2

1

IMPORTANT SAFETY INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF :INJURY

READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS. DO NOT START INSTALLATION UNTIL

YOU HAVE READ AND UNDERSTAND THESE DIRECTIONS. IF THERE IS SOMETHING YOU DO NOT

UNDERSTAND, PLEASE CALL US.

NEVER let children operate or play with gate controls.

Locate the control station and make sure it is (a) within sight of the gate and (b) at a minimum height of 5

feet so small children cannot reach it.

Install the enclosed entrapment warning signs next to the control station and in a prominent location.

For operators equipped with a manual release, instruct the end user on the correct operation of the manual

release. Use the manual release only when the gate is not moving. It is advised that the power be turned

off.

Always keep people and objects away from the gate. No one should cross the path of a moving gate.

The gate operator must be tested monthly. The gate must reverse on contact with a rigid object, or stop

when an object activates the non-contact sensor(s). Always re-test the operator after adjusting the limits

and/or force. Failure to adjust and re-test the gate operator properly may cause severe injury or death.

Keep gate(s) properly maintained. Have a qualified service technician make repairs to gate hardware and

make proper adjustments to gate operator.

This gate entrance/exit is for vehicles only. Pedestrians must use a separate entrance.

There is nothing on a gate operator that is easily repaired or adjusted without a great deal of experience.

Call a qualified gate service technician who knows your gate operator.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

(CONTINUED)

