InnovaPrep ACD-200 User manual

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 1

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 2

Table of Contents

1 Product Overview ................................................................................................................................. 3

1.1 Product Description .....................................................................................................................................3

1.2 Applications ................................................................................................................................................3 1.3

Materials Provided ......................................................................................................................................3

1.4 Materials Required But Not Provided...........................................................................................................4

1.5 Battery Power .............................................................................................................................................4

2 ACD-200 Bobcat Method of Operation .................................................................................................. 4

2.1 Sample Collection on an Electret Filter .........................................................................................................4

2.2 Wet Foam Elution........................................................................................................................................4 2.3

Foam Generation ........................................................................................................................................5

3 Components of the ACD-200 Bobcat ..................................................................................................... 6

3.1 Description of Components .........................................................................................................................6

3.2 Check Status Button and Associated LEDs ....................................................................................................7

4 Procedures ........................................................................................................................................... 8

4.1 Setting Up the ACD-200 Bobcat for Collection ..............................................................................................8

4.2 Optional Battery Operation .........................................................................................................................9

4.3 Installing the Filter .................................................................................................................................... 10

4.4 Collecting a Sample ................................................................................................................................... 10

4.5 Recovery of the Sample ............................................................................................................................. 11

4.6 Eluting a Filter Sample ............................................................................................................................... 11

4.7 Cleaning the System .................................................................................................................................. 11

4.8 Battery Charging ....................................................................................................................................... 12

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 3

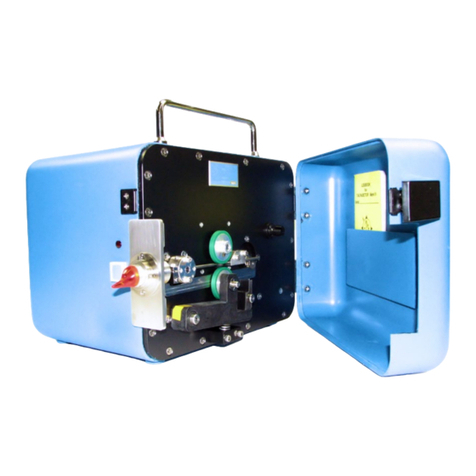

1 PRODUCT OVERVIEW

This section contains a product description of the InnovaPrep ACD-200 Bobcat™ Dry Filter Air Sampler and a brief look at

its applications.

1.1 PRODUCT DESCRIPTION

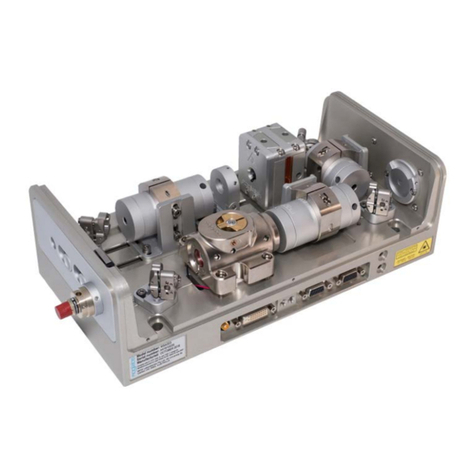

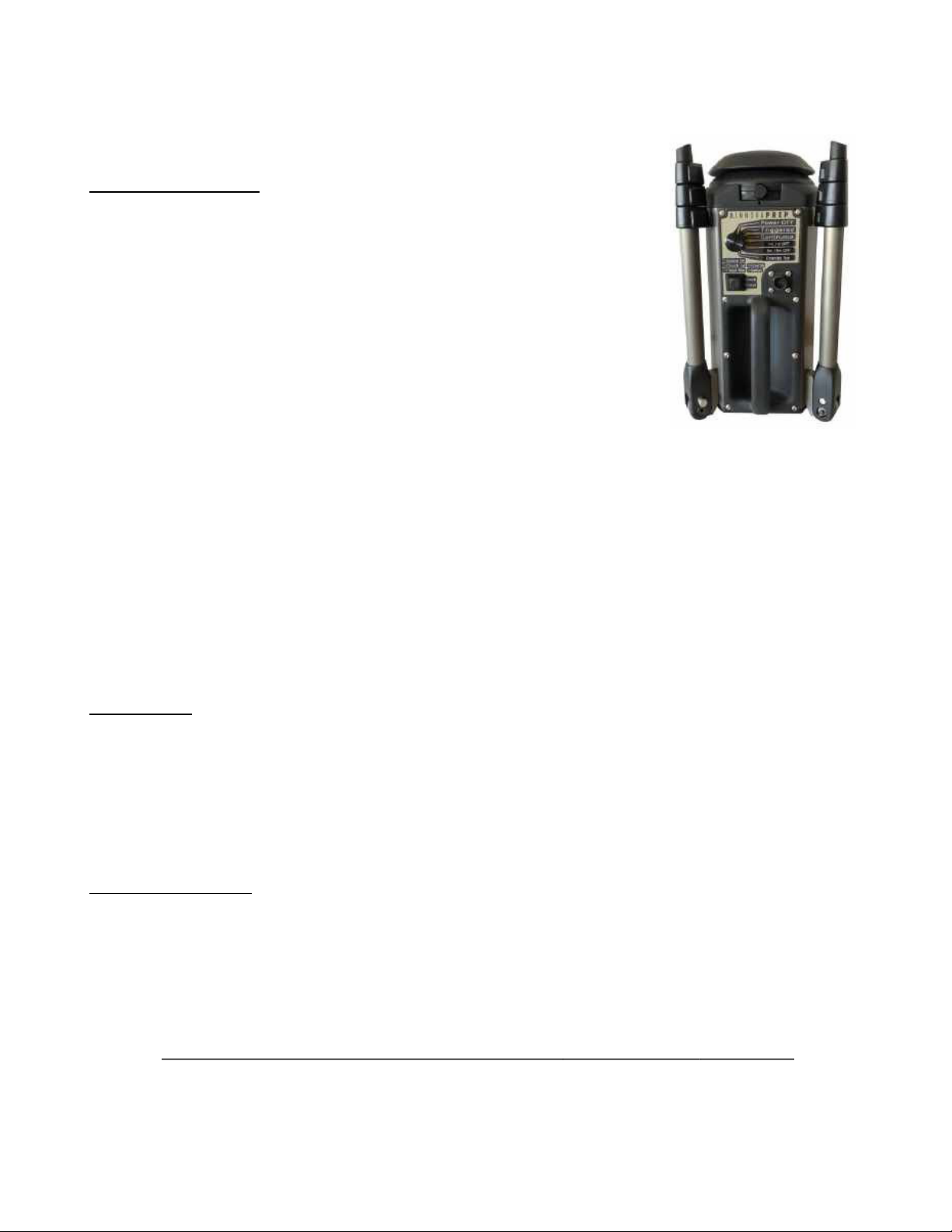

The InnovaPrep ACD-200 Bobcat, shown in Figure 1.1, is a lightweight, portable, dry

