GE Power Break II User manual

Other GE Circuit Breaker manuals

GE

GE Power Break II User manual

GE

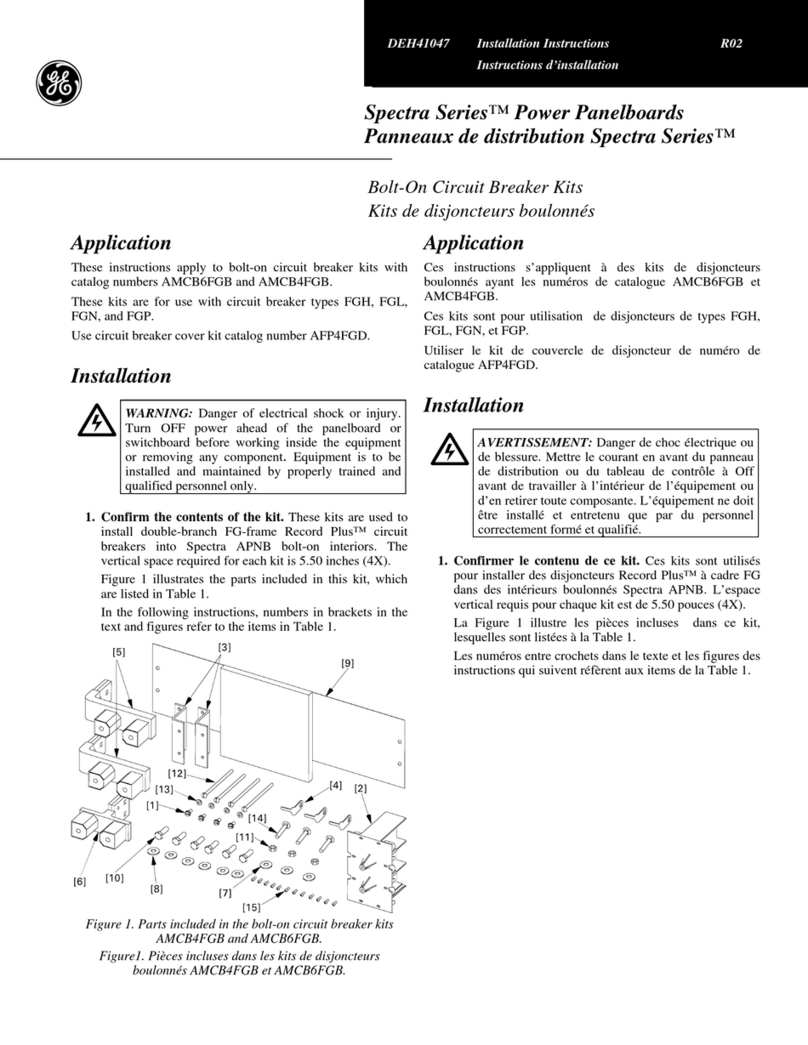

GE Spectra Series AMCB6FGB User manual

GE

GE AM-13.8-750-4C User manual

GE

GE EntelliGuard L User manual

GE

GE EntelliGuard G User manual

GE

GE Gerapid 2607 User manual

