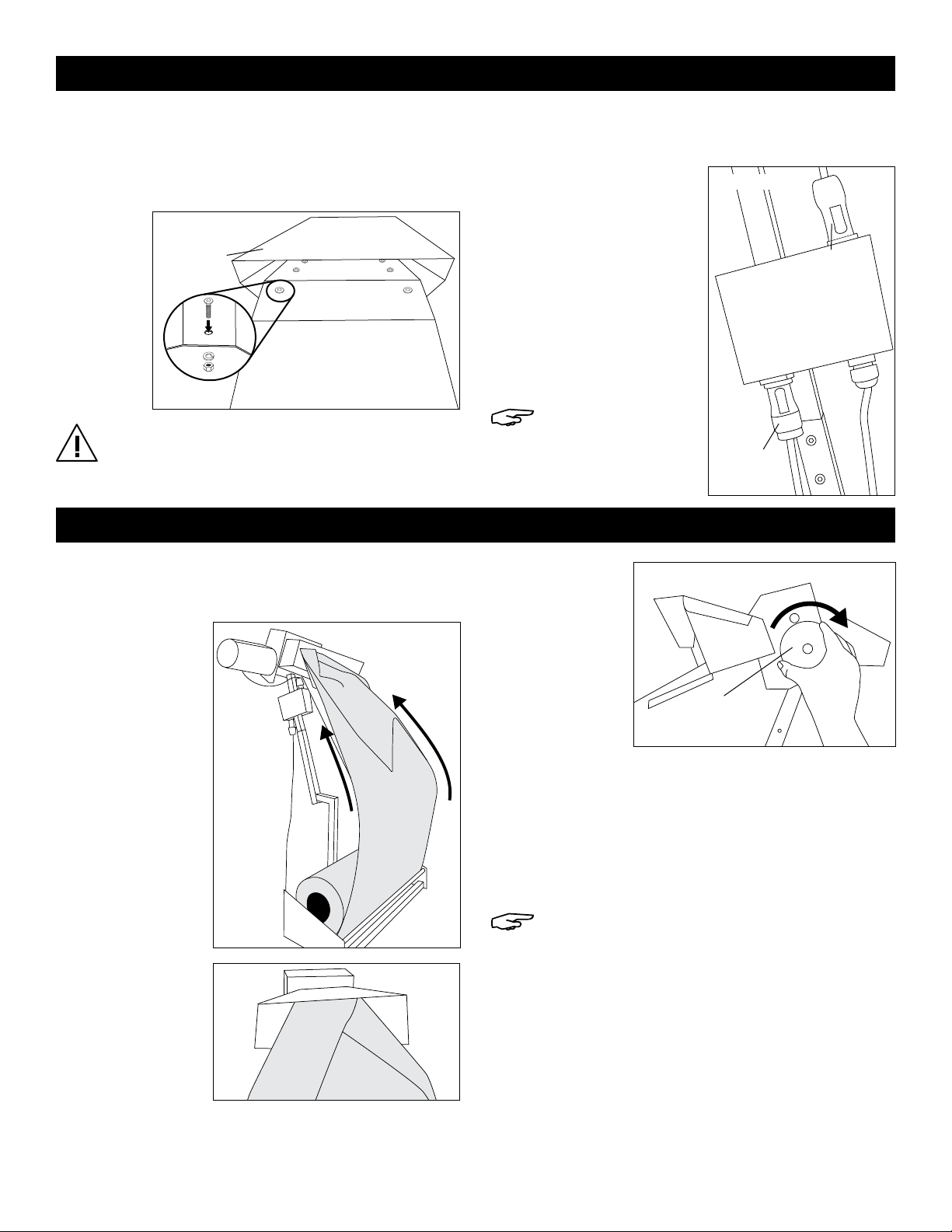

Figure 5

Paper

Ramp

Entrance

Funnel

ASSEMBLY CONTINUED

11. Place paper ramp onto paper entrance funnel

and secure with 10-32 x 1/2" bolts (6), ensuring bolt

head is on the inside of the funnel. Secure with #10

locking washers (6) and 10-32 nuts (6) underneath

the paper ramp. (See Figure 5)

CAUTION: If the bolt head is not on the inside of

the funnel, paper can catch on the bolt shaft

and nut.

12. Rotate unit 180 degrees back to original position,

with paper exit shoot facing front.

