3

OPERATION

1. Place sterilizer on a stable, heat tolerant

sur ace with access to appropriate electrical

power.

2. Remove the cover o the sterilizer by turning

the wing nuts in a counter-clockwise motion.

Always undo two opposite wing nuts at a time.

Turn cover and remove cover rom bottom. Next

remove inner container and inner container rack

rom sterilizer bottom (See Fig. A).

3. LUBRICATE METAL-TO-METAL SEAL Apply

lubrication to the entire beveled edge o the

bottom (See Fig. 1). We recommend using a high

temperature lubricant like high vacuum grease;

petroleum jelly may also be used as a substitute.

Only a thin ilm o lubrication is needed to

lubricate the metal-to-metal seal.

4. Place distilled or deionized water up to the

water line machined into the bottom o the

sterilizer. Water must be directly over the heating

element and NOT inside the inner container.

Next, place the inner container rack inside the

inner container with the lip side down (See Fig.

A). The purpose o the inner container rack is to

provide an air space at the bottom o the inner

container so that air may be evacuated and steam

is allowed to circulate reely throughout the entire

chamber.

5. With the inner container and inner container

rack out o the sterilizer place articles to be

sterilized inside the inner container on top o the

inner container rack. You may wish to place the

articles to be sterilized inside plastic bags speci -

ically designed or use inside steam sterilizers.

Arrange items so that steam may circulate reely

inside the chamber during the sterilization cycle.

Also, you can place a towel or cloth on top o the

items inside the container to absorb any moisture

that may drip down rom the cover onto the

items.

6. Check to see i your water level inside the

sterilizer is correct and then place loaded inner

container inside the sterilizer.

7. VERY IMPORTANT – make sure that the air

exhaust channel (located on the inside o the

inner container) is positioned on the right side o

the sterilizer. This is necessary so that when the

cover is placed on the unit you can guide the air

exhaust tube into the air exhaust tube channel

(See Fig. A).

8. Place the cover o the sterilizer making sure

that that index alignment arrow on the cover

aligns with the index line arrow on the side o the

bottom; AND that the air exhaust tube is inserted

into the air exhaust tube channel on the inner

container. With the cover aligned with the bottom

and the air exhaust tube inside the air exhaust

channel you may tighten the wing nuts on the

cover. Be sure to tighten wing nuts evenly,

always tightening down two opposite wing nuts

at one time. As you are tightening the wing nuts

be sure to maintain an even gap between the

cover and the bottom. Loosen or tighten the

wing nuts accordingly to maintain an even gap.

This will draw the cover down evenly and ensure

a proper seal. NEVER USE A WRENCH OR ANY

MECHANICAL DEVICE TO TIGHTEN WING

NUTS. NEVER HAMER OR STRIKE THE WING

NUTS OR COVER WHILE OPENING OR

CLOSING UNIT.

