Allen-Bradley 6181 User manual

Other Allen-Bradley Industrial PC manuals

Allen-Bradley

Allen-Bradley 6189V-35HDD1TB User manual

Allen-Bradley

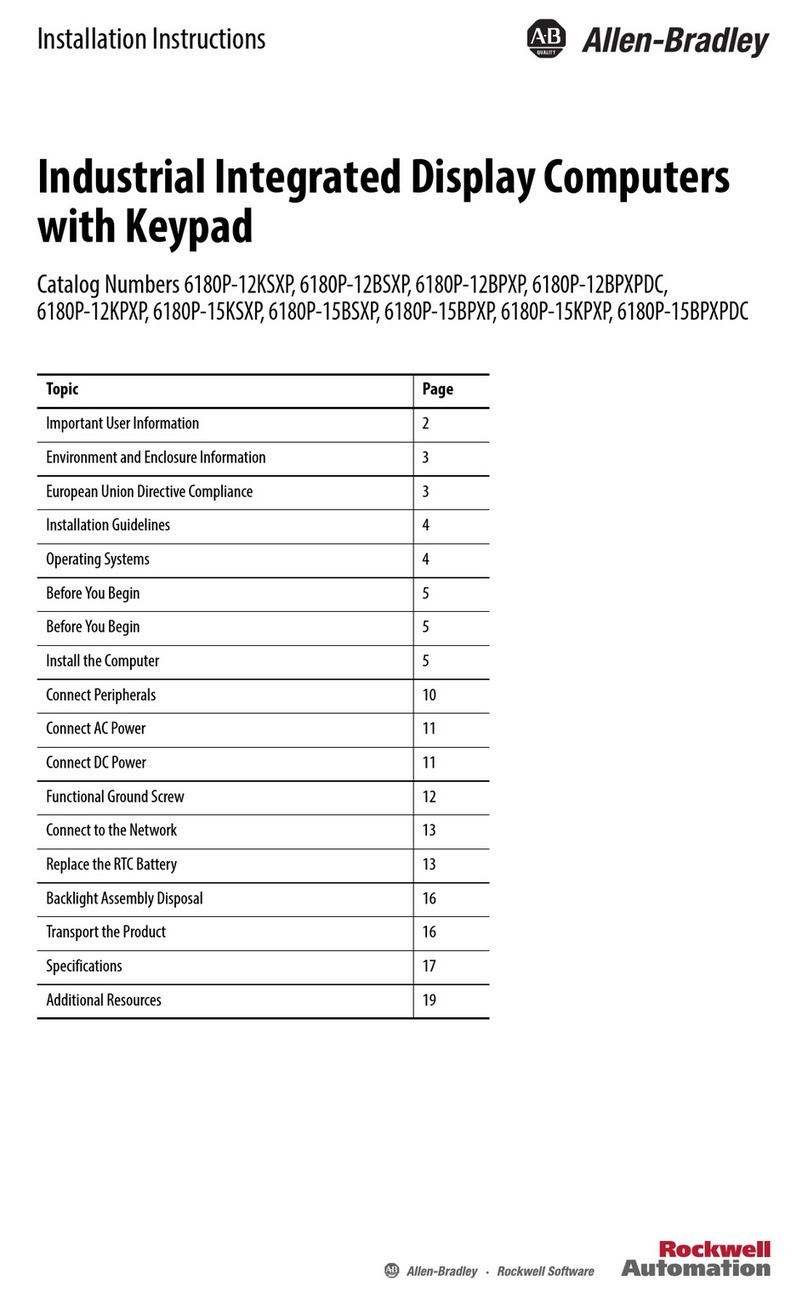

Allen-Bradley 6180P-12KSXP User manual

Allen-Bradley

Allen-Bradley H Series User manual

Allen-Bradley

Allen-Bradley 6177R-MM User manual

Allen-Bradley

Allen-Bradley 6155R-NSXP User manual

Allen-Bradley

Allen-Bradley 6181X-NPXPDC User manual

Allen-Bradley

Allen-Bradley 6180 User manual

Popular Industrial PC manuals by other brands

Dell

Dell Embedded Box PC 5000 Installation and operation manual

IBASE Technology

IBASE Technology ASB200-918 Series user manual

Lenovo

Lenovo ThinkCentre M90q Hardware Maintenance Manual

IXXAT

IXXAT Econ 100 Hardware manual

Kontron

Kontron KBox A-151-TGL user guide

AXIOMTEK

AXIOMTEK ICO500-518 Series user manual