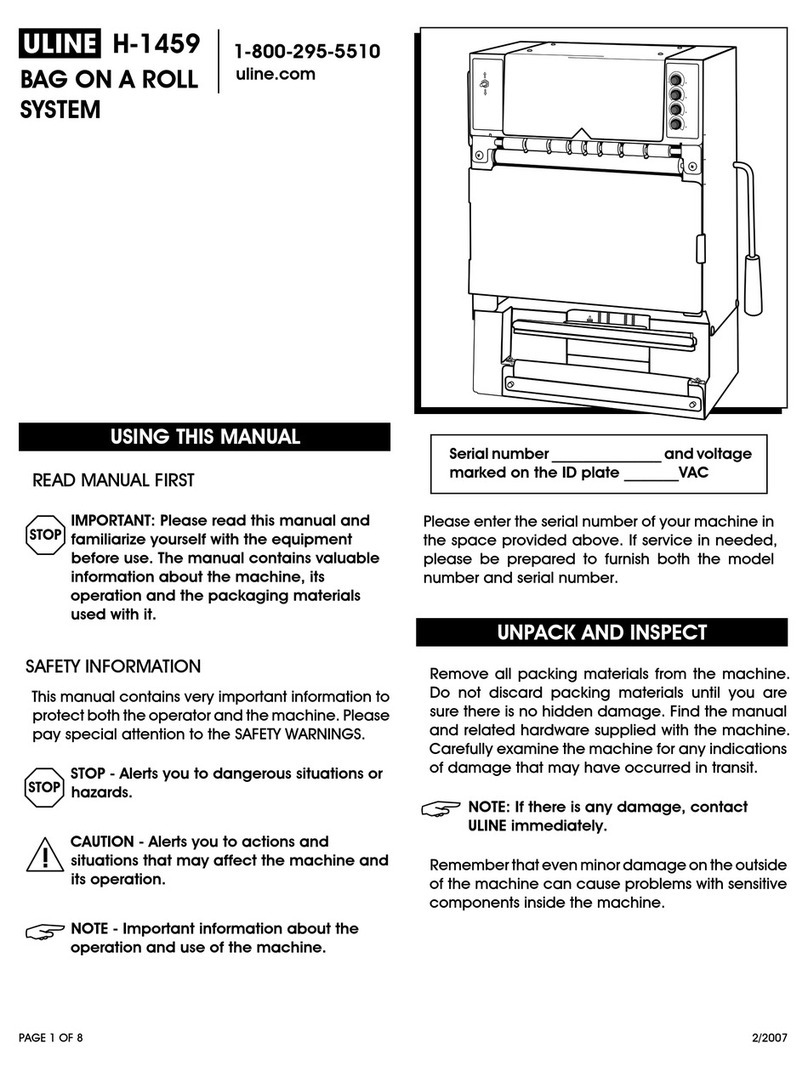

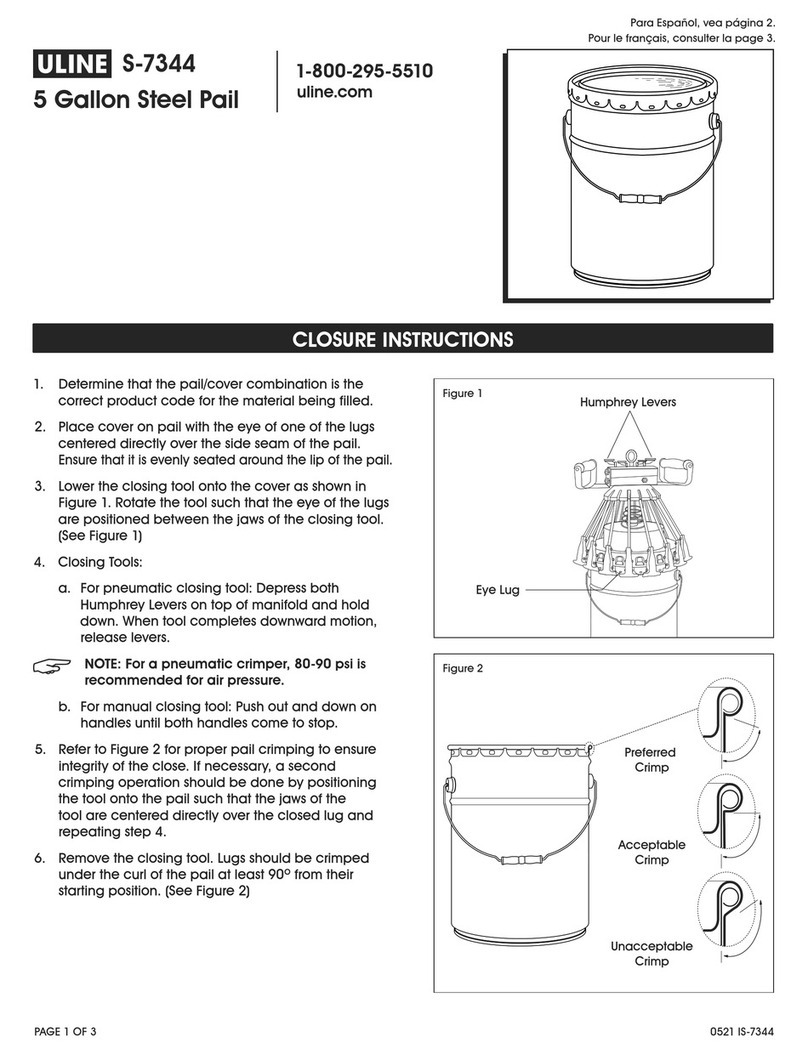

13. Insert blue motor

connector plug into

the blue plug on top of

power box and give a

quarter twist to lock.

(See Figure 6)

14. Insert gray foot pedal

connector plug into the

gray plug on the bottom

of the power box and

give a quarter twist to

lock. (See Figure 6)

NOTE: Both plugs

will click when

locked in place.

