Plastic Spring Driven Reel

2766 Series Instruction

Plastic Spring Driven Reel 2766 Series Instruction

Technical Details

Spring driven drum: for automatic retractable.

Locking ratchet: to maintain the desired length of hose in use.

Safety Precautions

GENERAL SAFETY RULES

WARNING: Read and understand all instructions.

WARNING:

The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions or situations that could occur. It must be understood by

the operator that common sense and caution are factors which cannot be built into this

product, but must be supplied by the operator.

Hose Reel Safety Precautions

1. Use proper eye protection when assembling and using the hose reel.

2.Keep children away from the work area.

3. Personal injury and/or equipment damage may result if proper safety precautions are not

observed.

4. Ensure that reel is properly installed before connecting input and output hoses.

5. Bleed fluid/gas pressure from system before servicing reel.

6. Before connecting reel to supply line ensure that pressure does not exceed maximum

working pressure rating of reel.

7. Remember, even low pressure is very dangerous and can cause personal injury or death.

8. If a leak occurs in the hose or reel, remove system pressure immediately.

9. Ensure that reel, hose, and equipment being service are properly grounded.

10. If reel ceases to unwind or rewind, remove system pressure immediately.

11. o not pull or jerk on hose.

Installation of Hose Reel

You will need to purchase appropriate hardware for mounting your new reel.

1) For mounting: For air series, Install reel on the wall and ceiling at most 9feet / 3m above the

floor. For water series, Install reel on the wall at most 4.5feet / 1.5m above the floor .

2) The reel base has two mounting holes for mounting on a suitable flat surface for air series

(four mounting holes for water series). Below figures is a template showing the correct

location of the mounting holes in the base.

3) Using the mounting holes in the base, mount the reel in the desired location. Be sure to use

appropriate hardware and tighten securely.

1 OF 4

REV 12/03/14

WARNING:

Read carefully and understand all INSTRUCTIONS before operating. Failure to

follow the safety rules and other basic safety precautions may result in serious

personal injury.

Save these instructions in a safe place and on hand so that they can be read

when required.

Item Medium

27667203-18

27667203-28

27667204-31

27667204-21

27667155-31

27667155-21

300/20

300/20

140/10

140/10

140/10

140/10

Air

Air

Water

Water

Water

Water

-20~60

-20~60

0~60

0~60

0~60

0~60

PVC

PVC

PVC

PVC

PVC

PVC

3/8" /10

3/8" /10

1/2" /12

1/2" /12

5/8" /15

5/8" /15

20/65

20/65

20/65

20/65

15/50

15/50

Work Tem.(˚C)

Material

Hose Capacity

I.D.

(inch/mm)

Length

(m/ft)

Max

Pressure

(psi/bar)