filter air sampler with a unique patented rapid filter elution system. The Bobcat

aerosol collector takes up little more than one-quarter of a cubic foot, has an internal

battery, built-in tripod, and can run continuously at 200 liters per minute for Up to 14

hours on continuous mode or 6 days on extended run when using the lithium ion

battery. The system has a built-in, omni-directional aerosol inlet, easy to read status

display, and a built-in handle. The system is equipped with a mass flow sensor that

allows for consistent sampling rates throughout the collection cycle. It can be

operated in four programmable run modes that allow the user to balance collection

rate with battery life. The system is easy to use and operators can be trained in a

little as 10 minutes. Installation of the filter cassettes and the controls can be

manipulated with gloved hands, while wearing personal protective equipment such as military-style

nuclear/biological/chemical (NBC) protective suits.

Following aerosol collection, the user snaps the Sample Cup onto the Filter to remove it from the Collector, then snaps the

Elutor onto the Filter. To extract the captured particles from the Filter, a canister containing the Elution fluid is pressed

into the Elutor. The Elution Fluid is released from the canister and turns to foam as it flushes the Filter. The wet foam

passes through the interstitial spaces of the Filter to efficiently extract captured particles. Sample elution takes

approximately 5 seconds and produces 6 to 7 milliliters of liquid sample. The foam quickly collapses back to a liquid in the

Sample Cup, making it available for sample processing and analysis.

1.2 APPLICATIONS

The InnovaPrep ACD-200 Bobcat is ideally suited for the collection of bioaerosols and particulate matter; including

submicron sized particles, airborne molecular contamination, and particulates. This system has been developed to address

a broad range of air sampling requirements. The Filter and Elution Kit are single-use, therefore there is no requirement for

decontamination between samples. Since no liquids are used in the collector, the system can be operated at temperatures

ranging from -20° C to +60° C in non-condensing environments.

1.3 MATERIALS PROVIDED

Inspect each component when unpacking. If damage is observed, do not use the instrument, and contact InnovaPrep

immediately. Remove any protective packaging that may be present around the instrument. Examine the packaging

material to be sure that materials that have been provided (see the list below) are removed. Please keep the custom foam

packaging insert for use in the event that a return shipment is necessary.

