TABLE

OF

CONTENTS

MESTANDARD

MAINTENANCE

....-...200

000

cece

cece

cere

teen

t

nee

ete

debe

eee

eee

e

ee

eset

ese

b

bene

ett

tbnbbececeeenens

4

1.

SERVICE

SCHEDULE

OF

COMPONENT

-ecc

ccc

rrr

ctr

tt

eee

ce

eee

enn

rete

eee

e

ene

t

tent

e

ents

ences

4

2.

CLEANING

cc

ccc

4

BISERVICE

JIG”

AND’

TOOUS:.

«cd

iccacosesteocnceetalstiaeyseddasnanarcegves

aay

ethan

caine

tea

Dacehiade

chine

5~7

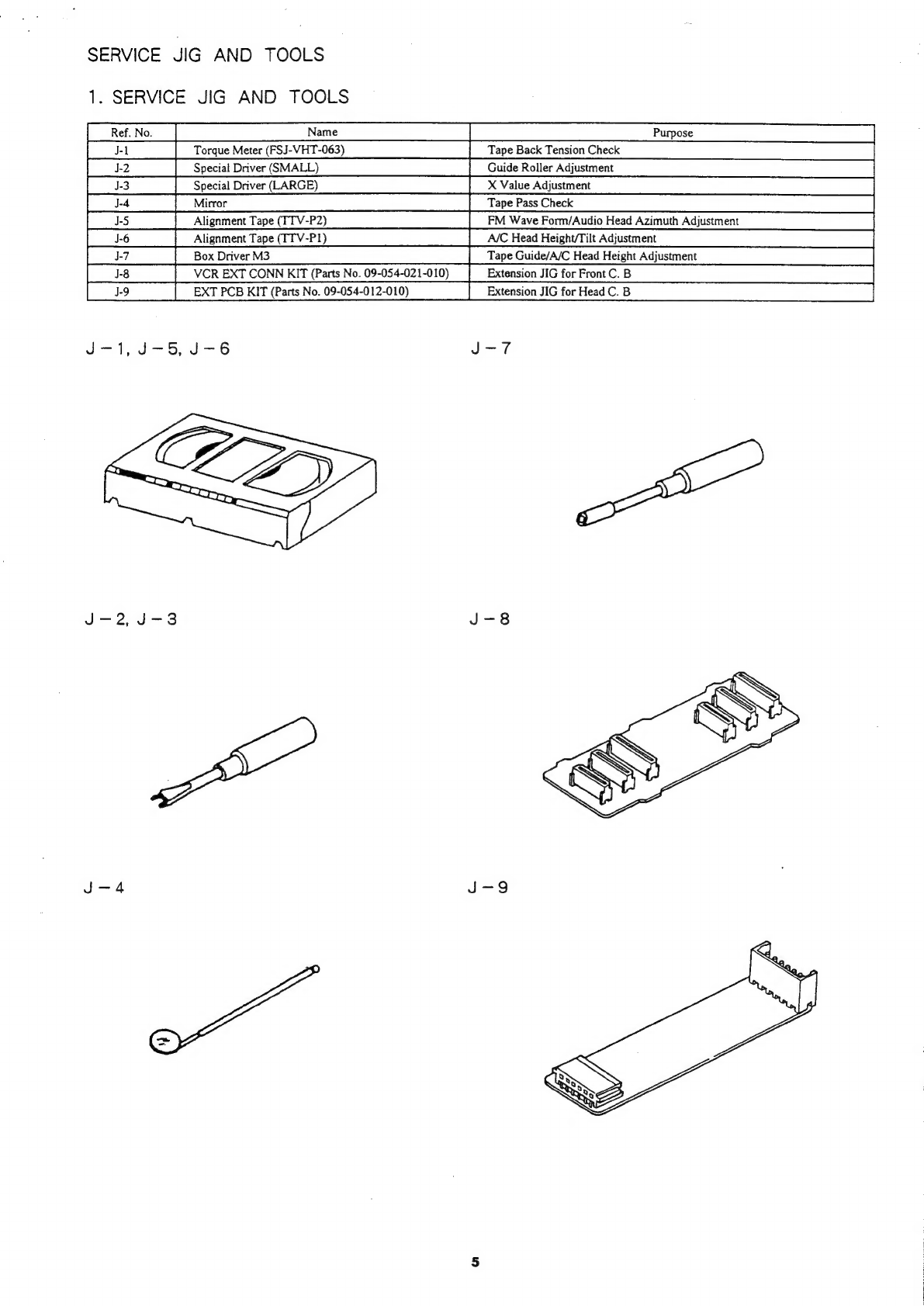

1.