For Water

For Air

Safety Precautions

General Safety Rules

HR40030 Instruction

Plastic Spring Driven Reel 2766 Series Instruction

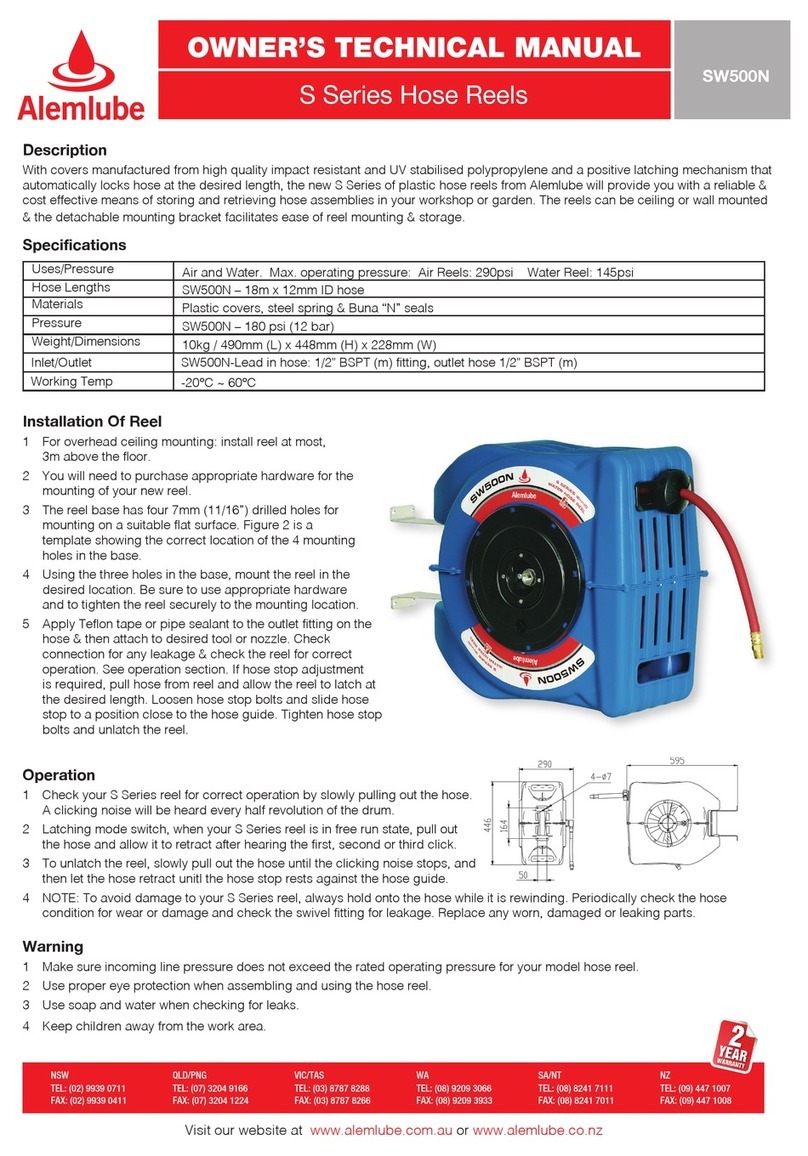

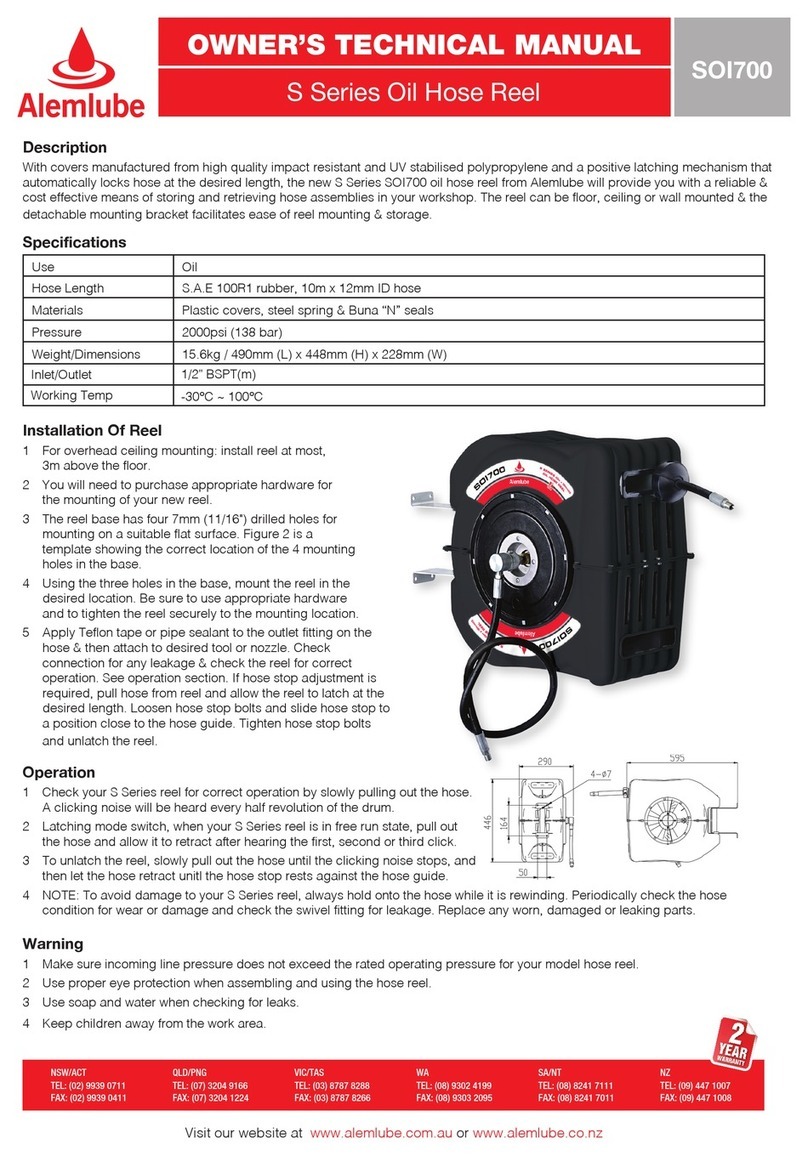

2766 for air wall & ceiling

2766 for water wall

4) The end of incoming hose can be connected to desired supply source.

