800383 1

© Copyright 2011, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Table of Contents

Model Identification ................................................3

Section 1 – Safety Information

Locating an Authorized Servicer ............................6

Section 2 – Introduction

Customer Service ....................................................7

Nameplate Location ................................................7

How Your Washer Works .......................................8

How Your Washer Works .....................................10

Section 3 – Troubleshooting

1. Troubleshooting coin drop .............................13

2. No Spin Condition – Models through

Serial No. 9811005967 ...................................18

3. Troubleshooting Knocking Noise ...................18

4. No motor rotation, or drive failure code

“E:DF” on electronic display units ..................20

Electromechanical Models

5. Start Up ..........................................................26

6. Start and Door Lock .......................................28

7. Fill Sequence ..................................................30

8. 20 Volt Control ..............................................32

9. 240 Volt Motor Power ...................................34

10. Timer Chart ..................................................36

11. Cycle Timer Motor Control Inputs ..............37

12. Cycle Timer Water Fill Input Logic ..............38

13. Washer “DC” Motor Functions .....................39

14. Control System Faults ....................................42

15. No Start on Coin Slide Front Control

Washers ...........................................................42

NetMaster Models

16. Microwand Does Not Communicate With

Control ...........................................................44

17. Coins Ignored When Entered .........................45

18. No Visible Display on Control ......................46

19. Washer Will Not Start – No Door Lock ........48

20. Washer Will Not Start – Control Analysis ....50

21. Washer Will Not Fill ......................................52

22. Washer Overflows .........................................54

23. Pump Does Not Operate ................................56

24. Door Locked, Motor Does Not Run (E:df on

display) ...........................................................58

MDC Models

25. Error Code Listing .........................................61

26. Coins Ignored When Entered .........................62

27. No Visible Display on Control ......................64

28. Washer Will Not Start – No Door Lock ........66

29. Washer Will Not Start – Control Analysis ....68

30. Washer Will Not Fill ......................................70

31. Washer Overflows .........................................72

32. Pump Does Not Operate ................................74

33. Door Locked, Motor Does Not Run (E:df on

display) ...........................................................76

Section 4 – Grounding

34. Wall Receptacle Polarity Check ....................79

35. Machine Ground Connections - Front Control

Washers (Electromechanical Models) ...........80

36. Machine Ground Connections - Rear Control

Washers ..........................................................82

Section 5 – Service Procedures

37. Control Panel (Electromechanical Models) ...85

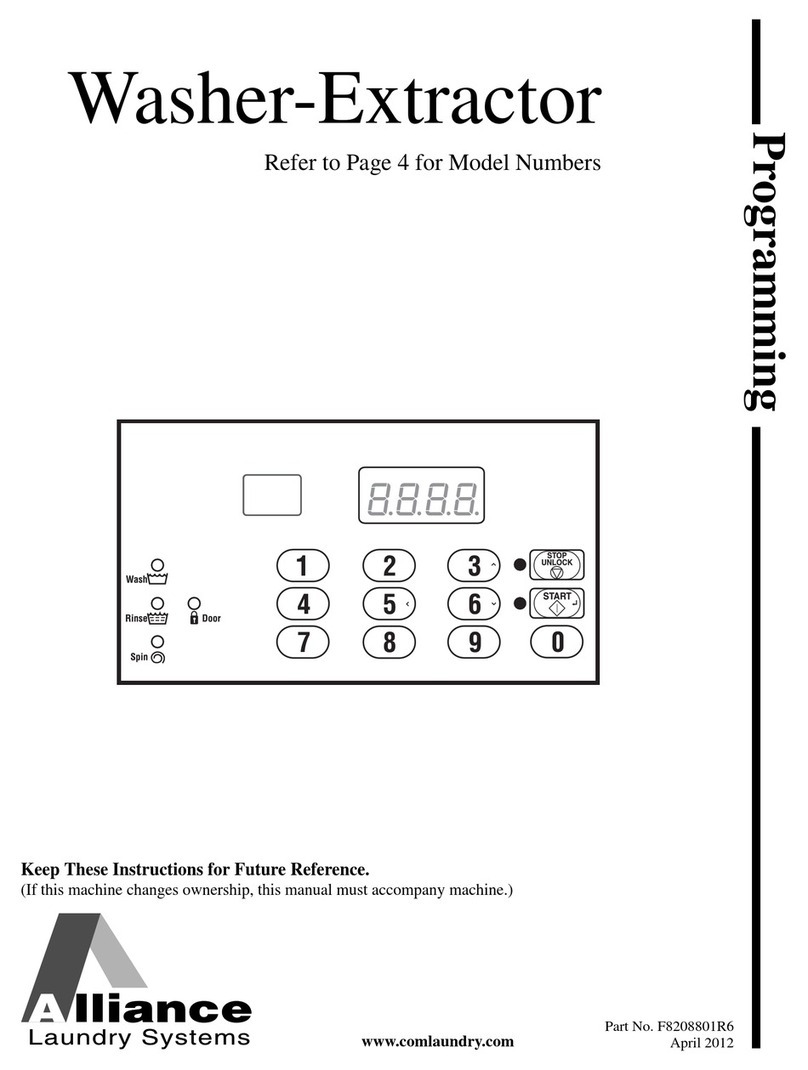

38. Control Panel (Electronic Control Models) ...86

39. Control Panel Overlay (Electromechanical

Models) ..........................................................91

40. Control Panel Overlay (Electronic Control

Models) ..........................................................92

41. Cabinet Top ....................................................94

42. Pressure Switch ..............................................99

43. Motor Control Board ...................................100

44. Timer Assembly ...........................................101

45. Control Cabinet Front ..................................103

46. Coin Drop ....................................................104

47. Card Reader .................................................112

48. Control Cabinet Wrapper .............................113

49. Relay ............................................................113

50. Electric Drain Pump .....................................115

51. Belt ...............................................................116

52. Mixing Valve ..............................................118

53. Front Panel ...................................................121

54. Loading Door ...............................................123

55. Door Seal and Hose Assembly ....................124

(continued)