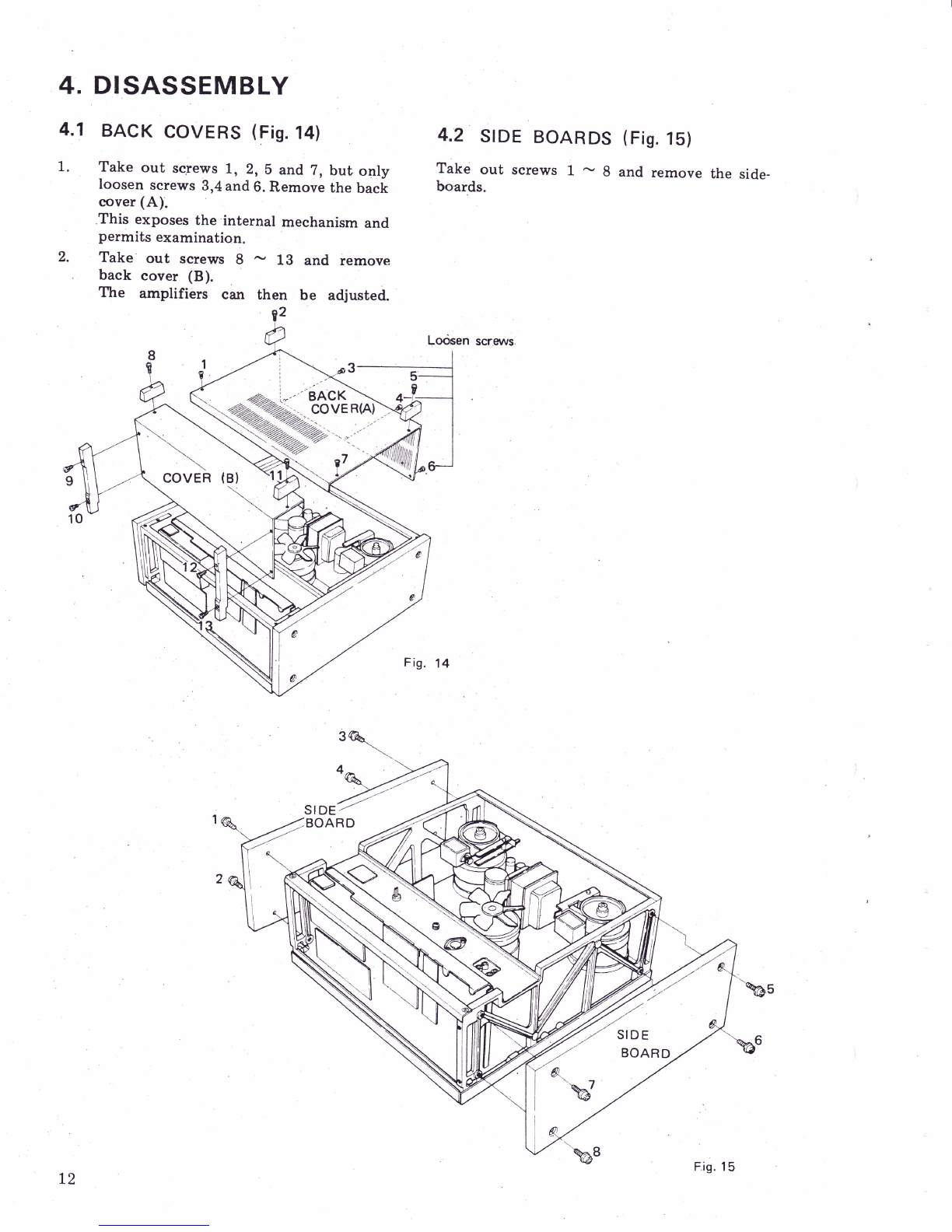

o Tape Protection at PLAYBACK

lmmediately From F.F. (or REW)

( Fig. 8)

If the PLAY button is pressed while the deck is

in the FAS1' FORWARD (or REWIND) mode,

the tape is brought to a halt briefly before

resuming travel at the specified speed, in order

to protect it.

As shown by Fig. 8. the circuit is structured

mainly around Q603 and Q604.

1. The base of Q604 is biased via R60? -

R606 - D606 - 510-2 (S11-2) while the

deck is in the FAST FORWARD (or

REWIND) mode. Q604 is thus ON and

relay RL601 is operative.

2. The base of Q603 is connected via R610 to

the collector of Q004. When e604 is ON,

the base of QG0B is reverse biased, and

Q603 is OFF.

3. C619 is charged via R604 (C618) - C619

- R606 - D606 - 510-2 (S1L-2).

4. When the PLAY button is pressed, 512-1

goes over to PLAY, S10-2 (S11-2) return

to their OFF positions, and the base bias

loop for Q604 (in step 1. above) is broken.

The charge accumulated in C61g, however.

Forms the base current of e604 and keeps

it on maintining the relay RL601 opera-

tive.

5. Even if 512-1 goes over to pLAy, while the

relay RL601 is operative, its relay contacts

(RL601) will not cause RL602 to operate.

6. As C619 discharges, so the base current of

Q604 drops, with a corresponding increase

in its internal resistance, and agreater

potential difference between the emitter

and collector.

7. When this potential difference reaches BV,

the reverse bias which had been applied to

Q603 becomes direct bias, urrd e603

comes ON.

8. When Q60B comes ON, C61g is rapidly

discharged via D60b - R60b - eOOg,

Q604 goes OFF, and the relay RL601

releases.

9. As soon as relay RL601 releases, a current

flows through R613 - RL602 N relay

contacts (RL601) - 51'J.-2 - 510-2, caus-

ing relay RL602 to operate so that the tape

commences to travel at the specified speed.

10. C619 is fully charged after some 6 seconds

of FAST FORWARD (or rewind), and it

takes about 6 or 7 seconds after the PLAY

button is pressed before the specified speed

of tape travel commences.

11. R604 serrres to delay the charging of C61g

and D605 does to accelerate its discharge.

If, therefore, the PLAY button is pressed

after only from 0.5 to 6 seconds of FAST

FORWARD or REWIND CG19 wilt not be

fully charged, the time taken for it to

discharge (that is during which Q604 will

remain ON), and the pause before the tape

commences travel at the specified speed

will be correspondingly shortened.

The Function of C618

Such delay circuit as shown in Fig g would

not protect the tape on those occasions when

the length of FAST FORWARD (or REWIND)

operation is so short - 0.5 seconds or less -

that the tape would not come to a complete

halt before attempting to commence travel at

the specified speed after pressiirg the PLAy

button. If not prevented, this would cause the

tape stretch or snap. This possibility arises

because of the inadequate charge in C619 due

to the very short time during which the tape

deck is in the FAST FORWARD or REWIND

mode. In order to prevent it the circuit shown

in Fig. 10, incorporating C61g was added. The

addition of C618 and R604 prevents the delay

in the charging of C619 and provides sufficient

voltage to hold Q604 ON instantaneously.

Fis.9 Fig. '10

umbers indicate each of characteristics:

O C619 onty

@ when C618 is incorporated (Fig.1g)

@ when R604 is incorporated (Fig.g)

Voltage necessary

to hold 0604 ON

Reoe I Rsto.

EW

Sro-z Srr- z

Fis. 8-_; tFis. 11