1I IIOW

TO NIICNSURE

DESIGNATED

VALUES

OF

SPECIFICATIONS

TAI'I] SPDtrD

DEVIATION

:

\{OW AND

FLUTTER

:

Reco.d the l,000cps. sine curve of

the tap€ speedat rating sp€eds

with

a standa.d sound recorder (AMPEX

351A, for instance)

which is little af-

fccted by lhe tape sPecd deviation

tlrroughout the whole i€ngth of the

tape. Put th;s standard taPe on th€

tapc recorder unde. test for playing

back, and nreasure its outPut bY a

couDte., then codvert thc value into

rating power frequeDcy to cvaluate

the tape speeddcviatior.

Fo. a rough measurement,the taPe

spe€ddeviation can alsobe measured

with a testing tape for speedby astop

Playback thc 3,000cpssianda.d tape

that guarante€s

wo\dand flutter with-

h 0.07

p€r cent,aid read the effect;ve

valuc otrwow mere.

Since

the sedsibility of wow and flut-

tcr frequency bclow 2cps and above

5cps.d.ops,the frequency over 5cps.

is put to 3db/OCT circuit,

and th€

frequency bclow 2.ps. is put to 6db/

OCT circuit for adjustment This ad-

justed value is called auditory com-

Connccr to thc input tcdninal of the

rcco.dcr, .ccord a sine curve swecp

f.equency at 100cps -10 db. from

Audio frequency Oscillator.

Adjusl toDe volume to flat, playback

the tapeby .onnectidg VTVM tosp€-

aL€rout put then read the frequency

response

to adjusl a maximum devia'

}.RLqUI]NCY

RESPONSE:

(OVI]RALL

I'REqUENCY

RESPONSE)

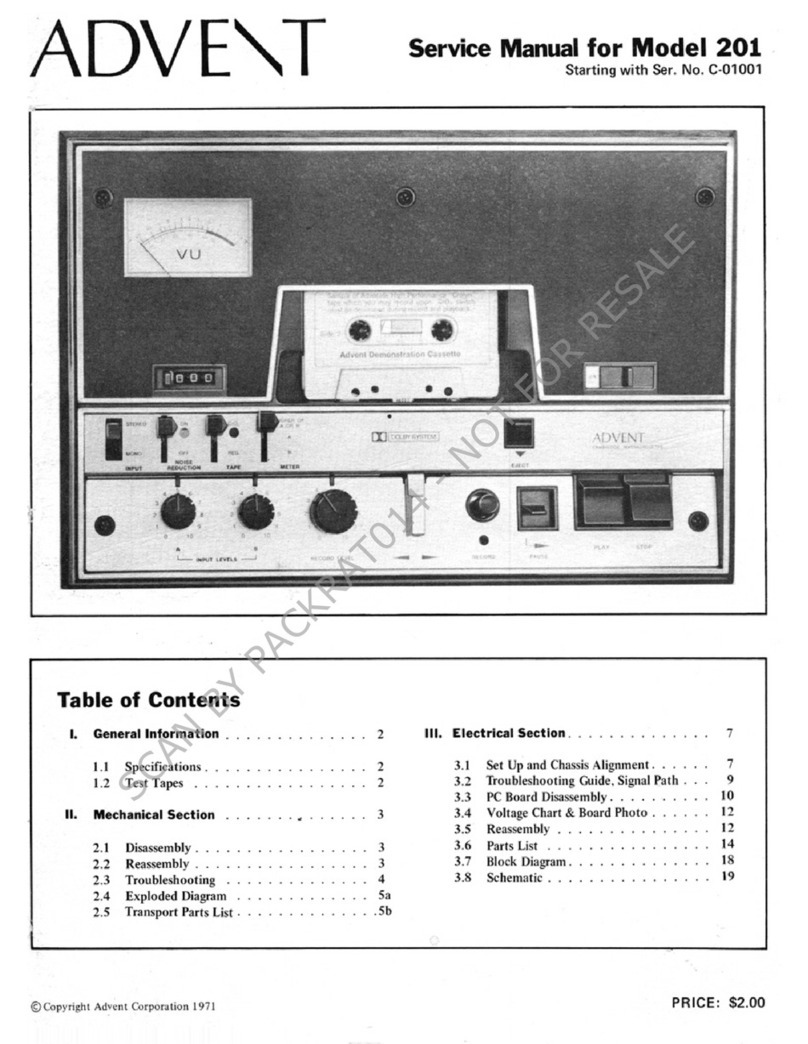

TOTAL HARMONIC

DISTORTION

FACTOR: Provide the input terminal ol the

,ecord.r with 1.000.ps.

':nF ,urvF

signalsand .ecord thesesignalson a

recording tape at the zerolevelonthe

recorder's

VU mete.

Then playback the siSnals

under the

no.mal recording condit;on to meas-

u.c the distortion factor by an oscil

lator. Remove the recording tapc

from the recorder,

then read the noisc

lcvelon theoscjllator

to 8ct therequ;r-

€d dhtortion factor by the following

formula:

d0:d-dl d2

d0..required

d...overall distortion factor

dl...noise

l€vel

d2...disto.tion

factorof theoscilla-

to. uscd

SICNAL TO

NOISE: Playback the sinecurve, 250cPS.

tape

rccorded on a standard recorder on

th€ reco.derto measur€

the voltag€

Removc the taPe, then measure the

noisc level under the samecondition

Calculate the ratio between the two

in d€cibel.

OUTPUT: I'layback on the recorder

thc 1,000cps.

sine curvc tape which was record€d

at the zero VU level on a standard

recorder. T€rDinatc the test recorder

with €ight ohms.

Square the voltag€ rcading, then di

vide the figure by eight ohms to get

thc r.m.s.

Powcroutput.

CROSS TALK: Record 1,000cps.

signal at +3VU on

the third tack, then playback this

signalthrough a l,000cps. Band Pass

Filter.

Compare the output of tracks I and 3

in decibels.

2-