Akai 4400 User manual

Other Akai Tape Deck manuals

Akai

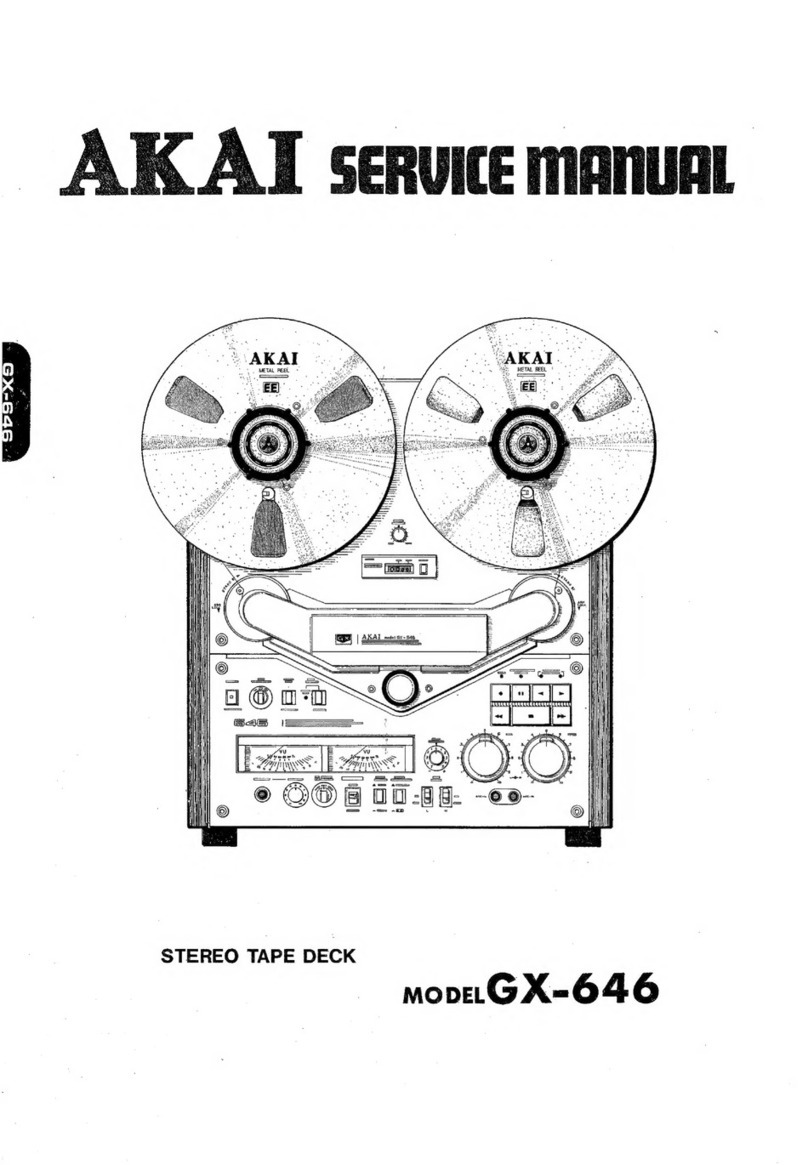

Akai GX-646 User manual

Akai

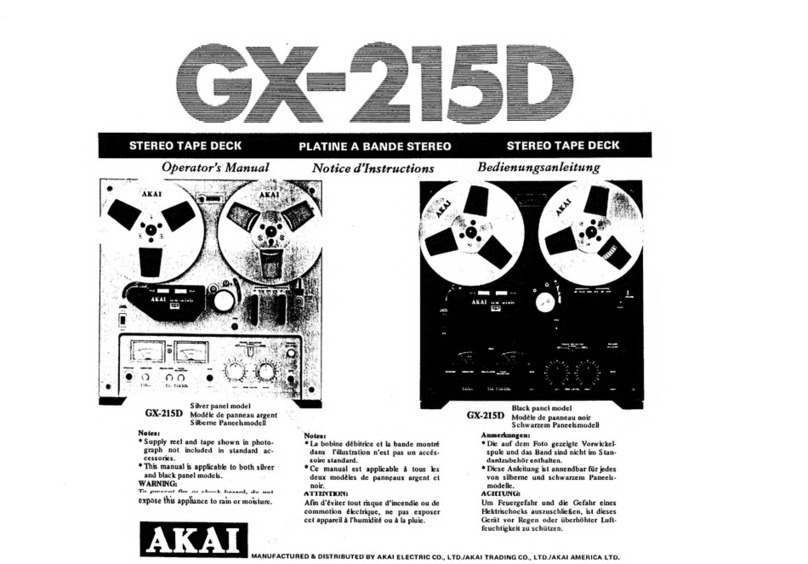

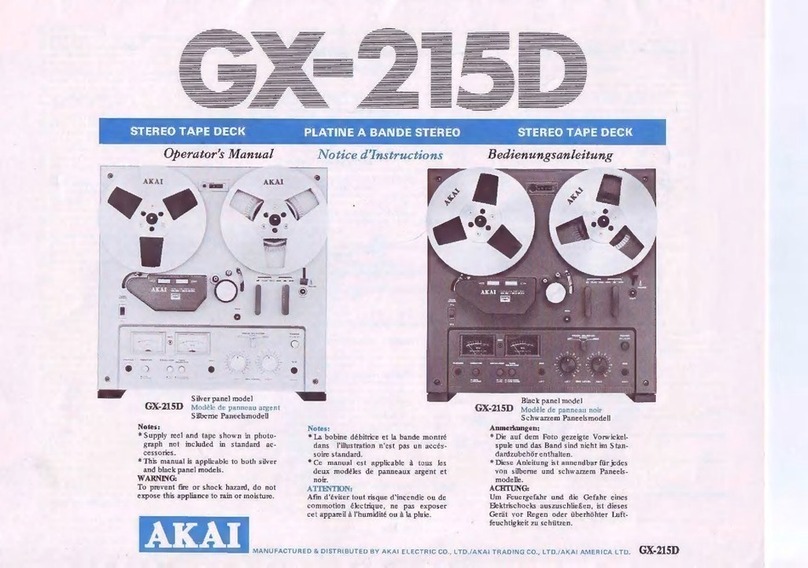

Akai GX-215D User manual

Akai

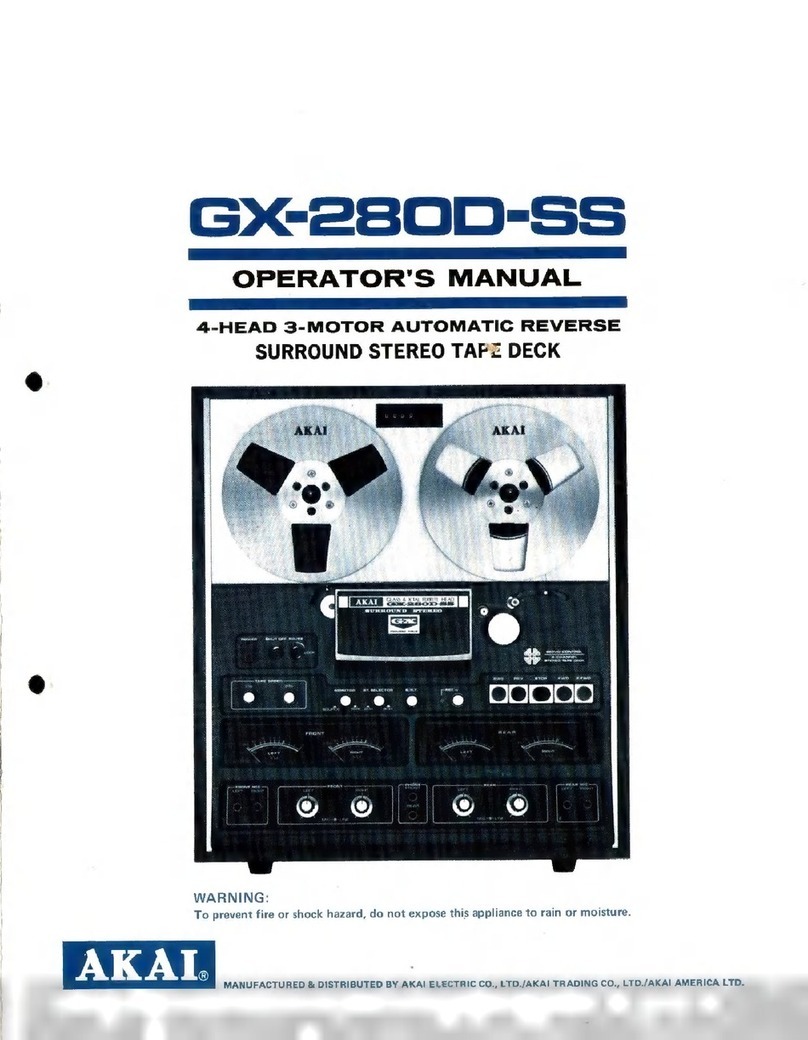

Akai GX-280D-SS User manual

Akai

Akai 1700 User manual

Akai

Akai GX-210D Operating and installation instructions

Akai

Akai GX-77 User manual

Akai

Akai GX-646 User manual

Akai

Akai 4000DB User manual

Akai

Akai X-1810 User manual

Akai

Akai GX-630D User manual