Component InnovaPrep P/N Quantity

InnovaPrep ACD-200 Bobcat

ACD-200

1

External Power Supply

AC01057

1

Power Cord

HC03019

1

FIGURE

1.1

ACD

-

200

BOBCAT

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 4

Power/Trigger Cable Assembly

AC01129

1

1.4 MATERIALS REQUIRED BUT NOT PROVIDED

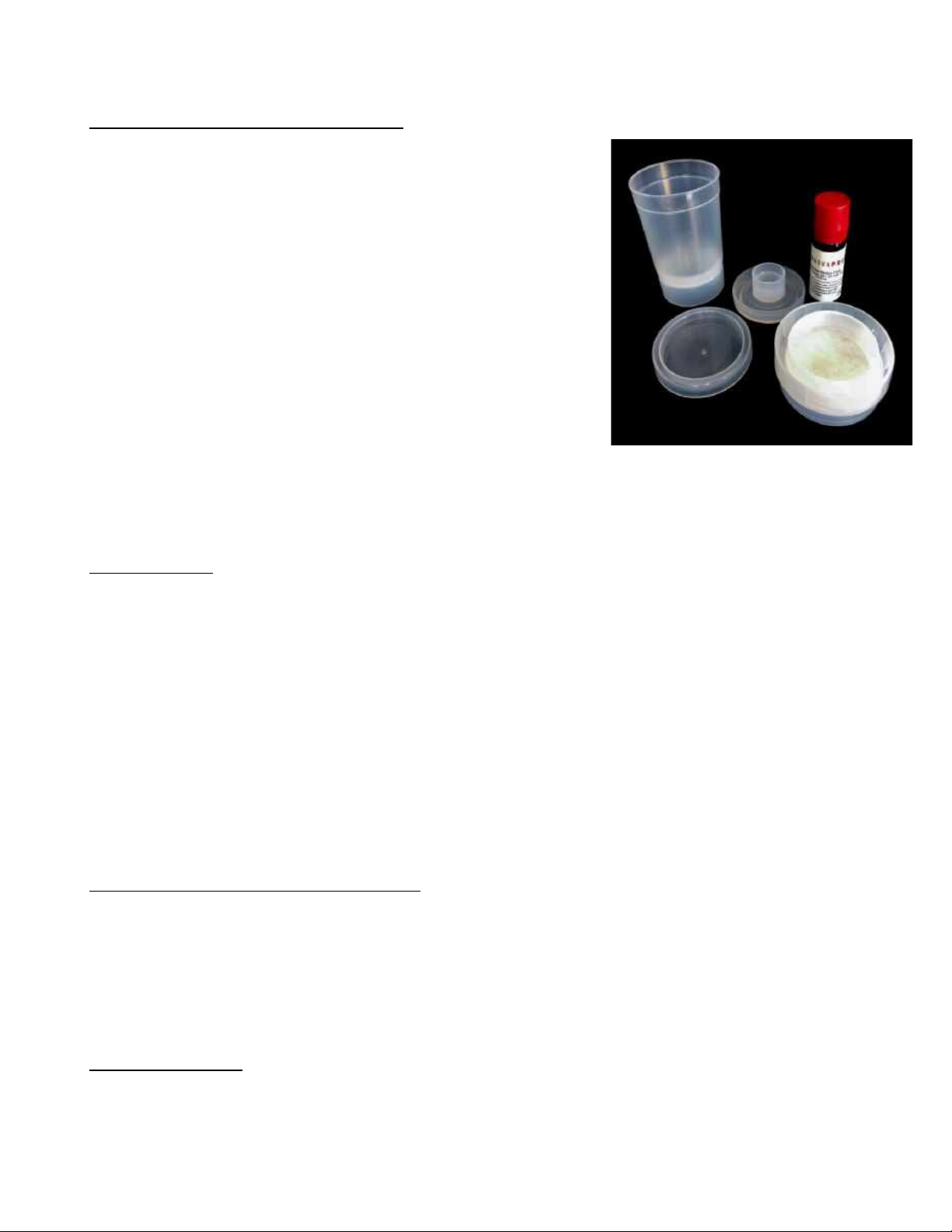

A Rapid Filter Elution Kit is required for sampling. Users have a choice of two

kits with different fluid types.

• Rapid Filter Elution Kit with TRIS - Item AC00201-T

• Rapid Filter Elution Kit with PBS - Item AC00201-P

Each Filter Elution Kit includes:

1. Filter

2. Sample Cup

3. Sample Cup Lid

4. Elutor

5. Elution Fluid Canister

These are available for purchase on the InnovaPrep website.

To operate the unit in “Trigger” mode you will need to purchase the Trigger Accessory.

1.5 BATTERY POWER

Battery is not included. Two rechargeable battery options are available for the ACD-200 Bobcat.

• 7.5 Ah Lithium Ion – Recommended for holding the longest charge (up to 12 hours on continuous mode). Item

AC01054

• 4.8 Ah Nickel Metal Hydride – Holds charge up to 7 hours on continuous mode. Item AC09006

2 ACD-200 BOBCAT METHOD OF OPERATION

The InnovaPrep ACD-200 Bobcat uses an electret filter to capture particles onto the surface of polymer fibers in the filter.

A novel Wet Foam Elution™ process is then employed to wash the particles off of the fiber surfaces into very small liquid

volumes.

2.1 SAMPLE COLLECTION ON AN ELECTRET FILTER

The system uses a dry 52 mm electret filter as the collection media. Electret filters are made with a combination of

positively charged and negatively charged fibers. This substantially increases the collection efficiency of the filter and

allows for the use of lower pressure drop filters, which, in turn, allows for higher sampling rates for extended periods using

battery power. Additional advantages include low consumable costs, ease of use, and high durability. It has the ability to

operate below 0°C — a limitation for most collectors.

2.2 WET FOAM ELUTION

The single-use kit comes with everything you need to recover a fluid sample, including the Filter, a Sample Cup with Lid,

an Elutor, and a canister of Elution Fluid. The patented Wet Foam Elution process (US Patent 8,100,112; 8,958,623;

9,738,918) is much more efficient than liquid rinsing for the following reasons:

2

3

1

4

5

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 5

• Volume Expansion

When rinsing a filter with liquid, most of the liquid volume is used to fill the dead space inside the filter housing;

only a small portion of the fluid is actually in contact with the filter surface. This can be minimized to an extent by

reducing the cross-sectional area of the fluid path across the filter, but a large portion of the liquid is still

underutilized. However, foam is 80-90% gas, which fills the empty space without contributing to the final sample

volume.

• Increased Viscosity

Liquid has a tendency toward “channeling” when flowing through a filter, that is, there is an area of high flow in

the center of the fluid path while the portion of flow in contact with the filter surface is much slower. The higher

viscosity of foam prevents channeling and creates a more uniform flow through the interstitial spaces of the filter.

• Bubble Dynamics

The micro-bubbles in the foam behave as deformable solids. As they travel through the filter they move as a rigid

body with a narrow lubricating layer, effectively squeegeeing the particles off of the surfaces of the filter fibers.

• Exfoliating Action

As the micro-bubbles in the foam impact against each other and burst, the turbulence and energy produced helps

to lift particles that are adhering to the filter fibers.

• Buffered Elution

The buffered elution fluid is conductive and breaks down the electrostatic charges holding the particles to the

electret filter, effectively releasing them in the liquid sample.

2.3 FOAM GENERATION

The Wet Foam Elution process uses a very specific high-quality foam to elute the filter. The elution fluid is composed of

water, a low concentration surfactant (0.075% Tween 20), and a pH buffer (Tris or PBS). This solution is carbonated at 130

psi, which dissolves significant amount of CO2 into the fluid. During the elution process, the valve opens as the elution

canister is pushed into the Elutor that is fitted onto the Filter, forcing the elution fluid through the pressure orifice, through

the filter and into the Sample Cup. As the fluid passes from the high-pressure environment on one side of the orifice, to

the low-pressure environment on the other side, the dissolved CO2 expands, comes out of the solution to form micro-

bubbles. These micro-bubbles increase the volume of the fluid six-fold or more as it passes through the filter. The foam

immediately collapses back into a liquid and is ready for sample processing and analysis.

3 COMPONENTS OF THE ACD-200 BOBCAT

The following section describes the components of the InnovaPrep ACD-200 Bobcat air sampler.