Motor

Connector

Foot Pedal

Connector

Figure 6

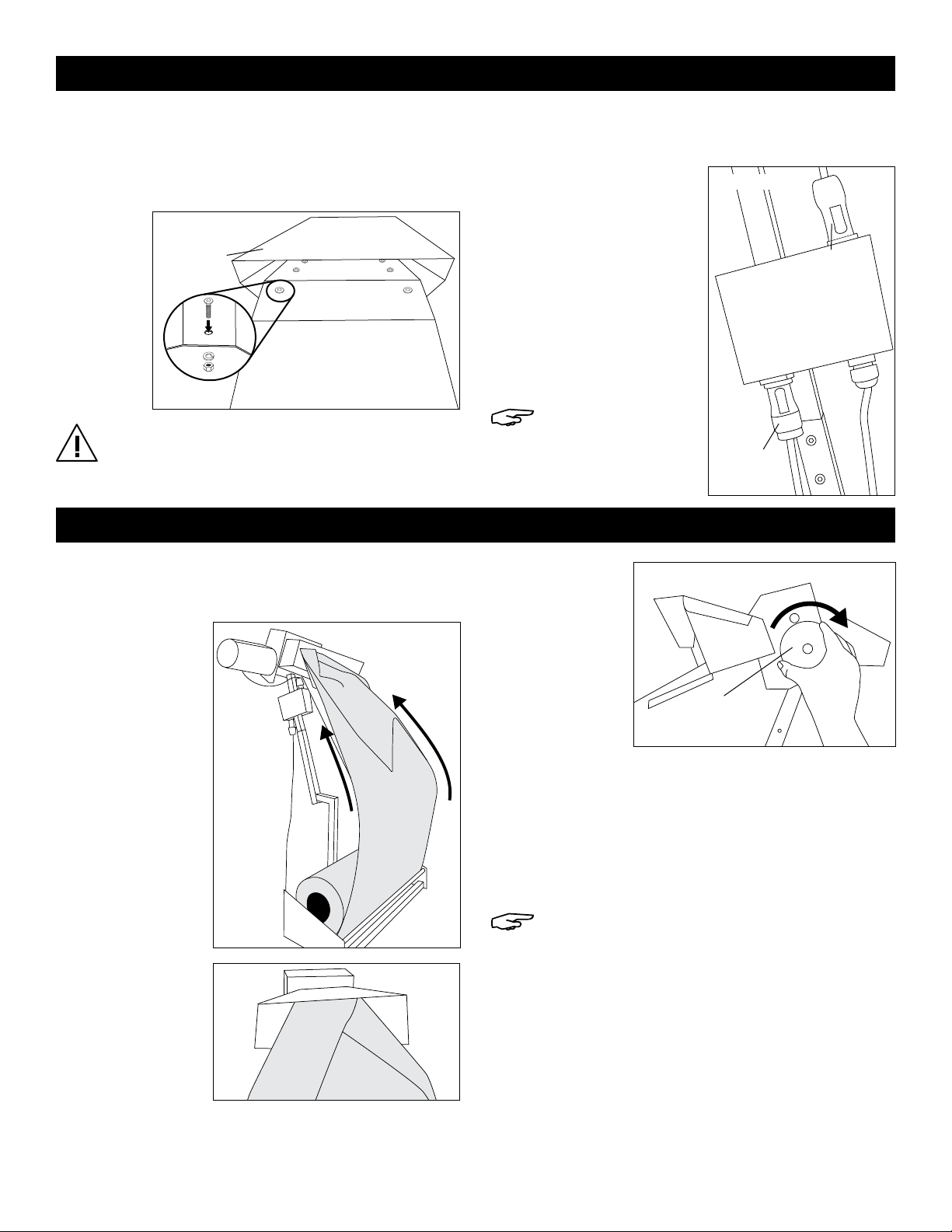

1. Plug power cord into a standard 115V outlet.

2. Make sure power switch is turned off.

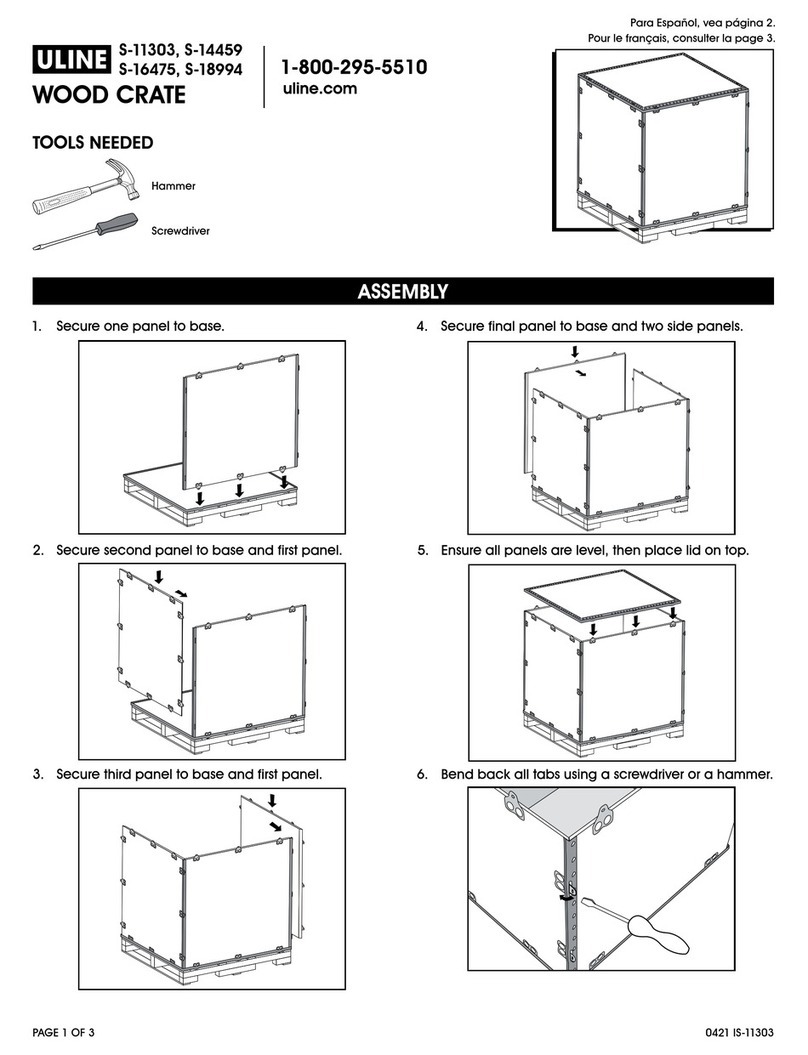