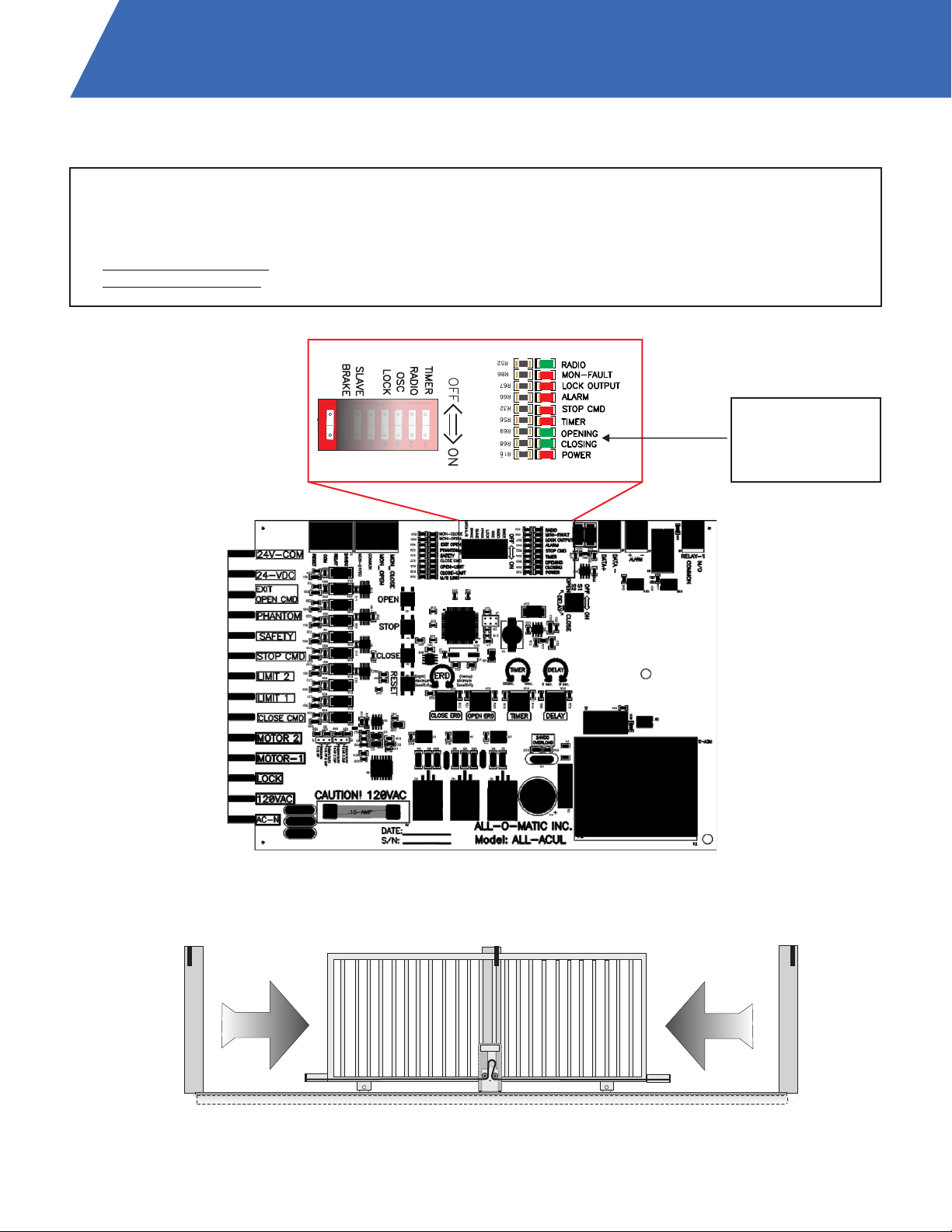

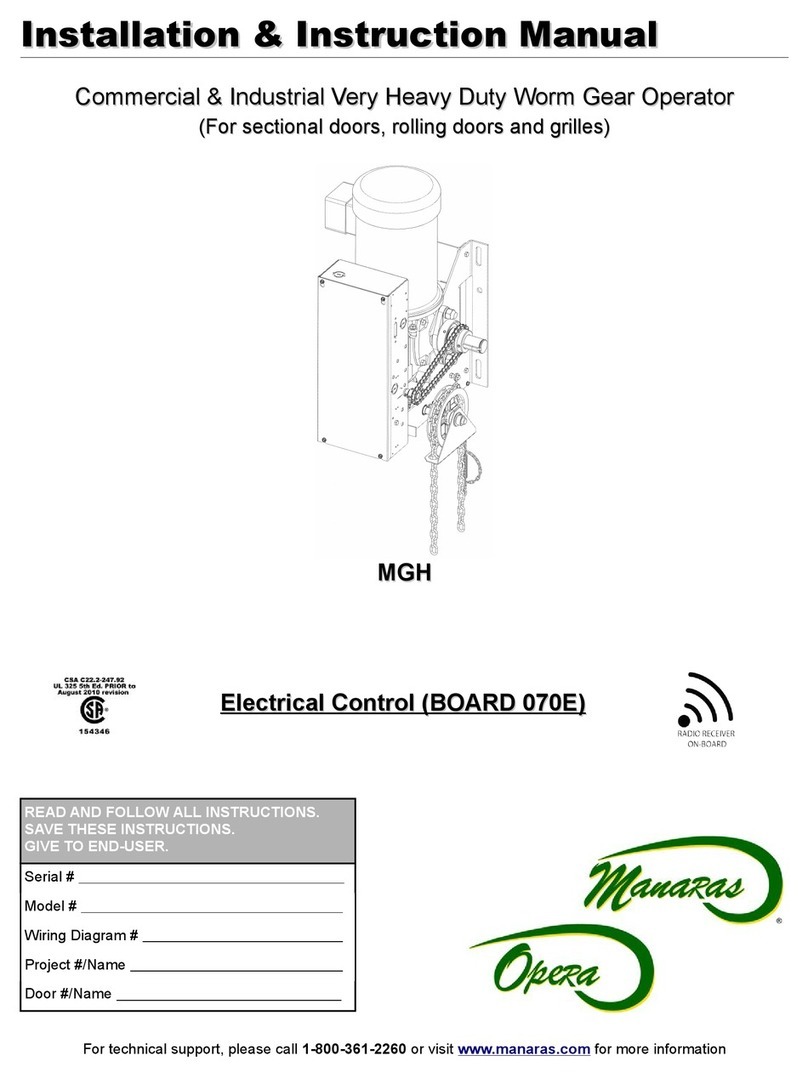

BEFORE GATE OPERATOR INSTALLATION

ŸConfirm that the gate operator being installed is

appropriate for the application.

ŸConfirm that the gate is designed and built

according to the current published industry

standards.