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 6

3.1 DESCRIPTION OF COMPONENTS

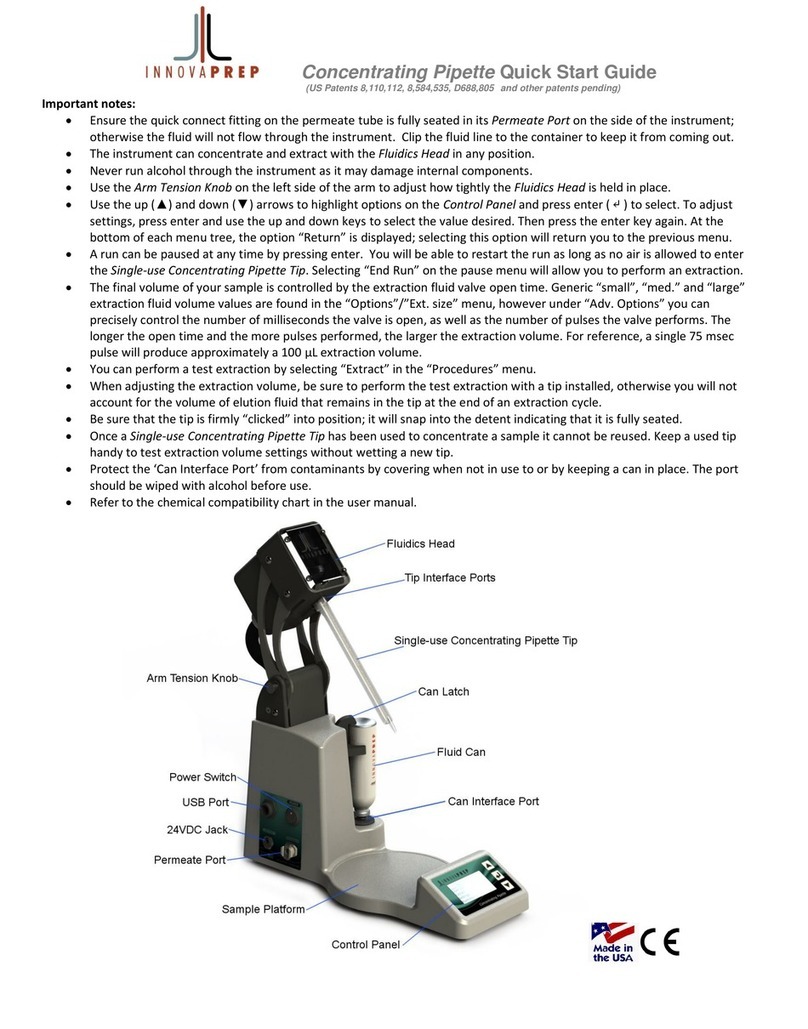

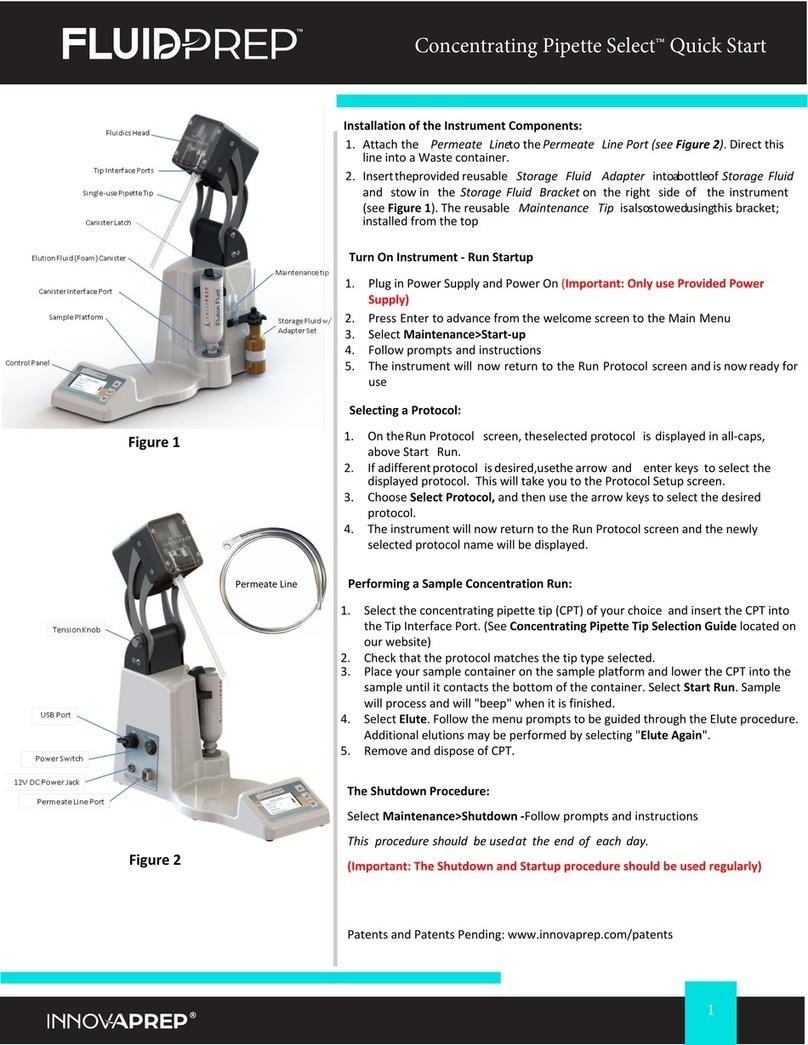

Description of the InnovaPrep ACD-200 Bobcat components listed in Figure 3.1, clockwise from top:

• Lid Release – Used to open the ACD-200 for loading or recovering a filter cartridge.

• Power and Trigger Port - Inlet for the included Power and for the optional Trigger Connector.

• Leg Hinges with Locking Push Pins – Releasing the push pins allows the user to fold the legs up against the unit for

compact storage and convenient transportation.

• Telescoping Tripod Legs – Each of the three legs consist of three segments that allow the user to raise and lower

the unit to the desired height.

• Leg Latches – Each leg has three leg latches that allow the user to telescope the legs to the desired length.

• Battery Cover – Located on the bottom of the unit, the battery cover holds the battery in place during operation.

Check Status Button – Used to verify the status of the system.

FIGURE

3.1

COMPONENTS OF THE AC

D

-

200

BOBCAT

Lid Release

Carrying Handle

Leg Hinges with Locking

Push Pins

Telescoping

Tripod

Legs

Power

and Trigger

Port

Mode Selection Knob

Check Status Button

Status Lights

Inlet Cap

Battery Cover

Leg Latches

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 7

• Status Lights – Green LED indicates the system is okay, red LEDs indicate if the lid is open, a filter is needed, the

flow rate is below desired level, or the battery power is low.

• Mode Selection Knob – Rotary knob for selecting the operating mode and turning the unit off.

• Inlet Cap – Protect from water ingress and is designed as part of the omni-directional inlet.