SERVICE

JIG

AND

TOOLS

PU

ee

eRe

eee

eee

eee

eRe

eee

eee

me

mee

heme

eee

eee

ee

eee

ee

eee

ee

meee

ee

eee

eee

eee

ee

5

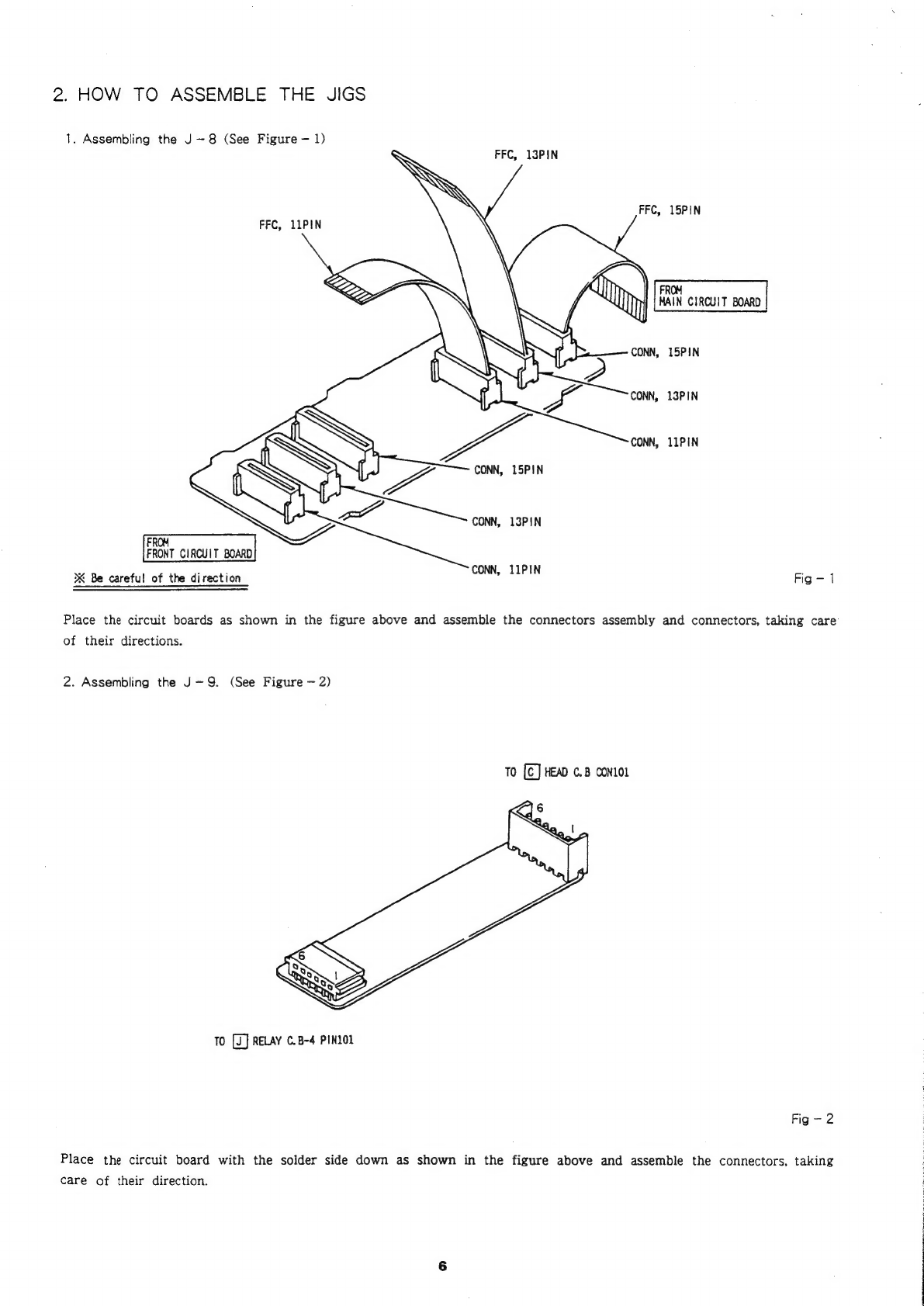

2.