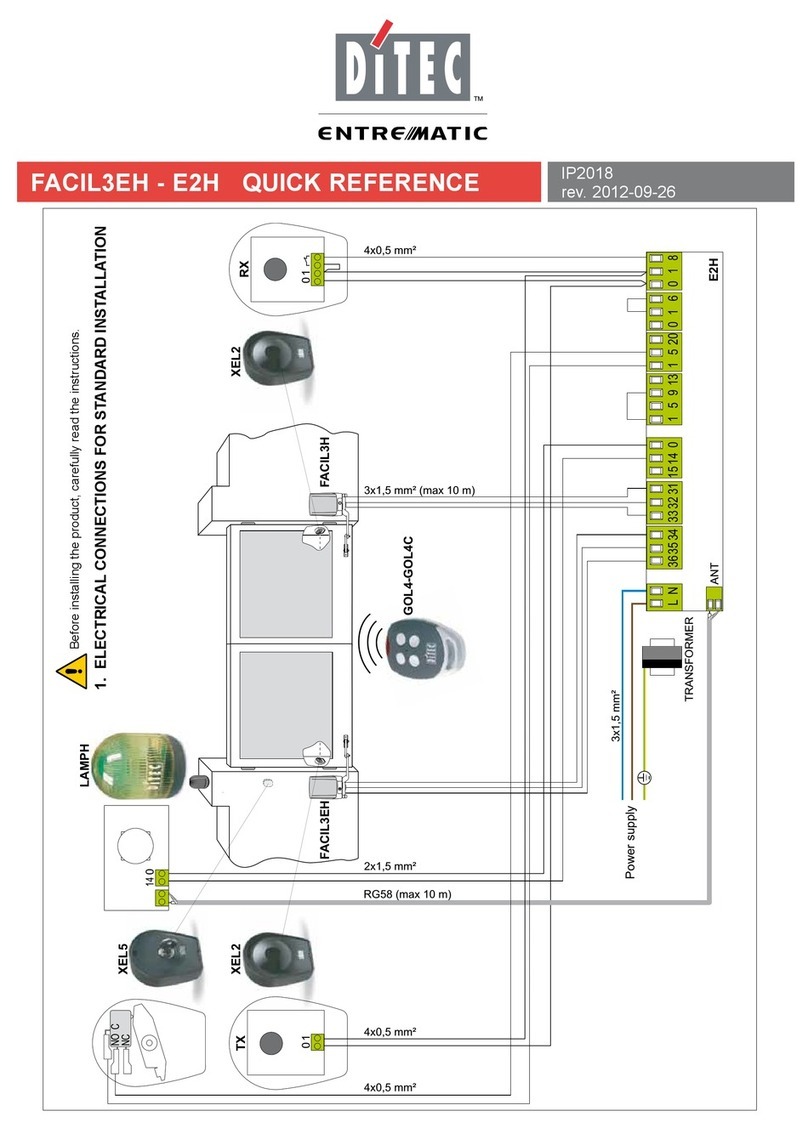

ŸConfirm that all appropriate safety features and

safety accessory devices are being installed,

including all entrapment protection devices.

ŸMake sure that the gate opens and closes freely

(by hand) before installing the operator.

ŸRepair or replace worn or damaged gate

hardware before installing the gate operator.

ŸEliminate all gaps in the sliding gate below a 6

foot height that permits a 2 1/4” sphere to pass

through any location. This includes the area of

the adjacent fence covered when the gate is in

the open position

ŸEliminate all gaps in a swing gate below a 4 foot

height that permits a 4” sphere to pass through

any location. This includes the hinge area of the

gate.