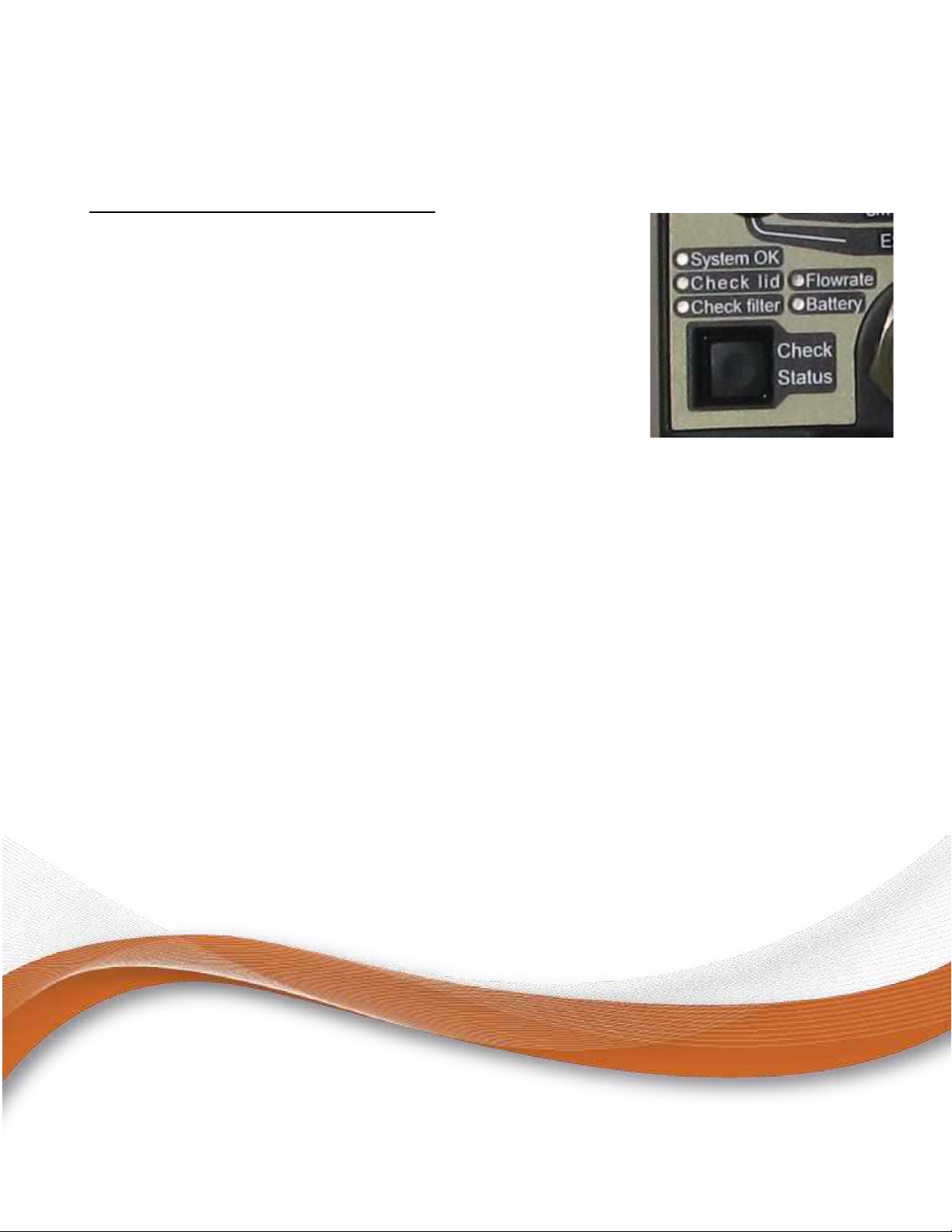

3.2 CHECK STATUS BUTTON AND ASSOCIATED LEDS

The ACD-200 is equipped with five LEDs that communicate the status of the unit to

the user. The appropriate LEDs are illuminated when the Check Status button is

pushed. The red Check Lid LED is illuminated when the lid is open. The red Check

Filter LED is illuminated if there is not a filter cassette present in the sampler. The

Flowrate LED is illuminated when the internal mass flow sensor is measuring a flow

rate less than what has been selected. This may be due to an overloaded filter or a

blockage at the exhaust vents located on the bottom of the unit. The Battery LED is

illuminated when the battery needs to be recharged.

FIGURE

3.2

CHECK STATUS BUTTON

AND LED

s

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 8

4 PROCEDURES

This chapter includes some of the basic procedures used while operating the Bobcat.