HOW

TO

ASSEMBLE

THE

JIGS

core

crete

tect

tte

ct

tee

ee

eee

ee

renee

meee

eee

eee

ene

e

Ee

eee

eee

ete

teens

6

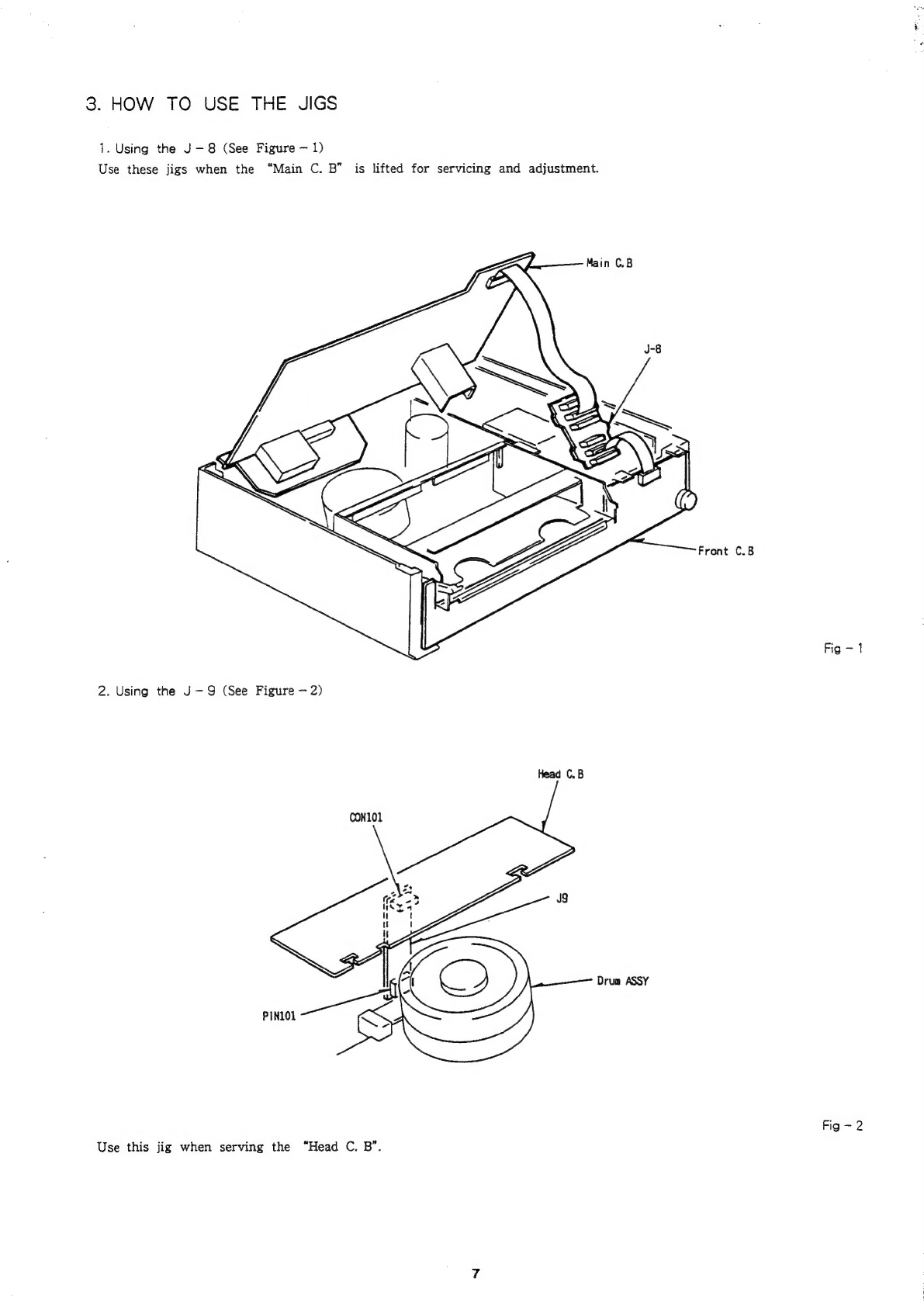

3.

HOW

TO

USE

THE

JIGS

Cc

7

Mi

DISASSEMBLY.

“INSTRUCTIONS

(oc.04

seuri

ied

cats

ueiides

siieethea

ccae

baesnuiieeeensaslnudases

aval

neseeaae

8~20

MEELECTRICAL

MAIN

PARTS

LIST

.....0.0ceccccccccce

cece

nee

e

eee

eben

eee

n

ete

e

eee

e

esse

eben

betes

eee

e

beeen

nas

21~23

ME

TRANSISTOR

ILLUSTRATION

......00.ccce

cece

cece

cece

cece

cere

ee

eect

ee

be

eee

eeeeeeecteeeeesstenetseneeeeeueeeneres

23

MEPRACTICAL::

SERVICE

FIGURE

xi

escnce

oreetei

wece

sa

tccaeiee

eas

ened

es

sah

Peas

bane

Wiest

suas

oe

atuaalbde

sees

ohe

24

BE

BLOCK

DIAGRAM:

secs

occ

es

dne5

ces

sineitied

ieee

culelete.

dane

ee

sists

semble

eie

tuna

aa

vide

Gh

gies

Sed

Ceiba

de

baile

nie

eare

alate

25~29

.