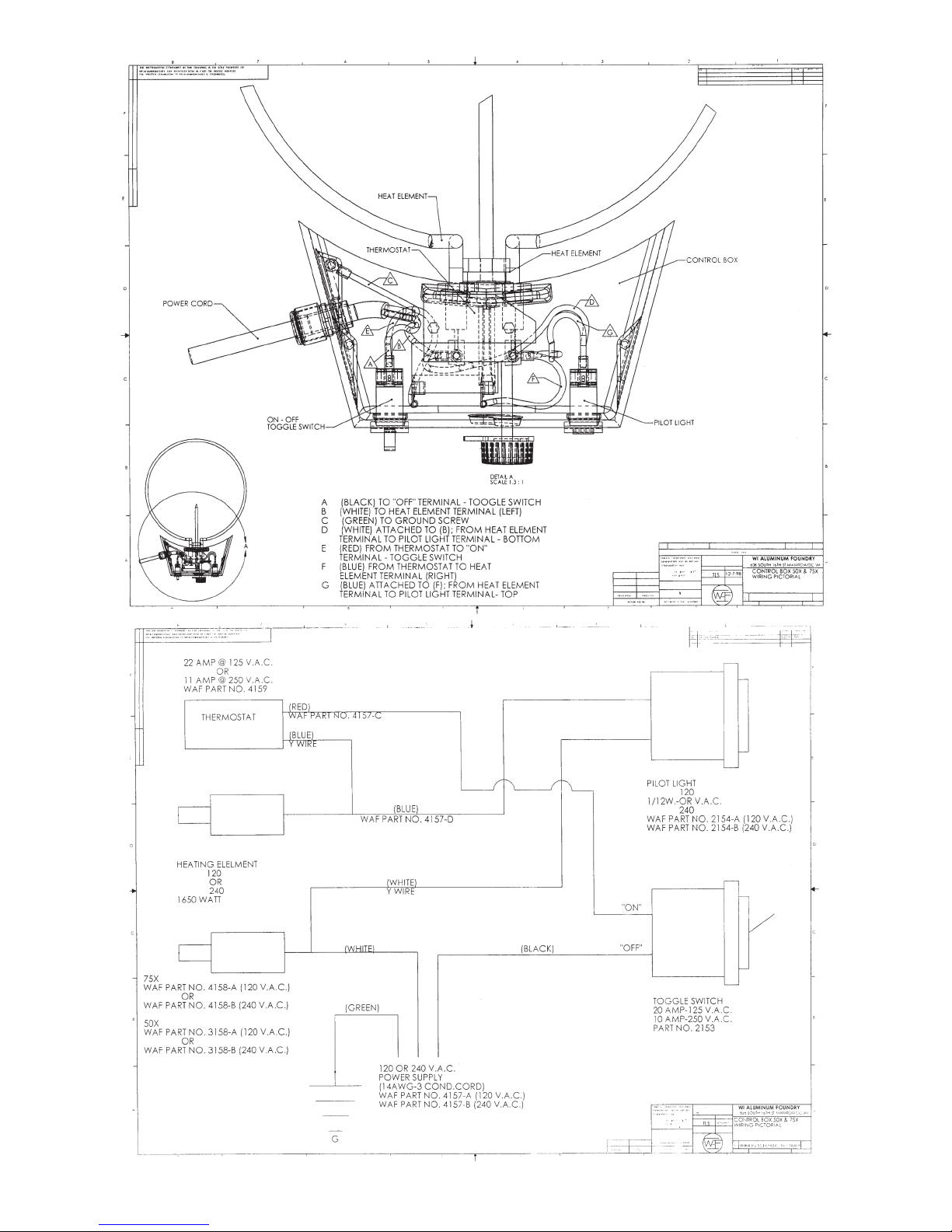

9. Plug power supply cord into the proper outlet

120V or 240V (re er to dial plate on ront o the

control box and note in the upper le t hand corner

i your unit is 120V or 240V). Next, turn the

on/o toggle switch to “on” position, the red pilot

light should be illuminated indicating that

electrical current is working and the heating

element is now operating. To increase heat, turn

the heat control knob in a clockwise direction; to

reduce heat, turn knob in a counter-clockwise

direction. Always maintain a close watch on the

pressure gauge and adjust heat accordingly.

10. OPEN CONTROL VALVE (See Fig. 2) by

moving the lever into the upright position. Steam

generated by the sterilizer will be drawn rom the

bottom o the unit up through the air exhaust tube

and out the control valve. STEAM MUST

CONTINUOUSLY ESCAPE FROM THE CONTROL

VALVE FOR AT LEAST 5 MINUTES. Once this

has occurred, CLOSE THE VALVE AND LET

PRESSURE BUILD UNTIL THE GAUGE READS IN

THE “GREEN” STERILIZATION ZONE, which is

between 17 to 21 PSI or 121°C/250°F to

127°C/259°F. Once you have completed the

above, OPEN THE CONTROL VALVE A SECOND

TIME AND VENT THE CHAMBER FOR AN

ADDITIONAL 3 TO 5 MINUTES. Please Note that

the greatest reason or a sterilization ailure is

trapped air in the chamber o the sterilizer.

Trapped air may prevent the steam rom perme-

ating the contents to be sterilized.