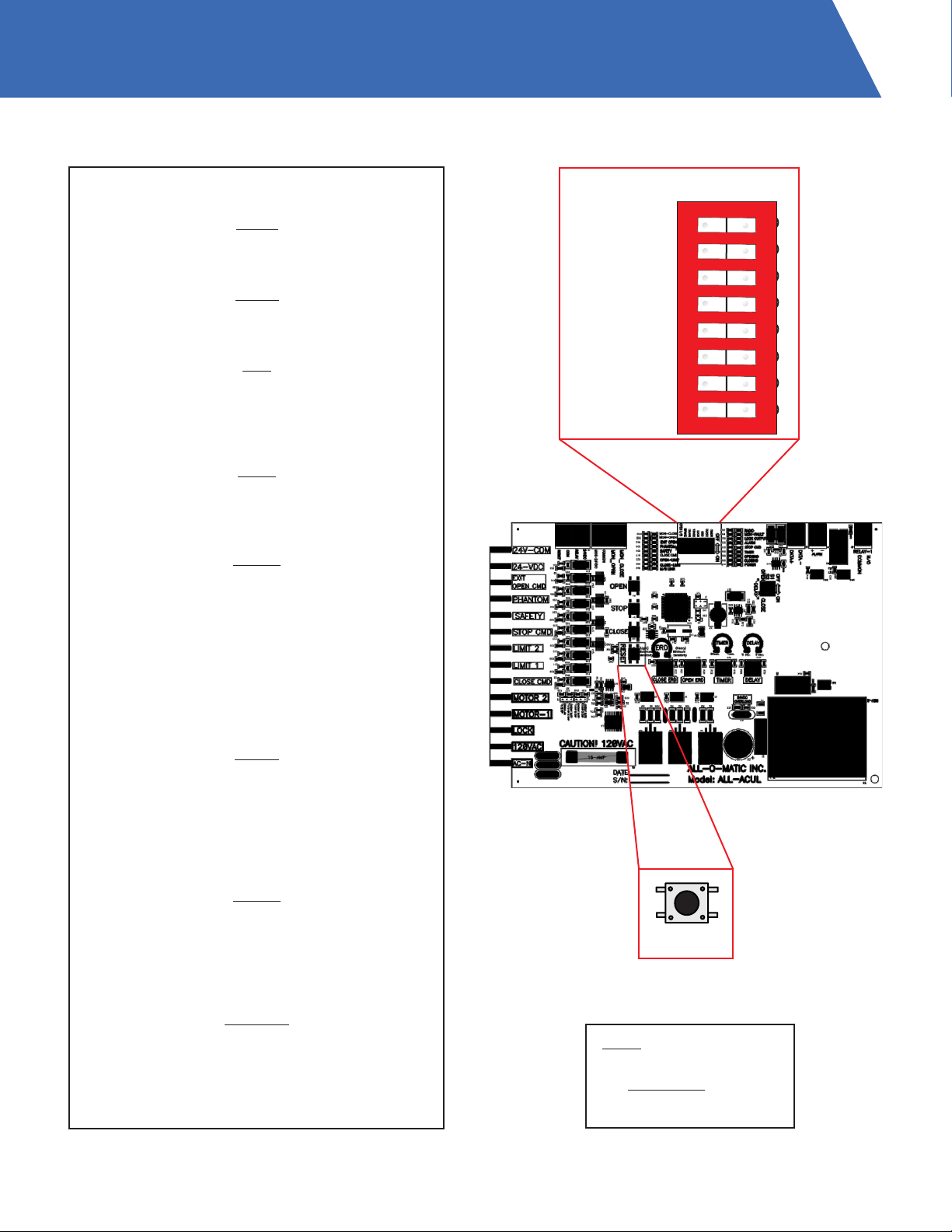

GATE OPERATOR INSTALLATION

ŸOperator must be disconnected from the power

source before attempting any installation of

accessories.

ŸInstall gate operator according to the installation

instructions in this manual.

ŸAdjust the operator clutch or load sensing device

to the minimum force setting that will allow for

reliable gate operation.

ŸInstall the operator inside the fence line. Do not

install the operator on the public side of the fence

line.

ŸInstall a proper electrical ground to the gate

operator.

ŸControls intended for user activation must be

located at least 6 feet away from any moving part

of the gate, and where the user is prevented

from reaching over, under, around, or through

the gate to operate the controls.

ŸOutdoor or easily accessible controls shall have

a security feature to prevent unauthorized use.

ŸThe stop and/or reset button must be located in

the line of sight of the gate. Activation of the

operator reset control shall not cause the

operator to move.

ŸInstall a minimum of 2 warning signs, one on

each side of the gate where they are easily

visible.

ŸTake pictures of the installation.

ŸTest all safety features for proper function before

placing the automatic vehicular gate in

operation.

MAINTENANCE

ŸTrain owners/users on the basic functions and

safety features of the gate system, including

how to turn off the power and operate the

manual disconnect feature.

ŸLeave safety instructions, product literature,

installation manual, and maintenance manual

with the owner or end user.

ŸExplain to the owner or end user the importance

of routine service and operator testing on a

monthly basis.

INSTALL THE GATE OPERATOR ONLY WHEN YOU

HAVE READ THE FOLLOWING