4.1 SETTING UP THE ACD-200 BOBCAT FOR COLLECTION

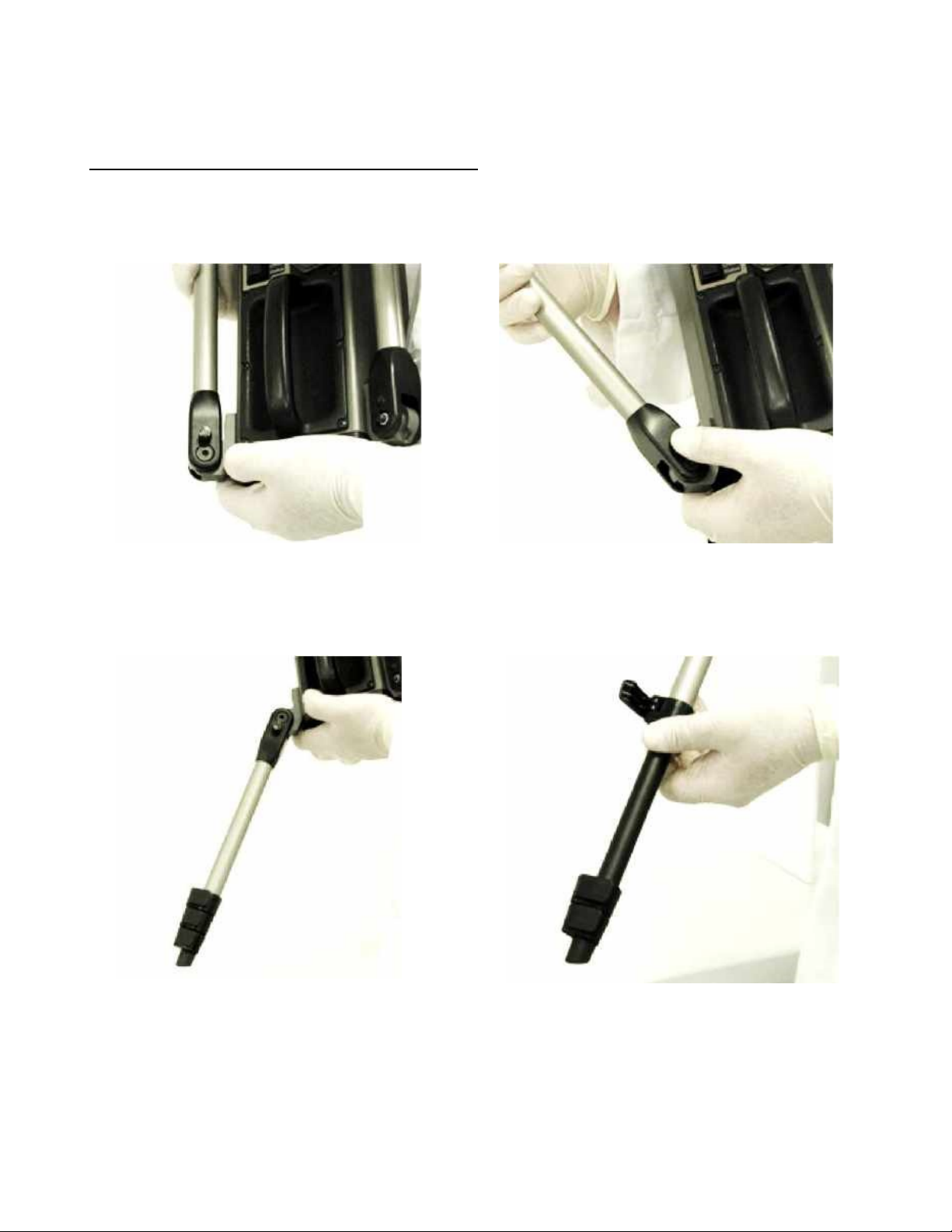

Select the desired area for sample collection. For each leg, push the locking push pin located on the leg hinge at the base

of the Bobcat as shown in Figure 4.1 and 4.2. It should be noted that the Bobcat cannot be operated with the legs in the

upright position since the exhaust vents are located on the bottom of the unit and the Inlet can’t be opened.

Unfold the leg until the push pin pops out and locks the leg into place as shown in Figure 4.3. Open the leg latches, as

shown in Figure 4.4, and telescope the legs out to the desired height.

Supporting the back of the unit with one hand, push the 10-Pin Connector (see Figure 4.5) on the Power and Trigger

Connector into the Power and Trigger Port on the front of the unit. It will automatically lock into place. Push the barrel

plug on the external power supply (see Figure 4.6) into the barrel jack on the Power and Trigger Connector. Plug one end

of the AC Power Cord (Figure 4.7) into the External Power Supply and plug the other end into an appropriate wall outlet.

FIGURE

4.1

LOCKING PUSH PIN LOC

ATION AT LEG HINGE

FIGURE

4.2

UNLOCKING AND UNFOLD

ING LEG

FIGURE

4.3

LEG PUSH PIN LOCKED

IN PLACE

FIGURE

4.4

OPENING LEG LATCH FO

R ADJUSTMENT

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 9

4.2 OPTIONAL BATTERY OPERATION

The ACD-200 has a rechargeable battery for

operating the unit in the field. Instructions for

using the battery are as follows. The battery

door is located on the bottom of the unit.

The Battery Cover is removed by pinching the

retaining clips on both sides, as shown in

Figure 4.9, and pulling the cover straight out of

the bottom of the unit, as shown in Figure 4.10.

The battery is installed into the unit with the

battery socket towards the front of the unit as

shown in Figure 4.11. Reinstall the Battery Cover by pushing it into the

bottom of the unit until both clips click into place.

FIGURE

4.5

POWER

AND TRIGGER

CONNECTOR

FIGURE

4.6

EXTERNAL POWER SUPPL

Y

WITH BARREL PLUG

FIGURE

4.7

AC POWER CORD

FIGURE

4.8

BATTERY COVER ON THE

BOTTOM OF THE UNIT

FIGURE

4.10

REMOVING

BATTERY COVER

FIGURE

4.11

INSTALLING

BATTERY

Battery Socket

FIGURE

4.9

PINCHING CLIPS ON

BATTERY COVER

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 10

4.3 INSTALLING THE FILTER

Open the ACD-200 by putting one hand on top of the Inlet and while grasping it, press the Release Button. The top will

open on its hinge. Insert the Filter into the top of the Collector as shown in Figure 4.12. The Filter housing is designed to

only fit in one way. Close the Inlet lid and hold it down to lock it in place, as shown in Figures 4.13 and 4.14.

A Trigger accessory is required to operate the Bobcat in the “Triggered” mode. The Trigger (Item # AC08078) is a 22ft

cabled switch available for models purchased after February 2018. For models purchased prior to February 2018, please

contact InnovaPrep for more information.

4.4

C

OLLECTING A

S

AMPLE

The unit is controlled with a single rotary switch

as shown in Figure

4

.15

.

The selections are Power OFF,

Triggered, Continuous, and three run modes:

Continuous mode

minute on, 1 minute off

1

—

sample collection at

Lpm

200

.

minutes on,

5

1

minutes off

5

—

sample collection at

Lpm

200

.

Extended Run

—

this selection samples for 1 minute on and

5

minute

s

off

with

sample

collec

tion

at 100 Lpm.

Five status lights are used to signal the system

’

s status and to alert the user

to errors. A check status push

-

button switch can be used to tu

rn the status

lights on

momentarily

so the

device is not readily seen in dark conditions

i.e. under “light discipline” conditions).