5) Outlet fittings on reel hose attach to desired tool, or nozzle. Check connection for leakage,

also check hose reel for correct operation. See: Operation section.

6) If hose stopper adjustment is required, pull hose from reel and allow to latch at desired

length. Loosen stopper bolts, and slide stopper to a position close to the hose guide. Tighten

stopper bolts, and unlatch the reel.

2 OF 4

Plastic Spring Driven Reel 2766 Series Instruction

Operation

1. Check reel for correct operation by slowly pulling out the hose.

2. To latch the reel, pull out the hose about 3 feet/1m and allow it to retract until the hose

stops retracting.

3. To unlatch the reel, slowly pull out the hose about 1 foot/0.3m then let the hose retract

until the hose stopper rests against the hose guide opening.

Note: To avoid damage to the reel, always hold on to the hose while it is rewinding.

4. Periodically check the hose condition for wear or damage, and check the swivel fitting

for leakage. Replace any worn, damaged, or leaking parts.

Maintenance

Make sure the hose is in proper working order.

Clean the hose with a cloth dipped in warm water to remove dirt or deposits and ensure

correct rewinding.

Do not use detergents or solvents which could prove incompatible with cable-winder materials.

Dismantling of the unit by unskilled personal could prove hazardous; the risk involved mainly

concern the preloaded springs.

Limited Warranty

1. The manufacturer warrantees this hose reel against defects in material and craftsmanship,

for a period of 24 months from date of purchase, but not including hose and O-ring parts.

2. Manufacturer’s liability is limited to replacement or repair of defective material within the

warranty period, when returned freight prepaid to the distributor or their designated

service depot.

3. The warranty does not cover damage caused by accident, misuse or faulty installation.

4. The reel must be installed and maintained in compliance with the instructions.

3 OF 4

HR40029 for air and water - wall and ceiling mount

Plastic Spring Driven Reel 2766 Series Instruction

2766 for air wall & ceiling

2766 for water wall

4) The end of incoming hose can be connected to desired supply source.

5) Outlet fittings on reel hose attach to desired tool, or nozzle. Check connection for leakage,

also check hose reel for correct operation. See: Operation section.

6) If hose stopper adjustment is required, pull hose from reel and allow to latch at desired

length. Loosen stopper bolts, and slide stopper to a position close to the hose guide. Tighten

stopper bolts, and unlatch the reel.

2 OF 4

Plastic Spring Driven Reel 2766 Series Instruction

Operation

1. Check reel for correct operation by slowly pulling out the hose.

2. To latch the reel, pull out the hose about 3 feet/1m and allow it to retract until the hose

stops retracting.

3. To unlatch the reel, slowly pull out the hose about 1 foot/0.3m then let the hose retract

until the hose stopper rests against the hose guide opening.

Note: To avoid damage to the reel, always hold on to the hose while it is rewinding.

4. Periodically check the hose condition for wear or damage, and check the swivel fitting

for leakage. Replace any worn, damaged, or leaking parts.

Maintenance

Make sure the hose is in proper working order.

Clean the hose with a cloth dipped in warm water to remove dirt or deposits and ensure

correct rewinding.

Do not use detergents or solvents which could prove incompatible with cable-winder materials.

Dismantling of the unit by unskilled personal could prove hazardous; the risk involved mainly

concern the preloaded springs.

Limited Warranty

1. The manufacturer warrantees this hose reel against defects in material and craftsmanship,

for a period of 24 months from date of purchase, but not including hose and O-ring parts.

2. Manufacturer’s liability is limited to replacement or repair of defective material within the

warranty period, when returned freight prepaid to the distributor or their designated

service depot.

3. The warranty does not cover damage caused by accident, misuse or faulty installation.

4. The reel must be installed and maintained in compliance with the instructions.

3 OF 4

Visit our website at www.alemlube.com.au or www.alemlube.co.nz

NSW

TEL: (02) 9677 1555

FAX: (02) 9675 1155

QLD/PNG

TEL: (07) 3204 9166

FAX: (07) 3204 1224

VIC/TAS

TEL: (03) 8787 8288

FAX: (03) 8787 8266

WA

TEL: (08) 9302 4199

FAX: (08) 9303 2095

SA/NT

TEL: (08) 8241 7111

FAX: (08) 8241 7011

NZ

TEL: (64) 9 447 1007

FAX: (64) 9 447 1008

2