11. Once the chamber is properly vented, close the

65k Control Value, then the sterilization cycle may

begin. Start timing the sterilization cycle when the

gauge needle is in the green sterilization zone on the

ace o the gauge between 17-21 PSI. We recommend

running a sterilization cycle o not less than 35 minutes

at a temperature o no less 121°C/250°F. Your

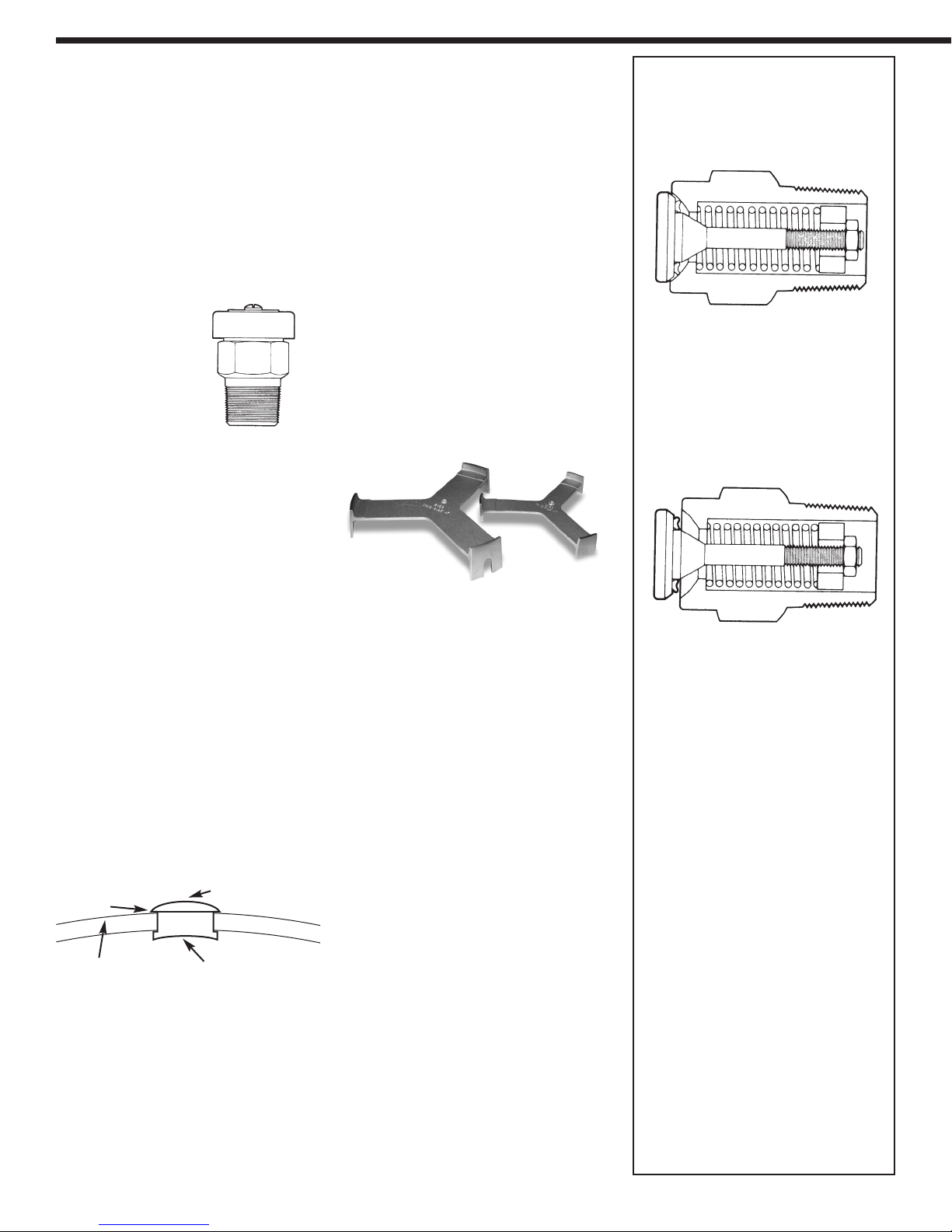

Fig. 1

Metal-to-metal seal

Apply lubricant here

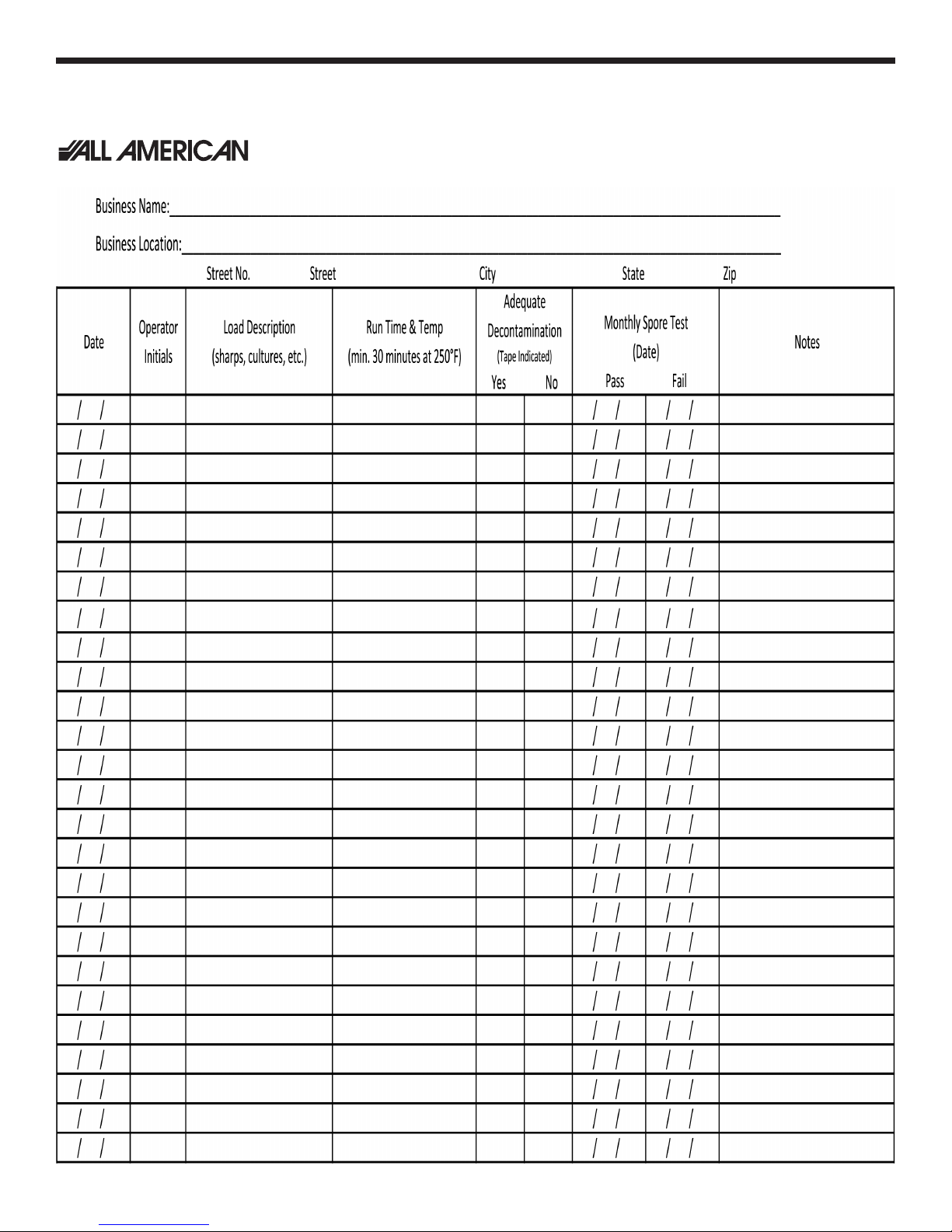

Open control valve Closed control valve

Fig. 2 Fig. 3

Lever horizontal

or closed

Lever vertical

or open

steam escape

holes

steam escape

holes

valve body

de lector

de lector