BLOCK

DIAGRAM

—

1

(VIDEO

SECTION)

PAO

e

eee

ete

eee rem

meee

emer

meer

rece

reer

eee

ree

e

een

arene

eee

eter

etnnse

25~26

+

BLOCK

DIAGRAM

~2

(SERVO//SYSTEM

CONTROL.

SECTION)

-erc

rec

c

eer

ee

ete

ete

eter

ene

tense

tenet

ence

een

ennans

27~28

.

BLOCK

DIAGRAM

=

3

(POWER

UNIT

SECTION)

Ce

29

WWIRE

HARNESS

DIAGRAM

da

eaeRermaenaen

sdaitle

Ml

aaeea

minis

Medina

tauedenal

eauas

Maw

Momus

weenie

ofa%

30~31

BME

WAVE

FORM

—1

(VIDEO

SECTION)

..--.-.-

cece

cece

eect

e

eee

e

cette

eb

eset

teense

eeteeneeevanreeennneeans

vaib

tines

32

MEWIRING

—

1

(VIDEO

“AUDIO

SECTION)

.---.

ccc

cece

cece

cece

ccc

e

eee

n

eee

e

eee

e

eee

ne

ene

teeta

eeneeebaeens

33~36

MEWAVE

FORM

—

2

(VIDEO

SECTION)

.-ccccc

ccc

c

eect

eee

eect

eect

nee

e

ene

ee

ee

eter

ene

n

eee

e

tebe

tebe

eet

eeaaed

37

BMESCHEMATIC

DIAGRAM

—1

(VIDEO

—1

SECTION)

..-..-

ee

cece

eee

ee

cee

eee

e

cence

bent

ee

tn

etnenes

38~39

MESCHEMATIC

DIAGRAM

—

2

(VIDEO

—

2

SECTION)

..---.-.

ccc

cece

eee

cect

ee

cnet

ence

beeen

eee

n

een

eenneenees

40

MESCHEMATIC

DIAGRAM

—

3

(AUDIO

SECTION)

«cece

cece

crete

ese

c

cece

cece

cece

reece

ner

eeererences

41

MEWAVE

FORM

—

3

(SERVO

SECTION)

cece

ccc

cece

reece

cece

cree cece

cee

eee

e

eee

eent

etn

eeceeeeees

42

MESCHEMATIC

DIAGRAM

—

4

(SERVO//SYSTEM

CONTROL

SECTION)

.-------:0:2:0-sseeeee

eee

ee

ee

ees

43~45

BESCHEMATIC

DIAGRAM

—5

(FRONT

SECTION)

.......-..

2c

ccc

cece

cece

cere

cece

net

e

ete

ne ee

een

ee

eten eens

46~47

HESCHEMATIC

DIAGRAM

—6

(HEAD

SECTION)

.....--.:

cee

cece

nec

c

eee

e

cence

nee

eee

een

teste

settee

eeenes

47~48

MI

WIRING

—

2

(FRONT

/HEAD/

MECHANISM

SECTION)

.--.-..--02

cee

cc

ence

eect

ee

ee

eee

nets

eee

e

een

eees

49~50

BB

SCHEMATIC

DIAGRAM

—

7

(POWER

SECTION)

...----0-

cece

cence

cence

cee

cere

cere

een

ee

ene

teen

een

eennes

51~52

MB

WIRING

—

3

(POWER

SECTION)

..----:-

cece

cece

cece

ete

cee

e

nee

e

een

e

eben

eee

ecb

eee

e

tebe

tenn

ener tees

51~52

BESYSTEM:

SWITCH

(MODE?

¢s2ssndncd

ote

Bete

ciate

ine

ey

elale

Ainteg

aR

EN

ena

eas

Ta

Sande

eine

waren

ts

53

WEDRUM

SERVO

SYSTEM

TIMING

CHART

.......--::ccecee

cece

eee

e

eet

ecenneeceeanees

wo

hectare

ahaa

sas

ta

PAL

So

tcle

54

BRIG:

DESCRIPTION

we22icc

season

na

sda

east

tlds

sie

ceed

Lt

eed

DA

Lie

ates

eat

ad

deen

av aw

va

veld

55

@

IC,

u

PD75108CW

—

WO02

BIG.

“BLOCK:

‘DIAGRAM

#26

fs

bind

ee

ea

te

eitiege

na

al

ena

oes

de

hee

ca

ales

ale

wtesen

dale

Sa

cee

nd

bd

owed

AM

56~57

@

IC,

MN67481

JIC,

LC8992/1IC,

LA7311//IC,

BA6219B