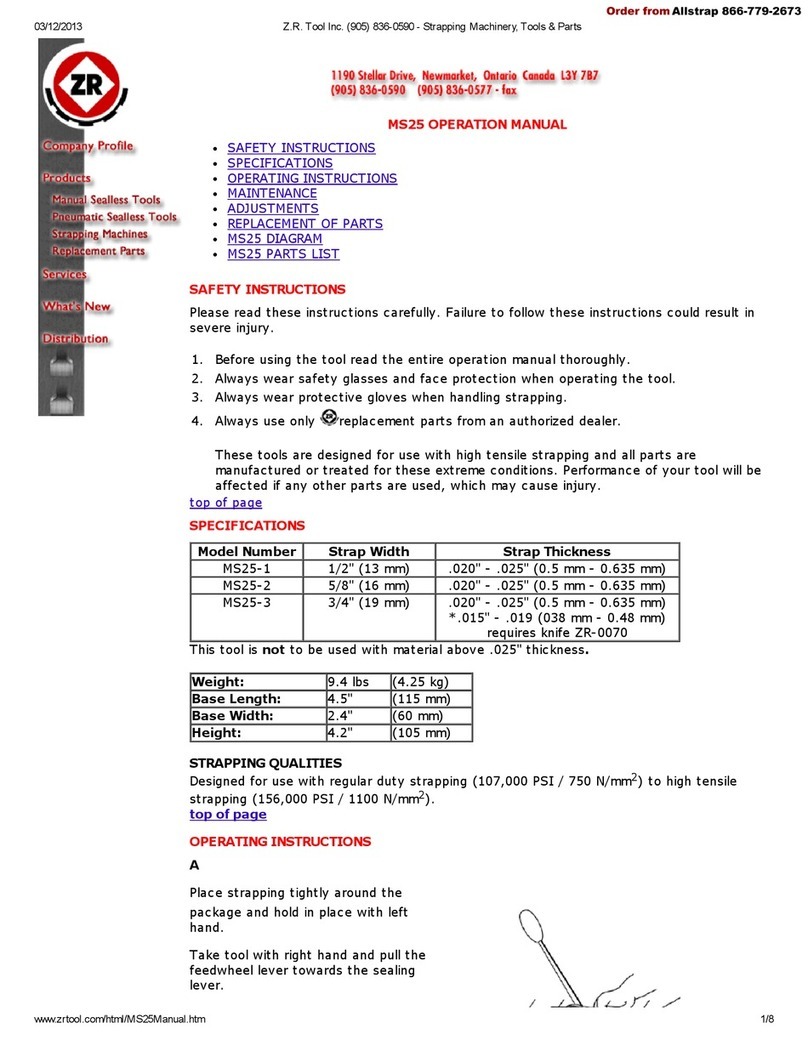

3. Pull spring-

loaded pin

and turn unit

180 degrees to

make paper

cradle easily

accessible.

4. Load kraft paper

onto the paper

cradle with

the paper roll

unspooling from

the outside.

(See Figure 7)

