4

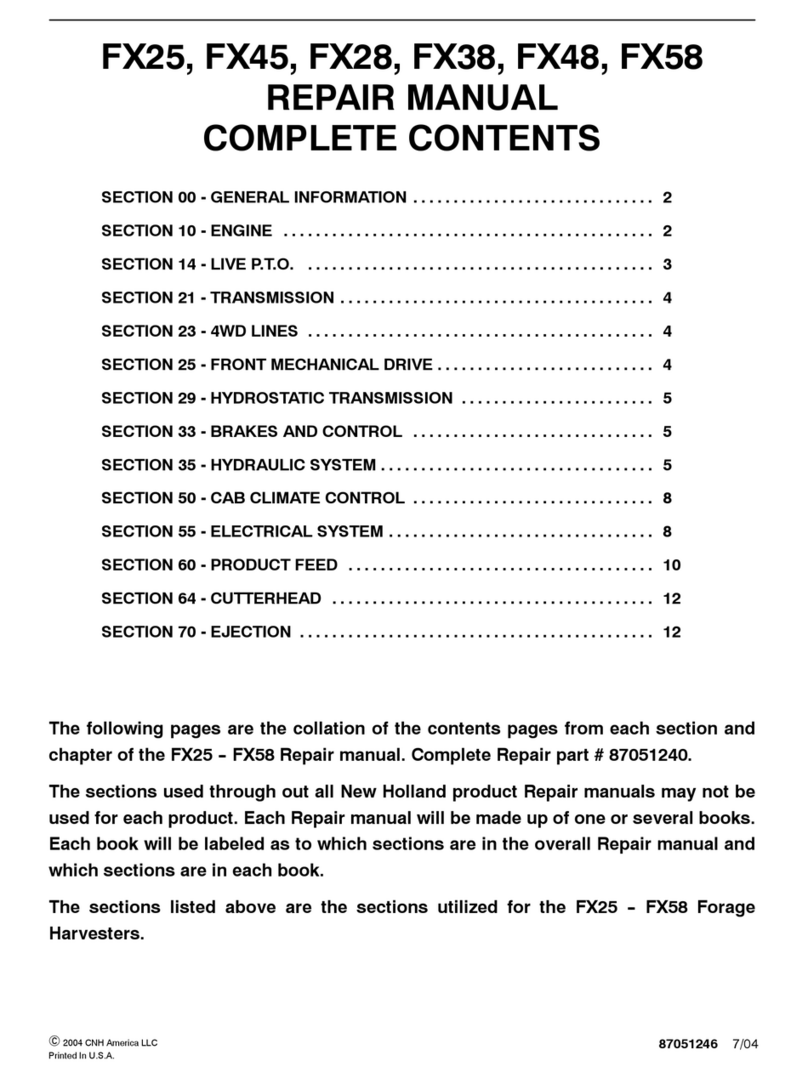

SECTION 21 -- TRANSMISSIONS

BOOK 2 - 87034094

Chapter 2 -- Power Shuttle Transmission (8 + 8 and 16 + 16 versions)

CONTENTS

Section Description Page

21 000 Main data 2.....................................................................

Torque values 4.................................................................

Special tools 5...................................................................

Cross-sectional views 10.........................................................

Description and operation 15.....................................................

21 118 85 Transmission--Gearbox, Disassembly--Assembly 16.................................

21 134 46 Power shuttle control valve, Disassembly--Assembly 18..............................

21 134 70 A + B Clutch valve solenoids, Removal--Installation 21...............................

21 134 70 Dump valve solenoid, Removal--Installation 22......................................

21 154 34

21 154 60 Clutch casing, Disassembly--Assembly 23..........................................

Description of systems (ECM and CDU) 28.........................................

Automatic self-diagnosis (ECM) 29................................................

ECM First start up 30............................................................

Diagnosis during operation 31....................................................

Calibration and diagnostic unit (CDU) 32...........................................

Power shuttle fault code priority 33................................................

Fault codes indication 36.........................................................

Calibration and diagnostics unit use 37.............................................

HH menu access 38.............................................................

H1 -- Clutches A and B calibration error codes 40....................................

H2 -- Clutches A and B calibration values display 45.................................

H3 -- System configuration 46.....................................................

H4 -- Power shuttle hardware and software revision levels 48.........................

H5 -- Control switch diagnosis 49..................................................

H6 -- Clutch A fill time 54.........................................................

H7 -- Clutch B fill time 56.........................................................

H8 -- Erasure of data stored in NVM 58............................................

H9 -- Voltmeter functions 59......................................................

HA -- Clutch pedal potentiometer and status switch 63................................

Clutch pedal potentiometer replacement 65.........................................