GE

GE GEH-62808 User manual

GE

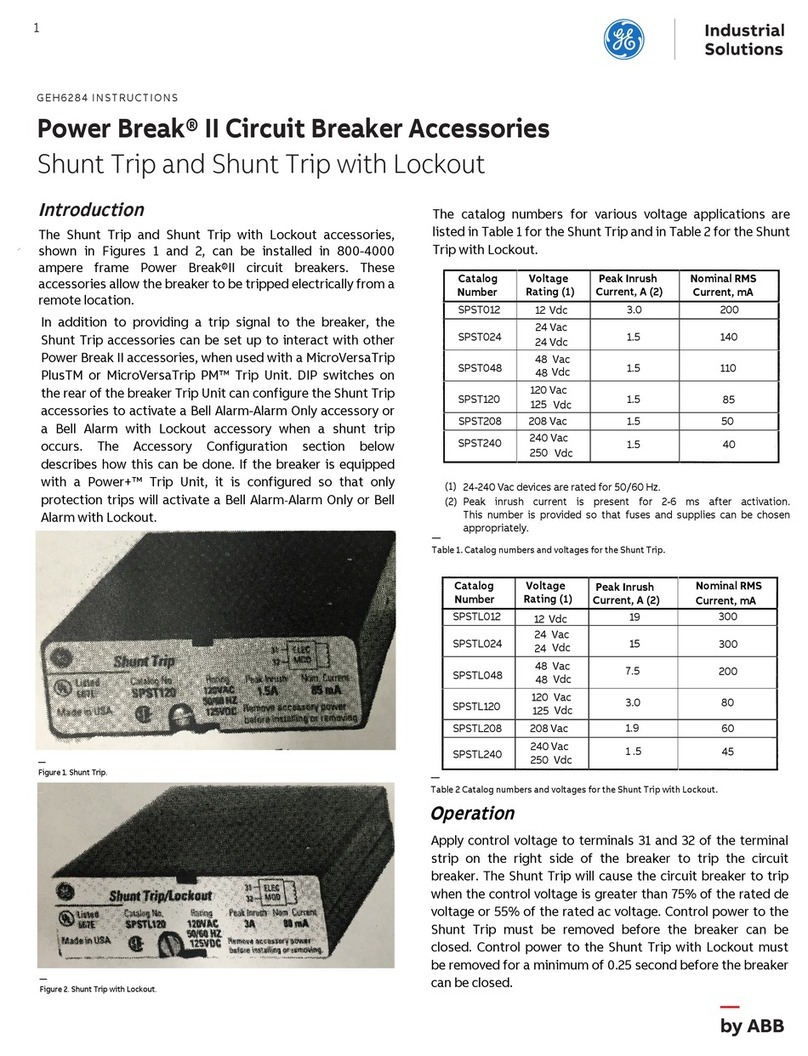

GE Shunt Trip User manual

GE

GE AKR User manual

GE

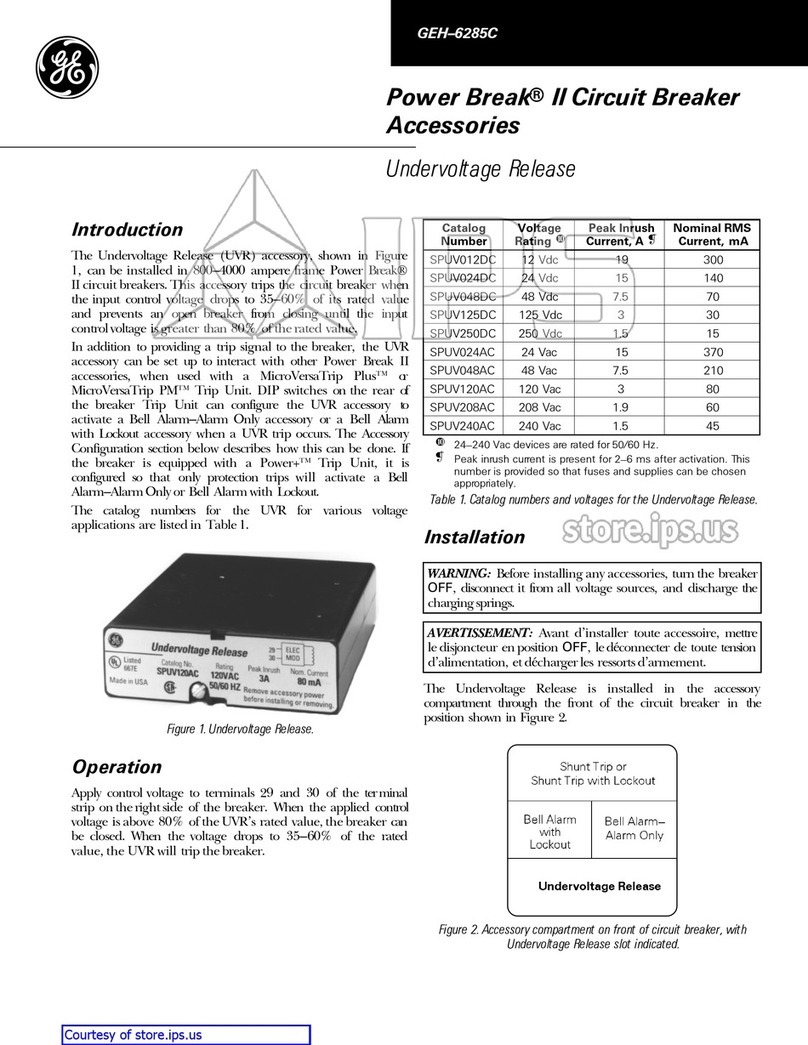

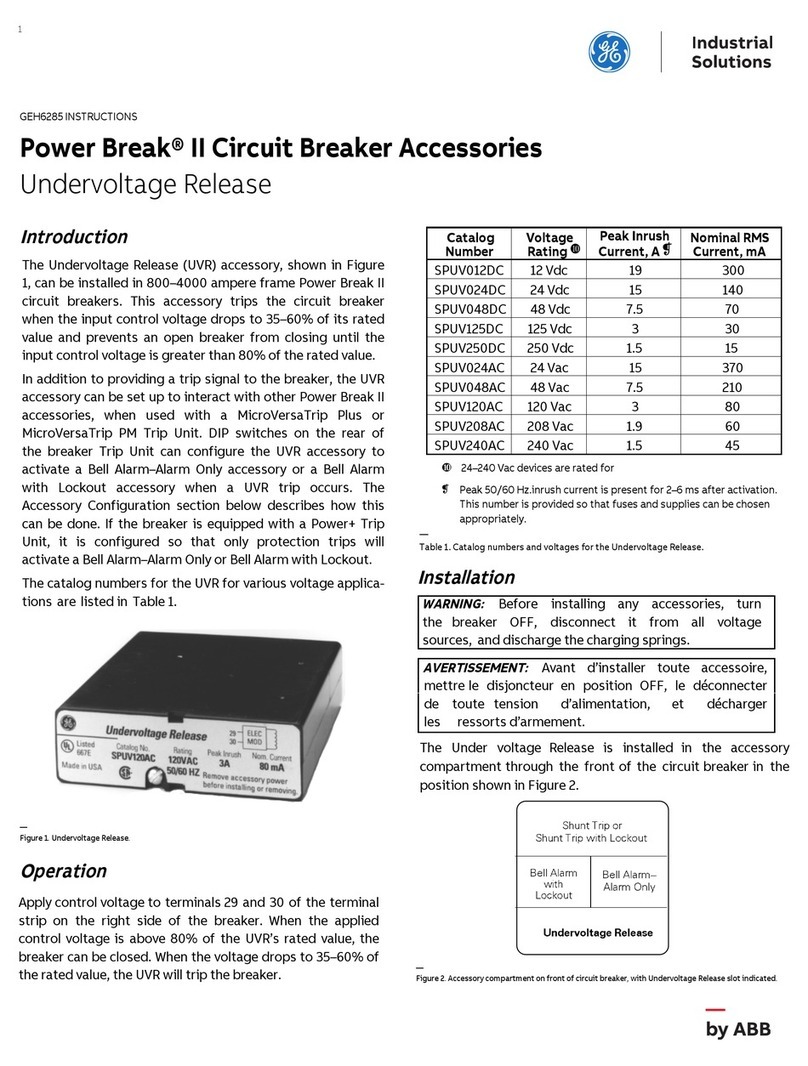

GE Power Break II SPUV012DC User manual

Popular Circuit Breaker manuals by other brands

Siemens

Siemens Sentron 3VA9157-0PK1 Series operating instructions

hager

hager TS 303 User instruction

ETI

ETI EFI-4B Instructions for mounting

nader

nader NDM3EU-225 operating instructions

TERASAKI

TERASAKI NHP TemBreak PRO P160 Series installation instructions

Gladiator

Gladiator GCB150 Installation instruction