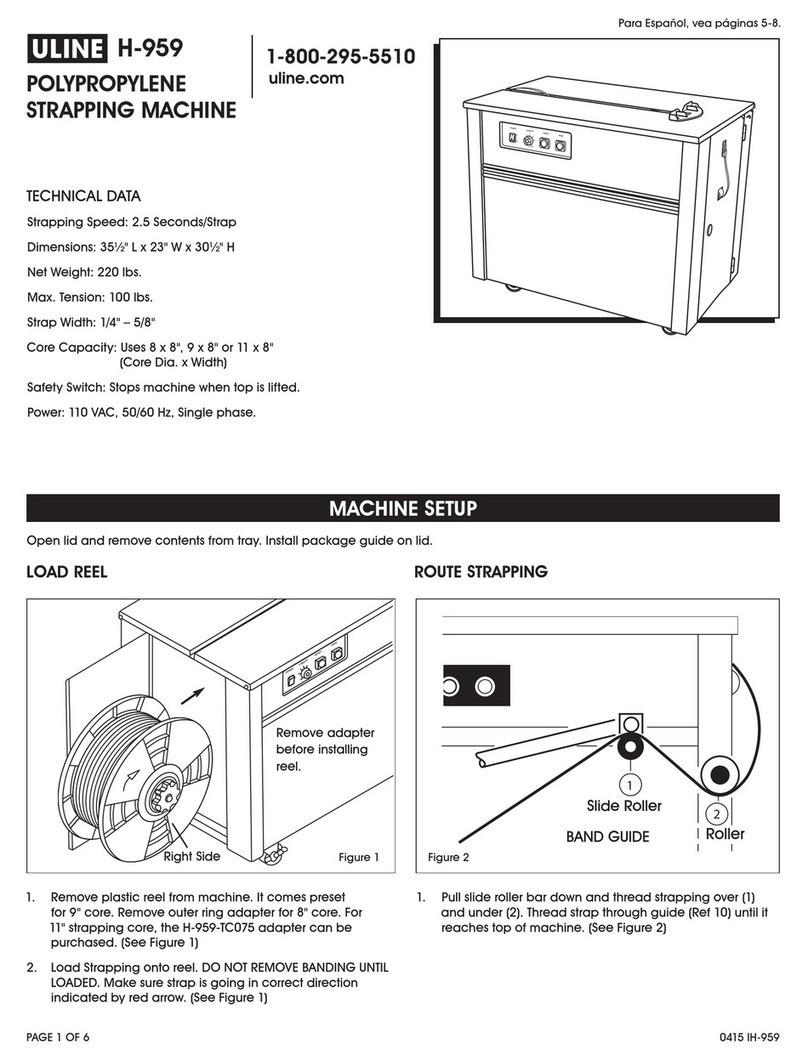

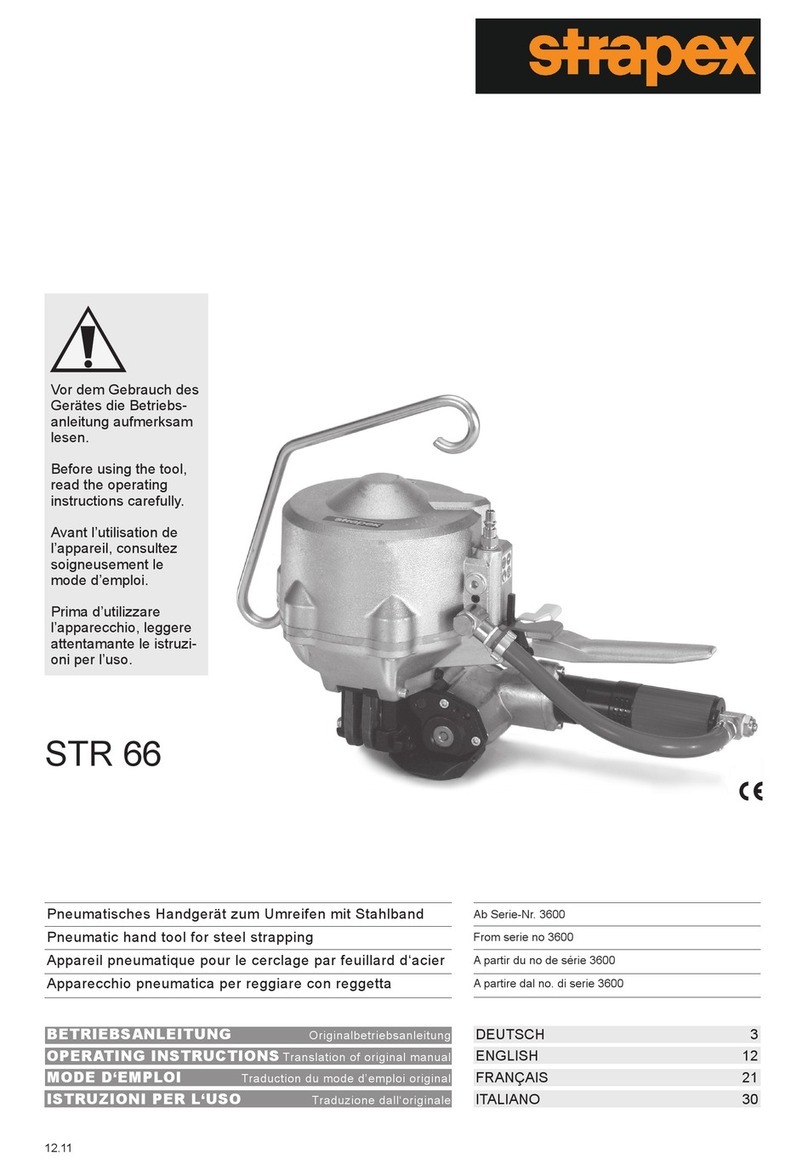

5. Pull end of

paper up

towards the

paper entrance

funnel and

fold paper into

itself in a rough

triangle shape.

(See Figure 8)

6. Insert paper

into the paper

entrance

funnel. Using

the threading

disk, turn knob

clockwise until

it catches the

paper and

feeds it through

the head and

out the exit shoot. (See Figure 9)

7. Rotate unit 180 degrees back to original position,

with the paper exit shoot facing front. Turn on with

power switch on the power box.

8. Press down on the foot pedal to eject paper from

the exit shoot.

NOTE: The machine will continue dispensing

paper until foot is let off the foot pedal.

9. Release foot pedal.

10. Grab the ejected paper and pull strongly in a

downward motion to tear paper from the machine.

OPERATION

Figure 7

Figure 9

Figure 8

Threading

Disk

Power Box

πCHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800-295-5510

uline.com