(

FIGURE

4.15

MODE SELECTION KNOB

FIGURE

4.12

INSTALLING

FILTER CASSETTE

FIGURE

4.13

CLOSING LID

FIGURE

4.14

RELEASE BUTTON

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 11

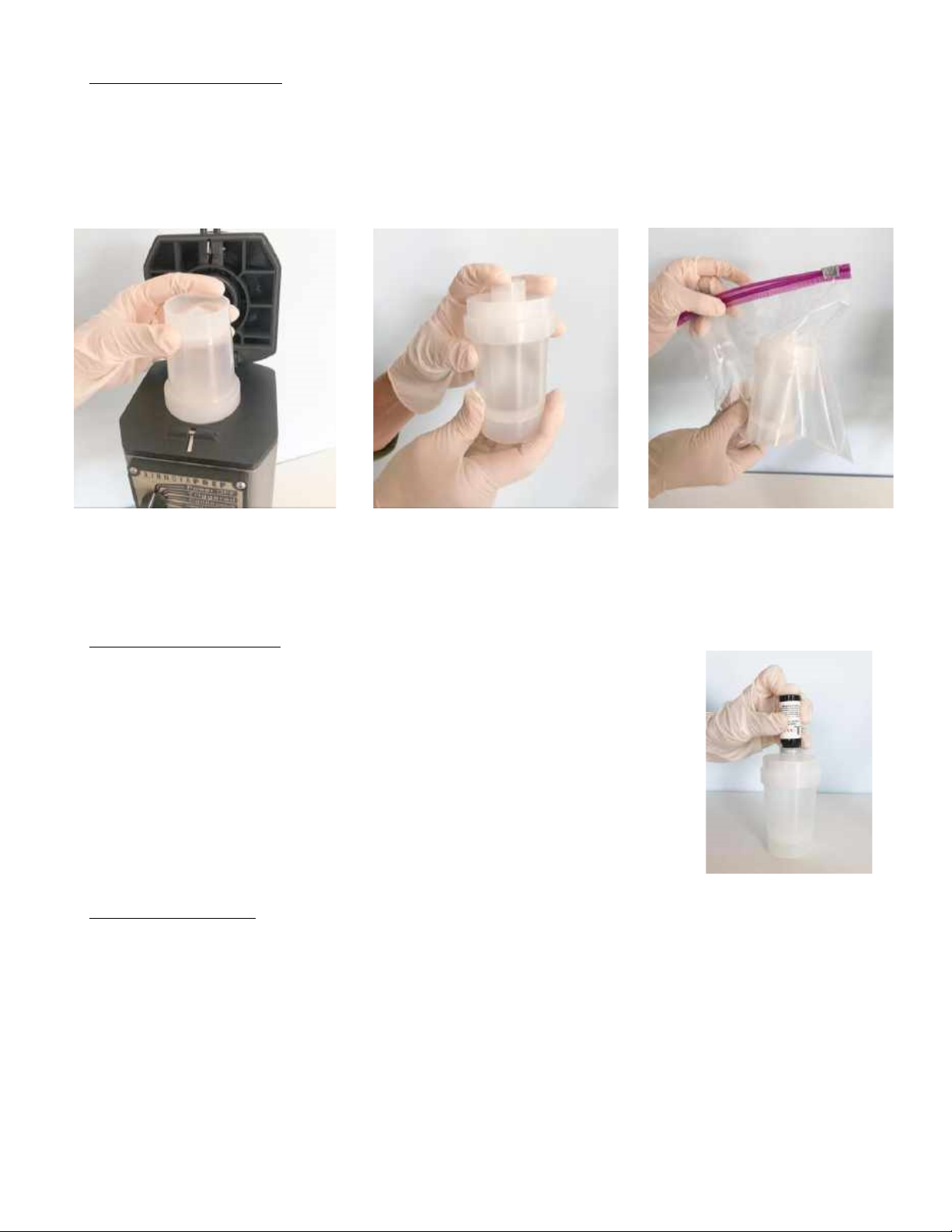

4.5 RECOVERY OF THE SAMPLE

When the run is completed, recover the Filter sample by unlatching the Inlet, and pressing the Sample Cup into the top of

the Filter as shown in Figure 4.16 and pressing firmly until it clicks all the way around the cup. The Filter and Sample Cup

are then lifted out of the collector, flipped over, and capped with the Elutor as shown in Figure 4.17 (make sure the Filter

and Elutor are fully seated) then seal in a zip-type bag for transporting dry as shown in Figure 4.18. Alternatively, the Filter

can be eluted into the Sample Cup, as shown in Figure 4.19, while in the field then capped with the Sample Cup Lid.

4.6 ELUTING A FILTER SAMPLE

To extract the captured particles from the filter contained, follow the procedures below:

1. Place the Sample Cup, Filter, and Elutor assembly, as shown in Figure 4.19, on a

stable surface.

2. Firmly press the Elution Canister into the Elutor, also shown in Figure 4.19. The

elution foam is released from the Elution Canister through the Filter when the

canister valve is pressed down. Hold the canister down until all the foam is

released. The foam quickly collapses back to a liquid in the sample cup, making it

available for sample processing and analysis.

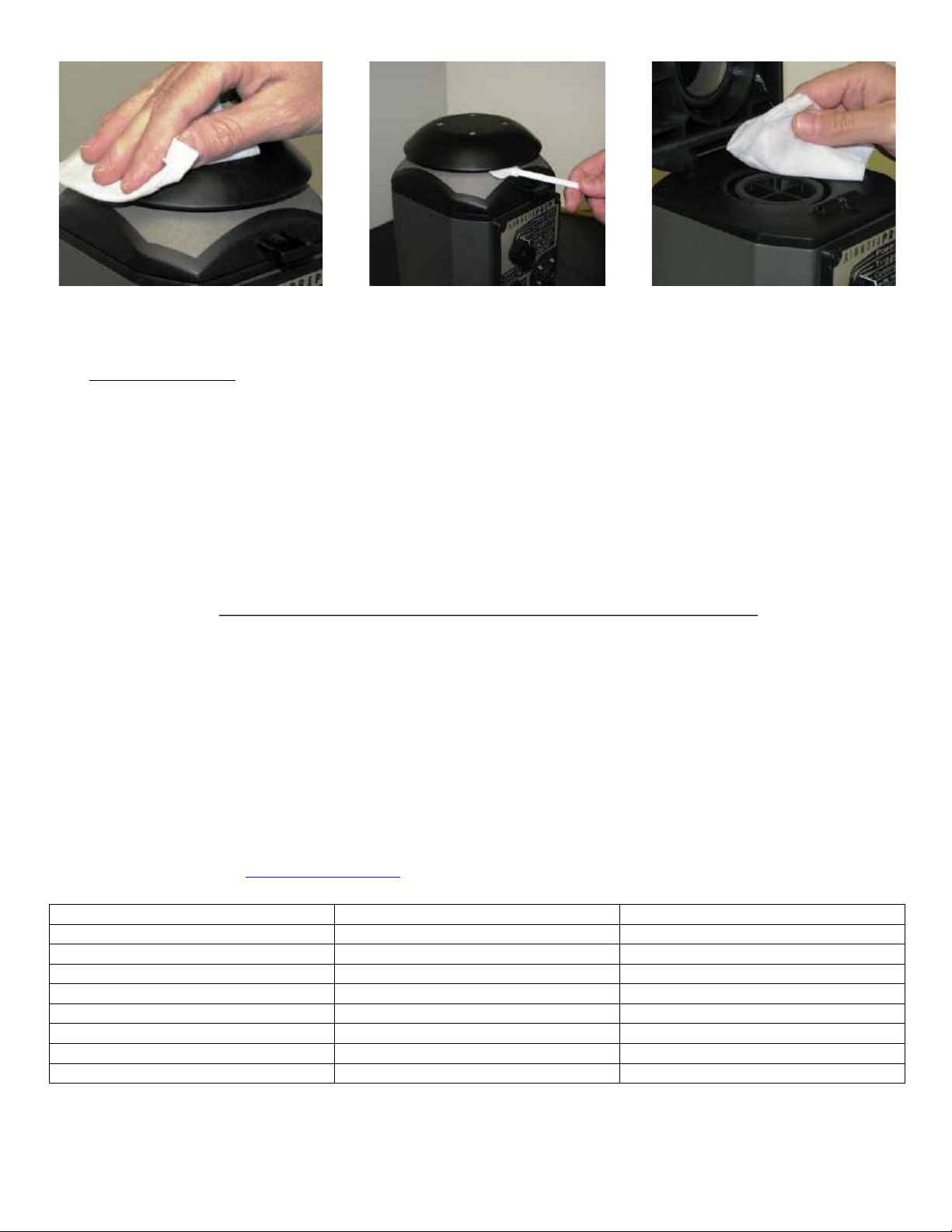

4.7 CLEANING THE SYSTEM

These procedures should be used when the instrument is placed in or removed from storage and for periodic cleaning.

This procedure is performed using the Bobcat Cleaning and Maintenance Kit (Part # AC00203) that is available for purchase

from InnovaPrep. Remove the sampler from the work area, hot zone, or contaminated area to an area where the cleaning

can be safely performed, if applicable, and disconnect the AC power converter and/or remove the battery.

Open one of the cleaning wipe packets contained in the Bobcat Cleaning and Maintenance Kit and use the enclosed

towelette to wipe down the exterior surface of the inlet as shown in Figure 4.20. Wet the foam tipped applicator with the

cleaning wipe and clean the inlet under the inlet cap as shown in Figure 4.21. Open the second cleaning wipe packet

contained in the Bobcat Cleaning and Maintenance Kit and use the enclosed towelette to wipe down the interior surfaces

of the sampler as shown in Figure 4.22.

FIGURE

4.16

SAMPLE CUP SNAPPED I

NTO

THE FILTER

FIGURE

4.17

ELUTOR

SNAPPED O

NTO

THE FILTER

FIGURE

4.18

ASSEMBLY IS BAGGED A

ND

READY

FOR TRANSPORT TO THE

LABORATORY

FIGURE

4.19

ELUTION OF FILTER

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 12

4.8 BATTERY CHARGING

The battery charger consists of two parts, the battery cap and a “wall wart” style AC power adapter, permanently

connected by a flexible cable. The AC power adapter is supplied with a standard North American AC plug installed. Other

AC plugs are available for International use; contact InnovaPrep for more information. Plug the AC power adapter into any

available AC mains socket. The LED on the power supply will illuminate, and the battery cap indicator will indicate the

Stand-by state (see below). Make sure that the connector and contact pads on the battery are clean and free of foreign

matter, and push the battery cap all the way into the battery connector. The charge cycle for the attached battery will

start automatically.

Indicator Light State of Charging Process

Slow Blinking Yellow Stand-by – Prequalification

Fast Blinking Yellow Precharge

Steady Yellow Normal Charge

Steady Green Full Charge

Red Battery or Charger Fault

Note: Maximum storage temperature for the battery is 40°C and charging temperature maximum is 37°C

Please contact InnovaPrep or an official InnovaPrep distributor for technical assistance and troubleshooting.

132 East Main Street, Box 68, Drexel, MO 64742 Phone:

816-619-3375

Revision

Date

Author

1

November 12, 2013

P. Murowchick

2

February 24, 2015

P. Murowchick

3

August 8, 2017

A. Packingham

4

March 8, 2018

A. Packingham

5

April 20, 2018

D. Alburty

6

August 28, 2018

A. Packingham

7

September 11, 2018

A. Packingham

8

February 18, 2020

A. Packingham

FIGURE

4.20

CLEANING EXTERIOR

SU

RFACES

FIGURE

4.21

CLEANING INLET WITH

FOAM TIPPED APPLICAT

OR

FIGURE

4.22

CLEANING INTERIOR

SURFACES

Copyright 2012-2018, InnovaPrep LLC www.innovaprep.com 13

Other manuals for ACD-200

1

Table of contents

Other InnovaPrep Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

CORNING

CORNING LSE 6703 instruction manual

ATS

ATS GDS Series Installation, operation and maintenance manual

Grant-bio

Grant-bio PCV-6000 operating instructions

Northwest Marine Technology

Northwest Marine Technology MKIV instruction manual

Applied Biosystems

Applied Biosystems CytoFluor 4000 Series user guide

Struers

Struers Discotom-100 instruction manual